Structural Steel Framing - MD Anderson Cancer Center

advertisement

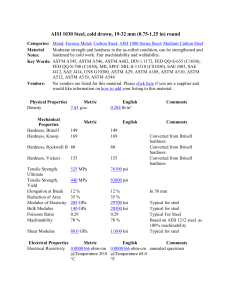

MD ANDERSON Project No. XX-XXXX A/E Name A/E Project No. MD ANDERSON PROJECT NAME Issue Description Month, 00, 0000 SECTION 05 12 00 – STRUCTURAL STEEL FRAMING PART 1 - GENERAL 1.01 RELATED DOCUMENTS A. Drawings and general provisions of the Contract, including General and Supplementary Conditions and Division 01 Specification Sections, apply to this Section. B. Specifications throughout all Divisions of the Project Manual are directly applicable to this Section, and this Section is directly applicable to them. 1.02 REFERENCE STANDARDS A. The latest published edition of a reference shall be applicable to this Project unless identified by a specific edition date. B. All reference amendments adopted prior to the effective date of this Contract shall be applicable to this Project. C. All materials, installation and workmanship shall comply with all applicable requirements and standards. 1.03 QUALITY ASSURANCE A. Comply with applicable provisions of the following specifications and documents. 1. AISC's "Specification for Structural Steel Buildings - Allowable Stress Design and Plastic Design." 2. AISC's "Load and Resistance Factor Design (LFRD) Specification for Structural Steel Buildings." 3. AISC's "Specification for Allowable Stress Design of Single-Angle Members." 4. AISC's "Specification for Load and Resistance Factor Design of Single-Angle Members." 5. AISC's "Seismic Provisions for Structural Steel Building." 6. ASTM A 6 (ASTM A 6M) "Specification for General Requirements for Rolled Steel Plates, Shapes, Sheet Piling, and Bars for Structural Use." 7. Research Council on Structural Connections' (RCSC) "Specification for Structural Joints Using ASTM A 325 or A 490 Bolts." 8. Research Council on Structural Connections' (RCSC) "Load and Resistance Factor Design Specification for Structural Joints Using ASTM A 325 or A 490 Bolts." B. Qualifications for Welding Work: Qualify welding procedures and welding operators in accordance with AWS "Qualification" requirements. 1. Provide certification that welders to be employed in work have satisfactorily passed AWS qualification tests. The University of Texas MD Anderson Cancer Center MS010107 STRUCTURAL STEEL FRAMING 05 12 00 1 OF 9 MD ANDERSON Project No. XX-XXXX A/E Name A/E Project No. MD ANDERSON PROJECT NAME Issue Description Month, 00, 0000 2. If recertification of welders is required, retesting will be Contractor's responsibility. 1.04 SUBMITTALS A. Product Data: 1. Product data or manufacturer's specifications and installation instructions for following products. Include laboratory test reports and other data to show compliance with specifications (including specified standards). a. Structural steel (each type), including certified copies of mill reports covering chemical and physical properties. b. High strength bolts (each type), including nuts and washers. 1) Include Direct Tension Indicators if used. c. Structural steel primer paint. d. Shrinkage resistant grout. B. Record Documents: 1. Shop drawings prepared under supervision of a licensed Structural Engineer, including complete details and schedules for fabrication and assembly of structural steel members, procedures, and diagrams. a. Include details of cuts, connections, camber, holes, and other pertinent data. Indicate welds by standard AWS symbols and show size, length, and type of each weld. b. Provide setting drawings, templates, and directions for installation of anchor bolts and other anchorages to be installed as work of other sections. 2. Test reports conducted on shop and field bolted and welded connections. Include data on type(s) of tests conducted and test results. 3. Certified copies of each survey conducted by a licensed Land Surveyor, showing elevations and locations of base plates and anchor bolts to receive structural steel and final elevations and locations for major members. Indicate discrepancies between actual installation and contract documents. 1.05 DELIVERY, STORAGE AND HANDLING A. Deliver materials to the Project Site at such intervals to ensure uninterrupted progress of work. B. Deliver anchor bolts and anchorage devices, which are to be embedded in cast in place concrete or masonry, in ample time to not to delay work. C. Store materials to permit easy access for inspection and identification. Keep steel members off ground by using pallets, platforms, or other supports. Protect steel members and packaged materials from erosion and deterioration. If bolts and nuts become dry or rusty, clean and re-lubricate before use. The University of Texas MD Anderson Cancer Center MS010107 STRUCTURAL STEEL FRAMING 05 12 00 2 OF 9 MD ANDERSON Project No. XX-XXXX A/E Name A/E Project No. MD ANDERSON PROJECT NAME Issue Description Month, 00, 0000 1. Do not store materials on structure in a manner that might cause distortion or damage to members or supporting structures. Repair or replace damaged materials or structures as directed. 1.06 PERFORMANCE REQUIREMENTS A. Engineer structural steel connections required by the Contract Documents to be selected or completed by the fabricator to withstand design loadings indicated. B. Engage a fabricator who utilizes a qualified professional engineer to prepare calculations, Shop Drawings, and other structural data for structural steel connections. PART 2 - PRODUCTS 2.01 GENERAL A. All materials shall meet or exceed all applicable referenced standards, federal, state and local requirements, and conform to codes and ordinances of authorities having jurisdiction. 2.02 MATERIALS A. Metal Surfaces, General: For fabrication of work that will be exposed to view, use only materials that are smooth and free of surface blemishes including pitting, rust and scale seam marks, roller marks, rolled trade names, and roughness. Remove such blemishes by grinding, or by welding and grinding, prior to cleaning, treating, and applying surface finishes. B. Structural Steel Shapes, Plates, and Bars: ASTM A 36 (ASTM A 36M). C. Cold Formed Steel Tubing: ASTM A 500, Grade B. D. Hot Formed Steel Tubing: ASTM A 501. E. Headed Stud Type Shear Connectors: ASTM A 108, Grade 1015 or 1020, cold finished carbon steel with dimensions complying with AISC Specifications. F. Anchor Rods, Bolts, Nuts, and Washers: As follows: 1. Unheaded Rods: ASTM A 36 (ASTM A 36M) 2. Unheaded Rods: ASTM A 572, Grade 50 (ASTM A 572M, Grade 345) 3. Unheaded Bolts: ASTM A 687, high strength 4. Headed Bolts: ASTM A 307, Grade A (ASTM F 568, Property Class 4.6); carbon-steel, hex-head bolts; and carbon-steel nuts. 5. Headed Bolts: ASTM A325 (ASTM A 325M), Type 1, heavy hex steel structural bolts and heavy hex carbon-steel nuts. 6. Headed Bolts: ASTM A 490 (ASTM A 490M), Type 1, heavy hex steel structural bolts and heavy hex carbon-steel nuts. 7. Washers: ASTM A 36 (ASTM A 36M) The University of Texas MD Anderson Cancer Center MS010107 STRUCTURAL STEEL FRAMING 05 12 00 3 OF 9 MD ANDERSON Project No. XX-XXXX A/E Name A/E Project No. MD ANDERSON PROJECT NAME Issue Description Month, 00, 0000 G. Nonhigh-Strength Bolts, Nuts, and Washers: ASTM A 307, Grade A (ASTM F 58, Property Class 4.6); carbon-steel, hex-head bolts; carbon-steel nuts; and flat, unhardened steel washers. 1. Finish: Plain, uncoated 2. Finish: Hot-dip zinc-coating, ASTM A 153, Class C 3. Finish: Mechanically deposited zinc-coating, ASTM B 695, Class 50 H. High-Strength Bolts, Nuts, and Washers: ASTM A 325 (ASTM A 325M), Type 1, heavy hex steel structural bolts, heavy hex carbon-steel nuts, and hardened carbon-steel washers. 1. Finish: Plain, uncoated 2. Finish: Hot-dip zinc-coating, ASTM A 153, Class C 3. Finish: Mechanically deposited zinc-coating, ASTM B 695, Class 50, epoxy coated 4. Direct-Tension Indicators: ASTm F 959, Type 325 a. Finish: Plain, uncoated b. Finish: Mechanically deposited zinc-coating, ASTM B 695, Class 50 c. I. Finish: Mechanically deposited zinc-coating, ASTM B 695, Class 50, epoxy coated High-Strength Bolts, Nuts, and Washers: ASTM A 490 (ASTM A 490M), Type 1, heavy hex steel structural bolts, heavy hex carbon-steel nuts, and hardened carbon-steel washers, uncoated. 1. Direct-Tension Indicators: ASTM F 959, Type 490 uncoated J. 2.03 Welding Electrodes: Comply with AWS requirements. PRIMER A. Primer: Fast-curing, lead- and chromate-free, universal modified-alkyd primer with good resistance to normal atmospheric corrosion, complying with performance requirements of FS TT-P-664. B. Primer: SSPC-Paint 23, latex primer. C. Galvanizing Repair Paint: High-zinc-dust-content paint for regalvanizing welds and repair painting galvanized steel, with dry film containing not less than 93 percent zinc dust by weight, and complying with DOD-P-21035A or SSPC-Paint 20. 2.04 GROUT A. Cement Grout: Portland cement (ASTM C 150, Type I or Type III) and clean, uniformly graded, natural sand (ASTM C 404, Size No. 2). Mix at a ratio of 1.0 part cement to 2-1/2 parts sand, by volume, with minimum water required for placement and hydration. The University of Texas MD Anderson Cancer Center MS010107 STRUCTURAL STEEL FRAMING 05 12 00 4 OF 9 MD ANDERSON Project No. XX-XXXX A/E Name A/E Project No. MD ANDERSON PROJECT NAME Issue Description Month, 00, 0000 B. Nonmetallic Shrinkage Resistant Grout: Premixed, nonmetallic, noncorrosive, nonstaining product containing selected silica sands, Portland cement, shrinkage compensating agents, plasticizing and water reducing agents, complying with ASTM C 1107 of consistency suitable for application, and a 30 minute working time. 2.05 FABRICATION A. Shop Fabrication and Assembly: Fabricate and assemble structural assemblies in shop to greatest extent possible. Fabricate items of structural steel in accordance with AISC Specifications and as indicated on final shop drawings. Provide camber in structural members where indicated. 1. Properly mark and match mark materials for field assembly. Fabricate for delivery sequence that will expedite erection and minimize field handling of materials. 2. Where finishing is required, complete assembly, including welding of units, before start of finishing operations. Provide finish surfaces of members exposed in final structure free of markings, burrs, and other defects. B. Connections: Weld or bolt shop connections, as indicated. C. Bolt field connections, except where welded connections or other connections are indicated. 1. Provide high strength threaded fasteners for principal bolted connections, except where unfinished bolts are indicated. 2. Provide unfinished threaded fasteners for only bolted connections of secondary framing members to primary members (including purlins, girts, and other framing members taking only nominal stresses) and for temporary bracing to facilitate erection. D. High Strength Bolted Construction: Install high strength threaded fasteners in accordance with AISC "Specifications for Structural Joints using ASTM A 325 or A 490 Bolts." E. Welded Construction: Comply with AWS Code for procedures, appearance and quality of welds, and methods used in correcting welding work. F. Assemble and weld built up sections by methods that will produce true alignment of axes without warp. G. Shear Connectors: Prepare steel surfaces as recommended by manufacturer of shear connectors. Weld shear connectors in field, spaced as shown, to beams and girders in composite construction. Use automatic end welding of headed stud shear connectors in accordance with manufacturer's printed instructions. H. Steel Wall Framing: Select members that are true and straight for fabrication of steel wall framing. Straighten as required to provide uniform, square, and true members in completed wall framing. I. Build up welded door frames attached to structural steel framing. Weld exposed joints continuously and grind smooth. Plug weld steel bar stops to frames, except where shown removable. Secure removable stops to frames with countersunk, cross recessed head machine screws, uniformly spaced not more than 10 inches on center, unless otherwise indicated. The University of Texas MD Anderson Cancer Center MS010107 STRUCTURAL STEEL FRAMING 05 12 00 5 OF 9 MD ANDERSON Project No. XX-XXXX A/E Name A/E Project No. J. MD ANDERSON PROJECT NAME Issue Description Month, 00, 0000 Holes for Other Work: Provide holes required for securing other work to structural steel framing and for passage of other work through steel framing members, as shown on final shop drawings. K. Provide threaded nuts welded to framing and other specialty items as indicated to receive other work. L. Cut, drill, or punch holes perpendicular to metal surfaces. Do not flame cut holes or enlarge holes by burning. Drill holes in bearing plates. M. Expansion Joints: Provide expansion joints in steel shelf angles when part of structural steel frame; locate at vertical brick expansion joints as indicated on drawings. 2.06 SHOP PAINTING A. Shop paint structural steel, except those members or portions of members to be embedded in concrete or mortar. Paint embedded steel that is partially exposed on exposed portions and initial 2 inches of embedded areas only. 1. Do not paint surfaces to be welded or high strength bolted with friction type connections. 2. Do not paint surfaces scheduled to receive sprayed on fireproofing. 3. Apply 2 coats of paint to surfaces that are inaccessible after assembly or erection. Change color of second coat to distinguish it from first. B. Surface Preparation: After inspection and before shipping, clean steelwork to be painted. Remove loose rust, loose mill scale, and spatter, slag, or flux deposits. Clean steel in accordance with Steel Structures Painting Council (SSPC) as follows: 1. SP 2 "Hand Tool Cleaning" 2. SP 3 "Power Tool Cleaning" 3. SP 6 "Commercial Blast Cleaning" 4. SP 7 "Brush Off Blast Cleaning" 5. SP 10 "Near White Blast Cleaning" C. Painting: Immediately after surface preparation, apply structural steel primer paint in accordance with manufacturer's instructions and at a rate to provide dry film thickness of not less than 1.5 mils. Use painting methods that result in full coverage of joints, corners, edges, and exposed surfaces. 2.07 GALVANIZING A. Hot-Dip Galvanized Finish: Apply zinc coating by the hot-dip process to structural steel indicated for galvanizing according to ASTM A 123. The University of Texas MD Anderson Cancer Center MS010107 STRUCTURAL STEEL FRAMING 05 12 00 6 OF 9 MD ANDERSON Project No. XX-XXXX A/E Name A/E Project No. 2.08 MD ANDERSON PROJECT NAME Issue Description Month, 00, 0000 SOURCE QUALITY CONTROL A. Materials and fabrication procedures are subject to inspection and tests in mill, shop, and field, conducted by a qualified inspection agency. Such inspections and tests will not relieve Contractor of responsibility for providing materials and fabrication procedures in compliance with specified requirements. 1. Promptly remove and replace materials or fabricated components that do not comply. B. Design of Members and Connections: Details shown are typical; similar details apply to similar conditions, unless otherwise indicated. Verify dimensions at the Project Site whenever possible without causing delay in the work. 1. Promptly notify Owner whenever design of members and connections for any portion of structure are not clearly indicated. PART 3 - EXECUTION 3.01 ERECTION A. Surveys: Employ a licensed land surveyor for accurate erection of structural steel. Check elevations of concrete and masonry bearing surfaces, and locations of anchor bolts and similar devices, before erection work proceeds, and report discrepancies to Owner. Do not proceed with erection until corrections have been made or until compensating adjustments to structural steel work have been agreed upon with Owner. B. Temporary Shoring and Bracing: Provide temporary shoring and bracing members with connections of sufficient strength to bear imposed loads. Remove temporary members and connections when permanent members are in place and final connections are made. Provide temporary guy lines to achieve proper alignment of structures as erection proceeds. C. Setting Bases and Bearing Plates: Clean concrete and masonry bearing surfaces of bond reducing materials and roughen to improve bond to surfaces. Clean bottom surface of base and bearing plates. 1. Set loose and attached base plates and bearing plates for structural members on wedges or other adjusting devices. 2. Tighten anchor bolts after supported members have been positioned and plumbed. Do not remove wedges or shims, but if protruding, cut off flush with edge of base or bearing plate prior to packing with grout. 3. Pack grout solidly between bearing surfaces and bases or plates to ensure that no voids remain. Finish exposed surfaces, protect installed materials, and allow to cure. 4. For proprietary grout materials, comply with manufacturer's instructions. D. Field Assembly: Set structural frames accurately to lines and elevations indicated. Align and adjust various members forming part of complete frame or structure before permanently fastening. Clean bearing surfaces and other surfaces that will be in permanent contact before assembly. Perform necessary adjustments to compensate for discrepancies in elevations and alignment. The University of Texas MD Anderson Cancer Center MS010107 STRUCTURAL STEEL FRAMING 05 12 00 7 OF 9 MD ANDERSON Project No. XX-XXXX A/E Name A/E Project No. MD ANDERSON PROJECT NAME Issue Description Month, 00, 0000 E. Level and plumb individual members of structure within specified AISC tolerances. F. Establish required leveling and plumbing measurements on mean operating temperature of structure. Make allowances for difference between temperature at time of erection and mean temperature at which structure will be when completed and in service. G. Splice members only where indicated and accepted on shop drawings. H. Erection Bolts: On exposed welded construction, remove erection bolts, fill holes with plug welds, and grind smooth at exposed surfaces. 1. Comply with AISC Specifications for bearing, adequacy of temporary connections, alignment, and removal of paint on surfaces adjacent to field welds. 2. Do not enlarge unfair holes in members by burning or by using drift pins, except in secondary bracing members. Ream holes that must be enlarged to admit bolts. I. Gas Cutting: Do not use gas cutting torches in field for correcting fabrication errors in primary structural framing. Cutting will be permitted only on secondary members that are not under stress, as acceptable to Owner. Finish gas cut sections equal to a sheared appearance when permitted. J. Touch Up Painting: Immediately after erection, clean field welds, bolted connections, and abraded areas of shop paint. Apply paint to exposed areas using same material as used for shop painting. 1. Apply by brush or spray to provide minimum dry film thickness of 1.5 mils. 3.02 QUALITY CONTROL A. Owner will engage an independent testing and inspection agency to inspect high-strength bolted connections and welded connections and to perform tests and prepare test reports. Testing agency shall conduct and interpret tests and state in each report whether test specimens comply with requirements, and specifically state any deviations there from. Provide access for testing agency to places where structural steel work is being fabricated or produced so that required inspection and testing can be accomplished. 1. Testing agency shall comply with all the regulations of the Department of Public Works of the City of Houston and shall certify in writing, upon completion of the Work, that all Work was performed in accordance with the construction documents and all applicable city ordinances. B. Testing agency shall conduct and interpret tests, state in each report whether test specimens comply with requirements, and specifically state any deviations there from. C. Provide access for testing agency to places where structural steel work is being fabricated or produced so that required inspection and testing can be accomplished. D. Testing agency may inspect structural steel at plant before shipment; however, Owner reserves right, at any time before final acceptance, to reject material not complying with specified requirements. The University of Texas MD Anderson Cancer Center MS010107 STRUCTURAL STEEL FRAMING 05 12 00 8 OF 9 MD ANDERSON Project No. XX-XXXX A/E Name A/E Project No. MD ANDERSON PROJECT NAME Issue Description Month, 00, 0000 E. Correct deficiencies in structural steel work that inspections and laboratory test reports have indicated to be not in compliance with requirements. Perform additional tests, at Contractor's expense, as necessary to reconfirm any noncompliance of original work and to show compliance of corrected work. F. Field-bolted connections will be tested and inspected according to RCSC's "Specification for Structural Joints Using ASTM A 325 or A 490 Bolts." G. Field-bolted connections will be tested and inspected according to RCSC's "Load and Resistance Factor Design Specification for Structural Joints Using ASTM A 325 or A 490 Bolts." 1. Direct-tension indicator gaps will be verified to comply with ASTM F 959, Table 2 H. In addition to visual inspection, field-welded connections will be inspected and tested according to AWS D1.1 and the inspection procedures listed below, at testing agency's options. 1. Liquid Penetrant Inspection: ASTM E 165 2. Magnetic Particle Inspection: ASTM E 709; performed on roof pass and on finished weld. Cracks or zones of incomplete fusion or penetration will not be accepted. 3. Radiographic Inspection: ASTM E 94 and ASTM E 142; minimum quality level "2-2T" 4. Ultrasonic Inspection: ASTM E 164 I. In addition to visual inspection, field-welded shear connectors will be inspected and tested according to requirements of AWS D1.1 for stud welding and as follows: 1. Bend tests will be performed when visual inspections reveal either less than a continuous 360 degree flash or welding repairs to any shear connector. 2. Tests will be conducted on additional shear connectors when weld fracture occurs on shear connectors already tested, according to requirements of AWS D1.1. 3.03 CLEANING A. Touchup Painting: Immediately after erection, clean field welds, bolted connections, and abraded areas of shop paint. Apply paint to exposed areas using same material as used for shop painting. 1. Apply by brush or spray to provide a minimum dry film thickness of 1.5 mils (0.038 mm). B. Galvanized Surfaces: Clean field welds, bolted connections, and abraded areas and apply galvanizing repair paint according to ASTM A 780. END OF SECTION 05 12 00 The University of Texas MD Anderson Cancer Center MS010107 STRUCTURAL STEEL FRAMING 05 12 00 9 OF 9