UNIT 3: MSDS's

advertisement

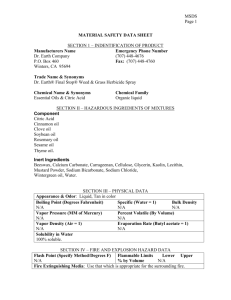

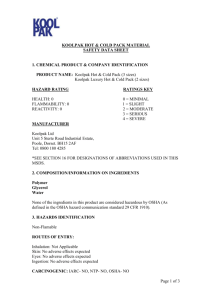

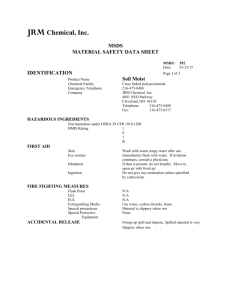

UNIT 3: MSDS's The second means by which WHMIS gets hazardous material information to workers is through MSDS's. WHMIS labels provided only brief and vital information to workers but MSDS's give more detailed information which is important in handling emergencies or clean-ups, or in designing controls for safe use of the hazardous material without worker exposure. MSDS's contain technical information needed for use by engineers, occupational hygienists, fire fighters, and medical personnel. Some of the terms will be strange to you. Nevertheless, it is important that you are able to read and understand an MSDS so that you know how to handle hazardous materials safely. This unit will explain the content and terms of MSDS's as well as the responsibilities of suppliers and employers concerning MSDS's. MSDS Content: Unlike a WHMIS label for which the contents differ depending on whether it's a supplier or workplace label, the kinds of information that must appear on all MSDS's is the same. The Hazardous Products Act requires that at least 9 different kinds of information appear on MSDS's for all controlled products: i. product information (what is it?) ii. preparation information about the MSDS (who wrote the MSDS?) iii. hazardous ingredients (what's dangerous in it?) iv. physical data (what are its properties?) v. fire or explosion hazard vi. reactivity data (what does it react with?) vii. toxicological data (health effects) viii. preventative measures (how to handle it safely) ix. first aid measures 3-1 There are a number of sub-categories of information in each section resulting in about 50 different pieces of information. Let's look at each of these 9 sections of an MSDS and their technical terms. i. product information: the name, address, and emergency telephone number of the product's manufacturer and supplier (if different) the use of the product (e.g., degreaser, rust remover, lubricant, etc.) the Product Identifier, i.e., the name of the product by the same name used on the label, e.g., "Prosolve", "Cleanall", etc. Optional product information includes the following: true chemical name as per I.U.P.A.C (International Union of Pure and Applied Chemists), e.g., 1,1,1-trichloroethane -- a degreasing solvent chemical family, e.g., acids, alkalis, chlorinated hydrocarbons, aldehydes, ketones, amines, etc. -- this assists in understanding potential hazards in chemical reactivity or health hazards discussed later. chemical formula, e.g., CCl3CH3 -- this is useful in that it allows you to predict what kind of irritants it might form in a fire. This chemical may form hydrochloric acid and toxic phosgene gas in a fire. molecular weight -- calculated by adding up the atomic weights of atoms that make up the molecule. For gases and vapours, if the molecular weight exceeds 29 (the molecular weight of air), the concentrated gas or vapour will sink in air and if less than 29, will rise in air. For example, chlorine gas has a molecular weight of 71, substantially heavier than air. synonyms -- commonly used trade names, e.g., dry-cleaning solvent , tetrachloroethylene, perchlorethylene, perc, carbon dichloride and ethylene tetrachloride are all synonyms for the same chemical. ii. preparation information: the name and phone number of the person or department who prepared the MSDS the date on which the MSDS was prepared or revised 3-2 iii. hazardous ingredients: -the name and concentration of all the ingredients of the product which come under any of the 8 hazard classes (corrosives, flammables, etc.). Unless otherwise stated, concentrations are in percent by weight. The Ingredients Disclosure List names more than 1700 chemicals which would be hazardous in mixtures if present at concentrations greater than about 1% (or 0.1% if they are very toxic). If any of these are present at or above the given concentrations, then the concentration and names of these hazardous ingredients must also be reported on the MSDS . -special 4-digit PIN (Product Identification Numbers) of a hazardous product on MSDS's. These are: -CAS (Chemical Abstract Service) registry number: a unique number assigned by an international chemical organization and used by chemists -UN (United Nations) number: an internationally recognized identification number of hazardous chemicals listed in the Transportation of Dangerous Goods Regulations and used by firefighters or other emergency personnel -NA (North America) number: a number assigned by the Canadian and U.S. Departments of Transport for hazardous chemicals which do not have a UN number - LD50 and LC50 of the ingredients (Lethal Dose & Lecthal Conc) LD50 is the dose of the ingredient that will kill half a test population of animals (e.g. rats, mice, rabbits) when that amount of the ingredient is given to them by a certain method (e.g., the substance is fed to them or applied to their skin). For example, see "Rat, Oral, LD50: 200mg/kg" means that 50% of a test population of rats died when they swallowed a dose of 200mg of the substance for every one kilogram of body weight. LC50 works the same way, except that this value refers to the concentration of the ingredient in air (expressed as ppm --- parts per million or mg/m3). When breathed in by a group of test animals over 4 hours, this concentration will kill 50% of them. When known, the MSDS must give the LD50 or LC50 for the entire mixture instead of each of the ingredients. This tells how hazardous the mixture is as a whole. The lower the LD50 or LC50, the more toxic it is. 3-3 LD50 (Lethal Dose 50%) is a dose of chemical which will kill (be lethal to) 50% of the test animals, e.g. rats, rabbits, mice, when fed to them or applied to their skin. "Rat, Oral, LD50: 200 mg/kg" means that 200mg of the chemical will kill 50% of the test animals weighing 1 kg. For test animals weighing 2 kg, twice as much (400mg) of the chemical would be required to give the same result-50% death. For adult humans, with body weight of 80kg (175lb), 80 times as much chemical would have to be swallowed or applied to the skin to give the same result-50% death. Convert mg to grams by dividing mg by 1000, e.g., 200mg 1000 = 0.2g The lower the LD50, the less it takes to cause death, the more toxic the chemical. The LD50 for sodium cyanide is only 6mg/kg. 1kg 200mg or 0.2g 80kg 200 × 80 = 16000mg or 16g LC50 (Lethal Concentration 50%) is the concentration of a gas in air which will kill (be lethal to) 50% of the test animals, e.g. rats, rabbits, mice, when breathed in by the animals in a definite period of time. Gas concentrations are measured in parts per million (ppm) or mg/m3. For example, the LC50 for hydrogen cyanide gas is 544 ppm (609 mg/m3) for 5 minutes. 3-4 iv. physical data: explains how the material behaves when in use. This section is broken down into 12 different categories. - physical state of the product -- tells whether the product is a gas, liquid, or solid at room temperature - odour and appearance -- describes the smell and look of a product Odour includes quality (almond-like, fruity, sweet, skunky, rotten egg-like, etc.), intensity (e.g., strong, mild, faint) Appearance includes colour, texture (greasy, waxy, soft), particle size (powder, granules, flakes). Liquids can be described as gelatinous (jellylike), viscous (syrupy), thick, or thin. - odour threshold -- tells how strong-smelling a substance is Odour Threshold is the level, in parts per million, at which most people will be able to smell the product. This can be helpful if the odour threshold is near the safe exposure level. If you can smell it, there's a problem. If the Odour Threshold is greater than the safe exposure level, then if you can smell the product, you're in danger. Get out of the area right away. The warning properties of odour thresholds are explained in the next table. warning properties odour threshold good fair poor 10 × below exposure limit up to 3 × above limit more than 3 × above limit Odour thresholds must be used with caution. Some chemical vapours (e.g., hydrogen sulfide, may de-sensitize (numb) the sense of smell. This is called "olfactory fatigue". 3-5 - specific gravity -- tells if a solid or liquid will float or sink in water Specific gravity is the weight of a solid or liquid compared to the weight of an equal volume of water. When the specific gravity is greater than 1.0, then the material will sink in water; if less, it will float. Most flammable liquids (e.g., gasoline) have a specific gravity less than 1.0. This is important information when fighting a fire -- the substance will float if water is used to try to extinguish the fire. Note, specific gravity and density are similar and have equal values for solids and liquids, however, density has units of g/cm3 while specific gravity has no units. For example, the specific gravity of aluminum metal is simply 2.7 while its density is 2.7 g/cm3 . - vapour density -- tells how heavy a gas is compared to air Vapour density is the density of a vapour compared to the density of air. When greater than 1.0, (e.g., carbon dioxide, chlorine), the vapour will sink and concentrate in low areas -- along the floor, in ditches, sumps, sewers, etc. This means the vapour may flow to an ignition source and ignite or it may displace air from the place making it unsafe to work there. If the vapour density is less than 1.0, it will rise. - vapor pressure -- tells how quickly a substance will evaporate Vapour pressure is the pressure of a vapour above its liquid or solid form in a closed container at 20 ºC and measured in mmHg. One atmosphere pressure is 760 mmHg. (1 mmHg is also called 1 torr). Vapour pressure is a measure of how much vapour will form above a substance. Materials with high vapour pressure can be hazardous, particularly in closed spaces. For example, diethyl ether ("Quick Start") has a vapour pressure of 452 mmHg at room temperature. Compare this to ethylene glycol (radiator antifreeze) with a vapour pressure of less than 1 mmHg. Both of these liquids will burn, however, quick start is very flammable (flash point = -45 ºC) but radiator antifreeze would have to be heated to a very high temperature to burn. Water has a vapour pressure of 17.5 mmHg at room temperature. 3-6 - evaporation rate -- like vapour pressure, tells how quickly a solid or liquid will evaporate and form a vapour, exposing you to possible inhalation danger. Evaporation rate is reported as a number which is the ratio of the evaporation rate of the product to the evaporation rate of a standard such as butyl acetate, ether, or other specified solvent. Because ether evaporates more quickly than butyl acetate, the chemical used for comparison must be listed. Evaporation rates are useful for estimating the inhalation hazard or fire hazard of various solvents. Compared to butyl acetate (normal-butyl acetate), evaporation rates are ranked as follows: FAST evaporating if greater than 3.0, e.g., methyl ethyl ketone = 3.8, hexane = 8.3 MEDIUM evaporating if 0.8 to 3.0, e.g., 95% ethanol = 1.4, MIBK = 1.6 SLOW evaporating below 0.8, e.g., xylene = 0.6, mineral spirits = 0.1 - boiling point -- the temperature at which a liquid boils Boiling points are determined at 760 mmHg pressure unless otherwise stated and are important because of the sudden volume change of the product and the amount of it in the air. Keep stored liquids below their boiling points. - freezing point -- the temperature at which a liquid freezes Volume changes may occur at the freezing point. Water based liquids expand when they freeze and may rupture their container. Keep stored liquids above their freezing points. - pH --a number which tells you how acidic or alkaline (basic) a solution is The pH scale is from 0 to 14. The strongest acids, like automobile battery acid (37% sulfuric acid), have a pH below 1. Strong alkalis, like some drain cleaners, have a pH up to 14, while pH 7 (pure water) is neutral (neither acidic nor basic). Solutions of pH above 11.5 or below 2.0 are corrosive. 3-7 The pH Scale soft drinks blood black coffee stomach acid 6.5 milk of magnesia 8.6 BASIC ACIDIC 0 1 2 3 4 5 6 vinegar & lemon juice battery acid 7 8 9 NEUTRAL unpolluted rain 10 11 12 13 14 Lake Erie ammonia -The pH scale is a measure of acidity of water with 0 being very acidic, 14 being very basic, and 7.0 being exactly neutral. - The scale is logarithmic, i.e., pH 4 is 10 times more acidic than pH 5. SOURCES: - industrial discharge of acids into water increases acidity (lowers pH) - industries burning coal and volcanoes emit acidic gases (sulfur dioxide) which combine with water in the atmosphere to produce acid rain (sulfuric acid - same kind as battery acid). -automobiles also emit acidic gases (nitrogen oxides) which combine with water in the atmosphere to produce another type of acid rain (nitric acid). - many aquatic plants release organic acids into water, i.e., peat moss and pine trees. - unpolluted rain is weakly acidic (5.6 pH) because it dissolves some carbon dioxide (CO2) from the air. DRAINS: - limestone, dolomite and other alkaline bedrock in lakes neutralizes acid and produces alkaline (basic) water. - industrial discharges of alkaline (basic) chemicals into water also neutralizes acidity and raise pH. 3-8 - coefficient of water/oil distribution -- tells to what extent a substance dissolves in oil or water. The technical term is "water-octanol coefficient" because the lab test used to determine the coefficient is done with n-octanol. A value less than 1 indicates better solubility of the product in oils and greases. Such a product may be absorbed through the skin. A value greater than 1 indicates better solubility in water. This type of product can be absorbed by mucosal tissue of the eyes or lungs. This information can be useful in assessing medical treatment, and selecting personal protective devices. The coefficient may also help with the general understanding of the affinity of the product for fatty tissue (called lipophilic properties) and planning clean-up procedures in the event of contamination of a water body. - other optional physical properties -- not required by the Controlled Products regulations but which a supplier may include on an MSDS are % volatile and solubility in water (at 20 ºC) - % volatile (by volume)-- is the percentage of a liquid or solid (by volume) that will evaporate at ambient temperature (room temperature). For example, butane is 100% volatile at room temperature (its boiling point is 0 ºC) - solubility in water (at 20 ºC) -- tells how much can be dissolved in water Solubility is the percentage concentration of material by weight in a saturated water solution at 20 ºC. Less than 0.1% is immiscible or insoluble, 0.1-1% is slightly soluble, 1-10% is moderately soluble, and more than 10% is very soluble. Water solubility is useful information for deciding upon what personal protective devices to wear and how to clean up spills. 3-9 Water soluble materials are easily absorbed by the mucous membranes of the nose and throat. v. fire or explosion hazards: conditions under which a substance becomes a flammable hazard and how to stop this substance from burning (e.g., water spray, dry chemical or carbon dioxide extinguisher). This section is particularly important with flammables, solvents, organic peroxides, explosives, metal dusts, etc. This section is broken down into 7 different categories. -flash point -- tells the lowest temperature at which a substance will burn in the presence of a flame or spark. In order for a liquid like gasoline to burn it must first be converted to a vapour by warming it up. The flash point is the lowest temperature at which vapours above a substance will ignite in air when exposed to a flame. Below the flash point, there is insufficient vapour to burn. Flash points are given as OC (open cup) or CC (closed cup) depending on the test apparatus used to measure them. Closed cup tests produce lower flash points for the same substance compared to open cup tests. The lower the flash point, the greater the fire hazard because it can ignite at lower temperatures. Gasoline has a flash point of -43 ºC-CC, which means that it won't ignite below this temperature in a closed container. In order to start your automobile at lower temperatures you will need to heat the engine block of your car or truck. -auto-ignition temperature --the lowest temperature at which a substance will burn without a flame or spark present. For gasoline, this is about 300 ºC. This is important in areas where gases or vapours may be exposed to high temperatures or hot surfaces. -upper flammable limit (UFL) and lower flammable limit (LFL) -- tell you that a vapour concentration within these limits will ignite or explode when exposed to a flame, spark, or other source of ignition. 3 - 10 For gasoline at 25ºC, the UFL is 7.4% and the LFL is 1.4%. When you "flood" a carburetor by pumping the gas peddle excessively, a car will not start since the vapour concentration of gasoline in the engine is above UFL -flammability -- tells how readily and under what conditions a substance will burn Under WHMIS legislation flammable and combustible materials are classified as Class B hazardous products. There are 6 divisions within Class B and these follow: 1. Flammable Gases are compressed gasses which form flammable mixtures in air either: a) when in a concentration of 13% or less by volume, or b) over a concentration range of 12% by volume or greater Propane is a flammable gas because it will burn in air at concentrations below 13% , i.e., 2.1-9.5%. Acetylene is a flammable gas because it will burn in air as low as 2.5% and up to 82% by volume. 2. Flammable Liquids have flash points less than 37.8 ºC (100 ºF)-CC. Gasoline (flash point -43 ºC) and ethanol (flash point +13 ºC) are flammable liquids. Flammable liquids are greater fire hazards than combustible liquids. 3. Combustible Liquids have flash points between 37.8 ºC and 93.3 ºC (200ºF). Toluene (flash point +85 ºC) is a combustible liquid. 4. Flammable Solids include the following: solids which can ignite simply due to friction, e.g., white phosphorus solids which burn vigorously and are difficult to extinguish, e.g., magnesium and aluminum powders solids in which the flame propagates (spreads) quickly, i.e., >0.1 in/s, e.g., carbon black powder, fine sawdust 5. Flammable Aerosols are flammable propellants such as Quick Start (diethyl ether), hair sprays, spray paints, light spray oils, etc. 3 - 11 6. Reactive Flammable Materials are spontaneously combustible in air, or explosive in contact with water, e.g., reactive metals like sodium, potassium, lithium, etc. -means of extinction -- lists the types of fire extinguishers suitable for the burning product. Extinguishers are rated as: type A containing water or carbon dioxide for extinguishing ordinary solid combustibles like paper, wood, etc., type B ("dry") containing halon powder for extinguishing flammable liquids like gasoline, type C containing carbon dioxide gas for extinguishing electrical fires, or type D containing inert material like sodium chloride, soda ash, or sand for extinguishing combustible metals like sodium. -hazardous combustion products -- tells you what hazardous products are released when a substance burns. For example, carbon monoxide is a hazardous "asphyxiant" (interfering with respiration) resulting from combustion of gasoline in an automobile engine. Hydrogen chloride is a corrosive gas released when PVC plastic is burned. Chlorinated hydrocarbon solvents like dry cleaning fluid (perchlorethylene) produce toxic phosgene gas when burned. -explosion data re: sensitivity to mechanical impact -- indicates how susceptible a material is to explosion when hit forcefully by another object, dropped, etc. Metal azides (used to propel auto air bags) are very shock sensitive. Explosive copper acetylide forms when acetylene (welders' fuel) is used in copper lines 3 - 12 -explosion data re: sensitivity to static discharge -- indicates how susceptible a material is to explosion in the presence of spark or shock due to static electricity. vi. Gasoline fumes can be ignited if you were to leave your car engine running while refueling at a gas station. reactivity data: this section describes stability of the product and alerts you to possible dangerous reactions with other chemicals. This information helps assure safe handling and storage procedures. this section has the following 4 categories: - chemical stability -- a chemical is unstable if it will vigorously decompose, polymerize, or become self-reactive under conditions of temperature, shock, vibration, or pressure Some peroxides and explosives are unstable and must be handled with caution. - incompatibility -- two substances are incompatible if, on combination, they react dangerously and produce toxic or corrosive by-products, excessive heat, or explosion Oxidizers (chlorine, peroxides, and pure oxygen) are incompatible with fuels, oils, and greases and will burn or explode when mixed. Incompatible substances must be stored separately. - reactivity -- this category provides information on reactivity other than that already provided. For example, household bleaches liberate chlorine gas when acidified. Never add acid to bleach! - hazardous decomposition products -- lists dangerous products produced when aged, heated, burned, etc. 3 - 13 Some ethers form explosive peroxide crystals around the lid of a container as they age. These can detonate the entire bottle when someone unsuspectingly opens the lid. Be aware of the shelf-life of your chemicals. Discard outdated chemicals and avoid ordering large quantities which must be stored indefinitely. vii. toxicological data (health effects): this section explains how the material is likely to enter the body and what short-term and long-term effects it is likely to have on an exposed worker, including signs and symptoms of exposure and pre-existing medical conditions which may be aggravated. this section contains 11 different categories as described below: - routes of entry --the 5 main ways a chemical can enter your body are: 1. eye contact occurs when a corrosive like sulfuric acid contacts the eye potentially causing eye damage. Workers handling 50% hydrogen peroxide wear tight fitting goggles because eye contact with this chemical causes instant, permanent eye damage! 2. skin contact (dermal contact) occurs when a corrosive, such as sulfuric acid, contacts the skin causing a localized irritation or burn. 3. skin absorption can occur because organic chemicals, such as solvents, can pass through the skin membrane. Absorbed chemicals are transported through the entire body by the circulatory system. Solvents such as naptha and varsol should not be used as hand cleaners. Use only commercial hand cleaners for this purpose. 4. inhalation can occur if a product exists in an airborne state such as a fume, dust, fiber, mist, or gas. The inhaled substance can be absorbed into the blood stream via the lungs. 5. ingestion (swallowing) may occur from contaminated fingers during eating or drinking. Eating is prohibited in all labs and workers are advised to wash their hands thoroughly before lunch breaks. - effects of acute exposure -- refers to adverse health effects resulting from short-term exposure to the material, either as a single exposure or 3 - 14 multiple exposures occurring within a short time, usually 24 hours or less. For example, acute exposure to the chemical asphyxiant, carbon monoxide, can, depending on the dose, induce symptoms ranging from headache and dizziness to coma and death. WHMIS Class D1 products (causing "immediate and serious toxic effects") cause acute effects. - effects of chronic exposure --refer to health effects which result from repeated exposure to the substance over a relatively long period of time. Chronic exposure to low levels of carbon monoxide may initiate or enhance heart problems particularly in individuals with heart problems. Repeated exposure to free silica in air may cause the lung disease, silicosis A chronic effect of alcoholism is liver damage and a chronic effect of smoking is lung cancer. WHMIS Class D2 products (causing "other toxic effects") cause chronic effects or less-serious acute effects. - exposure limits -- are the maximum limits of exposure to an airborne substance as recommended by bodies such as NIOSH (the National Institute for Occupational Safety and Health), ACGIH (American Conference of Governmental Industrial Hygienists), OSHA (Occupational Safety and Health Association, or as legislated by a health and safety regulatory agency such as the M.O.L. (Ministry of Labour). Exposure limits or Threshold Limit Values (TLV) generally represent conditions in which it is believed that nearly all workers may be repeatedly exposed day after day without adverse effect. There are 3 types of TLV's in common use: Exposure Limit - TWA -- the Time Weighted Average concentration for a normal 8-hour work-day or 40-hour work-week to which nearly all workers can be repeatedly exposed without adverse effects. Exposure Limit- STEL -- the Short-Term Exposure Limit, i.e., the maximum concentration to which workers can be periodically exposed for a period up to 15 minutes (a 15 minute TWA) without suffering from 3 - 15 irritation, chronic health effect, or "narcosis" (drowsiness) sufficient to increase risk of accidental injury or impair ability for self-rescue. Exposure Limit -C -- the Ceiling (maximum) concentration that must not be exceeded at any time. The data sheet should indicate which type of exposure limit is specified. When exposure limits are used in combination with odour thresholds, they may provide some warning mechanism as discussed earlier. 3 - 16 Dose/Response Relationship of Poisonous Substances: Adverse health effects of toxic materials vary according to the dose or amount you receive. The dose/response relationship for hydrogen sulfide (H2S) is shown below: Hydrogen Sulfide Toxic Effects 1000 ppm smell rotten eggs eyes nose & irritated throat irritated headache nausea death in 4-8 hours death in 1-4 hours death in 5 minutes 500 ppm 100 ppm 200 ppm 300 ppm 50 ppm 10 ppm 10 ppm 1.0 ppm 0.1 ppm Hydrogen sulfide has a TWA of 10 ppm, which means it is safe for most people to be exposed to this concentration for up to 8 hours per day without adverse effects. Its STEL is 15 ppm and its IDLH (immediately dangerous to life and health) value is given as 300 ppm. Note that the higher the dose, the worse the effect. All toxic materials exhibit dose/response relationships like this but the exposure limits vary from one to the next because some are more toxic than others. Some workers are particularly sensitive or allergic to a toxic material and may suffer adverse effects at lower concentrations than the TLV's. Hydrogen sulfide is insidious (unsuspectingly dangerous) because even though it is strong smelling at low levels, it soon deadens the sense of smell (olfactory fatigue) causing the worker to not realize he/she is being exposed. H2S is a Class D-division 1, acutely toxic hazardous product. 3 - 17 -irritancy of product --describes its ability to cause localized inflammation, burning, or swelling of the skin or eyes. Primary irritants, like acids, alkalis, amines, and ketones are strong irritants. Use effective eye and skin protection when handling primary irritants. A Class E corrosive need not also be labeled as a D2 irritant. -sensitivity or sensitizing capability of the product -- a sensitizer is a substance which on first exposure likely causes little or no reaction in persons or test animals, but which on repeated exposure may cause a marked response even beyond the contacted site. Skin sensitization (sensitization dermatitis) is known to occur with organic paint solvents and some chloro-platinum compounds. Respiratory sensitization (asthma) may result from repeated exposure to some plastic resins and especially isocyanates. - carcinogenicity -- carcinogens are cancer-causing agents. Two prominent groups, the ACGIH and the IARC (International Agency for Research on Cancer) annually publish a list of carcinogens. These lists identify various chemical as "confirmed carcinogens", "probable carcinogens", "suspect or possible carcinogens", "cannot be determined as carcinogens", or "probably not carcinogens". The lists of the 2 organizations vary somewhat however, examples of chemicals which are most frequently cited as carcinogens include: asbestos, vinyl chloride, chromium (VI) compounds, benzene, ethylene oxide, chloroform, lead, cadmium, and tobacco, amoung others. -mutagenicity -- a mutagen is a substance causing mutations (changes) in the genetic material of living cells. Changes to the reproductive cells may cause heritable genetic effects (inherited from one generation to another). Changes to non-reproductive cells may cause increased risk of cancer. Ionizing radiation is one example of a mutagen. 3 - 18 -teratogenicity and embryotoxicity -- is the ability to produce injuries in offspring (fetuses and embryos in the womb) before birth without harming the mother. The first 8 weeks after conception are most sensitive. Carbon monoxide, cigarette smoke, and alcohol are teratogens (embryotoxins). -reproductive toxicity -- is sterility or other adverse effects on the reproductive capability. - synergistic materials --are any materials that react with the controlled product to produce a toxic effect that is greater than the sum of the effects of the effects of the material and the product acting separately. Inhalation of cigarette smoke and asbestos have been shown to produce a risk of lung cancer far greater than each agent alone. Thus smoking and asbestos inhalation have hazardous synergistic effects. WHMIS Class D2 products, i.e., "materials causing other toxic effects" are split into 2 subdivisions, i.e., "Very Toxic Materials" and "Toxic Materials": Class D2 Subdivision A Class D2 Subdivision B Very Toxic Materials Toxic Materials chronic toxins other chronic toxins mutagens of reproductive cells mutagens of non-reproductive cells respiratory sensitizers skin sensitizers carcinogens skin and eye irritants teratogens and embryotoxins reproductive toxins 3 - 19 viii. preventitive measures: recommends safe procedures for handling, use, and storage of the material, based on all the hazard information given in other sections of the MSDS. This section tells what engineering controls (like ventilation) are needed and what personal protective equipment (goggles, gloves, respirators, etc.) are needed to work safely with the product. categories within this section are described below: - personal protective equipment -- to be worn by the worker Personal protective equipment includes: Gloves (e.g., neoprene or cotton), respiratory equipment including dust filters, chemical-cartridge filters and self contained breathing apparatus (SCBA), eye protection such as safety glasses, monogoggles, and face shields, footwear such as rubber boots, clothing such as PVC acid suits, and other like rubber oversleeves or barrier creams for exposed skin. - engineering controls -- are methods of eliminating or minimizing worker exposure to the product. Engineering controls include: ventilation systems such as fume hoods and local exhausts for airborne contaminants, air scrubbers and purifiers for dusts, lead screens for radiation protection, vibration dampers and sound absorbing panels for noise reduction in heavy machinery operations. 3 - 20 -waste disposal methods -- gives information such as: waste container composition or design, i.e., steel drums of waste lubricant must be plastic lined to prevent leakage safe procedures for treating wastes, i.e., decomposing hydrogen peroxide on stones will make it safe to discard. the names and locations of approved environmental waste treatment sites for hazardous wastes. - leak and spill procedures -- give safe procedures in the event of leak, spill, or other release of the substance, including: e.g., neutralize acids with sodium bicarbonate, soda ash or lime. e.g., organic solvents should be absorbed with activated charcoal protective clothing or respiratory protection needed for clean-up crew - handling procedures and equipment -- are special instructions, e.g. "dilute by adding this acid to water, never add water to this acid!" mix at low rpm to avoid shearing (breaking down) the polymer -storage requirements -- e.g., keep away from heat, or open flame store separately from all oxidizers like chlorine, oxygen, etc. keep from freezing, keep airtight, etc. -special shipping information -- e.g., peroxides are shipped in vented, glass containers surrounded by absorbent insulation and placed in a non tipping box hydrofluoric acid must be shipped in Teflon or polyethylene, not glass. 3 - 21 ix. first aid measures: describes immediate treatment to be given to a person who has been affected by exposure to the material. Treatment steps are usually given in chronological order: what to do first, second, third, etc. starting with removal of the victim from the unsafe area. first aid treatments are given for each route of entry: inhalation (e.g., give oxygen for carbon monoxide or chlorine gas), skin and eye contact (e.g., flush with plenty of water for at least 15 minutes), and ingestion (e.g. do/do not induce vomiting and call physician) special medical treatment may be described, e.g., hydrofluoric acid burns must be treated by soaking the affected area in 5% hyamine solution or by subcutaneous injection with 10% calcium gluconate. Summary of MSDS Content: Recall that the 9 sections of MSDS information we have just reviewed are the minimum requirements for content on a data sheet. These are: i. product information (what is it?) ii. preparation information about the MSDS (who wrote the MSDS?) iii. hazardous ingredients (what's dangerous in it?) iv. physical data (what are its properties?) v. fire or explosion hazard vi. reactivity data (what does it react with?) vii. toxicological data (health effects) viii. preventitive measures (how to handle it safely) ix. first aid measures Also recall that a supplier may request and receive permission (under the HMIRA) not to disclose the chemical identity or concentration of any ingredient in a controlled product, however, under no circumstances may any general health hazard information be withheld. Further, in the event of an emergency, the supplier must disclose any necessary confidential business information to any physician or nurse who requests it. 3 - 22 The Suppliers' Responsibilities for MSDS's: provide MSDS's for all controlled products shipped to any Canadian workplace. update MSDS's every 3 years or within 90 days of a change in current health information as collected by the Canadian Centre for Occupational Health and Safety (CCOHS) in Hamilton, Ontario. make MSDS's available to employers in both English and French if requested. Exemptions for Suppliers: the chemical identity of teratogens, embryotoxins, carcinogens, mutagens, and respiratory sensitizers in a product need not be disclosed if they are present in a concentration less than 0.1% of the total mixture. ingredients in naturally occurring mixtures like natural gas do not have to be disclosed as long as the mixture contains the generic name. a supplier can distribute one generic MSDS for similar products such as a variety of paints that differ only in pigment colour. Employers' Responsibilities for MSDS's: must ensure that a controlled product is not used in the workplace unless an up to date MSDS is available to workers who use the product, those who may be exposed to it, and to the health and safety committee representatives. if an MSDS is not available from a supplier, the employer is responsible for preparing or obtaining one. may chose to store MSDS's electronically (on computer) provided that a workers have access to an active computer terminal during all working hours and that they are trained how to use it. Also, a written copy must be provided to workers if requested. must educate workers how to read and use MSDS's. 3 - 23 Problems with MSDS's: MSDS's do not state whether a product is controlled or not. Many suppliers provide MSDS's for products that are not controlled. MSDS's do not state the hazard product class, nor do they display the hazard class symbols. WHMIS regulations do not specify an exact form for MSDS's provided all the necessary information is present under titles which are the same or "similar" to those we have studied. Thus each MSDS from different supplier will likely be somewhat different and will require more searching on the part of the worker to find the desired information. U.S. MSDS's do not comply with WHMIS standards. There is no requirement to disclose a date or product use on U.S. MSDS's. An employer will not always know if it has the most current MSDS because the supplier is not legally obliged to re-issue new MSDS's until a product is re-ordered by a customer. How to Read an MSDS: The general approach is: 1. identify the chemical by its product identifier, supplier name, and appearance and odour (do not take a whiff). 2. understand its hazards, i.e., check its hazard class, fire and explosion data, reactivity data, toxicological properties and check the MSDS date. 3. understand the safe handling procedures, obtain recommended personal protective equipment, and use as per the written instructions. 4. read the first aid and spill procedures. 5. review this information with your supervisor and your fellow worker. International MSDS's: In 1990, the European Common Market, the International Labour Organization, and the Chemical Producers Association (U.S.A.) collaborated to produce an international MSDS. It has 16 headings instead of 9, but it has much the same content as the WHMIS MSDS. The only new topic is one entitled "ecological information". The WHMIS MSDS may eventually change to be consistent with international MSDS. 3 - 24 EXERCISE FOR UNIT 3 1. Name the 9 different kinds of information that must be present on MSDS's of all controlled products. 1) .......................................... 6) .......................................... 2) .......................................... 7) .......................................... 3) .......................................... 8) .......................................... 4) .......................................... 9) .......................................... 5) .......................................... 2. Under the Hazardous Ingredients section, you should find the terms LC and LD. Answer the following as true (T) or false (F). .............. a) LD means "Lethal Dose" given by mouth or injection. .............. b) LC means "Lethal Concentration" breathed in from the air. .............. c) The greater the LD50 of LC50, the more toxic the chemical. 3. Under the "Physical Data" section, you should find important terms such as "odour threshold", specific gravity, vapour density, vapour pressure, pH, etc. Answer the following as true (T) or false (F). .............. a) Odour threshold may be helpful because it can warn a worker that he/she is being exposed to a chemical before a dangerous level is reached. .............. b) All hazardous chemicals have odour thresholds. .............. c) As long as the odour seems faint, it is safe to breathe chemicals with low odour thresholds. .............. d) A liquid with a specific gravity of 1.4 will sink in water. .............. e) A gas with a vapour density of greater than 1 will rise in air. .............. f) You should store liquids above their freezing point. .............. g) A substance with a water/oil coefficient of less than one can be absorbed through your skin. 3 - 25 4. State whether a solution with the following pH values is a strong acid, a strong base (alkaline), or neutral. ........................... a) pH = 2 or less ........................... b) pH = 12 or more ........................... c) pH = 6 to 8. 5. Complete the following: a) The lowest temperature at which a liquid will ignite without the presence of a flame or spark is called .................................................................. . b) The lowest temperature at which a liquid produces enough vapours to ignite in the presence of a flame or spark is called the .............................................................. . c) A vapour-air mixture cannot burn if it is too rich or too lean. The maximum flammable concentration of a vapour in air is called the ................................. ................................. ................................... The minimum flammable concentration of a vapour in air is called the ................................. ................................. ...................................... d) Which liquid has the lower flash point? -flammable or combustible e) Which liquid is the greater fire hazard? -flammable or combustible f) Give the letters of any types of fire extinguishers (A, B, C, or D) which could be safely used to extinguish the following types of fires. -burning wood or cloth ................... -electrical fires ............................. -burning metal dust ............................ -burning oil ................................... g) Name 1 chemical for each of the following: -flammable gas ............................. -flammable liquid .................... -combustible liquid ........................ ........................... -flammable -flammable aerosol .................... solid -reactive flammable ...................... 3 - 26 6. What section of the MSDS would you look in to find information on possible dangerous reactions of a substance when mixed with other chemicals? ........................................................ 7. Draw arrows on the following diagram to show the "routes of entry". e ye conta ct inha la tion swa llowing skin conta ct skin a bsorption or inje ction 8. Name 2 major routes of entry: .......................... and ......................... Name 2 minor routes of entry. ......................... and ........................ 9. Each of the following are either acute or chronic effects or exposures. Place the word acute or the word chronic beside each statement. ....................... -immediate and serious effects due to 1 major exposure ....................... -delayed effects due to prolonged or repeated exposure ....................... -hazard Class D1 ....................... -hazard Class D2 ....................... -a long term problem for painters ....................... -may occur if a worker is splashed with a corrosive acid 3 - 27 10. Match the following statements by drawing arrows. TLV-TWA is a maximum (ceiling) exposure which cannot be exceeded TLV-STEL is an exposure averaged over an 8 hour day or a forty hour week TLV-C is a 15 minute short-term exposure allowed only four times a day with intervals at least 60 minutes between each exposure 11. Answer the following as true (T) or false (F). .............. a) The more exposure you get to a hazardous substance, the less harm it will do to you because your body adapts to it. .............. b) Hazardous materials cannot be worked with safely. 12. Match the following statements by drawing arrows. CARCINOGENS TERATOGENS or EMBRYOTOXINS MUTAGENS are believed to harm an unborn child especially during the period of 2 to 8 weeks after conception. are believed to cause genetic changes in living cells are believed to cause cancer 13. Name 3 substances which are believed to cause cancer. .............................., ...................................., ......................................... 3 - 28 14. Name 3 substances which are believed to cause birth defects. ................................, ....................................., ........................................ 15. Name one example of a mutagen. ........................................ 16. What is the name of the section of the MSDS which lists the personal protective equipment necessary to safely handle a hazardous chemical? ................................................................................ 17. Answer the following as true (T) or false (F). .............. a) MSDS's must be updated every 3 years or within 90 days of a change in current health information. .............. b) Suppliers must provide MSDS's to employers in both English and French if requested. .............. c) If an MSDS is not available from a supplier, the employer can use a hazardous material without one. ............... d) Employers must educate workers how to read and use MSDS's. ............... e) MSDS's must also show the hazard class symbols. 18. There are some international symbols (not WHMIS symbols) which you may see on labels of hazardous products showing what personal protective equipment (ppe) should be worn for safety. Some of these are shown below. For each, state the ppe which is shown in the symbol. 3 - 29 MATERIAL SAFETY DATA SHEET ACTIVITY Examine the MSDS's in the following pages. These are MSDS's for some of the substances commonly handled by dental workers. Go through them section by section, and identify any areas that concern you and about which you feel you would need further information or explanation. 3 - 30