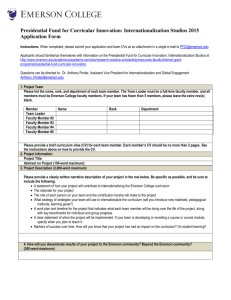

23 May 2003 - Emerson Process Management

advertisement

Page 1 of 5 23rd October 2008 Emerson’s Smart Wireless Solutions Improve Wellhead Monitoring at BP Wytch Farm Self-organising wireless network proves easy to install and highly reliable in crowded metal wellhead environment of onshore oil field. Emerson Process Management has successfully applied its Smart Wireless selforganising field network to monitor wellhead annular pressure at BP’s Wytch Farm onshore oilfield. Wytch Farm is Western Europe's largest onshore oilfield, comprising three separate oil reservoirs that lie under Poole Harbour and Poole Bay in Dorset, UK. Emerson’s Smart Wireless transmitters enable continuous monitoring of the wellhead pressure that indicates the condition of the well. Previously the pressure was measured by using gauges that were manually read once or twice a day. Continuous monitoring eliminates the need for daily visits to the wellhead and enables unusual readings to be identified earlier and action taken to investigate and rectify faults before they develop into serious problems. As part of a drive to improve operations, BP wanted to increase the available information, improve worker efficiency, and remove the need for operator rounds. “Manual reading of pressure gauges on the wellhead was identified as one area we could improve,” explained Chris Geen, BP Manager “but we found that wired transmitters were simply too expensive due to the wiring infrastructure needed, so wireless is the perfect technology for this application.” The Smart Wireless network installed on one of the well sites at Wytch Farm includes 40 Rosemount® wireless pressure transmitters. Two transmitters are mounted on each wellhead and a single Smart Wireless Gateway, mounted outside the process area, connects the transmitters to the control system. Data is collated in a PI historian database with the information used for regular maintenance and safety reports. Page 2 of 5 Installation was quick and easy: the manifolds were isolated; the old dial gauges removed, and the wireless transmitters screwed into the existing connectors. Despite short access periods to the site, it took less than eight hours in total (spread over two days) to complete including removal of all the old gauges, replacing them with the Rosemount wireless transmitters and performing a three point manual calibration check on every device. All devices were on-line within 30 minutes. The wellhead area was fairly open on one side but had cable trays, dense pipe work, and other metal obstructions on the other side, shielding some of the transmitters from the gateway location. Despite this challenging environment, as each transmitter was powered up, the devices found the gateway and the mesh was established. As new devices were added, they quickly and easily joined the self-organising network. Signal strength and consistency during the operational period has been excellent. “Wytch Farm has been a critical pilot project for BP to see if self-organising wireless mesh technology would be suitable for other similar projects. Following the success of this installation, BP is planning to install Emerson Smart Wireless transmitters in similar applications on offshore platforms,” said Geen. With Emerson’s self-organising technology, each wireless device can act as a router for other nearby devices, passing messages along until they reach their destination. If there is an obstruction, transmissions are simply re-routed along the network until a clear path to the Smart Wireless Gateway is found. As conditions change or new obstacles are encountered in a plant, such as temporary scaffolding, new equipment, or a parked construction trailer, these wireless networks simply reorganise and find a way to get their signals through. All of this happens automatically, without any involvement by the user, providing redundant communication paths and better reliability than direct, line-of-sight communications between individual devices and a receiver. This self-organising technology optimises data reliability while minimising power consumption. It also reduces the effort and infrastructure necessary to set up a successful wireless network. Page 3 of 5 Smart Wireless products and technology are an extension of Emerson’s PlantWeb® digital plant architecture. For more information on Smart Wireless, go to www.EmersonProcess.eu/SmartWireless - ENDS Images There are two images to accompany this release. Please include the copyright reference as stated. The low resolution images can be seen below and the high resolution images can be opened by clicking on the link. Caption BP Wytch Farm is Western Europe's largest onshore oilfield Link to high res image. Download larger JPG image (2.5 MB) Image: ©BP p.l.c BP Wytch Farm comprises three separate oil reservoirs that lie under Poole Harbour and Poole Bay in Dorset, UK. Image: ©BP p.l.c Download larger JPG image (2.5 MB) Page 4 of 5 Notes for the Editor About Emerson Process Management Emerson Process Management (www.EmersonProcess.com), an Emerson business, is a leader in helping businesses automate their production, processing and distribution in the chemical, oil and gas, refining, pulp and paper, power, water and wastewater treatment, metals and mining, food and beverage, pharmaceutical and other industries. The company combines superior products and technology with industry-specific engineering, consulting, project management and maintenance services. Its brands include PlantWeb®, Fisher®, Micro Motion®, Rosemount®, Rosemount Analytical®, Daniel®, Bristol®, DeltaV™, Ovation®, and AMS® Suite. About Emerson Emerson, based in St. Louis, is a global leader in bringing technology and engineering together to provide innovative solutions to customers through its network power, process management, industrial automation, climate technologies, and appliance and tools businesses. For more information, visit www.Emerson.com PlantWeb and Rosemount, are marks owned by one of the Emerson Process Management legal entities. Other marks are property of their respective owners. Page 5 of 5 CONTACT ADDRESSES: If you wish to publish for your readers the contact information for Emerson Process Management, the relevant information will be: Emerson Process Management Blegistrasse 21 6341 Baar Switzerland Email: infocentral@ap.emersonprocess.com Web: www.EmersonProcess.eu FURTHER PRESS INFORMATION: Our Ref: 501695Eur Issued by: HHC Lewis Limited 22-26 Commercial Road Southampton SO15 1GE UK Tel: +44 (0)23 8022 6361 Fax: +44 (0)23 8033 1585 Technical enquiries to: Email: Adrian Chesney adrian.chesney@hhc-lewis.co.uk