Cutting

advertisement

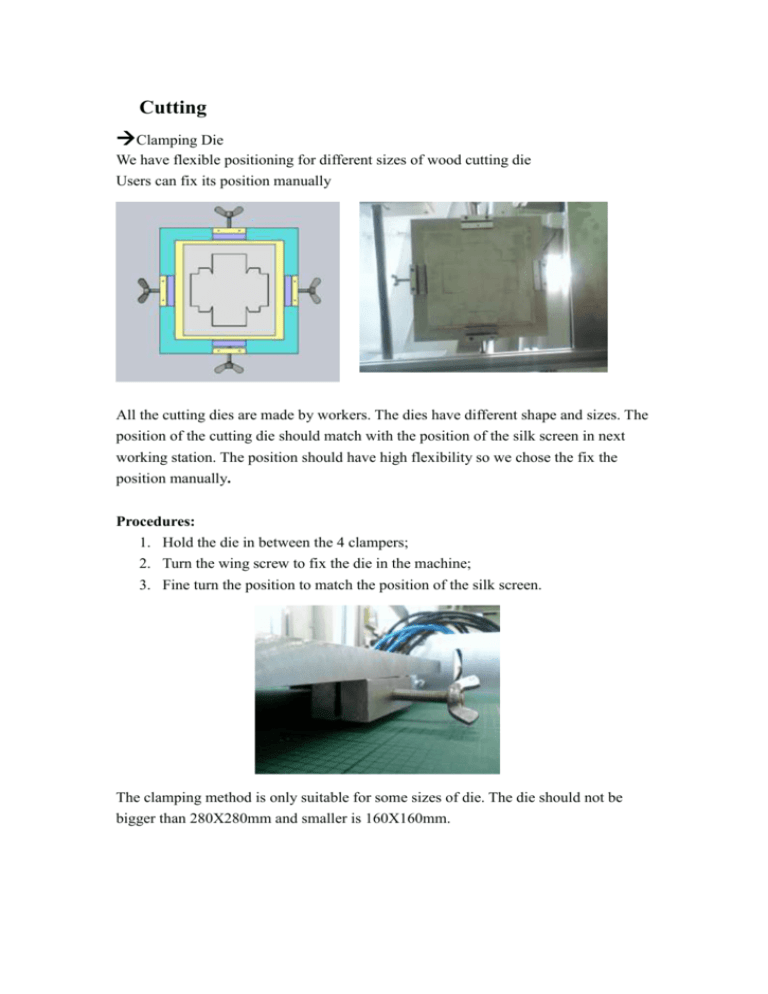

Cutting Clamping Die We have flexible positioning for different sizes of wood cutting die Users can fix its position manually All the cutting dies are made by workers. The dies have different shape and sizes. The position of the cutting die should match with the position of the silk screen in next working station. The position should have high flexibility so we chose the fix the position manually. Procedures: 1. Hold the die in between the 4 clampers; 2. Turn the wing screw to fix the die in the machine; 3. Fine turn the position to match the position of the silk screen. The clamping method is only suitable for some sizes of die. The die should not be bigger than 280X280mm and smaller is 160X160mm. Die modification 2 1 3 1. The shape would not be fully cut out. It would remain intact on the paper and keep rolling to the next station. 2. We add two small holes at the 2 corners for detecting position by sensor in the next 2 stations. It can ensure the process is done at the right position. 3. We reduce the thickness of ejecting layer from 10mm to 6mm and minimize the surface area in order to reduce the punching force and keep its original function. At the very beginning, we calculated the punching force of the die with 10mm ejecting layer. Cutting platform We chose cutting Mat as the cutting platform to prevent damage of cutting die and increase tooling life. Our customer is now using steel cutting platform. Cutting die would hit the platform once it cut paper. Therefore, the cutting die is easily worn away. Workers have to fine turn the mould distance very carefully in order to stop die before cut thought the platform. Nevertheless, workers still need to replace the die frequently. We used a hand-held puncher to punch paper on a plastic platform. The cutting quality was satisfied. Therefore, we use plastic cutting mat as the cutting platform. Pneumatic Control We use pneumatic control for punching motion. We need to calculate the cutting force of the paper. Calculating applied force to cut the paper The applied force should be able to compress EVA ejecting layer and cut paper. According to our experiment, To reduce the applied force, we have removed the ejecting layer. According to the paper properties from www.Matweb.com, the film Tensile Strength at Break of several types of paper is from 39MPa to 841MPa depending on paper thickness. We take the thickness as 10 mil so the file tensile strength at break is 110MPa As the maximum elongation of paper is small (around 10%), we take the stain as 1 Tensile Strength = Stress/1 = Stress Force/Area Force = Tensile Strength x Area = 110 106 160 4 0.1 106 = 7040 N The load of pneumatic cylinder is 7920/9.81= 717.6kg Therefore, we should choose a cylinder with output load around 717.6 kg. According to Table 1, we should choose a cylinder with bore size 160mm. Table 1 After calculating the force required to cut paper, we find that the cylinder bore size should be 160mm ideally. However, supplier did not have such cylinder in stock so we have got another type of cylinder with 63mm bore size. The ideal type of cylinder Provided Cylinder Vacuum generator In the final design of gluing part, since the cut paper will be stuck by the white glue after silk screen printing, a vacuum generator is used to provide an air pressure and sucking force toward the paper. Vacuum generator used in the proposed design: Single Stage Rotary Vacuum Pump Description: Voltage: 220 V/50 Hz Free Air Displacement: 3 CFM 3.6 CFM Ultimate Vacuum: 75 Microns(10 Pa) With plenty number of holes drilled on the sucking board: A sucking force is generated on bottom side of the paper, which is strong enough to overcome the viscosity formed between the white glue and top side of the paper