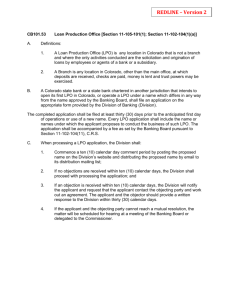

Annex 3

advertisement