Final - University of New Mexico

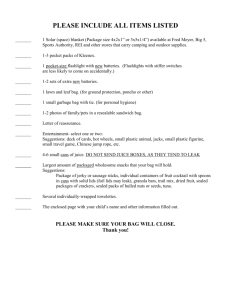

advertisement