business plan - Web2.ViaPVT.sk

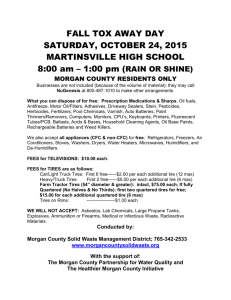

advertisement

World wide leader in the elaboration of technologies for the 21-st century. Solutions for the global ecological problems. BUSINESS PLAN Factories for the processing of old automobile tires by a cryogenic method based on the production of cheap, on-site liquid nitrogen. Attention! The newest technology completely excluding use of nitrogen at processing of old automobile tires are developed. Look addition to business plan. (Production with no wastes) The following products are obtained: High quality rubber crumb (75-85% from the total weight). High quality metal (15-25% from the total weight). Textile (0-5% from the total weight). Owner of the intellectual property: INTERENERGORESURS Company September 17, 2001 Table of contents: 1. Introduction. ......................................................................................................................................................... 2 2. The aims of the business plan. ........................................................................................................................ 3 2. Market analysis. .................................................................................................................................................. 3 3.1 Analysis of the raw material market. ............................................................................................................ 3 3.2 Analysis of the market for sales. .................................................................................................................. 4 3.3 Analysis of the competition. .......................................................................................................................... 5 4. Short comparative analysis of the presently used methods for the processing of old automobile tires. 5 4.1. 4.2. 4.3. Processing of the old automobile tires by mechanical methods. ........................................................ 5 Processing of old automobile tires with ozone. ...................................................................................... 6 Processing of old automobile tires by the cryogenic method............................................................... 6 5. Description of project. The new cryogenic method offered by the IER Company for the processing of old automobile tires. ...................................................................................................................................................... 6 5.1. The advantages of our method. ................................................................................................................ 6 5.2 The Comparative table of economic factors............................................................................................... 7 5.3 Scheme of automatic line for processing old automobile tires. ............................................................... 8 6. Addition to business plan. The newest technology of processing of old automobile tire covers. Cooling by cold air - 120°C without use of nitrogen. ............................................................................................... 9 6.1. Scheme of automatic line for processing old automobile tires. ........................................................... 9 6.2. Description of offered newest technology. ............................................................................................ 10 6.3. Advantages of offered technology and description structure of production. ................................... 10 6.4. Economic parameters. ............................................................................................................................. 11 7. Development of the business. ........................................................................................................................ 11 1. Introduction. Our use of motor vehicles creates a major by-product -- scrap tires. World-wide more than 3 billion tires are dumped every year. And how many is already stockpiled on dumps!!! Only United States dumps 288,000,000 tire every year. More than 250 million scrap tires are generated in North America each year, adding to more than three billion scrap tires already stockpiled. About 80% of a tire is made from Oil. (a non - renewable natural resource). Prior to the 90’s, most of this waste ended up illegally or improperly dumped into the environment. Besides creating eyesores of the landscape, dumped whole tires created a haven for rodents and a breeding ground for insects - particularly mosquitoes. (NOTE: Mosquitoes are responsible for killing thousands of humans EVERY YEAR). Along with the issue of mosquitoes and rodents is the ever-present danger of the tires catching fire. Once a pile of whole tires combusts, it is EXTREMELY difficult to extinguish. Tires contain a lot of petroleum and actually have greater BTU value than coal! (NOTE: An automobile tire contains 280,000 BTU of energy - equivalent to 2.5 gallons of oil or 20 pounds of coal!) Cleanup costs are estimated by some, to exceed the original expense to collect and processing the tires. The expense to extinguish and remediate a site when it catches fire can run into the millions of dollars. The negative health implications alone spurred many groups to demand a solution to the problem. Our method of processing: over-all, the running operation. Stops fires from happening & all deadly pollution's thereof, ground, water and air. Stops The Spread of Human Diseases via Mosquitoes. This is a "ZERO Chimney Process" no air emissions. Produces Sellable Products, high quality and low price. Creates NEW JOBS for people of all skill levels. This Process is "SUPER-CLEANLY". Eliminate millions of land polluting old tires that already pollute our environment, cause death and harm to thousands of people, wildlife, and our natural resources every year. And Reclaim land and non - renewable fuel / energy. 2 2. The aims of the business plan. The basic aim of the business plan is investment, which is needed for the elaboration of the project and technical documentation and manufacture of the first industrial line and for building the plant for processing of automobile tires. The stages necessary for the investment: a) Creation of the working documentation for the different nodes and lines of the factory. b) Manufacture and execution of the control tests and runs for the main equipment. c) Building of the equipment for one production line, start-up to working regime and testing of the products thus manufactured. The common necessary investment is 1,000,000 EURO. Term of performance of works - about nine months from the start of the investment. The return of investment is shorter than two years considered from the moment of starting of commercial production. If we take in account the catastrophic dimensions of the problem of destroying the old automobile tires and the low productivity of the existing factories, then the technology offered by the INTERENERGORESURS Company is the unique possibility to solve this problem on a global scale. The risk of the investors is minimal! 3. Market analysis. 3.1 Analysis of the raw material market. The huge quantity of automobile tires produced yearly worldwide and their relative short functioning life warrants a practically unlimited raw material market. Thus, for example, only in the USA, some 288,000,000 tires are thrown out to dumps yearly. In West Europe is annually produced: in Germany 550,000 tons, in France 350,000 tons, in the Great Britain- 290,000 tons and in Italy 150,000 tons. At the end of the millennium only in Western Europe the quantity of accumulated tires was greater than 2,500,000 tons. In Great Britain, yearly 105,000 tons (some 36% of the quantity manufactured) of outworn automobile tires are sent to the sites of storage or are buried. In Western Europe the cost of burial is at least 200 USD per ton. The owner of the used tires has to pay at least 1.2 USD per tire if it sent to the storage site and 0.7 USD if he is transporting it to the collecting center. Diagram of annual production and dumped the car tires in West Europe. 600 thousands tons 500 400 300 200 100 0 Italy production France Great Britain Germany amount unsuitable to use of tires 3 3.2 Analysis of the market for sales. The factories for processing old tires are producing: rubber crumbs, metallic cord and textiles which are commercial products. The spectrum of uses for rubber crumbs is quite broad. Depending on the size of the particles these are used for: - manufacture of new tires (up to 10-15% added); - manufacture of technical rubber products for cars (“Ford” uses as additive up to 25% rubber powder); - manufacture of hoses (up to 40%); - manufacture of water resistant coatings for roofs (up to 40%); - manufacture of railroad sleepers (up to 60%); - manufacture of filled rugs (10-100%); - manufacture of shoe soles (10-100%); - manufacture of wheel for carriages for handicapped people (10-100%); - manufacture of coatings for roads (14-15 tons per kilometer of road); - manufacture of coatings for tennis grounds and areas for children; - manufacture of concrete for buildings, as additive. - and many other uses. Now a special attention is directed to the manufacture of special coatings for roads with the addition of the fine fractions of the rubber powder – 60 to 100 mesh (the most expensive fraction obtained by the cryogenic method). These coatings have increased coefficients of adhesion and of absorption of noise. In Western Europe more than 900,000 km of roads have to be serviced per year, in the US more than 700,000 km, in Canada 100,000 and in Japan 130,000 km. For the replacement of the old road coating with a new one based on rubber powder, it will be used approximately 25,000,000 tons of fine fraction of the rubber crumbs. To this there will be also added the sound barriers which are installed along the highways in the inhabited areas- in Western Europe 136,000 km, in the USA 187,000 km. 16000 1000 900 800 700 600 500 400 300 200 100 0 thousand tons 14000 12000 10000 8000 6000 4000 2000 0 Canada Japan USA thousand tons thousand km need for powder West Europe thousand km The crumb fraction of the highest quality is considered with a size range 80 to 120 mesh (as finer is the material as lower is its negative effect on the main material- rubber) This fraction has the best perspective for the sales for the manufacture of the road coatings, manufacture of new tires, concrete for construction and other products of high quality and reliability. This fraction of powder has the highest price but also the highest cost of manufacture. For example the difference market price minus cost of manufacture for the powder of 30 mesh was recently 5-6 cents per 1 kg. (for comparison the same value is 15 cents for the fraction of 10 mesh is 15 cents per 1 kg) while the manufacture of the fraction 80-100 mesh was at a loss. The offered technology will change this situation completely making the product available and highly profitable. 4 The metallic cord, some 15% of the weight of the automobile tires is also good for sale. The offered technology has the advantage of a perfect cleaning of the metallic cord which is thus rubber-free and is a valuable metal for recycling. In the case of a factory that is processing 70 tons of tires per day, the yearly production of clean metallic cord can attain 3500 tons. The new technology also allows the production of secondary products i.e. liquid argon and oxygen, also commercial products with no additional energy consume. Balanced analysis of incomes and expenses. 4% 1% 21% 74% Incom from sale of powder Expense part Incom from selling the scrap metal Incom from selling the fluid gases 3.3 Analysis of the competition. The quantity of used automobile tires collected at dumps or just thrown away is steadily increasing and this is a proof of the weak development of the field of processing. For the present we cannot speak about a competition between the processing units for raw materials or for markets of sales. The existent technologies for processing of automobile tires are disproportionate compared to the huge and ever increasing quantities of raw material and actually they are in a very incipient phase. Thus, a factory with a capacity of processing of 70 tons tires per day is able to process less than 0.7% of the yearly volume of old tires deposited at dumps in the countries of Western Europe. There are not available similar statistics for Eastern Europe. However even if we consider that this is only the third part of the quantity available in the Western part, then only for the processing of half of the old automobile tires there will be needed at least 80-100 factories working in continuous regime. The market for the manufacture of the equipment needed by the factories according to the technology offered by the INTERENERGORESURS Company, without entering the area of production and selling of rubber powder is open for at least 10 years, actually more. 4. Short comparative analysis of the presently used methods for the processing of old automobile tires. 4.1. Processing of the old automobile tires by mechanical methods. Disadvantages: The forms of the resin particles obtained by this method are very irregular and their surface is lacerated (“shaggy”) and this enhances the processes of oxidation which take place during the grinding of the material. Thus the properties of the starting material are damaged and it cannot be more used for high quality rubber products. There is not possible to get a 100% separation between the rubber and the other components of the tires- textile or the metallic insertion, even if magnetic separators or cyclones are used. This leads to the deterioration of the quality of the products and to an increased wear of the processing equipment due to the metallic insertion left in the rubber. Due to the release of powders and to the high temperatures, as well as to the release of active chemicals in the atmosphere, this method is bad for the environment. 5 Significant wear of the cutting and grinding equipment (knives, gears etc.) takes place and this leads to increased expenses during the functioning of the equipment.. 4.2. Processing of old automobile tires with ozone. Disadvantages: The method is not used on a large scale and actually it was left in the experimental stage. The particles have inadequate characteristics of form and surface. The resin damaged by ozone has altered properties. The ozone in excess (unused) has to be destroyed because it is dangerous for the people when it is present in high concentrations in the air, having thus a negative effect on the ecological effect of the plant. The unique positive factor in this case is the good extraction of the metallic cord and of the textile. 4.3. Processing of old automobile tires by the cryogenic method. The old automobile tires are frozen till become fragile and are ground and the metallic and textile insertions are separated. The method has the highest productivity and is absolutely ecologically friendly. The rubber material has optimal characteristics and the particles have a smooth surface, thus the physical and chemical properties of the stuff are much improved and it can be used for the manufacture of new items in which it is included up to 80%. Disadvantages: Increased consume of energy, high overhead expenses and high cost of the liquid nitrogen used as well as high losses (up to 30%) during its filling and pouring which all are increasing the price of the products. In order to increase the surface of cooling, the tires are torn in smaller pieces and this makes the technology more difficult especially as regarding the removal of the metallic and textile insertions. The method can be used mainly for obtaining of rubber particles not smaller than 40 mesh. Such methods are not allowing the manufacture of rubber particles with uniform granulometry and thus a special equipment for separation of the fractions has to be included and both the cost of the equipment and the cost of the materials are increased significantly. For example the price of a “Rotex” separator is 15 to 20 thousand US $ while more productive systems are up to 80 thousand US $. The separation of steel, usually takes place at grinding of the rubber to sizes around one inch, and therefore only 50-70% of the steel can be extracted by magnetic methods, and the metallic cord is charged with residual rubber and has a lower value as recovered metal. The further removal of metallic and textile insertions is obtained by continued decrease of the particle size of the rubber, and thus the textile insertion is transformed in “down” and is mixed with the metal and, at one hand is further decreasing its value for recycling and, on the other hand, is a very easily combustible material thus needing special methods of protection against fire i.e. more expenses. 5. Description of project. The new cryogenic method offered by the IER Company for the processing of old automobile tires. The automobile tire covers after washing, previously are cut on pieces, which then move in the tunnel of precooling, where are cooled by vapours of nitrogen. Further on a conveyor they get in the basic tunnel, where are cooled by liquid nitrogen. For productivity of processing up to 1000 kg / hour the length of the tunnel of precooling up to 17 m, and length of the basic tunnel of deep cooling makes up to 9 m. The pieces of tire covers are frozen up to a state of brittleness and then are grinded with the subsequent separation of a metal cord and textiles. The method differs by highest productivity and is absolutely ecologically clean. On this technology it is possible to produce a rubber crumb with given parameters and sleek surface of particles that considerably improves its physicochemical properties and allows to utilize for manufacture of new rubber product with amount of insert up to 80 %. 5.1. The advantages of our method. Additional to the lower cost of liquid nitrogen, a clear advantage is the principle of its manufacture “in situ” during the production cycle thus excluding the cost of transport, decreasing the cost for space and for the creation of reserves in order to warrant a continuous process. 6 Disadvantages of the described method (cryogenic - nitric): As for cooling, will is used, as cooling agent, liquid nitrogen with temperature -196°C, that the temperatures of a glass transition are much lower, this process of cooling differs by large thermodynamic losses and energy expenses. High overhead expenses and cost of transportation of liquid nitrogen, and losses during its filling and pouring and storage (up to 30 %). All this enlarges the prime cost of the products. The technology, developed by us, manufacture of liquid nitrogen on a place of its use, eliminates disadvantages specified above. The theoretical consumption of liquid nitrogen only on freezing of tire covers in view of use of heat capacity of vapours of nitrogen makes 0.5 kg / kg. However, in practice, because of imperfection of heat exchange between nitrogen and tire cover, this numeral is increased on 15-20 of %. On single in Ukraine purchased in Germany, plant on processing tire covers, it is numeral is equal to 0.65kg/kg. At its real productivity of 700 kg of tire covers at hour. Besides, the technological losses of liquid nitrogen in kg - on kg of tire covers on a plant make about 0.2 kg / kg. Thus own plant expenses of liquid nitrogen on kg of tire covers, on a plant make 0.8 kg / kg. Thus, cost of freezing of 700 kg of tire covers at hour, makes from $ 80 up to $ 100. The tendency on growth of cost of liquid nitrogen is obvious. It also is the basic disadvantage. 5.2 The Comparative table of economic factors. Table with the economical indicators of the technology of the IER Company ( production of rubber powder) compared with the existent processes in this field. Cost of manufacture Cost of manufacture Market price new method Particle size (mesh) existing method US $ per ton US $ per ton US $ per ton. 10 260-270 100-110 170 20 300-310 200-220 180 30 330-340 270-280 188 40 370-380 370-400 197 80 720-730 830-850 210 100 870-890 1000-1100 220 The offered productivity of one line – greater than 500 kg powder per hour (ground to 100 mesh) for a personal – 4 men per shift, 3 shifts per day. A factory for processing of old automobile tires can include up to 7 such lines, i.e. having a production of 3 tons of powder and about 1000 kg metalcord per hour for 1214 men per shift. The calculated profit of one line is 2,000,000 US $. Correspondingly, the entire factory has a profit of 14,000,000 US $ per year. Industrial area, which includes 7 lines of processing - 1 100 m2. Store of raw material on 350 tons - 2 000 m2. Storage products for sale - 500 m2. General area of territory of a factory makes - 4 500 m2. 7 Scheme of automatic line for processing old automobile tires. Store of raw material. 2. Cooling machine Cooling Chamber. Domestic place Argon Oxygen 2. Mill Drying Packing moving of the tires addition of liquid nitrogen liquid argon and oxygen supplementary cooling cooled air using excess heat 8 Separator Textile Magnetic destroyer Мetal Argon Oxygen Sizing 1. Cooling Chamber. 1. Cooling machine Washing Drying Heating 5.3 Storage products for sale 6. Addition to business plan. The newest technology of processing of old automobile tire covers. Cooling by cold air - 120°C without use of nitrogen. 6.1. Scheme of automatic line for processing old automobile tires. Store of raw material. Cooling machine Cooling Chamber. Control system Preparation (Washing, Drying) Destruction, Cryogenic mill Drying Sorting, Packing Storage products for sale Rubber Metal Moving of the tire covers Communication with a control system Use utilized of heat Movement of the cooling agent 9 6.2. Description of offered newest technology. The method of cooling of air, up to temperature -120°С is well known. This temperature is reached of work of the cascade (5, 6, and more) powerful compressors connected consistently. Basic disadvantages of this method - the bulky equipment and significant consumption of energy. The offered technology is based on the absolutely new, economic approach of deriving of low temperatures. The cooling of tire covers is carried out by usual air previously cooled in air coolers special compression refrigerating machines of a penetrating cold. As against known compression multistage refrigerating machines, here cold is gained in a single-stage vapour a compression refrigerating cycle on multicomponent mixtures of the refrigerating agents with interior regeneration. This cycle by virtue of features of thermodynamics, refrigerating agents, is more economic than any of known on 30-40 %, and the equipment ensuring processing of old tire covers by this way - has much more smaller dimensions and cost in comparison with existing. The consumption of energy is considerably reduced. The technology allows to deriving a cheap cold with temperature up to -135°С (instead of -196°С as in case of liquid nitrogen), is direct on a place of processing of old tire covers in necessary amount. 6.3. Advantages of offered technology and description structure of production. The system of cooling, without use of nitrogen, allows completely to proceed to compression cooling by air, up to temperature are lower the temperatures of a glass transition, that is up to -120°С. The tunnel for process of cooling has three zones with different temperature -10°С, -60°С, -120°С, that provides the most economic expedient and cheapest cooling of tire covers. Except low prime cost of deriving of a cold, advantage is the principle of its deriving in the necessary amount, is immediate during a production cycle, that excludes the transport expenses, are economize production area, since there is no need to install equipment, for manufacture of fluid nitrogen, to create reserve volumes of liquid nitrogen, station of pumping-over of liquid nitrogen, for maintenance of continuous manufacture. Know-how includes on production: 1. Technology of heat utilization from refrigerating machines. The surplus thermal energy makes up to 90 % of set power consumption of refrigerating machinery. Is warmly will be used for preheating water (washing), preheating of air (drying) and heating of all locations of a plant, in a winter period. Components which allow it to make - system of velocity heat exchangers effectively removing a thermal energy, by a thrown off hot part of refrigerating machines. 2. Thermal generators, will be utilized for effective pinch of temperature of water, since utilized heat (item 1) will not suffice, for a necessary heating + 60°C, which is required for washing and drying. Required heat for a heating of water and drying, should be higher utilized heat on 25-30 of % that is complemented thermal generators. 3. The ultrasonic nozzles, for washing allow saving water with application of vibration of a jet (in a ultrasonic gamut) that allows considerably to shorten time of washing and to improve quality, at diminution of volumes of water. 4. The ultrasonic method of destruction of the frozen tire cover is founded on a different own resonant frequency of rubber and steel cord. Therefore after a powerful impulse of a ultrasound on a resonant frequency of rubber, rubber is molders on small parts, and the steel cord remains without change and utilized, as commercial product. 5. The crushing much fractional machine yields a rubber crumb of the given size, because previously, the crumb gets between rolls with screw slots of colliding gyration, with precise adjustment. The given aggregate size of a crumb depends on the geometrical sizes of slots. And they are gained absolutely identical and exact geometrical shape. Not less important is: absence during processing use, what or chemical components; absence of electromagnetic extraction of a metal cord; absence of heat production at destruction of rubber; the absence of a condensate, which leaves in process drying. Therefore, the chemical composition of a crumb completely corresponds to composition of rubber of the old tire cover, which has arrived in processing. At such of processing, the odds in the cost price of deriving of a crumb of thin and rough fractions are extremely small. It is expedient to utilize an offered processing line, for deriving the most qualitative rubber crumb (80-100 mesh) as in this case its profitability maximum. 10 The most efficient process of the work to lines (the plant) 3 shifts. Total hours - 20 On the regulations, preventive works and loading of the first party of old tire covers before the beginnings of each shift are necessary 4 hours. The basic time, line works in a continuous mode. The approximate cost of a line on processing old tire covers at serial manufacturing, makes 600 000 - 650 000 EURO. Prepares to presenting, package of the applications for invention. Cryogenic technologies: 1. Way of deriving of low temperatures up to -135°С without use of nitrogen. 2. Equipment for deriving of low temperatures up to -135°С without use of nitrogen. 3. Way of cooling of old tire covers by air cooled up to temperature -120°С without use of nitrogen. 4. The equipment for cooling old tire covers by air cooled up to temperature -120°С without use of nitrogen. 5. The way of preparation of old tire covers, for effective and fast freezing by air having temperature is lower than temperature of a glass transition. New technologies: 1. Ultrasonic nozzle of the machine for washing. 2. Ultrasonic disintegrator (destruction of tire covers by ultrasound). 3. The equipment for crushing rubber. On all other equipment - there are patents. 6.4. Economic parameters. Possible power expenses at work of one line. The calculate expenses of energy is made for the following conditions: Amount of processed rubber 700 kg / hours. Output about 550 kg of a rubber crumb and 150 kg of metal. The estimated expense of energy on freezing about 115 kW. The estimated expense of energy for processing (crushing and packing and so on) - 15 kW. The common expense of energy one line spent for processing 700 kg of tire covers at hour about 130 - 150 kW. The prices for electrical energy and liquid nitrogen in various regions, in view of the various tariffs and price - are not investigated by us. On our calculation, at use of technology of cooling of old tire covers by cold air, without use of nitrogen, as a result of reduction of the equipment, economy of energy, reduction servicing personnel and wages - the prime cost of one ton rubber crumb will make: 1 2 3 Size 10 (mesh) Size 20 (mesh) Size 30 (mesh) max. $100, max. $105, max. $110 4 5 6 Size 40 (mesh) Size 80 (mesh) Size 100 (mesh) max. $120 max. $130 max. $135 7. Development of the business. The main direction of the activity of INTERENERGORESURS Ltd. will be the construction of a series of factories for the processing of the automobile tires aiming the production of high quality fine fraction rubber powder as well as of secondary products as: metal scrap, liquid argon and oxygen. It is possible to organize the manufacture of rubber products based on a cheap high quality raw material. Also the production of equipment for completing the factories and installing, adjustment, start-up for exploit and servicing of the factories. Selling of the rights for inventions, licenses for production both for separate aggregates and for integral processing lines. 11