cii-ifdc awards for excellence in infrastructure

advertisement

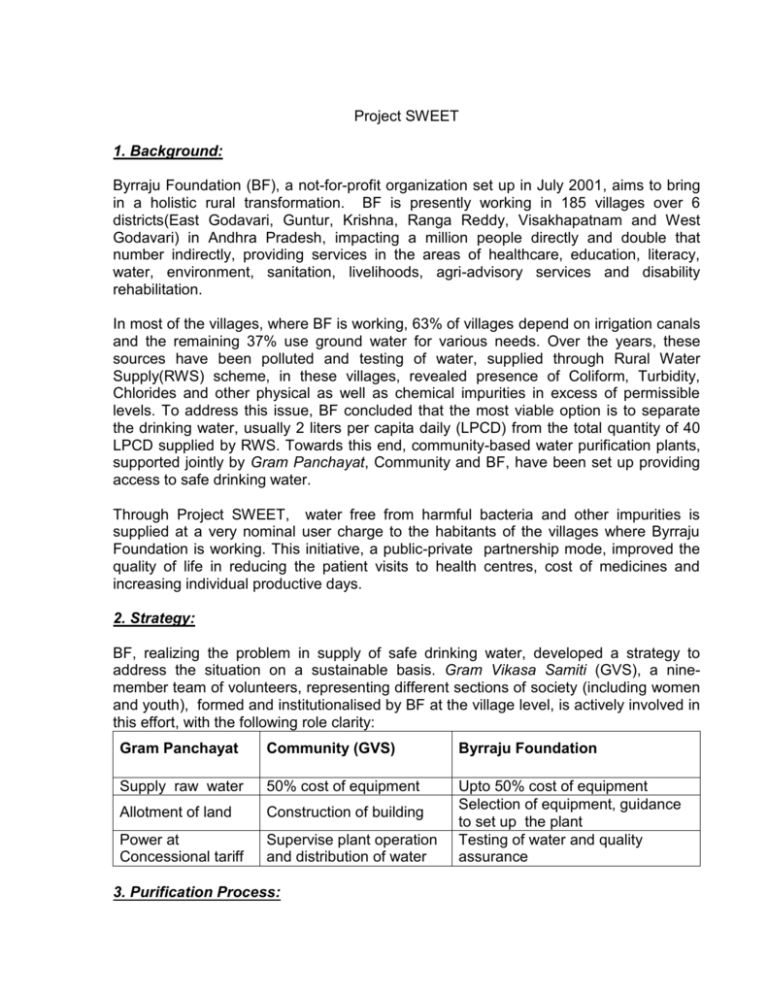

Project SWEET 1. Background: Byrraju Foundation (BF), a not-for-profit organization set up in July 2001, aims to bring in a holistic rural transformation. BF is presently working in 185 villages over 6 districts(East Godavari, Guntur, Krishna, Ranga Reddy, Visakhapatnam and West Godavari) in Andhra Pradesh, impacting a million people directly and double that number indirectly, providing services in the areas of healthcare, education, literacy, water, environment, sanitation, livelihoods, agri-advisory services and disability rehabilitation. In most of the villages, where BF is working, 63% of villages depend on irrigation canals and the remaining 37% use ground water for various needs. Over the years, these sources have been polluted and testing of water, supplied through Rural Water Supply(RWS) scheme, in these villages, revealed presence of Coliform, Turbidity, Chlorides and other physical as well as chemical impurities in excess of permissible levels. To address this issue, BF concluded that the most viable option is to separate the drinking water, usually 2 liters per capita daily (LPCD) from the total quantity of 40 LPCD supplied by RWS. Towards this end, community-based water purification plants, supported jointly by Gram Panchayat, Community and BF, have been set up providing access to safe drinking water. Through Project SWEET, water free from harmful bacteria and other impurities is supplied at a very nominal user charge to the habitants of the villages where Byrraju Foundation is working. This initiative, a public-private partnership mode, improved the quality of life in reducing the patient visits to health centres, cost of medicines and increasing individual productive days. 2. Strategy: BF, realizing the problem in supply of safe drinking water, developed a strategy to address the situation on a sustainable basis. Gram Vikasa Samiti (GVS), a ninemember team of volunteers, representing different sections of society (including women and youth), formed and institutionalised by BF at the village level, is actively involved in this effort, with the following role clarity: Gram Panchayat Community (GVS) Byrraju Foundation Supply raw water 50% cost of equipment Allotment of land Construction of building Power at Concessional tariff Supervise plant operation and distribution of water Upto 50% cost of equipment Selection of equipment, guidance to set up the plant Testing of water and quality assurance 3. Purification Process: Based on the characteristics of raw water, appropriate process, i.e., Reverse Osmosis (RO) if the level of total dissolved solids(TDS) is beyond 500 ppm or fluorides in excess of 1 ppm, otherwise conventional ultra-violet (UV), is followed for treatment. Plants producing 1000-2000 litres an hour water, using the best technology, to be operated by trained villagers, are accordingly set up. A schematic diagram indicating various steps of treatment is shown below: Chlorine Dosing (non-RO) Raw Water Raw Water Tank Coagulation System Pressure Sand Filter Ozonation Activated Carbon Filter Softener Micron Filters Blending for minimum level of minerals Product water Tank Filling Point with UV Radiation (Stage-2) Blending Tank UV Radiation (Stage-1) RO Membranes High Pressure Pump (for conventional process, Membranes, high pressure pump and softener are not needed) 4. Operation and Maintenance: To overcome the power-cuts, plant is operated on single-phase (available for 12-16 hours a day in village) on flexible timings, using voltage stabilisers for maintaining quality of power. 100% standby for all the critical components, like, Pumps, Motors, UV Lamps, Multi-port Valves and adequate stocks of consumables are maintained within and/or near the Plant. Annual maintenance contract is entered into with the suppliers of the Plant to ensure trouble free operation, at an economical cost. For every 5 plants, a maintenance team is deployed within close vicinity of a cluster of villages by the supplier of equipment, so as to attend to regular preventive and break-down maintenance. Layout of Plant and components have been standardised so that the plants, operating on similar conditions, can effectively share inventories for proper operation. 5. Capacity Building: Capacity building of community in identification and solving of problems by participation in a systematic manner enhances operational capabilities of a program. To facilitate this, BF imparts skills to GVS on self-reliance to set up and meet operational expenses for various services through user charges and/or mobilization of funds and also leadership development for its efficient and systematic implementation. For operation of Water Plant, unemployed youth, identified by GVS, are imparted training on various issues. After stabilization of the unit, creating awareness to drink safe water, planning logistics for delivery of water and ironing out any deficiencies in other operational matters, running of the plant is handed over to GVS or a self-help group(SHG), with first option to plant operators forming as a SHG. BF has already handed over management of 9 plants to local entrepreneurs under the close supervision of GVS and more are in the pipeline to be handled so. 6. Sustainability: Sustainability of the project is ensured as (a) Project is demand driven, (b) Users are involved right from the conceptual stage of the project, (c) Empowering GVS in overseeing management of the scheme, and (d) Cost recovery mechanism with participation of consumer. Project SWEET connects the formal financial markets with community thus becoming a working evidence of a link between social capital and financial intermediation. The economics of operation, which is the result of improvement over the years, is depicted below: No Item ConveRO ntional 1 Capital Expenditure (incl building Rs 350000) in Rs 700000 800000 2 Production of water per day in liters (average) 7000 7000 3 Distribution of water per day in liters (average) 6000 6000 4 User Charges @ Rs 1.50 for 12-liter can per year 264000 264000 5 Annual Recurring costs in Rs -Manpower (3 persons) 108000 108000 -Power, Consumables, Maintenance, Depreciation 76000 118000 and miscellaneous expenses TOTAL expenditure per year in Rs 184000 226000 6 SURPLUS per year in Rs 80000 38000 BF would facilitate economic sustainability of community in poorer sections so that the social leadership can implement holistic transformation programs effectively. Project SWEET, which breaks even at distribution of 4000-4500 liters daily, is an income generating enterprise, ploughing back the surplus for implementing various activities in the community. One helper is engaged, for delivering 120-150 water cans, by rickshaw at the door-step of consumer, on charging additional amount of Rs 0.50-1.50 per can, depending on the distance. A van is deployed for carrying water cans to little far away places, say beyond 4-5 km from the plant. In all, employment for 5-6 persons is ensured per each plant. 7. Replication: The concept of Project SWEET has been proven making the community to operate it on their own because (a) The technical design of the plant, the process and the choice of equipment are very sound (b) The recurring cost of the plant is not a burden on the sponsor, and (c) Willing participation of the community is possible. The model, with incipient potential of generating income, is replicable across other regions/countries in a sustainable manner. BF guided 8 organizations in implementing the scheme in 12 locations so far. United Nations-Human Settlement Programme (UN-HABITAT), under Water for Asian Cities Program, signed a Cooperation Agreement with BF in setting up one plant each in Indore (installed in Dec 2007), Jabalpur, Laos, Nepal and Uganda. 8. Impact: Access to clean drinking water has transformed the village landscape in many ways as its consumption improved health leading to reduced expenditure incurred otherwise towards treatment of water borne diseases, reportedly accounting for 80% of ailments. The impact is quite perceptible among the children, with reduced absenteeism in attending School leading to improved learning, as water from these plants is supplied free to the schools and health center. The initiative benefited the community in the following aspects: Access to safe water provided to 850,000 people in 170 villages through establishment of 54 water plants (since July 2004). BF helped other agencies in setting up of 12 plants, serving nearly 100,000 people in other villages. About 46% of people on regular basis and 5-10% people occasionally consume BF water. Over 300 million liters of safe water distributed to the poorer sections of the society, covering old age pensioners, Orphanages, Anganwadis, Schools, etc. Number of patients visiting BF health clinics in the villages with access to BF water dropped by 15-30% and the expenditure on medicines declined by 10-22% after consumption of BF water, leading to improved quality of life, attributed mainly due to relief from water borne diseases. Provided livelihoods to nearly 330 youth for operating 66 plants, within villages. 9. Environmental and Quality Issues: BF’s water initiative addresses environmental issues through treatment of contaminated water. The reject and wash water (usually 4% of total production in case of conventional process and upto 50% in case of RO system), after purification, is recycled to charge the ground water table or used for irrigation purpose. The product water is distributed in food-grade HDPE cans, which are recycled, without posing problem of degrading the environment. In summer months, effective micro-organism solution, made by BF, is used for controlling growth of algae, which increases in summer period due to intense sunlight and also restricted supply of fresh water, in the pond thus following environmental friendly practice. The yarn of discarded micron filters, is used to make products, like door mat, swing, muffler, cushion cover, floor mopper, thus not wasting this material either. Quality of product water is tested everyday at plant for key parameters, like, bacteria, TDS, residual chlorine, pH, etc. Detailed tests are carried out in a well-equipped Laboratory in a Degree College at Bhimavaram(West Godavari Dist) on weekly/fortnightly basis. Based on these test results, it has been observed that the water samples passed quality tests, 99.8% times across all the plants, during the last one year, against the set target of 99.5%. 10. Innovative Features: Project SWEET is unique and innovative, owing to the following features: Affordability: It delivers drinking water meeting WHO standards available at 12.5 paise a liter to 100% of the population in the villages covered by the project. Technology for rural poor: It takes advanced technology for producing safe drinking water to an unreached village. People centered approach: Pro-poor friendly pricing, door delivery and providing livelihoods to men and women groups within the villages and above all improved quality of life. Agreement with Gram Panchayat for use of raw water and supply of purified water within and a couple of neighboring villages. Encouragement of behavioral change: Opinion leaders from within the community can create awareness on benefits of safe drinking water and how to use it judiciously. Flexible timings of operation: In villages, availability of single-phase and 3-phase power is restricted to 12-16 hours and 6-7 hours, respectively, in a day. To overcome the power outages, plant operation is staggered over the day and working hours of the staff are adjusted accordingly. Maintenance of plant: 100% standby for all main components and adequate stocks of consumables are always ensured. Maintenance contract is entered into with plant supplier to take care of both preventive and break-down maintenance, by locating a maintenance team for every 5 plants. Quality assurance: Quality check is carried out at both plant level for key parameters(bacteria, TDS, etc., on daily basis) and in a well-equipped Laboratory for detailed analysis(on weekly basis). Sustainability: User charges collected for supplying treated water ensure this. Ozonation: Use of ozone and hydrogen peroxide controls natural organic chemicals, pesticides, etc., and improves shelf life of water. Low cost vial: H2S vial, used for detecting bacteria, was developed in-house, costing Rs 2 (17% market price). The glassware is cleaned/autoclaved for reuse. 11. Recognition: The water scheme of BF has received the following awards (copies attached): ‘Best Water NGO-Water Quality’ in India for the successive years 2006-07 and 2007-08 by Water Digest and UNESCO. Japanese Award for ‘Most Innovative Development Project-2007’(2nd prize) by Global Development Network. ‘Andhra Pradesh Scientist Award-2007’ upon FLCL (Water) for his note outstanding contribution in the subject area by AP Council of Science and Technology, Government of AP. ‘Contributors to the Noble Cause: Can Science provide Water to Humanity in Future?’ upon FLCL(Water) by Sri Prakash Vidyaniketan Group of Schools, Visakhapatnam ‘Outstanding Display’ by the delegates of 95th Indian Science Congress held at Visakhapatnam in January 2008. Project SWEET- Technology Documentation and Dissemination The experience gained over last 4 years (since Jan 2004) in implementing the Project SWEET has been developed into a detailed Process Document, and the same is distributed freely amongst interested agencies. Further, the technological and social outcomes obtained are widely disseminated through presentation/ publication of papers as listed below: 1. “The Byrraju Foundation’s 4P model of Quality Drinking Water in Villages” published in ‘India Infrastructure Report-2008: Business Models of Future' by Oxford University Press (Edited by 3i Network: IIM-Ahmedabad, IIT-Kanpur, and IFDC), Feb’08, pp 183-185. 2. “Safe Drinking Water Scheme in Villages: A Sustainable 4-P Model” presented (invited talk) in two separate Plenary Sessions ‘Science and Technology Challenges for Domestic Rural Water Security in Rural India’ and ‘Public-Private-Industry Interaction’ during 95th Indian Science Congress on ‘Knowledge Based Society using Environmentally Sustainable Science and Technology’, Visakhapatnam, Jan’08. 3. “Pro-poor Water Purification and Bottling” published in ‘Local Actions for Sustainable Development: Water and Sanitation in Asia-Pacific Region’ by UNHABITAT, ADB & Asia-Pacific Water Forum, Dec’07, pp 99-102. 4. “Provision of Safe Drinking water in Villages on Sustainable Basis: PanchayatPublic-Private Partnership Model” presented at ‘Water Summit-2007: PublicPrivate-Community Partnership in Water Management’, Hyderabad, Nov’07. 5. “Safe Drinking Water in Villages: A Step Towards Rural Transformation”, published in ‘Catalyst for Human Development’(journal), Mar’07, pp12-14. 6. “Byrraju Foundation’s Initiatives in Provision of Safe Drinking Water in Villages” presented at Rotary International Seminar on Water Management, Jaipur, Nov’06. 7. “An NGO’s Effort in Making Clean Drinking Water and Sanitation Accessible and Affordable to over a Million” published in ‘WAC India News’, Volume-II, Issue-10, Aug’06, Page-3. 8. “Can Rural Communities Afford Good Quality Drinking Water” published in ‘WES-Net India:Water and Environment Sanitation’, Volume-3(Item No 11), Aug’06. 9. “An Innovative Model for Supply of Safe Drinking Water in Villages at Affordable Charges” presented at 93rd Indian Science Congress on ‘Integrated Rural Development: Science & Technology’, Hyderabad, Jan’06. 10. “Safe Drinking Water in Rural Areas of Delta Regions-Challenges and Some Experiences” presented at XII World Water Congress on ‘Water for Sustainable Development-Towards Innovative Solutions’, New Delhi, Nov’05. Project SWEET-News Features Both print and electronic media covered the scheme and some newspaper items are listed below (copy enclosed): 1. ‘Innovative Scheme with BF’s support’, Eenadu (Edition: Tadepalligudem), 2.7.2004 (in Telugu) 2. ‘This village is drinking safe water’, Eenadu (Edition: Tadepalligudem), 28.7.2004 (in Telugu) 3. ‘BF’s contribution for development of villages’, Vaartha (Edition: Hyderabad), 24.2.2005 (in Telugu) 4. ‘Launching of water plant under BF’s supervision’, Eenadu (Edition: Tadepalligudem), 5.5.2005 (in Telugu) 5. ‘Momorable Moments- by President of India: Appreciation for BF’s water scheme’ Andhra Jyothi (Edition: Vijayawada), 10.1.2006 6. ‘Filtration Plant with the support of Dow Chemicals and BF-Solution to drinking water problems of Dasaigudem villagers’, Eenadu (Edition: Suryapet), 4.11.2006 (in Telugu) 7. ‘Benefit to Indore, Jabalpur and Gwalior:12 liters of water for Rs 1.50’, Nai Duniya (Edition: New Delhi), 13.11.2006 (in Hindi) 8. ‘BF’s efforts for addressing shortage of safe water’, Vaartha (Edition: Rajahmundry), 17.5.2007 (in Telugu) 9. ‘MLAs Study Andhra water works’, Hindustan Times (Edition: Bhopal), 26.12.2007 10. ‘Free..but safe drinking water’, Surya (Edition: Visakhapatnam), 7.1.2008 (in English) 11. ‘BF quenches the thrust’, Vaartha (Edition: Visakhapatnam), 7.1.2008 (in Telugu) 12. Video on Project SWEET (CD) Project SWEET-Evaluation by Experts Various researchers from academia and social sector visited the water plants and evaluated various aspects of Project SWEET. Brief summary of the views from 4 such experts are furnished below: a. Prof M Ravindran, Special Adviser(Rural Technology Action Group), IIT, Chennai600036(formerly Director of National Institute of Ocean Technology) Email: ravindranvanaja@gmail.com; Tel: 044-22578380 The scheme, aided by knowledge and experience of water team with ‘down to earth’ and realistic approach to commission the water plants, has following features: Innovativeness: Ensured community participation and made them the proud owner of the plant. They get a better quality of water compared to city almost at no cost and their participation in decision making gives it a 'bottoms-up approach', essential for success of such programs. Sustainability: Has high potential for success in terms of continuity and sustainability because (a) community owns and runs the plant (b) O&M cost is met from the user charges (c) equipment is of high quality and detailed procedures are worked out for maintenance and (d) program is managed by a competent team. Potential for replication: Easily replicable because (a) design of the plant, process and choice of machineries are very sound (b) running cost of the plant is not a burden on the sponsor and (c) willing participation of the community is ensured. Social impact: Has tremendous social impact as it ensures freedom from water borne diseases, accounting for about 85% of all the ailments. Children will grow in healthy environment and community contributes to the wellbeing of its own people. b. Prof PV Indiresan, Padma Bhushan, B-57, Hill View Apts, Vasant Vihar, New Delhi110057 (formerly Director of IIT-Madras and Past President-Indian National Academy of Engineering) Email: indiresan@gmail.com; Tel: 011-26145091 BF has introduced several innovative developments in a number of villages in Godavari Districts of AP. I had the privilege of visiting the villages twice, including the time I accompanied President Dr APJ Abdul Kalam, who chose to visit the project (January 2006) because it satisfied his ideas of the scheme PURA-Providing Urban Amenities in Rural Areas. BF demonstrated before Dr Kalam a low cost RO process for providing potable water at an affordable price. The rural development, as operated by BF, is multi-dimensional, and comprehensive. BF’s approach breaks new ground and this change is long over due. Pioneering efforts of the BF deserve every possible encouragement and every kind of recognition. c. Prof KN Satyanarayana, Head-Bldg Tech& Constn Mgmt, Dept of Civil Engg, IITMadras, Chennai-600036, Email: satyakn@iitm.ac.in; Tel: 044-22574268 During my frequent visits to villages in West Godavari Dist, I saw water plants and also talked to the beneficiaries. A few participants of PG course on Technology and Sustainable Development and graduate students from our Institute made detailed study of water program of BF. I am impressed with its emphasis on supplying quality water using appropriate technology. I stopped carrying bottled water and using BF water during my visits to my relations in the villages having such plants. BF, through this initiative, ensured involvement of community in raising major part of investment and also facilitated employment of 5-6 persons within village. Quality of equipment, appropriate technology, sound maintenance practices and community participation should bode well for the sustainability of the initiative. d. Dr Shrikant V Joshi, Associate Director, International Advanced Research Centre for Powder Metallurgy and New Materials, Balapur, Hyderabad-500005; Email: svjoshi@arci.res.in;Tel: 040-24441077 The water team played a pivotal role in ensuring the stupendous success of the scheme, a remarkable initiative that made noteworthy contribution in providing safe drinking water. This innovative project has led to awareness and demonstrated that such well conceived schemes have significant potential for replication. We found in BF an able and willing ally for field testing of nano-silver based low cost filter candles that we developed, which was based on their successful efforts in safe drinking water. BF is a shining example of what an NGO can achieve through their vision and actions to bring path-breaking rural transformation. The scheme exemplifies how BF has been striving tirelessly to improve conditions in rural India. Byrraju Foundation - Project SWEET Sl No 1 2 3 4 Year 09 30 Statement of Financials and Cash Flow No of Investment in Rs Lakh people with access BF to safe Panchayat Community (in kind) water 150000 7.0 51.0 24.5 21 65 325000 20.0 105.0 18 55 275000 16.0 06 20 125000 54 170 850000 No of Water Plants Set up 200405 200506 200607 200708 (upto Feb’08) Total Note: 1. 2. 3. No of villages covered By the Project Total Revenue (User charges) in Rs Lakh 82.5 04.86 53.0 178.0 37.34 80.0 45.0 141.0 81.82 6.0 31.0 14.0 51.0 93.96 49.0 267.0 136.5 452.5 217.98 Gram Panchayat alloted land (120-150 square meters) for construction of building near main water source free of cost (estimated @ Rs 1 lakh). Community, including non-resident villagers, contributed towards construction of building (500 square feet), costing Rs 3.50-4.00 lakh Community contributed 50% towards the cost of Equipment (Rs 2.00-2.50 lakh) with BF sharing the balance amount (Rs 2.00-2.50 lakh) List of Plants in Adopted villages enclosed. Byrraju Foundation- Project SWEET Participant Villages of BF with Water Plants No Village (Installation date of Plant) EAST GODAVARI DISTRICT: 1 Podagatlapalli (Oct’04) 2 Ponnamanda (Nov’04) 3 Pallamkurru (Nov’04) 4 Godilanka(May’05) 5 Kesennakurrupalem(Apr’06) 6 Chinakondepudi(Jun’06) 7 Mogalikuduru(Aug’06) 8 Vadapalem(Oct’06) 9 Vuyyurivarimeraka(Oct’06) 10 Rajupalem-Pallipalem(May’07) 11 Muramulla(Jan’07) 12 Yedurulanka(Jan’08) 13 Yandagandi(Feb’08) 14 Penikeru(Feb’08) GUNTUR DISTRICT: 15 Khajipalem (Jan’05) 16 Pittalavanipalem (Oct’06) KRISHNA DISTRICT: 17 Pothumarru (Dec’04) RANGA REDDY DISTRICT: 18 Kandlakoyya (Feb’05) 19 Gudla Pochampalli (Jun’07) WEST GODAVARI DISTRICT: 20 Gollalakoderu (Jul’04) 21 Juvvalapalem (Oct’04) 22 Vempadu (Nov’04) 23 Srungavruksham (Apr’05) 24 Poduru (May’05) 25 Pathepuram (May’05) 26 Jalllikakinada (Jun’05) 27 Mogollu (Jul’05) 28 Kommara (Aug’05) 29 Mahadevapatnam (Oct’05) 30 Cherukumilli (Nov’05) 31 Lankalakoderu (Jan’06) 32 Jinnuru (Jan’06) 33 Kolamuru (Feb’06) 34 Mallipudi (Feb’06) 35 Dumpagadapa (Feb’06) Mandal Ravulapalem Rozole Katrenikona Allavaram I. Polavaram Seethanagaram Mamidikuduru Kothapeta Sakhinetipalli Mummidivaram Mummidivaram I Polavaram K Gangavaram Alamuru Pittalavanipalem Pittalavanipalem Kalidindi Medchal Medchal Palakoderu Kalla Kalla Palakoderu Poduru Nidamarru Ganapavaram Palakoderu Attili Undi Akiveedu Palakollu Poduru Undi Penumantra Akiveedu 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 Panduvva (Mar’06) Palakoderu (Apr’06) Siddapuram (Apr’06) Pratallameraka (Aug’06) Chinchinada (Aug’06) Kolanapalli (Nov’06) Khandavalli (Dec’06) Gummaluru (Jan’07) Yendagandi (Jan’07) Mortha (Feb’07) Pedapulleru (Mar’07) Elurupadu (Mar’07) Kesavaram (Mar’07) Jakkaram (May’07) Matsyapuri (May’07) Alampuram (Jul’07) Peda Amiram (Sep’07) Singavaram (Oct’07) Kopalle (Jan’08) Undi Palakoderu Akiveedu Kalla Yelamanchili Kalla Peravali Poduru Undi Undrajavaram Undi Kalla Ganapavaram Kalla Veravasaram TP Gudem Kalla Nidadavolu Kalla Replication of Water Plants: No Village (Installation date) 1 Gollaprolu (May’06) 2 Dasaigudem (Nov’06) District and State East Godavari, AP Nalgonda, AP 3 Chimidithapadu (Mar’07) 4 Railapur (May’07) Prakasam, AP Ranga Reddy, AP Nalgonda, AP Ranga Reddy, AP Krishna, AP Supporting Agency Garavasana Fdn Dow Chem Ltd, Suven Life Sciences and Gram Panchayat Nayudamma Fdn Centre for Water& Sanitation (CWS) CWS and Panchayat Dow Chem Ltd and Grammena Mahila Sanstha UN-HABITAT & Dist Urban Devp Agency NCL Industries CWS and Panchayat CWS and Panchayat Medak, AP Krishna, AP CWS and Panchayat NCL Industries 5 Gajulamalkapuram(Oct’07) Nalgonda, AP 6 Solipet (Nov’07) Nalgonda, AP 7 Indore (Dec’07) 8 Kodada (Feb’08) 9 Munirabad (Feb’08) 10 Hanuman Junction (Feb’08) 11 Toopran (Feb’08) 12 Kondapalli (Feb’08) Indore, MP