Title of paper should be centered and type with 16 point bold

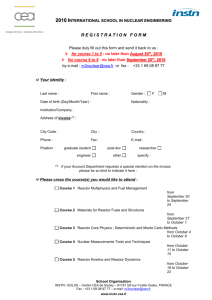

advertisement

"ITER EQUATORIAL PORT PLUG ENGINEERING: DESIGN AND REMOTE HANDLING ACTIVITIES SUPPORTED BY VIRTUAL REALITY TOOLS" Delphine Kellera, Christian Dechellea, Louis Doceula, Sylvain Madeleinea, Jean-Pierre Martinsa, Yvan Meassonb, Julien Wagreza a b CEA, IRFM, F-13108 SAINT-PAUL-LEZ-DURANCE, France CEA, LIST, Interactive Robotics Unit, 18 route du Panorama, BP6, FONTENAY AUX ROSES, F- 92265 France In the context of ITER, CEA/IRFM has participated to the design and integration of several components in the Equatorial Port Plug region. Particularly, in the framework of the grant F4E-2008-GRT-09-PNS-TBM, CEA/IRFM has contributed to the Test Blanket Module System (TBS) design and robot access feasibility study in the Port cell. Simulations of the maintenance procedure were studied and fully integrated to the design process, enabling to provide space reservation for human and robotic access. For this mean, CEA/IRFM has used a CEA LIST virtual reality simulation software directly integrated to the Solidworks CAD software. The feasibility to connect/disconnect the pipes in front of the Bioshield by a set of potential standard industrial arms was demonstrated. Aiming to give more realism to maintenance scenario and CAD models, CEA IRFM has decided to build a Virtual Reality platform in the institute, integrated to the design office. With the expertise of CEA LIST, this platform aims to provide the nearest possible links between design and remote handling needs. This paper presents the outcome of the robot access study and discusses about the Virtual Reality tools that are being developed for these applications. Keywords: ITER, Equatorial Port Plug, maintenance, Test Blanket Module System, Remote Handling, Virtual Reality. 1. Introduction 2.1 TBS layout [1,2] In the context of the grant F4E-2008-GRT-09-PNSTBM, between F4E and TBM Consortium of Associates, CEA/IRFM has contributed to the design and maintenance scenario that prepares the bases for the TBM systems maintenance sequence taking into consideration ITER space requirements versus interfaces. The objectives of the task were to study the accessibility to the working zone located in front of the Bioshield and the feasibility to connect/dis-connect pipes by means of a set of standard industrial arms. Figure 1 shows the integration of the TBS in the ITER environment and figure 2 the overall dimensions of the TBS and general layout. A minimum of 4 interfaces have been identified to enable TBM assembly/dis-assembly. Interface 1 (IF1) is located between the TBM boxes and shield block. Interface 2a (IF2a) is located between the Port duct and the Port extension. Interface 2b (IF2b) is located behind the Bioshield and in the front side of the Ancillary Equipment Unit (AEU). Interface 3 (IF3) is located between the Ancillary Equipment Unit and the shaft of the Port Cell. 2. TBS in Equatorial Port Plug #16 2.2 TBS maintenance needs Fig.1 View of the Equatorial Port #16 in the installation _______________________________________________________________________________ author’s email: delphine.keller@cea.fr A specific ALARA analysis concerning intervention in the Port extension will define if qualified operators can operate in this region. Anyway, at the conceptual design stage, the feasibility to perform this operation by means of robotic system has to be validated. Thus, the design has to cope with both scenarios: human and robotic access constraints to interface IF2a (see figure 2). Fig.2 TBS layout inside Equatorial Port #16 and overall dimensions 2.3 Accessibility to IF2a interface Outside the TBS maintenance period, the RH system is parked outside the Port Cell. For the present study, the starting point is considered at the Port Cell door. In order to reach IF2a interface, the RH system has to cross several entities taking into account RH accessibility requirements. The different entities are: AEU, Bioshield, Entities in the Port extension. 2.4 Assumptions for the simulation Robotic arm (1), Deployable carrier (2), Tool rack (3), Container for pipes insulation (4), Cable reel (5), Controller (6), Ancillary equipment (ex : plasma torch source) (7), Standard AEU frame (8). Maintenance corridor Due to biomechanical norms, the first maintenance corridor was 500mm wide in order to allow human access. Simulation will show the limitations. Task The cutting task is the task that is simulated. Indeed, cutting task is the most critical operation regarding tritium contamination risks and tools generating heat and chips during operation. Several components are positioned: RH Platform Unit 2.5 Sequence of operation A first assessment of the sequence of operation allowed to identify the step of the full operation, the type of task (hands-on or RH) and the phases that need to be simulated. Two solutions were studied: 1. empty the pipes - The possibility to integrate RH unit on the AEU 2. solutions to avoid contamination (confinement) - A dedicated RH unit 3. disconnect the AEU and the exterior systems A preliminary integration concept of the platform has been made for space reservation (figure 3). 4. cut the pipes at IF3 interface 5. cut the pipes at the IF2b interface 6. remove the AEU 7. bring the RH cutting module 8. open the Bioshield window 9. deploy the RH cutting module in the interspace 10. solution to avoid contamination (confinement) 11. Remove the insulation from the pipes 12. cut the pipes between the pipe forest and the TBM sets Fig.3 First assessment of the RH Unit This platform could use the same platform that supports the AEU. 13. remove the RH cutting module 14. open/remove the Bioshield 15. remove the sealing device on the Port 16. fit the docking flange on the Port 17. Remove the Port Plug Steps 1 to 6 and steps 10 and 14 are hands-on or are not studied yet. Steps 15 to 17 are standard ITER operations. Steps 7, 9, 11, 12, 13 were studied in the simulations and are presented in this paper. 3. Robotic accessibility studies 3.1 Objective The objective of the simulations is to validate early in the design phase that a standard industrial robot can reach every pipes without difficulties. These simulations permit to point out difficulties and enable to make proposals to the design in order to simplify the access. Feedbacks from Fission installations show that if dismantling contraints are not taken into consideration into the design phase, it leads to technical challenges in terms of RH system with long R&D programs [2]. 3.2 Simulations A set of industrial robotic arms have been selected to perform the task. The maintenance scenario described in section 2.4 has been simulated with the MAGRITTEWORKS software from CEA LIST (figure 4) 3.3 Results and feedbacks for design changes The main results of the first simulation are: The corridor has to be larger to use most standard industrial robotic arms. The circular arrangement is a good idea but it has to be much more open on the robot side. The aperture from the corridor to the pipes has to be larger. The first simulation enables to better understand the RH requirements that have to be taken into account for the TBS design. Criteria of reliability, minimization of connection / disconnection time, cost and maintenance easiness were taken into account and lead to the choice of more common industrial robot for the task. For example, an optimization of pipes arrangements allow to simplify the robot supporting structure and the robot itself as less degree of freedom are needed to reach the pipes. The last design takes into consideration these requirements (figure 5). Large opening 500 mm 700 mm Fig.5 Design evolutions after RH simulation A last simulation has been built and permits to validate that the scenario is feasible by a standard robotic system supported by a simplified platform (figure 6) Fig.4 Simulation of the cutting task at interface IF2a These simulations enable to verify the RH compatibility assessment and tools that have been designed for the purpose. Particularly, we verify that the kinematics is suitable with the task to perform. Thus, specific tools, like the RH compatible pinch to remove the insulation were tested to verify if all insulation can be removed by RH means. These simulations require specific preparation work which consist to simplify CAD models and to reorganize the areas where evolve the RH tools for optimal TBS components manipulability. Fig.6 Last simulation for insulation removal 4. Virtual Reality tools for design 4.1 Interest The use of such Virtual Reality tools integrated to CAD software enables to provide synergy between the design and Remote Handling needs. The aim is to be able to build the maintenance scenario during the design process of a component. This way, any changes needed in the design could be immediately taken into account into the VR simulation and the new maintenance procedure can be updated. 4.2 CAD models compatibility preparation for VR tools The most important step for VR simulation is model preparation. The design model in native format is unsuitable for the VR simulation tool. As a compromise as to be found between real time simulation and realism, the initial CAD model has to be simplified to optimize CPU charge with enough details for the simulation. 4.3 Loop between simulation and design In the context of ITER, maintenance and RH operation is an important issue. Sooner the design takes maintenance requirements into consideration, easier will be the development (feasibility, reliability, time and cost). It is a dedicated room equipped with peripheral devices which enable to render feeling which are interesting for the operators regarding the task to achieve. The objective of the Virtual Reality platform at IRFM is to simulate maintenance scenario with masterslave manipulators, the operator is immersed in the scene as if he had to do it in real. This mean could help to validate RH compatibility assessment for ITER operation maintenance and to optimize the design process in a context of an experimental machine which design is daily evolving. This platform could be used in fine for maintenance scenario validation, design review and also for operator training. 4.4 Magritteworks CEA LIST is developing a Virtual Reality simulation software directly integrated to the Solidworks CAD software for RH applications. The operator can interact with the virtual environment in real time through a 6D space mouse or a haptic device with force feedback. A robotic toolbox integrated to MAGRITTEWORKS enables to simulate various kinematics, direct and inverse. Remote tasks are not repetitive, often undefined since work depends on observations during the interventions. Most of the time, the operator does not have direct vision on the operation workplace. Sometimes he does not even have video feedback. Robots are not always very accurate and the operator must compensate for this inaccuracy to execute tasks in the safest way preserving the environment and the equipment. MAGRITTEWORKS offers graphic assistances, making easy robots programming and control. It interfaces to robots and tools through an execution controller, allowing updating model state according to the real situation. In MAGRITTEWORKS, specific processes functions like tool changer can be simulated [3]. Fig.6 Example of a Virtual Reality platform in CEA LIST. Acknowledgments This work has been performed with the expertise of CEA LIST and under an agreement for the use of MAGRITTEWORKS simulation tool. This work was supported within the framework of the grant F4E-2008-GRT-09-PNS-TBM. CONCLUSIONS AND PERSPECTIVES References Virtual Reality platform [1] Aiming to give more realism to the maintenance scenario and CAD models, CEA IRFM decided to build a Virtual Reality platform in the institute, integrated to the design office. CEA IRFM has 20 years of expertise in integration of system on Tokamak, design of Fusion component and Fusion. With the expertise of CEA LIST which has 20 years of experience in the field of Virtual Reality, Remote Handling and software development, this platform aims to provide the nearest possible links between design and remote handling needs. The Virtual Reality platform at CEA IRFM shows a great potential to succeed in our design and integration activities in a complex environnement like ITER. It has been financed by French funds. [2] [3] [4] J.-F. Salavy and al., Fusion Engineering and Design, Vol 83, Issues 7-9, Dec 2008, Pages 1157-1162 LV Boccaccini and al., Fusion Engineering and Design, Vol 84, Issues 2-6, Jun 2009, Pages 333-337 Ph. Desbats et al., ENC 2005, Remote Handling Technologies overview. Ch. Leroux et al., Astra 2004, Magritte: a graphic supervisor for remote handling interventions.