Lesson Plan

advertisement

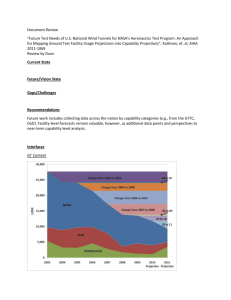

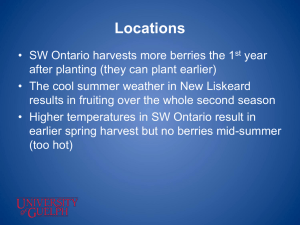

Instructional Plan Instructor: Unit: High Tunnel Fruit and Vegetable Production Fruit and Vegetable Production #3 – Classify characteristics of selecting and planning for Competency: fruit and vegetable production. Lesson 1 Title: Introduction to High Tunnels Estimated Time: 1 to 2 50-minute class periods Objectives / Study Questions: At the conclusion of this lesson students will be able to: Recognize the difference between a high tunnel and a greenhouse structure. Identify the advantages of high tunnels. Recall limitations to the use of high tunnels. Materials, Supplies, Equipment, References, and Other Resources: Materials/Supplies/Equipment: PowerPoint Presentation – Lesson One: Introduction to High Tunnels Chalk Board/White Board Internet Connection and Speakers for YouTube Video References and Other Resources: High Tunnel Manual O’Connell, S. (2008). Grafted Tomato Performance in Organic Production Systems: Nutrient Uptake, Plant Growth, and Fruit Yield. Thesis. North Carolina State University. Available online at: http://repository.lib.ncsu.edu/ir/bitstream/1840.16/2281/1/etd.pdf Spaw, M., & Williams, K.A. (2004). Full Moon Farm Builds High Tunnels: A Case Study in Site Planning for Crop Structures. Hort Technology, 14(3), 92-95. Taber, H.G., Havlovic, B., & Howell, N. (2006). High Tunnel Tomato Production. 2006 Annual Progress Report, ISU Armstrong Research and Demonstration Farm. Hightunnels.org - http://www.hightunnels.org/foreducators.htm Interest Approach (Motivation): (SLIDE 1) Ask questions of students (show of hands): Who has heard of high tunnels? What a high tunnel is or how a high tunnel is different than a greenhouse? Let’s watch a bit of this short video to see some photos of high tunnels. On a piece of paper, take a few notes about what you see. After we watch some of the video, we’ll discuss what you noticed about high tunnels from the pictures in the clip. (Show http://www.youtube.com/watch?v=OvMme37PDwE. Or search “High Tunnels” in youtube.com. The video is posted by Growers Supply. The video is over 3 minutes long and is only pictures of high tunnels. You may choose to only show a short portion of the video.) Ask these follow up questions after viewing the video: From the pictures, how would you describe a high tunnel? What do you believe is the purpose of a high tunnel? How is a high tunnel different from a greenhouse? What other things did you notice about high tunnels from the video? (If you choose, capture student responses on chalkboard/white board) Communicate Objectives, Define Problem or Decision to be Made, or Identify Questions to Investigate: Today we’re starting our unit on high tunnel production. Today we’ll begin by getting familiar with the topic. (SLIDE 2) Our objectives for today’s lesson are: Recognize the difference between a high tunnel and a greenhouse structure. Identify the advantages to high tunnels. Recall limitations to the use of high tunnels. Instructor Directions / Materials Content Outline, Instructional Procedures, and/or Key Questions Though high tunnels do resemble greenhouses, they are much different. Objective One Recognize the difference between You may have heard the term “hoop house” before, this is another common a high tunnel and a greenhouse name for high tunnels. structure. The primary purpose of high tunnels is to extend the growing season and intensify production. Growing in a high tunnel allows for greater SLIDE 3 diversification of farming operations. High tunnels also require less capital (money) than growing in a greenhouse, and often can yield higher returns. SLIDE 4 High tunnels are used to extend the harvest season of many high-value crops. They are often added to fruit and vegetable growing operations because they increase marketing opportunities. High tunnels help growers extend the season on both ends (early spring and into late fall). SLIDE 5 SLIDE 6 High tunnels are simple, plastic-covered structures. They often come in many different shapes and sizes, and can be made from many different materials. High tunnels are tall enough structures to walk-in and to grow tall, trellised crops, such as tomatoes There is no set standard for the dimensions of high tunnels - They can range from 14 to 30 feet wide by 30 to 96 feet long High tunnels, like greenhouses, must be irrigated because rain cannot reach the crops inside the high tunnel They are different from greenhouses in a number of ways: - They are passive-solar-heated structures and use no artificial heat, as greenhouses do - They are also passively ventilated. A grower can manually rollup the sides and often the end walls can be opened or removed when temperatures in the high tunnel get too high. Greenhouses, on the other hand, utilize artificial ventilation such as fans, tubes and forced air. - Plants in a high tunnel are typically grown directly in the ground, unlike plants grown in greenhouses which are often grown in containers set up on growing tables. - As mentioned earlier, high tunnels are typically covered with a single layer of plastic. Greenhouses may be covered with glass, rigid panels, or double-layers of plastic High tunnels typically cost much less than greenhouses to construct. They may cost as little as $.50/ft2 to construct, while commercial greenhouses can cost up to $20/ft2 Instructor Directions / Materials Content Outline, Instructional Procedures, and/or Key Questions How many of you have grown fruits or vegetables in a garden or have Objective Two Identify the advantages of high helped your parents or grandparents with a garden? Think to those experiences with gardening. With what you now know about high tunnels, tunnels what do you think the advantages are to utilizing high tunnels in fruit and vegetable production? (Gather student answers and record on the chalk board/white board. If their responses show up as you go through the advantages in the PowerPoint, highlight their correct responses.) Growing in a high tunnel does provide a number of advantages to fruit and vegetable production: Extended growing seasons: High tunnels can be one hardiness zone warmer than the field; the altered soil temperature and climate in a high tunnel extends the growing season crops, enabling them to be planed earlier in the spring and to produce a crop later in the fall. SLIDE 7 Planting can often begin 4 to 8 weeks earlier in the spring and production can typically continue 2-5 weeks later than outdoor production in the fall. This often results in growers being able to receive a premium price for their out-of-season produce. Weather protection: High tunnels protect the growing crop from environmental stresses, such as drought, driving rain, hail, wind, and temperature extremes. Often this protection and the extended growing seasons result in the ability to grow crops that are not usually grown in the area. Labor efficiency: Since it is a covered structure, most tasks (planting, pruning, trellising, pest control, harvest, etc) can be performed unaffected by the weather. Several production seasons are possible, so for commercial (large scale) growers, year-round employment positions are possible. High tunnels do require higher labor inputs (a greater amount of time) in order to achieve maximum production, such as raising and lowering the sides several times a day as weather conditions demand. SLIDE 8 Environmental control: Growers have more control over growing conditions and the environment inside a high tunnel. They can control the water, fertility, and to some extent, the temperature (through the use of providing shade, trapping heat, and ventilating so that temperatures do not get too high). As a result, greater yields of quality produce can be harvested. Weed growth is reduced in a high tunnel because of the continuously dry environment with drip irrigation for the crops. Instructor Directions / Materials Content Outline, Instructional Procedures, and/or Key Questions Reduced incidence of plant diseases: The need for disease, weed, and wildlife management is reduced in a high tunnel compared to field production, so pesticide inputs are minimized. Often no pesticides are needed. The lack of water on the foliage (because of drip irrigation) significantly reduces the incidence of foliar diseases. SLIDE 9 Improved Quality: Due to the protected microclimate, produce grown in a well-managed high tunnel tends to be of higher quality and produce higher yields than field-grown crops. Also, a greater shelf-life of leafy greens and raspberries has been reported. Increased revenue per square foot: Overall, the greatest advantage of growing in a high tunnel, combining all of the previously discussed advantages, is the potential for increased revenue. SLIDE 10 This increased revenue can come from higher premiums received for outof-season crops, increased quality and yield, the value in the marketplace (such as growing organic or reduced pesticide use), and reduced cost of inputs. Objective Three Recall limitations to the use of high tunnels SLIDE 11 SLIDE 12 Of course, growers should be mindful that net income may be adversely affected depending on the crop grown and their management skills. When you think about what you know about growing in a garden or in a greenhouse, what do you think the challenges or limitations to growing in a high tunnel may be? When considering high tunnel production, it is important to look at the whole picture. More detailed attention is required on water and nutrient management, temperature control, crop selection and continuous production strategies. Producing in a high tunnel is also typically more costly than growing in a field, due to the structure’s capital costs and increased manual labor requirements. Initial cost and maintenance: The high cost of high tunnels often requires multiple years to pay for itself (to make enough money to cover the initial input costs of constructing the tunnel). Barring a significant weather event (such as a tornado), a galvanized metal high tunnel frame should last 30 to 40 years. However, the plastic covering will need to be replaced at least every four or five years. Other upkeep costs, such as repairing and changing parts of the high tunnel constructed of wood, will also be necessary. Different pest problems: As we discussed in the advantages, there are fewer disease problems with Instructor Directions / Materials SLIDE 13 SLIDE 14 High Tunnel Economics Content Outline, Instructional Procedures, and/or Key Questions high tunnels. However, there tends to be increased insect pressure. High tunnels create a favorable environment for insect pests that are typically not seen in the field or are not an annual problem. Examples of these insects are the tomato hornworm, cutworm, thrips, mites and aphids. Regular monitoring and labor: High tunnels must be closely monitored to control the climate, especially in the spring and fall, when the temperatures in a closed high tunnel can quickly rise to harmful levels for crops. Additional investments in electrical installation and thermostatically controlled side and overhead ventilation will reduce the need for such frequent monitoring. Crop rotation: The limited space in a high tunnel makes crop rotation difficult when single crops, such as tomatoes, are grown for several consecutive years. Growers should consider proper crop rotations for soil fertility and nutrition, reduction of soil-borne pathogens, and pest control. Growing a crop in a high tunnel often costs more than in a field, so growers must carefully chose what crops or combination of crops will yield the highest return. While almost all crops CAN be grown in a high tunnel, not all crops make economic sense to produce in a high tunnel. (This will be discussed in greater detail in a later lesson.) SLIDE 15 Closure/Summary: Evaluation: When determining what to produce in a high tunnel, growers should consider: The value of the crop Length of its growing season Labor required for production Yield of the crop Potential market price As we think back on everything we’ve discussed in this lesson, How are high tunnels different than greenhouses? What are some of the reasons people use high tunnels? What are the advantages to using high tunnels? How would you explain some of the primary challenges or limitations to growing in a high tunnel? This lesson kicked off our unit on high tunnel production. In the next several lessons, we’ll be learning about selecting a site for constructing a high tunnel, managing the soil and fertility within a high tunnel, how to select the right high tunnel for your needs, maintaining a high tunnel, growing in a high tunnel, integrated pest management, and business planning and marketing (how you can make MONEY from growing fruits and veggies!) Have students journal their response to one of the following reflection questions on a separate, blank sheet of paper. In your opinion, what is the most interesting thing you have learned Instructor Directions / Materials SLIDE 16 Content Outline, Instructional Procedures, and/or Key Questions about high tunnels so far? Would you be interested in fruit and vegetable production in a high tunnel? Could you see yourself growing in a high tunnel as an SAE project or part of your agricultural education program? Your agricultural education program has the opportunity to receive a high tunnel. Do you think they should get one? Why or why not? What talking points would you use to convince your school board and agriculture teacher that a high tunnel is or is not a good investment?