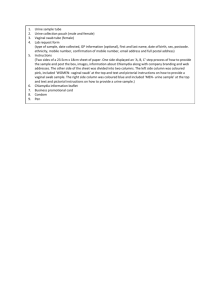

Control requirements for the TTPOOM Project

advertisement

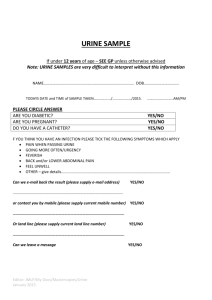

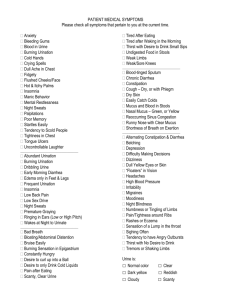

Development of a Wheelchair Mounted Urinary Toileting Device for a Client with Complete Amelia. Mr Robert Bingham (RPH) 1.0. INTRODUCTION: The adoption of a “no-lift” policy for carers of disabled patients initiated some special manual handling situations for some of our clients. For one of our clients, Monica, a middle aged lady with complete amelia, an absence of arms and legs meant that the options for grasping to lift was limited. Lifting and positioning was carried out in a “Bear Hug” fashion. The seat cushion in her current wheelchair1 was modified with a removable section to allow the use of a hospital urine bottle. The following proposal was developed to allow independent urination. The system will allow Monica to drive up to a urinal, or toilet bowl, extend the urination tube out from under the wheelchair and over the bowl, urinate and then disinfect and dry herself completely independently. 2.0. DESCRIPTION: The TTPOOM Project allows our client to void her bladder while seated in her wheelchair. Monica sits in a foam-in-place custom cushion that has inserted into it a polyethylene funnel to collect the urine. The urine is ducted down a silicone tube supported by a retractable boom that has been extended over a suitable receptacle. Following urination, the external genitalia is flushed with a suitable disinfectant, the excess being ducted through the same urine tube. Following disinfectant flushing, the genitalia are dried with heated air from an air pump. This also has the effect of drying the remaining urine and disinfectant from the urine tube. Once this urination process has been completed, the boom is retracted and stowed under the seat. 2.1. Funnel: The funnel is made from polyethylene and is vacuum formed over a male mould. The rim of the funnel is flanged and has 3 tubing connections (See Figure 1). These connections are for; 1. draining the urine and excess disinfectant, 2. the disinfectant spray nozzles, and 3. the heated air drying hose. Figure 1: Urine funnel. The flange of the funnel is contoured to provide contact around her pubic area enclosing the labia majora and supported by her perineum and symphis pubis. Either side of the funnel and between the funnel flange and seat cushion are inflatable bladders to press the funnel against Monica’s sympis pubis and perineum so as to provide a firm seal when urinating. When not in use the bladders are deflated to to relieve pressure around the sealing area. The bladders can be seen in figure 2 with the funnel raised. Figure 2: Inflation bladders The bladders are inflated with through the sealed system schematically described in figure 3. The pressure in the bladders is preset with an adjustable pressure switch that directly controls pump motor operation. The electrically actuated valve prevents back-flow through the motor when the bladder has inflated and allows back-flow to deflate the bladder. Figure 3: Schematic of the inflation bladder circuit. 2.2. Retractable Boom: The retractable boom assembly, which is stored under the seat pan when retracted, carries the 16mm OD x 10mm ID medical grade silicon urine drain tube. When retracted the tube is kinked in 2 places sealing the urinary system. The boom extends the opening of the urine tube 400mm laterally from the wheelchair. The retractable boom is driven by a 24V 4W DC motor through a right angle 50:1 reduction gearbox. End positions are detected by lever type V3 microswitches. 2.3. Disinfection: A dilute solution of Savlon® (20:1) is sprayed over the genital area for disinfection after urination. The solution is delivered via 2 Toyota windscreen washer nozzles embedded into the funnel. These are spherical so that the spray pattern can be adjusted to provide an effective distribution of the disinfectant. Disinfectant is delivered by a 12VDC centrifugal pump, similar to that used to inflate the bladders, via a flow control valve and non-return valve as shown in figure 4. The reservoir for the dilute disinfectant is adapted from a model aircraft fuel tank. This is filled through the filling nozzle using a syringe. Figure 4: Schematic of the disinfectant spray circuit. 2.4. Heating/Drying: The heater blower provides warm air to dry residual disinfectant both from the genital area and urine tube. The air is pumped into the upper entry of the funnel and exits through the urine tube. The blower is a 12VDC camping mattress inflator pump housed in a lined 12mm MDF box to limit the noise. Heating is provided is a tube on the outlet of the sound proof box where air is forced over a resistance wire heater (24V 6.0A). A thermal overload switch is mounted in the circuit to prevent accidental over temperature conditions. The hot air is ducted to the funnel through a 21mm dia. PE disposable ventilator tube. 3.0. CONTROL SEQUENCE: The proposed operation sequence is as follows: The wheelchair is positioned so that there is a suitable urine receptacle positioned within 400mm laterally of the wheelchair and the following sequence is initiated. 1. The boom is extended through Monica moving the toggle lever on the control box to the right with her chin. 2. The boom retracted limit switch becomes normally closed starting the bladder inflation pump and opening the valve. (Figure 3). The pump operates until the appropriate pressure (approximately 100mmHg) is achieved, opening the adjustable pressure switch. This stops the pump and closes the valve. The boom retracted limit switch also toggles the 4 way toggle switch from seat tilt mode to urination mode. 3. The boom extends until the extended limit switch opens to stop the boom extension motor. This illuminates a light on the control box indicates to indicate to Monica that the boom is fully extended and she can urinate. 4. Following urination, Monica pushes the toggle lever forward to activate the disinfectant pump and direct the disinfectant flow through the spray nozzles. (Figure 4). 5. After disinfection the toggle lever is pulled back to open the solenoid valve to allow the bladders to deflate and start the blower/heater to dry the genital area. Bladder deflation is assisted by a reduced pressure in the sealed reservoir. 6. The boom is retracted by moving the toggle lever to the left until it is fully retracted whereupon the boom retracted limit switch is opened turning off the boom extension motor. Opening this limit switch also returns the toggle switch to seat tilt mode. 4.0. FURTHER DEVELOPMENT: At this stage the system has been trialed successfully in a mock-up situation. A number of issues still require to be assessed once the system is integrated into Monica’s wheelchair. These issues include; whether the system will form an effective seal around the genital area during urination, the ability to maintain efficient drying when used regularly, the presence of the funnel in constant skin contact and any effects on skin breakdown, the ability of carers to effectively service the system, ie. maintain fluid levels, replace funnels and hoses, the long term viability of sealing the seat cushion with Otto Bock Super Skin ®, and Monica’s inability to put the toilet seat up. 5.0. REFERENCES: 1 Bingham R. and Jones T, “A Radical Mobility Device for a Client With Complete Amelia” Proceedings ARATA 2001 Conference- Brisbane.