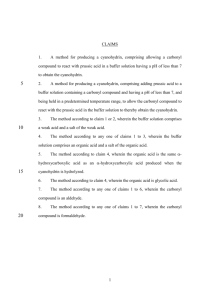

TITLE OF THE INVENTION

advertisement

FP11-0261-00 METHOD FOR PRODUCING CYANOHYDRIN DETAILED DESCRIPTION TECHNICAL FIELD [0001] 5 The present invention relates to a method for producing a cyanohydrin. TECHNICAL BACKGROUND [0002] Cyanohydrin compounds are important as intermediates used for synthesis of, for example, -hydroxycarboxylic compounds, -hydroxyketone compounds or -aminoalcohol compounds often used for production of 10 pharmaceutically effective substances and biologically active substances including vitamins and pyrethroid compounds. [0003] The most common cyanohydrin compound is glycolonitrile, and disclosed examples of methods for producing glycolonitrile include methods described, for example, in Patent Literature 1 to 4. 15 [0004] Patent Literature 1 describes dropwise charging prussic acid to a formalin solution in which a catalytic amount of sodium acetate is dissolved, at a liquid temperature of 15 to 30C at a pH of 4.8 to 6.0 held, as required, by adding acetic acid or sodium acetate, to carry out the reaction under the same condition. [0005] Patent Literature 2 describes a production method of glycolonitrile in which a 20 small amount of acidic sulfite ions is made to be present in the reaction system in production of glycolonitrile by allowing formaldehyde to react with prussic acid in an aqueous medium, and specifically describes supplying suitably a sodium sulfite aqueous solution to a reaction tank while a pH of the reaction solution is regulated to become 4.0 to 5.0. 1 FP11-0261-00 [0006] Patent Literature 3 describes a production method of glycolonitrile by allowing prussic acid to react with formaldehyde in an aqueous medium, in which method if the temperature of a reaction band is denoted as T (C) and the pH of a reaction solution is denoted as P, a product of T and P is 155 to 240, and specifically 5 describes, for example, adding a small amount of sulfur dioxide, sulfurous acid, sulfuric acid or the like in order to decrease the pH, and adding a small amount of sodium sulfite, caustic soda or the like in order to raise the pH. [0007] Further, Patent Literature 4 describes a preparation method of glycolonitrile, which includes (a) a step of providing a flow supplying aqueous formaldehyde 10 heated at about 90C to about 150C during measurable time, and (b) a step of bringing the flow supplying the heated aqueous material of (a) into contact with hydrogen cyanide at a suitable temperature for synthesis of glycolonitrile to thereby produce glycolonitrile. The Patent Literature further describes that the pH of a glycolonitrile synthesis reaction chamber is made to be about 3 to about 10, and 15 preferably about 5 to about 8. [0008] Patent Literature 1: Japanese Patent Application Laid-Open Publication No. 62-267257 Patent Literature 2: Japanese Patent Application Laid-Open Publication No. 53-68725 20 Patent Literature 3: Japanese Patent Application Laid-Open Publication No. 6-135923 Patent Literature 4: National Publication of International Patent Application No. 2008-525467 DISCLOSURE OF THE INVENTION 25 [0009] However, the methods described in Patent Literature 1 to 3 have a problem 2 FP11-0261-00 of a poor working efficiency because the methods need a suitable pH regulation during the reaction progress. The method described in Patent Literature 4 has cases where the formation rate of the cyanohydrin is not always high. The methods described in Patent Literature 1 to 4 have difficulty in precisely controlling 5 the reaction rate of formaldehyde with prussic acid. [0010] Then, the present invention provides a method for producing a cyanohydrin, the method being able to precisely control the reaction rate of a carbonyl compound with prussic acid, and to produce the cyanohydrin in a sufficiently high formation rate, without regulating the pH during the reaction progress. 10 [0011]That is, the present invention provides a method for producing a cyanohydrin, which obtains the cyanohydrin by allowing a carbonyl compound to react with prussic acid in a buffer solution of a pH of less than 7. [0012] Usually, the reaction rate of a carbonyl compound with prussic acid depends on the pH, and the pH varies along with the reaction progress. In conventional 15 production methods, although the pH is suitably regulated in conformance with the variation in the pH, it is difficult for such a method to hold the pH precisely at a constant, and this fact is considered to be a cause of bringing difficulty in controlling the reaction rate. By contrast, since the production method according to the present invention makes the reaction progress in a buffer solution, the pH during the 20 reaction progress is held at a constant without regulating the pH. Therefore, in the present invention, the reaction rate of a carbonyl compound with prussic acid can be controlled precisely. [0013] Further according to the present invention, a cyanohydrin can be produced at a high formation rate. Although the reason therefor is not completely clear, it is 25 considered that in the present invention, since the reaction is carried out in a buffer solution, the decrease in the formation rate due to the variation in the pH hardly 3 FP11-0261-00 occurs to thereby achieve a high formation rate. [0014] The present invention also provides a production method of a cyanohydrin, which obtains the cyanohydrin by adding prussic acid to a buffer solution, which contains a carbonyl compound and has a pH of less than 7, and is being held in a 5 predetermined temperature range, to allow the carbonyl compound to react with the prussic acid in the buffer solution to thereby obtain the cyanohydrin. According to such a production method, the reaction rate of a carbonyl compound with prussic acid can be controlled precisely without regulating the pH, and a cyanohydrin can be produced at a high formation rate. 10 [0015] In the present invention, the buffer solution preferably contains a weak acid and a salt of the weak acid. The buffer solution also preferably contains an organic acid and a salt of the organic acid. Use of such a buffer solution can suppress still more the variation in the pH in the reaction of a carbonyl compound with prussic acid. Therefore, the effect of the present invention works more surely. 15 [0016] The organic acid is preferably the same -hydroxycarboxylic acid as an hydroxycarboxylic acid produced when a cyanohydrin is hydrolyzed. Use of such an organic acid facilitates purification of an -hydroxycarboxylic acid in the case where a cyanohydrin produced is further hydrolyzed to obtain the hydroxycarboxylic acid. 20 Further, the formation rate of the cyanohydrin more improves. [0017] The organic acid is preferably glycolic acid. Use of a buffer solution containing glycolic acid and a salt of glycolic acid can suppress still more the variation in the pH, and also still more improves the formation rate of a cyanohydrin. [0018] The carbonyl compound is preferably an aldehyde, and more preferably 25 formaldehyde. A cyanohydrin obtained from such a carbonyl compound is very useful as an intermediate for producing pharmaceutically effective substances, and 4 FP11-0261-00 biologically active substances such as vitamins or pyrethroid compounds. [0019] The present invention can provide a production method of a cyanohydrin, the method being able to precisely control the reaction rate of a carbonyl compound with prussic acid, and to produce the cyanohydrin at a sufficiently high formation 5 rate, without regulating the pH during the reaction progress. PREFERRED EMBODIMENTS OF THE INVENTION [0020] A preferred embodiment of the cyanohydrin according to the present invention will be described hereinafter. [0021] A production method of a cyanohydrin according to the present embodiment 10 provides the cyanohydrin by allowing a carbonyl compound to react with prussic acid in a buffer solution of a pH of less than 7. [0022] Here, the carbonyl compound is a compound having a carbonyl group, and examples thereof include compounds represented by the following formula (1). [0023] 15 [Chemical Formula 1] O (1) 1 R 2 R [0024] In the formula, R1 and R2 each independently denote a hydrogen atom, an alkyl group having 1 to 6 carbon atoms, an aryl group having 6 to 14 carbon atoms, or an alkylaryl group having 7 to 9 carbon atoms. 20 [0025] Examples of the alkyl group having 1 to 6 carbon atoms include a methyl group, an ethyl group, a propyl group, a butyl group, a pentyl group and a hexyl group. These alkyl groups may be straight-chain ones or branched-chain ones or may form rings. [0026] The aryl group having 6 to 14 carbon atoms includes a phenyl group, a tolyl 5 FP11-0261-00 group, a xylyl group, a naphthyl group, a biphenyl group and an anthryl group. [0027] The alkylaryl group having 7 to 9 carbon atoms includes a benzyl group, an ethylphenyl group and a cinnamyl group. [0028] The carbonyl group specifically includes ketones such as acetone (a 5 compound in which either of R1 and R2 is a methyl group), methyl ethyl ketone (a compound in which one of R1 and R2 is a methyl group and the other thereof is an ethyl group) and isobutyl methyl ketone (a compound in which one of R1 and R2 is a methyl group and the other thereof is an isobutyl group); and aldehydes such as formaldehyde (a compound in which either of R1 and R2 is a hydrogen atom), 10 acetaldehyde (a compound in which one of R1 and R2 is a hydrogen atom and the other thereof is a methyl group), propionaldehyde (a compound in which one of R1 and R2 is a hydrogen atom and the other thereof is an ethyl group) and benzaldehyde (a compound in which one of R1 and R2 is a hydrogen atom and the other thereof is a phenyl group); and the like. 15 [0029] In the formula (1), a compound in which neither of R1 and R2 is a hydrogen atom is a ketone, and a compound in which at least one of R1 and R2 is a hydrogen atom is an aldehyde. [0030] The carbonyl compound is preferably an aldehyde. That is, in the formula (1), at least one of R1 and R2 is preferably a hydrogen atom. Aldehydes efficiently 20 react more easily with prussic acid and can produce cyanohydrins at a higher formation rate than ketones. Among aldehydes, formaldehyde is preferable from the viewpoint of being capable of producing glycolonitrile, which is useful as an intermediate for production of glycine, hydantoin and the like. [0031] The carbonyl compound can be used for the reaction, for example, as an 25 aqueous solution. That is, in the case where the carbonyl compound is formaldehyde, the carbonyl compound can be used for the reaction as a 6 FP11-0261-00 formaldehyde aqueous solution. [0032] Prussic acid can be used for the reaction in an optional form such as a gas, a liquid or an aqueous solution, and is preferably used as a liquid or an aqueous solution. 5 [0033] The amount of prussic acid used for the reaction is preferably 1 to 1.2 times and more preferably 1 to 1.1 times the total amount of a carbonyl compound in molecular number, from the viewpoint of improving the formation rate of a cyanohydrin. [0034] Cyanohydrins obtained by a reaction of a carbonyl compound with prussic 10 acid are, for example, compounds represented by the following formula (2). [0035] [Chemical Formula 2] HO CN (2) 1 R 2 R [0036] In the formula, R1 and R2 have the same meaning as R1 and R2 in the formula 15 (1). [0037] Specifically, the respective cyanohydrins can be obtained: for example, glycolonitrile (byname: hydroxyacetonitrile, a compound in which either of R1 and R2 in the formula (2) is a hydrogen atom), from formaldehyde; acetone cyanohydrin (byname: -hydroxyisobutyronitrile, a compound in which either of R1 and R2 in the 20 formula (2) is a methyl atom), from acetone; and mandelonitrile (a compound in which one of R1 and R2 in the formula (2) is a hydrogen atom and the other thereof is a phenyl group), from benzaldehyde. [0038] The reaction of a carbonyl compound with prussic acid is preferably carried out in the presence of a catalyst. 25 The catalyst includes sodium cyanide and potassium cyanide. 7 FP11-0261-00 [0039] The use amount of a catalyst is preferably 0.01 to 0.5 mol%, and more preferably 0.05 to 0.1 mol%, with respect to the total amount of the carbonyl compound used for the reaction. [0040] The buffer solution refers to a solution having a buffer action, that is, a 5 solution whose pH variation is small even if a predetermined amount of an acid or a base is added. The buffer solution is suitably an aqueous solution containing a weak acid and a salt of the weak acid, and more suitably an aqueous solution containing an organic acid and a salt of the organic acid. [0041] The weak acid includes organic acids such as acetic acid, formic acid, 10 glycolic acid, citric acid, tartaric acid, mandelic acid, glutaric acid, malic acid, malonic acid, phthalic acid and succinic acid; inorganic acids such as phosphoric acid and boric acid; and the like, and among these, organic acids are preferable. [0042] The salt of the weak acid includes alkaline metal salts such as sodium salts and potassium salts of the weak acids; alkaline earth metal salts such as magnesium 15 salts and barium salts; and the like. [0043] The weak acid is preferably an -hydroxycarboxylic acid. Use of a buffer solution containing an -hydroxycarboxylic acid and a salt of the hydroxycarboxylic acid can provide a cyanohydrin at a high formation rate. [0044] Examples of -hydroxycarboxylic acids include compounds represented by 20 the following formula (3). [0045] [Chemical Formula 3] HO CO2H (3) 3 R 4 R [0046] In the formula, R3 and R4 each independently denote a hydrogen atom, an 25 alkyl group having 1 to 6 carbon atoms, an aryl group having 6 to 14 carbon atoms, 8 FP11-0261-00 or an alkylaryl group having 7 to 9 carbon atoms. Examples of the alkyl group having 1 to 6 carbon atoms, the aryl group having 6 to 14 carbon atoms, and the alkylaryl group having 7 to 9 carbon atoms are the same ones as in the above, respectively. 5 [0047] Meanwhile, cyanohydrins produce -hydroxycarboxylic acids, for example, by the hydrolysis reaction using microorganisms. The -hydroxycarboxylic acids thus produced are often used and useful for production of pharmaceutically effective substances and biologically active substances such as vitamins and pyrethroid compounds. 10 [0048] Then, if the same -hydroxycarboxylic acid as an -hydroxycarboxylic acid produced when a cyanohydrin produced is hydrolyzed is used as the weak acid, the same -hydroxycarboxylic acid can be used for the above-mentioned hydrolyis reaction, without purifying the cyanohydrin after the reaction. At this time, the hydrolysis reaction using a microorganism is not inhibited by the presence of the - 15 hydroxycarboxylic acid, and since the -hydroxycarboxylic acid is the same one as an -hydroxycarboxylic acid produced by the hydrolysis reaction, the purification operation is not inhibited. From such a viewpoint, as the weak acid, the same hydroxycarboxylic acid as an -hydroxycarboxylic acid produced when a cyanohydrin produced is hydrolyzed is preferably used. 20 Such an - hydroxycarboxylic acid can be represented by the following formula (4). [0049] [Chemical Formula 4] HO CO2H (4) 1 R 2 R [0050]In the formula, R1 and R2 are the same groups as R1 and R2 in the formula (1). 25 [0051] That is, for example, in the case of using formaldehyde as the carbonyl 9 FP11-0261-00 compound according to the present embodiment, a buffer solution is preferably a buffer solution containing glycolic acid and a salt of glycolic acid. [0052] The pH of a buffer solution is less than 7, and from the viewpoint of improving the formation rate of a cyanohydrin, the pH is preferably 1 to 6, and more 5 preferably 3 to 5. Too high a pH thereof progresses the reverse reaction from a cyanohydrin to a carbonyl compound, and additionally easily causes an abrupt abnormal reaction and has a tendency of decreasing the formation rate of the cyanohydrin. By contrast, if the pH is too low, the reaction itself is stable, but the reaction rate becomes slow. 10 [0053] The reaction rate of the reaction of a carbonyl compound with prussic acid can be controlled precisely by suitably varying the pH of a buffer solution. The pH of the buffer solution can be regulated suitably by varying the molecular ratio of a weak acid and a salt of the weak acid. For example, in the case of using glycolic acid as a weak acid and sodium glycolate as a salt of the weak acid, by making the 15 molecular ratio (GA/GANa) of glycolic acid (GA) to sodium glycolate (GANa) to be 0.43 on a presumption from the acid dissociation constant (3.63 at 25C) of glycolic acid, a buffer solution of a pH of 4 can be prepared. [0054] For example, when the acid dissociation constant of a weak acid is denoted as Ka, in order to prepare a buffer solution of a pH of X, the molecular ratio Y (a 20 molecular number of the weak acid / a molecular number of a salt of the weak acid) of the weak acid to the salt of the weak acid may be made to be a value represented by the following expression (i). Y = 10(pKa-x) (i) [0055] A buffer solution is preferably one prepared such that the difference between 25 the pH at the reaction start time of a carbonyl compound and prussic acid and the pH at the reaction completion time becomes 0 to 1, and more preferably one prepared 10 FP11-0261-00 such that the difference becomes 0 to 0.5. By suppressing the variation width of the pH as described above, the formation rate of a cyanohydrin improves more remarkably. Additionally, the reaction rate can thereby be controlled more precisely. 5 [0056] In the production method according to the present embodiment, by regulating the contents of a weak acid and a salt of the weak acid in a buffer solution, the variation width of the pH can be suppressed in the range described above. Specifically, by making the content of a weak acid to be 0.02 to 0.24 mol% with respect to the total amount of a carbonyl compound used for the reaction and the 10 content of a salt of the weak acid to be 0.04 to 0.52 mol% thereto, the variation width of the pH can be suppressed in the range described above. [0057] The production method of a cyanohydrin according to the present embodiment can be carried out, for example, by adding prussic acid to a buffer solution, which contains a carbonyl compound and has a pH of less than 7, and is 15 being held in a predetermined temperature range, to allow the carbonyl compound to react with the prussic acid in the buffer solution. [0058] The predetermined temperature range described above is, from the viewpoint of improving the formation rate of a cyanohydrin, usually 10 to 90C, preferably 20 to 80C, and still more preferably 30 to 60C. Too high a temperature thereof 20 progresses the reverse reaction from a cyanohydrin to a carbonyl compound, and additionally easily causes an abrupt abnormal reaction and has a tendency of decreasing the formation rate of the cyanohydrin. By contrast, if the temperature is too low, the reaction itself is stable, but the reaction rate becomes slow. [0059] The reaction of a carbonyl compound with prussic acid is carried out 25 preferably while the prussic acid is being added to a buffer solution containing the carbonyl compound and having a regulated temperature as described above. The 11 FP11-0261-00 addition rate is preferably 0.05 to 10 mol%/min, and more preferably 0.1 to 5 mol%/min, with respect to the total amount of the carbonyl compound. Too high an addition rate thereof involves a rapid pH variation in some cases, and too low an addition rate thereof elongates the process time and decreases the working efficiency. 5 The temperature of the buffer solution is preferably regulated so as to be maintained in the predetermined temperature range described above during the addition of the prussic acid; and also after the completion of the addition of the prussic acid, the temperature is preferably regulated so as to be maintained in the predetermined temperature range described above until the completion of the reaction. 10 [0060] The reaction time of the reaction of a carbonyl compound with prussic acid is usually about 1 to 10 hours. As described above, since the reaction rate is regulated by varying the pH of a buffer solution, the reaction time can be suitably regulated in conformance with the reaction rate. [0061] The reaction of a carbonyl compound with prussic acid may be carried out 15 under atmospheric pressure or under increased pressure in a reaction region. The production method according to the present embodiment can be carried out well by either of a batch process and a continuous process. In the case of employing a continuous process, it is preferable that a reaction region is divided into two or more and the reaction is carried out in a multistage. 20 [0062] After the completion of the reaction of a carbonyl compound with prussic acid, the pH of the reaction solution containing a cyanohydrin is regulated preferably at 2 or less, and more preferably 1.5 or less, for example, by adding an acid such as sulfuric acid. By regulating the pH of the reaction solution in such a manner, the reverse reaction from the cyanohydrin to the carbonyl compound is 25 suppressed and the storage stability of the cyanohydrin in the reaction solution improves. 12 FP11-0261-00 [0063] Then, for example, by removing the solvent and the residual prussic acid under reduced pressure to concentrate the reaction solution whose pH has been regulated as described above, the cyanohydrin can be obtained. The temperature at the concentration time is preferably 50C or lower. 5 If the temperature at the concentration time is higher than 50C, the cyanohydrin has a risk of decomposing. [0064] Hitherto, the preferred embodiment according to the present invention has been described, but the present invention is not limited to the above-mentioned embodiment. METHOD OF INDUSTRIAL APPLICATION OF THE INVENTION 10 Examples [0065] Then, the present invention will be described in more detail by way of Examples. However, the present invention is not limited to the following Examples, and can be carried out through suitable modifications in the range of not changing the gist of the present invention. 15 [0066] (Example 1) 79.54 parts by mass of a 37-mass% formaldehyde aqueous solution, 0.17 part by mass of glycolic acid (purity: 97 mass%), 0.50 part by mass of sodium glycolate (purity: 97 mass%), and 60 parts by mass of water were weighed and charged in a 20 reactor; and the mixture was heated to 45C while being stirred and dissolved. A pH at 45C of the mixed solution was 3.9. [0067] 27.81 parts by mass of liquid prussic acid was dropwise charged over 30 min in the mixed solution. A pH of the reaction solution right after the dropwise charge of the total amount of the liquid prussic acid was 4.1. Thereafter, the reaction 25 solution was stirred at 45C further for 1 hour. The pH of the reaction solution at 13 FP11-0261-00 the completion of the reaction was 4.1, and the formation rate of glycolonitrile was 96% (in terms of formaldehyde). [0068] (Example 2) 5 79.54 parts by mass of a 37-mass% formaldehyde aqueous solution, 0.02 part by mass of glycolic acid (purity: 97 mass%), 0.05 part by mass of sodium glycolate (purity: 97 mass%), and 60 parts by mass of water were weighed and charged in a reactor; and the mixture was heated to 45C while being stirred and dissolved. A pH at 45C of the mixed solution was 3.6. 10 [0069] 27.81 parts by mass of liquid prussic acid was dropwise charged over 30 min in the mixed solution. A pH of the reaction solution right after the dropwise charge of the total amount of the liquid prussic acid was 3.7. Thereafter, the reaction solution was stirred at 45C further for 1.5 hours. The pH of the reaction solution at the completion of the reaction was 3.8, and the formation rate of glycolonitrile 15 was 96% (in terms of formaldehyde). [0070] (Example 3) 79.54 parts by mass of a 37-mass% formaldehyde aqueous solution, 0.33 part by mass of glycolic acid (purity: 97 mass%), 0.99 part by mass of sodium glycolate 20 (purity: 97 mass%), and 60 parts by mass of water were weighed and charged in a reactor; and the mixture was heated to 45C while being stirred and dissolved. A pH at 45C of the mixed solution was 4.0. [0071] 27.81 parts by mass of liquid prussic acid was dropwise charged over 30 min in the mixed solution. A pH of the reaction solution right after the dropwise charge 25 of the total amount of the liquid prussic acid was 4.2. Thereafter, the reaction solution was stirred at 45C further for 1 hour. The pH of the reaction solution at 14 FP11-0261-00 the completion of the reaction was 4.2, and the formation rate of glycolonitrile was 97% (in terms of formaldehyde). [0072] (Example 4) 5 57.32 parts by mass of acetoaldehyde, 0.30 part by mass of lactic acid (purity: 90 mass%), 0.81 part by mass of sodium lactate (purity: 90 mass%), and 24.05 parts by mass of water were weighed and charged in a reactor; and the mixture was cooled to 7C while being stirred and dissolved. A pH at 7C of the mixed solution was 5.3. 10 [0073] 36.90 parts by mass of liquid prussic acid was dropwise charged over 1 hour in the mixed solution. A pH of the reaction solution right after the dropwise charge of the total amount of the liquid prussic acid was 4.5. Thereafter, the reaction solution was heated to 20C and stirred further for 2 hours. The pH of the reaction solution at the completion of the reaction was 4.3, and the formation rate of 15 lactonitrile was 99% (in terms of acetoaldehyde). [0074] (Comparative Example 1) 79.54 parts by mass of 37-mass% formaldehyde and 60 parts by mass of water were weighed and charged in a reactor; and the mixture was heated to 45C 20 while being stirred. A pH at 45C of the solution was 4.4. [0075] 0.06 part by mass of a 0.5-mass% sulfuric acid aqueous solution and 0.13 part by mass of a 0.1-mass% caustic soda aqueous solution were added to the solution to make the pH to be 4.1. When 27.03 parts by mass of liquid prussic acid was dropwise charged over 30 min in the solution, the pH of the reaction solution 25 gradually decreased and the pH of the reaction solution right after the dropwise charge of the total amount of the liquid prussic acid became 2.7. Thereafter, the 15 FP11-0261-00 reaction solution was stirred at 45C further for 1 hour. The pH of the reaction solution after the 1-hour stirring was 2.7, and the formation rate of glycolonitrile was 86% (in terms of formaldehyde). [0076] From the above results, it is found that if a carbonyl compound and prussic 5 acid are allowed to react in a solution whose pH has been only regulated simply using an acid and a base, the pH varies along with the reaction progress and the formation rate of a cyanohydrin does not rise so much. By contrast, it is found that if a carbonyl compound and prussic acid are allowed to react in a buffer solution whose pH has been regulated to an acidic side, since the pH does not vary largely, 10 the reaction rate is stabilized in a suitable range and the formation rate of the cyanohydrin rises. 16