Experimental Materials

United Arab Emirates University

Collage Requirement Division

Faculty of Engineering

Chemistry of Engineering and application I

CHEM 1252

Group Members: ID number:

Section #55

Lab Instructor: Dr.

Omar Chaalal

Date of Submission: March 18, 2008

Spring 2008

| P a g e 1

Contents:

Lists of figures, tables and chart ……………………………3

Abstract ………………………………………………………. 4

Intro duction ……………………………………………………4

Experimental materials ……………………………………...5

Experimental procedure ……………………………………..6

Samples calculation

Theoretical amount of alum ………………………………7

Experimental amount of alum ……………………………8

Finding volume for H2

……………………………………. 9

Finding melting point ……………………………………..10

Result and Observations …………………………………10

Conclusions …………………………………………………. 12

Recommendation ……………………………………………12

References ………………………………………………….. 13

Appendices ………………………………………………….13

| P a g e 2

Lists of figures:

Figure 1 ………………………………………………………..16

Figure 2 ………………………………………………………...5

Figure 3 …………………………………………………………5

Figure 4 …………………………………………………………5

Figure 5 …………………………………………………………5

Figure 6 …………………………………………………………5

Figure 7 …………………………………………………………5

Figure 8 …………………………………………………………5

Figure 9 …………………………………………………………5

Lists of tables:

Table 1…………………………………………………………10

Table 2 ………………………………………………………...11

Lists of chart:

Chart1 …………………………………………………………12

Chart2 …………………………………………………………15

Chart3 …………………………………………………………15

Chart4 …………………………………………………………16

| P a g e 3

ABESTRACT:

Our environment faces many problems, one of the most threatened problems are the waste of elements and the pollutions as a result of human activities. Aluminum is known for its low density, high tensile strength and its high resistance to corrosion, these qualities made aluminum a widely used substance in engineering applications.

Aluminum products that stand the test of time have a smaller impact on the environment.

In this experiment, recycling aluminum cans was studied and performed, by using a method that involved Sulfuric acid and Potassium hydroxide, which was result in producing new metals called Alum. We found the experimental amount of alum and we calculated the theoretical amount, after that we found the percentage error between them. Finally, we measured the melting point.

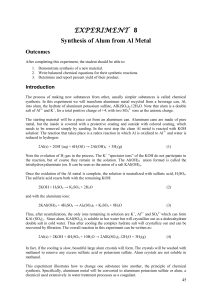

Introduction:

Recycling aluminium becomes one of the most important industries in the world. So it becomes a phenomenon issue and talking about it is something important.

Recycling reduce the pollution and save our energy sources. It helps us to reduce the environmental pollution. Recycling aluminum has many benefits such as: Making things from recycled materials causes less pollution, less rubbish will need to be buried in the ground, due to the recycling operation and many other benefits that we can gain from this process.

Aluminium can be recycled chemically by using the scrap aluminium to react with a base like (KOH (aq) ) in an aqueous media and then with sulfuric acid

(H2SO4

(aq)

). This is a hydrated double salt, precipitates in a form of large crystals as we see from the equation below:

K

2

SO

4

(aq) + Al

2

(SO

4

)

3

(aq) + 12 H

2

O →

2KAl (SO

4)2

.12H

2

O (s)

But the general chemical reaction that describes the formation of alum is as follows:

Al (s) + 11H

2

O (l) + KOH (aq) + 2H

2

SO

4

(aq) → KAl(SO

4

)

2

.12H

2

O (s) + 3/2 H

2

(g)

| P a g e 4

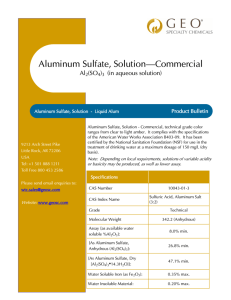

Experimental Materials:

(4mole) of Potassium Hydroxide (KOH)

(9mole) of Sulfuric Acid (H

2

SO

4

)

A piece of Aluminum

Electronic Balance

Heating Plate

Filter paper

Heating source (Drying Oven)

Thermometer

Flasks

A Buchner filtration system

Capillary tube for melting-point determination

Graduated cylinder

Figure 2; Electronic Balance

Figure 3; PH meter

Figure 5; Buchner filtration system Figure 6; Measuring Cylinders

Figure 8; Aluminium

Figure 4; Melting point apparatus

Figure 7; volumetric flask

Figure 9; Filter paper

| P a g e 5

Experiment procedure

The steps that have been followed during the experiment procedure are:

Step 1: Preparing samples .

A piece of aluminum foil was cut into three pieces of different size. These three samples were weighed by the electronic balance and were in the range of 0.25, 0.50 and 1.00 gram. Then each sample was put in a 125-ml beaker and each beaker was labeled according to the mass of the sample.

Step 2: Reacting with KOH

The samples were placed in the fume hood and about 10 to 50 ml of 4M KOH solution was added to each sample. The samples were then heated gently while swirling them until the reaction completed.

2 Al (s) + 2KOH (aq) +2H2O (l) → 2KAl (OH) 4 (aq) + 3H2 (g)

Step 3: Filtration

When the reactions in each sample stopped, (hydrogen gas was not evolving) the reaction mixtures were heated until the liquid level was reduced to approximately 10-

25 ml. After that the reaction mixtures were removed from the fume hood and were filtered in a 125 ml beaker .

Step 4: Adding the H2SO4

5-30 ml of 9M of sulfuric acid (H2SO4) was added to the filtrates. A white solid precipitate, which was Al (OH)3, was observed upon the addition of the sulfuric acid.

2KAl (OH) 4 (aq) +H2SO4 (aq) → 2Al (OH) 3 (s) + H2O (l) +K2SO4 (aq)

Next, the samples were heated once again while they were stirred until the precipitate dissolved.

2Al (OH) 3 (s) + 3H2SO4 (aq) → Al2 (SO4) 3 (aq) +6H2O (l)

Finally, the samples were left in the laboratory for one week in a cold area .

| P a g e 6

Step5: Measuring the masses and the melting points

After one week, crystals of alum were formed in the three samples.

K2SO4 (aq) + Al 2 (SO4) 3 (aq) + 12H2O → 2KAl (SO4) 2 .12H2O(s)

These crystals were filtered out by using the Buchner filtration system. Subsequently the samples of crystals were put in wash glasses and were put in the drying oven in order to dry. The masses of the samples were measured using the electronic balance once again. Finally, the melting points of the three samples were measured by using the melting point apparatus.

Samples Calculations

General Reaction:

Al (s) + 11H

2

O (l) + KOH (aq) + 2H

2

SO

4

(aq) → KAl(SO

4

)

2

.12H

2

O (s) + 3/2 H

2

(g)

Theoretical amounts of alum

1 g Sample:

Molar mass for KAl(SO4 )2.12H2O = 474

According to the above formula ratio which is 1:1

KAl(SO4 )2.12H2O

474 g

x

27 g

1 g x = [(1)(474)]/27 = 17.56 g of alum

Al

0.5 g Sample :

KAl(SO4 )2.12H2O

474 g 27 g

Al

x 0.5 g x = [(0.5)(474)]/27 = 8.78 g of alum

Molar mass for Al = 27

| P a g e 7

0.25 g Sample:

KAl(SO4 )2.12H2O

474 g

x

Al

27 g

0.25 g x = [(0.25)(474)]/27 = 4.39 g of alum

Experimental amounts of alum

Mass of filter paper and wash glass = 50.80 g

Masses of crystal samples when dry = mass of crystals with filter paper and wash glass – mass of filter paper and wash glass: g: 75.85 – 50.80 = 25.05 g

0.50 g: 63.03 – 50.80 = 12.23 g

0.25 g: 57.16 – 50.80 = 6.361 g

Percentage of Error

l Experimental amount of alum – Theoretical amount of alum l

= X 100

Theoretical amount of alum

1 g Sample:

= l 25.05 - 17.57 l X 100/17.57

= 42.5 %

0.5 g Sample:

= l 12.23 – 8.79 l X 100/8.79

= 39.1 %

| P a g e 8

0.25 g Sample:

= l 6.361 – 4.39 l X 100/4.39

= 44.8 %

Finding the volume of H2 for each sample

The ideal gas low will be used in order to find the volume of H2:

VP = n*RT

Where n is the number of moles, P is the pressure of the gas (atm), V is its volume (L) and T is the temperature (K). It was found that the gas constant R is equal to 0.08206

L.atm/(mol.K)

According to the alum formation equation we can find the hydrogen volume for each sample.

Al(s) + 11H2O (I) + KOH (aq) + 2H2SO4 (aq) KAL (SO4)2.12H2O (s) +

3/2 H2 (g)

For every one mole of (Al) reacting (3/2) moles of H2 produced.

The room temperature = 25 ºC K = 25 + 273 = 298 K

R (Ideal gas constant) = 0.08206 L.atm/(mol.K), P = 1 atm

1g Sample:

Concentration (C) = number of moles (n) / Volume (V)

V used for KOH = 50 mL = 0.05 L

→ n for KOH = CV = (4)(0.05) = 0.2 mol

C for KOH = 4M

(According to chemical equation)

H2 KOH

3/2 mol

x

1 mol

0.2 mol x = [(0.2)(1.5)]/1 = 0.3 mol H2

→ V for H2 = [(0.3)(0.08206)(298.15)]/1 = 7.34 L

0.5g Sample:

V used for KOH = 25 mL = 0.025 L

→ n for KOH = CV = (4)(0.025) = 0.1 mol

C for KOH = 4M

H2

3/2 mol

x

KOH

1 mol

0.1 mol

| P a g e 9

x = [(0.12)(1.5)]/1 = 0.15 mol H2

→ V for H2 = [(0.15)(0.08206)(298.15)]/1 = 3.7 L

0.25g Sample:

V used for KOH = 12.5 mL = 0.013L

→ n for KOH = CV = (4)(0.013) = 0.05 mol

C for KOH = 4M

H2

3/2 mol x

KOH

1 mol

0.05 mol x = [(0.5)(1.5)]/1 = 0.075 mol H2

→ V for H2 = [(0.075)(0.08206)(298.15)]/1 = 1.83 L

Melting point of alum

Melting point = 81 ◦C and is the same for all of them

Melting Point Standard Deviation = 6.98

Results

Table 1: illustrate the Mass and the volume of the materials that were used.

Sample

1

Mass of

Aluminum gm

Table 1: Results of Recycling Aluminum

Volume of 4M

KOH , ml

Volume of

H

2

9M

SO

4

,ml

Mass of alum crystal, gm

Melting point of alum

1 50 30 25.05

81

15

7.5

12.23

6.361

81

81

2 0.50

25

3 0.25

12.5

Notes/Observations:

1Dissolution of the Aluminum.

Average melting point of

Al

81 ◦C

2Upraise of gas hydrogen when we put H2SO4.

3After putting H2SO4 to the solution of Al, the white powder was created.

| P a g e 10

4Crystallization of Alum.

5The values of mass of Al (gm) and mss of alum (gm) were compared together to find the amount of alum for each sample.

After the recycling process had been done, it was found that there was a different between the theoretical yield and the actual yield of the Alum and that was due to the following reason:

* The sample didn’t dried very much, so there was some water which enlarges the amount of the produced Alum that was almost the reason of getting amount of Alum larger than what was calculated.

* This error could be due to many sources such as instrumental error (due to the apparatus used), personal error (while filtrating the crystals and transferring them to the wash glasses) and random error.

Table 2: shows the theoretical and experimental yield of Alum;

Table 2: Results of Recycling Aluminum

Experimental amount of alum, g

Theoretical amount of alum, g

Theoretical

Volume of H

2

, L

25.05

12.23

17.56

8.78

7.34

3.7

6.361

4.39

1.83

Furthermore, the melting points were calculated and their average was calculated.

After which, the average were converted from Celsius to Kelvin's by using this law: T

(K) = T (oC) + 273.15. In order to get the volume of H2 we used the Ideal Gas Law

(PV=NRT) where P =1 atm, R= 0.080206 and N=1.5 at standard conditions.

| P a g e 11

Chart 1: reveals the relation between the mass of the Alum and the volume of H2;

Relation ship between the mount of AL and the Volume of H2 that was produced

6

5

4

3

8

7

2

1

0

0 5 10 15

Amount of AL, gm

20 25 30

It's noticed that the volume of hydrogen gas increased when the amount of Al increased. So that, the relationship between them was proportional.

Conclusion:

The most common metal we need to consider when we are talking about recycling is aluminium. In this experiment we learned several things. We understood how to calculate the amount of aluminum in theoretical and experimental ways.

We did some steps in this experiment to calculate and measured several values; first, we found the theoretical mass of Alum to compare it with the experimental value that we found it before. Then, the Alum melting point we found it by calculating the average of the initial value (when the alum crystals melt began melting) and the final value (when the alum crystals melt at all) in order to perform a comparison with the theoretical value of the melting point of the Alum. Finally, we measured the amount of hydrogen gas which produced in each sample by using the final equation of the reaction and by the Ideal gas law.

Several skills were developed during this experiment. We learned how to work as a team and how to deal with laboratory equipments.

| P a g e 12

References

1A. Darwish, N., Chemistry and Engineering Applications CHEM 1252

Laboratory Manual for the Engineering Projects Experiments ,U.A.E.

2Chemistry, The Central Science, written by Brown, Lemay and Bursten, Tenth

Edition

3NASA Ultra-Efficient Engine Technology, Commonly Used Elements and their Properties. Retrieved (6th April 2006), from http://www.ueet.nasa.gov/elements.htm

Appendices

Aluminum History

In 1808, Sir Humphrey Davy (Britain); discovered the existence of the shiny metal we are so dependent on today and gave it a name - Aluminum.

In 182, P. Berthier (France); discovered a hard, reddish, clay-like material containing 52 per cent aluminum oxide near the village of Les Baux in southern

France. He called it bauxite - after the village. Today, we recognize bauxite as the most common ore of aluminum. (Bauxite specimens are available on our specimens page)

In 1825, Hans Christian Oersted (Denmark); produced very small quantities of aluminum metal by mixing dilute potassium amalgam with anhydrous aluminum chloride. When the two were allowed to react chemically, a residue of slightly impure aluminum was produced.

| P a g e 13

In 1827, Freidrich Wohler (Germany); developed a method for producing aluminum powder through a chemical reaction between potassium and anhydrous aluminum chloride.

In 1845, Wohler; determined the specific gravity of aluminum (2.7) which illustrated one of its unique physical properties - it was extremely light in weight compared to most metals known at the time.

In 1854, Henri Sainte-Claire Deville (France); create the first commercial process for producing aluminum which - at that time - was more valuable than gold.

In 1855; A bar of aluminum was exhibited alongside the Crown Jewels at the

Paris Exhibition.

In 1885, Hamilton Y. Cassner (USA); improved on Deville's process for producing aluminum and 15 tons were produced that year!

In 1886, Two unknown young scientists, Paul Louis Toussaint Heroult

(France) and Charles Martin Hall (USA); working separately and unaware of each other's work, simultaneously invented a new electrolytic process

(eventually called the Hall-Heroult process) which is the basis for all aluminum production today. They discovered that if they dissolved aluminum oxide

(alumina) in a bath of molten cryolite and passed a powerful electric current through it, molten aluminum would be deposited at the bottom.

In 1888; The first aluminum companies were founded in France, Switzerland and the USA

In 1889, Freidrich Bayer (Austria); son of the founder of the Bayer chemical company, invented the Bayer Process for the large scale production of alumina from bauxite.

| P a g e 14

Data Tables and related charts:

Chart 2: Statistics of aluminum beverage cans sold and recycled;

Chart 3: the comparison between the recycled and wasted cans during the last three decades ;

| P a g e 15

Chart4: Aluminum Recycling Advantages;

100%

80%

60%

40%

20%

0%

…an “Energy Bank”

100%

• Recycling only needs 5% of the energy.

• Recycling emits 95% less greenhouse gas emissions.

New Alumin um

5%

Recycled Alumin um

Figure 1:Millions of cans are wasted and threw which has a great effects in the environment either casing pollutions or elements waste ;

| P a g e 16