ARFF Truck Specs - CPR - Wyoming Airport Operators Association

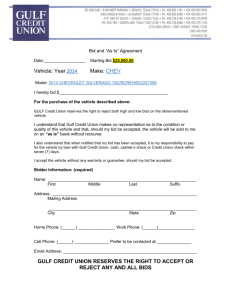

advertisement