HU-REP-DD

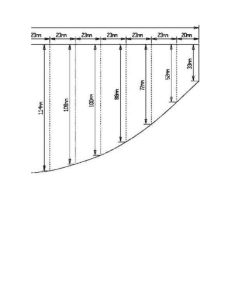

advertisement

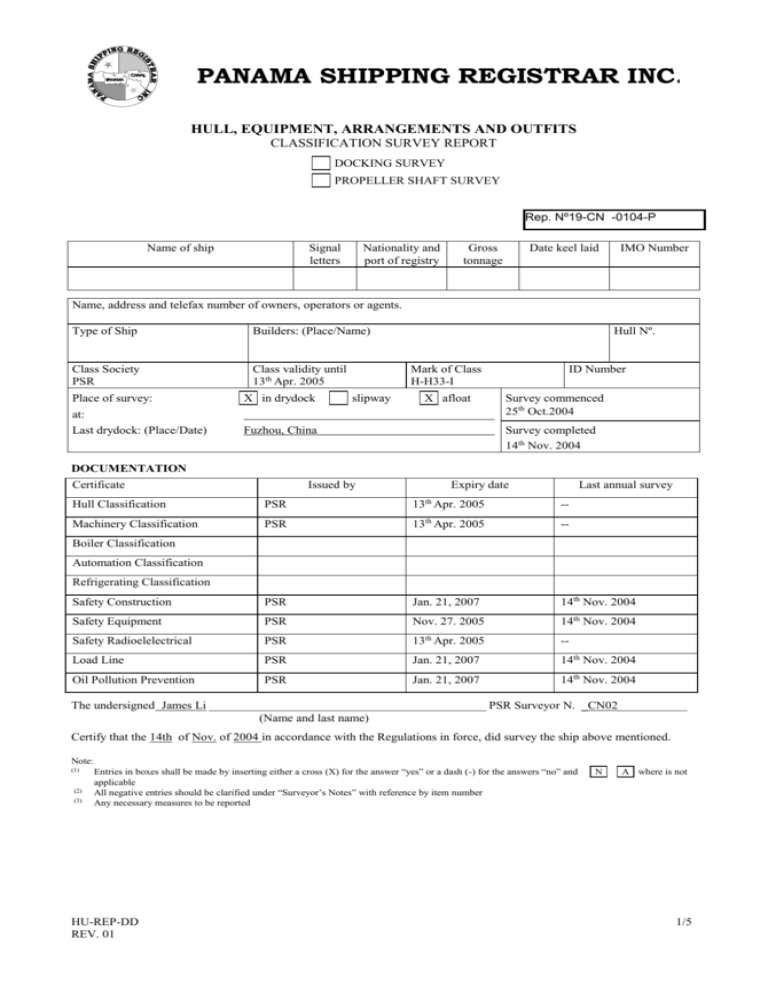

PANAMA SHIPPING REGISTRAR INC. HULL, EQUIPMENT, ARRANGEMENTS AND OUTFITS CLASSIFICATION SURVEY REPORT DOCKING SURVEY PROPELLER SHAFT SURVEY Rep. Nº19-CN -0104-P Name of ship Signal letters Nationality and port of registry Gross tonnage Date keel laid IMO Number Name, address and telefax number of owners, operators or agents. Type of Ship Builders: (Place/Name) Class Society PSR Class validity until 13th Apr. 2005 Place of survey: X in drydock at: Last drydock: (Place/Date) Fuzhou, China Hull Nº. Mark of Class H-H33-I slipway X afloat ID Number Survey commenced 25th Oct.2004 Survey completed 14th Nov. 2004 DOCUMENTATION Certificate Issued by Expiry date th Last annual survey Hull Classification PSR 13 Apr. 2005 -- Machinery Classification PSR 13th Apr. 2005 -- Safety Construction PSR Jan. 21, 2007 14th Nov. 2004 Safety Equipment PSR Nov. 27. 2005 14th Nov. 2004 Safety Radioelelectrical PSR 13th Apr. 2005 -- Load Line PSR Jan. 21, 2007 14th Nov. 2004 Oil Pollution Prevention PSR Jan. 21, 2007 14th Nov. 2004 Boiler Classification Automation Classification Refrigerating Classification The undersigned James Li ____________________________________________ PSR Surveyor N. _CN02___________ (Name and last name) Certify that the 14th of Nov. of 2004 in accordance with the Regulations in force, did survey the ship above mentioned. Note: (1) (2) (3) Entries in boxes shall be made by inserting either a cross (X) for the answer “yes” or a dash (-) for the answers “no” and applicable All negative entries should be clarified under “Surveyor’s Notes” with reference by item number Any necessary measures to be reported HU-REP-DD REV. 01 N A where is not 1/5 1. 1.1 GENERAL Ship Hull: STELL AND WELDING (Indicate join method) 1.2 Hull Material STEEL superstructure STEEL 1.3 Structural strengthening system: TRANSVERSAL deckhouse STEEL (longitudinal, transversal and mixed) 1.4 Decks: 6 (quantity) 1.5 Watertight bulkheads: 1.5.1 transversal TWO / F.P.T.-C.H. & C.H.-E.R. (quantity, location) . 1.5.2. longitudinal NONE (quantity) 1.6 Reports regarding quality control of the hull joints and test of the hull watertightness, superstructure, deckhouse and its closing devices GOOD IN ORDER 1.7 Steering gear 1.7.1 Type of rudder plate 1.7.2. Type of drive: 1.8 SINGLE PALTE principal HYDROLIC emergency MANUAL Anchor arrangement 1.8.1 Anchors TWO & TWO SPARE, STOCKLESS, 6000 KG (quantity, type, weight) 1.8.2 Chains (cables) DIA 68, 302.5, CALBE (thickness, full length, type) 1.8.3 Anchor machinery WINDLASS, DYDROLIC (type, drive) 1.9 Mooring Installation 1.9.1 Ropes and cables SYNTHETIC, 14, 60 M, 250 M (material, quantity, diameter, length) 1.9.2 Mooring gear 4, HYDROLIC, MOTOR (quantity, type, drive) 1.10 Towage installation 1.10.1 Cables or hawsers CABLE/STEEL ROPE, DIA 15, 300 M (material, quantity, diameter, length) 1.10.2 Towage winch NONE (hook drive type) HU-REP-DD REV. 01 2/5 1.11 Structural fire protection N.A. due to built before 01st Sep. 1984 1.11.1 Protection method 1.11.2 Fire fighting main bulkheads (location) 1.11.3 Type A constructions (location) 1.11.4 Type B constructions (location) 1.11.5 Doors and other type A closings (location) 1.11.6 Material used in the false ceiling, thermal and acoustic isolation cover, decorative finished, furniture, decks floors and others 1.12 Fire fighting system 1.12.1 Extinguishing system FIXED FIRE EXTINGUISHER SYSTEM(CO2) FOR E/R (denomination, type) 1.12.2 Fire fighting signaling system SIREN AND GENERAL ALARM (denomination) 1.13 Cargo gear, in accordance with the Cargo Gear Book Nº -- 1.14 The life saving appliances are provided for a total of 37 persons on board included -and are in accordance with the Safety Equipment Certificate Nº 02-CN14-0409-R 1.15 Signaling apparatus and navigation equipment are in accordance with the Safety Equipment Certificate Nº 02-CN14-0409-R 1.16 Emergency outfits: are / are not according to the Regulations. 1.17 Stability and floating system passengers Ship is provided with a: 1.17.1 Stability information Nº 2 1.17.2 Floating information Nº 2 1.17.3 Cargo information Nº 2 1.17.4 Bulk stowage plan Nº 2 HU-REP-DD REV. 01 3/5 1. DOCKING SURVEY 1.1 2. Yes No The outside of shell plating stem, stern frame, including bottom, side and bow, keel, stern, sternframe, rudder (s), propeller (s) and all sea connections (strainer plate removed) including sea valve bodies, overboard discharge valves and their fastenings have been examined and found satisfactory. X 1.2 The rudder has / has not been lifted. Notes: i. Rudder is to be lifted for inspection, if docking survey is credited as part of Periodical Special Surveys. ii. If the rudder has been lifted, give the inspection details below: 1.3 Chain cables have been ranged out, examined and measured, the anchors partially raised and lowered using the windlass, and chain lockers have been cleaned and examined internally and found satisfactory. X Note: This item is to be carried out at owner’s request when docking survey is credited as part of Periodical Special Survey No. 2 and thereafter. 1.4 The existing clearances of rudder bearings (axial and radial) have been measured and found as follows: 1.5 The existing clearances between propeller shaft and stern bearing have been measured and found as follows: PROPELLER SHAFT (S) SURVEY 2.1 The propeller shaft (s) has / have been drawn and the type of the shafts found as checked below: X Continuous liner (including separate liner with approved rubber lining). X Separate liner. X Bare shaft made of corrosion-resisting material. X Sled-runner type keyway. X Key-less shaft. X Flanged shaft. X Oil bath with seals. 2.2 The tapered end (s) and keyway (s) have been carefully examined by means of ........................................... MAGNETIC TEST .................................................................................................... and found satisfactory. X 2.3 The tightness of shaft liner (s) have been examined and found satisfactory. X 2.4 The glands which can effectively prevent sea water from contacting the steel shaft have been examined and found satisfactory. X 2.5 The ................................... side stern bearing bush (es) has / have been rewooded / remetalled at this time and the clearances between propeller shaft and stern bearing have been measured and found as follows: N.A. 2.6 Include the following reports: 2.6.1 Measurement of tail shaft and bushings (clearance) 2.6.2 Measurement of government apparatus 2.6.3 Propeller (s) 2.6.4 Zinc plates distribution 2.6.5 Shell plating thickness measurements 2.6.6 Shaft liner 2.6.7 Chain calibration HU-REP-DD REV. 01 4/5 SURVEYOR’S NOTES: For negative entries, major repairs and additional information, if any, describe in detail NONE RESULT OF SURVEYS: According to the results of the survey (s) undertaken, the undersigned recommends that the ship be retained as classed with this Society, subject to compliance with the previous and new recommendations. ENTRIES MADE INTO CERTIFICATE: Issued at: _______FUZHOU, CHINA__________________ on the__14th Nov. 2004_______________________ PSR Surveyor James Li/CN02 HU-REP-DD REV. 01 5/5