dr-01

advertisement

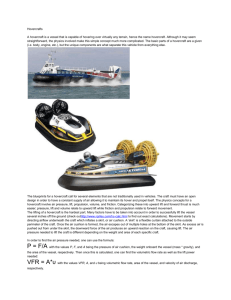

1998 – 99 NCDA Final Design Report Team 1: Hovercraft April 25, 1999 Brandon Fichera B. Sean Gallagher Gregory Pease David Rabeno Sponsor: Dr. Stephanie Wright Delaware Aerospace Academy Advisor: Dr. Michael Keefe Table of Contents Pg. # I. SUMMARY 2 II. INTRODUCTION 3 III. CUSTOMERS/WANTS/CONSTRAINTS 4 IV. BENCHMARKING 6 V. METRICS 8 VI. CONCEPT GENERATION 9 VII. CONCEPT SELECTION 12 VIII. FABRICATION AND ASSEMBLY 15 IX. TESTING 17 X. RE-DESIGN/SUGGESTED MODIFICATIONS 18 XI. CONCLUSION 19 XII. BUDGET 20 XIII. APPENDICES 21 A. Shapes of Footprint and Sample Calculation B. Educational Poster C. Laboratory Experiment D. Theoretical Work and Graphs E. Hovercraft Safety and Operations Manual F. Engineering Drawings 1 SUMMARY: The purpose of this report is to present a detailed explanation of the work and thought processes that are our senior design project. Presented here is the final design concept including background and its complete history. In defining the actual project, it was important to determine all the people that could use our hovercraft. Once the customers were established, we had to take into account their role in the project and to determine their specific wants. Once this list of customers and wants were developed, the wants were evaluated with respect to customer importance. This was done so that we were better able to prioritize our efforts. Benchmarking was performed to learn more about hovercraft principles and operation. Benchmarking was also used to develop yardsticks for measuring the quality of our design concepts. These yardsticks became metrics and were how we compared our different concept ideas. Before intelligent discussion of ideas could be undertaken, further research was needed. This research consisted of the derivation of relevant equations, discussion with experts and trips to libraries. This deepened the understanding of the mechanics behind the problem. After benchmarking and research, brainstorming sessions were held to generate concepts as to how the problem could be solved. During these brainstorming sessions, all ideas were considered to be valid, no matter how absurd they might seem. All manner of footprint, educational, fun, lift and thrust possibilities were considered. Once the ideas were developed, they were compared to wants and constraints via the metrics. After which, some where discarded, some were kept, and some were combined to produce a cohesive design concept that we believe to be the best solution according to the specific problem. The concept selected presents a complete idea for our solution to the problem. 2 INTRODUCTION: Dr. Stephanie Wright, president of the Delaware Aerospace Academy (DAA), has sponsored senior design projects for the past few years. The DAA specializes in educating children about the technology involved in the space program. In teaching, they hope to raise an interest in the United States Space Program by presenting relatively new and interesting technology that has yet to be widely distributed. This year, Dr. Wright desires a hovercraft to be used at the DAA technical camps by students of grades 7 – 9. The hovercraft is to float on a cushion of air and will be used to simulate exploration of a new planet and will also teach certain scientific principles to the students. After discussing the scope of the project with Dr. Wright and other customers, we formed a mission statement, which included our own goals for the design. The statement reads as follows: To design a two person hovercraft for the DAA that will demonstrate the relevant scientific principles involved, simulate planetary exploration, interest children in the space program, and provide a fun, safe and educational environment for everyone involved. The craft will be used as an educational tool to teach scientific principles to children in high school and junior high demonstrations. By utilizing a two-pilot operating system, it teaches teamwork and cooperation. Since hovercrafts are not very widespread, a vehicle that actually floats on a cushion of air should especially intrigue the children. Allowing the children to pilot the craft, we believe, will make the experience fun. 3 CUSTOMERS/WANTS/CONSTRAINTS: A customer is anyone that would have a substantial interest in the final prototype or design. After talking with our sponsor and considering all people that could possibly play a role in the design and final product, we came up with a ranked list of customers. The list is as follows (in order of importance): 1) 2) 3) 4) 5) 6) 7) 8) Dr. Stephanie Wright – DAA Eric Rabeno – Junior High Student Bethany Fichera - High School Student Martin Rabeno – High School Teacher Selina DiCiccio – Junior High Teacher Ron Perkins – Educational Innovations Dr. Robert Bloom – Aerospace Engineer (DAA) Dr. Mark Elison - Principal of Junior High and High School Dr. Wright was our most important customer because her organization sponsored the project, provided the funds and will be the primary user of the hovercraft for demonstrations. Students were our next most important customers because they are the people that should benefit the most from the project. We needed the students’ input to understand how to let them have fun while being educated. In addition to students, other members of the educational community that were our customers are their teachers. After we designed our concept, we had to make sure that high school and junior high school teachers understood what we were trying to accomplish. Since they are professional educators, their input as to how to make the design educational was essential to our success. Educational Innovations supplies lab and science equipment to schools which teachers use to explain certain scientific principles to children. Mr. Perkins, company representative, is one of our customers because of the insight he can provide as to what works well and what doesn’t work well as an educational tool. In addition, he provides help with the educational aspect of the mission. The school system superintendents and principals were included as customers because they are concerned with the education of their students. As well as education, their knowledge of what safety considerations were needed for the craft to be considered safe in a school environment proved invaluable. 4 After talking with these customers and discussing each of their wants from the project, a list of wants was developed and SSD was used to rank them. The wants are listed below. 1) 2) 3) 4) 5) 6) 7) 8) 9) Demonstrate scientific principles Make it fun Have it look ‘cool’ Maneuverability Reliability Transportability Reproducibility Durability Affordability We were fortunate in our design process to be able to meet our customers’ wants without having to make many trade-offs. The trade-offs we made were slight. For example, to make the craft cool looking we needed to spend more money, decreasing the craft’s affordability. Constraints dictated how well the wants were satisfied. The constraints are listed as follows: 1) 2) 3) 4) Operation (The hovercraft must hover) Allowable Funds ($2000) Size of door in Room 109 Spencer Lab (4.5’ X 6.3’) Number of pilots (must be able to fit two) 5 BENCHMARKING (System and Functional): Benchmarking, a process that continued throughout the duration of the project has proven to be very valuable in the design of the hovercraft. Initial benchmarking was done on a variety of overall hovercraft systems as well as components in order to determine best practices. Initial benchmarking determined that there was not a complete system on the market that satisfied the wants of our specific design problem. The system closest to what is desired is the Triflyer Hovercraft from Robert Q. Riley Enterprises. The Triflyer was able to handle a maximum payload of 800 lbs. (3 people), traveled 75 mph and was 12' x 6'. This design satisfied the weight requirement, but was extremely overpowered for what we were looking for. Since this system was very close to the desired goal, plans for the Triflyer were ordered studied for concept and component design. This gave insight as to industry standards for such components as steering, skirt design and typical mounting points for engines and fans. Other benchmarks are shown in the table below. Table1: Benchmarking Robert Q. Riley Enterprises (Triflyer) Plans for hovercraft. Best practice Robert Q. Riley Enterprises (Pegasus) Round hovercraft plans, max weight 150 lbs. Design has no viable propulsion method. Universal Hovercraft (Kits and components) Kits offered are smaller than desired. Cost well above budget. Offer fans for lift and thrust. Staff very helpful. Hoverclub of America Published a variety of articles describing principles of hovercraft such as lift, thrust, and design tips. Hovertech Levitation using electromagnets Universal hovercraft supply’s hovercraft kits and components such as fans for personal hovercrafts. Our fan and hub assemblies for lift and thrust were purchased from this company, as well as material for the skirt (neoprene coated nylon). Functional Benchmarking was done on a variety of systems and ideas in order to generate concepts and determine components for the design. Also, functional benchmarking became important in the educational and recreational aspect of our project. We performed some searches that would help us become familiar with different teaching methods. Six Flags Great Adventure and the Smithsonian Air and Space Museum were studied in order to come up with a way to 6 satisfy our wants of educational and fun. Six Flags uses speed, sounds, colors, and fast movement in order to make their rides fun for children and adults of all ages. The Air and Space museum takes a more reserved approach towards fun and learning. They use videos, descriptive posters and/or exhibitions, and rely on some hands on demonstrations to facilitate learning and fun. As far as the operational aspect of the hovercraft is concerned, components such as engines (Briggs and Stratton, Tecumseh, Honda), were researched and priced form a variety of distributors, such as Grainger and Northern Tool Supply. Fans, skirt material, wood and other building materials were also investigated to get a better idea of what needs to be ordered, their costs, and the lead time associated with each as well as usefulness in fulfilling the design requirements. 7 METRICS: During the benchmarking process, notes were taken with regard to operation on some of the important items that are normally measured in order to estimate the quality of a hovercraft design. Our design can not be compared to our competitor’s best practices unless a common yardstick is developed upon which to base the evaluation. By observing what items the competitors measured to determine quality as well as conversing with our customers, we developed a list of metrics for our wants. Once the metrics were established, target values were assigned to them based on Dr. Wright’s wants and the competitor’s values. The list of metrics and their corresponding target values is shown below. 1) 2) 3) 4) 5) 6) 7) 8) 9) 10) 11) 12) Number of Principles Taught – 3 Performance on a lab experiment (to be explained) - average score = 80% Object Clearance (from bottom of craft to ground) - 6” Skirt to Ground Clearance - 0.5” Speed of vehicle – 5 - 10 mph Acceleration of vehicle – 1mph/s Directions of Travel – 360 degrees (all horizontal directions) Travel Range – unlimited (limited by fuel capacity alone) Turning Radius – 15 m Fuel Efficiency/Capacity – 3.5 continuous hours. Cost - $2000 max Weight - 1000 lbs. 8 CONCEPT GENERATION: This specific design project is unique in that there are three main goals of this project that are very closely tied to each other: education, fun and functionality. These three requirements lead to a very unique process of concept generation. As a result of brainstorming and benchmarking, several ideas were obtained that would satisfy the specific needs of education, fun, and operation individually. Once a few concept ideas for each requirement were obtained, the next stage was to try and combine the most feasible ideas corresponding to each aspect into a cohesive concept that would satisfy all parts of the problem best according to our metrics and result in a well balanced concept. Because this project is geared towards children, we looked to two proven leaders in the fields of education and fun: museums and amusement parks. For best practices, the Smithsonian Air and Space Museum and Six Flags Adventure Parks were chosen. The “Smithsonian Approach” is superb for learning. They are internationally known as providing excellent exhibits in their museums. Their methods of education are especially helpful since they additionally incorporate fun in their exhibits through hands on experiences. The “Amusement Park Approach” dealt strictly with fun by making rides bigger and faster with lots of noises and colors. Using these techniques, amusement parks are able to keep people entertained. The third part of concept generation, and the one that best utilized the engineering tools we’ve acquired over the past four years, was the design for the prototype hovercraft. Fans, magnets, and suspension systems were researched for ways of lifting the hovercraft. One concept was to have magnets on the ground along with opposing ones on the craft. The magnets would repel each other and lift the craft. Suspension systems could be used to move the hovercraft around while suspending it above the ground, using a cable attached to the frame. Fans are the traditional and most common method for providing the lift forces. Power generation concepts using liquid fuel, batteries and fuel cells were studied. Fuel cells are costly but provide a great deal of clean energy. Batteries are an inexpensive but are heavy. Liquid fuels are abundant, lightweight and inexpensive. One aspect that goes along in designing the lift system is the type of skirt to be used around the bottom to keep air trapped under the craft. Two concepts were generated for the skirt design. A bag skirt, which is a lot like an inflated inner tube under the craft, or a C skirt, which is a piece of material draped along the craft much like a table cloth. 9 Shape is another important consideration in concept generation. Shape determines the surface area. The pressure multiplied by the bottom surface area limits the lifting weight. A number of shapes were looked at when considering the design of the footprint. The main concern with shape would be in obtaining one so that the area under the craft allowed for a relatively small air pressure. Several shapes considered are included in Appendix A along with a sample pressure calculation. Thrust is another area where concepts could differ. Benchmarking showed that a fan system used for thrust seemed to be the best practice. Other possible thrust methods would be to have the craft pulled/pushed by another person, or using some sort of jet propulsion. Maneuverability could be done with a rudder system, or by having multiple fans that rotate to change the direction of airflow. The second of these options would be more expensive and also difficult to construct so that high school children would be able to control it. Pilot positioning was also a concern. The pilots could be positioned one behind the other or side by side. The craft needs to hover almost perfectly level so that a consistent gap height is achieved. The positioning of the pilots is important in this aspect. Placing the pilots front to back would make it hard to design the craft so that the two pilots could cooperate on steering and propulsion. Positioning the pilots side by side would allow us to place all control items on a “dashboard” in the front of the craft that would be easily accessible by either pilot. The following drawing shows the differences that an unbalanced craft would exhibit as opposed to a level craft. 10 The air rushing out from under the craft in the second drawing would detract from the overall hovering capability of the craft. 11 CONCEPT SELECTION: With all these concepts possible as a means of satisfying each of the three aspects of our project, it became a matter of studying our metrics and constraints. These would be used to pick a specific concept for each of recreation, fun, and operation. After these components were picked, it was necessary to figure out how to combine each of the three concepts into one complete design for a fun, educational and working hovercraft. Arriving at a harmonious union of education, fun, and operation proved to be easy to accomplish. The solution combines both the methods of the Smithsonian and Six Flags. Included in this approach is a poster that students will be able to look at that discusses what hovercrafts can be used for, how they relate to the space program, and also the principles our prototype relies on for successful operation (slides are located in Appendix B). Also included is a lab experiment to be performed on the concept of lift (located in Appendix C) which will give the children the hands on aspect of the science that the Smithsonian Institute does so well. Finally, piloting the actual hovercraft will allow the children to see everything the first two items has taught them. They will be able to take the information from the poster and experiment and apply it to a working hovercraft that will provide plenty of excitement. It is felt that students will learn the most by reading the poster and performing the lab before operating the hovercraft. The students will build a simple hovercraft themselves in the short lab. The lab is designed to show how lifting force, air pressure, and footprint sizes are related. After completing these steps, students will be allowed to ride the hovercraft with a better understanding of its working principles. To determine the final result of the lab and poster, several iterations of each have been done. The poster and model were brought into a classroom where verbal feedback and reactions from the students helped us to make the necessary changes to both items. All students crowded around the model from the lab and wanted to touch it and push it. Several students asked how to build it and wanted to try making a miniature model on their own time. Their reactions and the resulting iterations increased the amount of understanding by the students, which allowed the presentation to educate more effectively. Based on the results of talking to several students and their teacher, the presentation of important concepts has been altered until optimal understanding was obtained. 12 The final hovercraft is a 10-ft long and 6-ft wide rectangle. Drawings are shown in Appendix D. This shape was picked because of the footprint, it was the easiest shape to manufacture of the shapes considered and it optimized the area underneath the craft for the lift system. The lifting is done with a single fan located in the front of hovercraft. A fan system was chosen over a magnetic system due to the cost restriction on the project. In addition, the magnetic system did not allow unlimited planar range. It also did not simulate exploration as the magnets would already have to be placed in the area prior to that area being explored. Suspension systems were eliminated for one major reason: the craft would not be hovering. Thus, we chose the fan systems as the best of our options based on the wants and metrics and the “hovering” constraint. Gas power was chosen due to the cost and power output per pound of a gas engine compared to electric. An 8 HP gas engine costs about $400 and weighs about 60 lbs. The batteries to operate an equivalent electric motor weigh twice as much and replacement batteries are expensive. Fuel cells were eliminated on cost alone. A fuel cell to power an electric motor costs in the tens of thousands of dollars. We determined the lift fan diameter, after consulting with Universal Hovercraft. According to their calculations, the fan needed to lift our weight with an 8 HP motor is 26" in diameter and has four blades. The lift engine is mounted in the front of the craft above the fan (the engine will be a vertical shaft engine). The location for the engine was determined by looking at competitors best practices. A bag skirt was chosen for the design for two reasons. Bag skirts allow for a more complex shape of a craft. The C skirt is a very unstable system because it has the tendency to flap out, releasing air and lowering the craft. In addition, objects passing under the craft have a tendency to be picked up by the skirt. This increases the possibility of ripping the skirt, the weight (if the skirt carries the object) and, if the object is heavy enough, the possibility that the craft will abruptly stop. In the final design, we decided to position the pilots side by side. If the pilots were positioned front to back, the pilot’s compartment would have to be longer. With a design longer than the current one, the prototype would not be able to leave the Senior Design Room. 13 Balancing any difference in weight between the pilots can be compensated with weights under the seat. Another fan and a 3.5 HP horizontal shaft motor on the back of the hovercraft will accomplish the thrust for the craft according to our theoretical calculations. This is not only industry standard, but it also the best practice for what we seek. Maneuvering of the craft is done by a rudder system attached to the rear of the thrust fan assembly. The two rudders will be coupled and the steering system for the rudders is assembled so that the steering “column” will be on the dashboard and accessible by either pilot. This will allow for teamwork as both the steering and the lift throttle will be placed on the “dashboard” allowing each pilot to operate one of the two systems. 14 FABRICATION AND ASSEMBLY: The final development and fabrication times Engineering Concept Development 110 hours Fabrication 610 hours Redesign and Modification 20 hours TOTAL: 740 hours The frame of the hovercraft is a rib structure designed to be lightweight and strong at the same time. The ribs were constructed with 1” x 2” pine. A template was laid out on a piece of plywood and the pine was cut and made into kits for each rib. The template was then used to construct the ribs and ensure all ribs came out to be the same dimensions. The template was then modified to allow for the construction of the second type of rib used in the driver compartment and also the third type used at both ends. Once all the ribs were constructed, the next step was to hang the ribs on two 2” x 4” x 10’ stringers (see drawing). The ribs were spaced out according to the drawings and attached to these stringers. Next, the 10’ x 1” x 2” stringers were put in to place. This was followed by the installment of the rest of the members used for support around the lift and thrust fans. The craft was then turned so the bottom was face up and ¼” plywood was used to cover the entire bottom. One piece contained a 30” diameter hole, cut on a CNC router for accuracy, to accommodate the lift duct. Bondo was then applied at the seams to help make the bottom airtight. Once this was done the wood was sealed with a polyester resin and the skids were installed. Upon the completion of the bottom, the craft was turned right side up. The crew compartment’s bottom was covered with ¼” plywood and 1/8” Luan applied over the rest of the craft. Bodywork was done with joint compound and Bondo to even out the body and give it a more professional appearance. 15 The skirt was fabricated using the material obtained from Universal Hovercraft. The material was cut and then sewn together using Kevlar thread and super-glue to create the corners. Sheet metal screws were used to attach the skirt to the craft. A small flap of material was placed over a portion of the lift duct to direct some air from the lift fan into the bag skirt. The lift duct was created using a roll of aluminum flashing. The aluminum was wrapped four times and machine screws were used to help it keep its shape. This duct was then placed in the two 30” holes and ran through the entire craft. The lift engine was mounted to a composite plate made of vinyl-ester resin, 3 layers of 24oz woven roving E-glass, a ¼” balsa core and then 3 more layers of E-glass. This was then mounted to two pieces of angle iron used to span the lift duct. The fan was mounted to the engine shaft using the hub provided by Universal Hovercraft and a 1in. diameter split taper bushing. At this point the first lift test was successfully conducted with one person in the craft. A windshield was constructed next using pultruded fiberglass box beams and a piece of polycarbonate. This was attached with four bolts keeping in mind it would need to be removed in order to remove the craft from the room. Two boat seats were installed side by side in the crew compartment for the pilots. Also, the controls for the lift and thrust fans and the steering system were mounted on a “dashboard” so that the two pilots could work together to operate the three systems. In order to allow the craft to be removed from the building, the thrust housing was required to be removable. The box to contain the fan was made with 1” x 6” pine. A ¼” x ¼” protective screen was placed over the outer opening. All of this was attached to a piece of ¼” plywood. This assembly is bolted to the craft to allow the assembly to be removable (see drawings). The thrust motor was placed above the back of the hovercraft on a box 8” high to allow the fan to be centered in the housing. The two rudders were made from 1” Styrofoam. The steering is done by sliding the handle in the “dashboard” from right to left depending on the desired direction of travel. This is attached to the rudders using ¼” nylon cord. The entire craft was next painted with a semi-gloss black paint. After this was complete, yellow caution labeling was applied to areas that were dangerous. The construction was completed with the mounting of a fire extinguisher. After the hovercraft is removed from the senior design room and before the craft is delivered, safety screens will be placed over the front lift fan and also the remaining portion of the thrust assembly. 16 TESTING (Lift System): 1) Hovering Capability Weight Skirt to ground clearance Just Craft Trial 1 Trial 2 Trial 3 50 lbs. 6" 6" 6" 100 lbs. 6" 6" 6" 150 lbs. 5.8" 5.5" 5.75" 200 lbs. 5.75" 5.6" 5.5" 250 lbs. 5" 5.25" 5" 300 lbs. 4.25" 4.33" 4.2" 4) Time it takes craft to settle after shutting engine off Average 6" 6" 5.68 5.62 5.08 4.26 2) Approx. angle of hover We found that getting the craft to hover flat is just a matter of balancing it. With two pilots of relatively equal weight, the craft hovers almost exactly horizontal. Time Trial # 1 pilot 2 pilots 1 1 sec. 1 sec. 2 1 sec. 1 sec. 3 1 sec. 1 sec. 4 1 sec. 1 sec. 5 1 sec. 1 sec. * We found that as soon as the engine is cut, the craft settles down on its skids pretty quickly. It is not so sudden as to deter from the safety of the craft 5) Stability Height of Oscillations Small to nothing. With the throttle in one position, 3) Amount of time from when the engine starts until it is hovering Time Trial # 1 2 3 4 5 1 pilot 2 sec. 3.5 sec. 4 sec. 2.5 sec. 2.5 sec. 2 pilots 3 sec. 3.5 sec. 2.5 sec. 2 sec. 3 sec. * Basically, the time it takes the craft fully rise depends on how the pilot operates the throttle. the craft will hover at a constant height 6) Does the craft hover in place or does it tend to go in a certain direction? This depends on two factors: wind and terrain. On perfectly flat ground with no wind, the craft hovers in place. With hills and wind, the craft tends to move. 7) Do we have to adjust the skirt each time we start it or will it hover by simply starting the fan? The hovercraft will rest on the skids so that the skirt does not have to be adjusted each Thrust: Since the thrust fan was not the proper kind, the thrust force needed to move the craft was tested using a scale to measure the force required to move it. It was found that the calculations for the thrust were indeed accurate. With 300lbs in addition to the empty weight of the craft, 60lbs of force was required to move forward and only 15lbs of force was required to turn. 17 RE-DESIGN/SUGGESTED MODIFICATIONS: During the testing of the lift system it was noticed that the lift fan had risen up the shaft and was rubbing against the engine support plate. To prevent this from happening again a 1” bronze collar was placed on the shaft above the hub for the fan. This will prevent the hub from hitting the engine plate again. A new engine plate was also fabricated to replace the damaged plate. The thrust fan, which had been donated to the project, turned out to be pitched wrong for the motor set-up. The fan needed to push air when turned clockwise, but instead the fan pulled air. To rectify this, a new fan had to be ordered with the correct pitch that would work based mainly upon our theoretical calculations and also on our testing results using the scale. Depending on the weight of the pilots, ballast must be added to compensate. This can be changed during operation to allow the craft to float level. Water jugs can be placed in the front of the craft to allow for extra weight. 18 CONCLUSION: The task of constructing a prototype hovercraft according to Dr. Stephanie Wright’s wants that satisfied our mission statement has proven to be a successful one. With only one minor setback, we satisfied all of our wants according to the problem definition. The first three wants (demonstrate scientific principles, fun, and cool looking) were satisfied very well according to the feedback received from our sponsor, the students, and the teachers we talked to. The most significant accomplishment of the project was being able to theoretically design a mechanism for lifting the hovercraft to a desired height according to our desired weight and then having the assembly work almost exactly how we designed it. The desired height of hovering with two children (from base of craft to ground) was listed in the metrics as 6”. Upon testing of the lift system, it was found that with the equivalent weight of two students, the craft hovered at a height of 5.25”. This is very close to our target value. The only setback came with the discovery that the fan we were going to use for thrust force was pitched the wrong way. This combined with the fact that the thrust engine did not work initially and had to be repaired did not leave enough time before the final presentation to have a new fan delivered and the thrust system tested using the fan/motor combination. However, to compensate for this, we used scales to test the amount of actual thrust force needed to move the craft and to turn the craft. We discovered during these tests that our theoretical calculations for thrust force were accurate and also found out that it would only take 15 lbs. of force to turn the craft. This number coincides well with the theoretical calculations also. With these test results, we were able to order a new thrust fan that will satisfy the thrust requirements and finalize the project. With the completion of the thrust system, we will have satisfied all the wants given to us by the customers. The one concern when starting the project was the relatively small budget of $2,000 dollars. After careful benchmarking and research, we were able to come up with and construct a complete solution for $1779.36, which is under budget. Before we began working on the project, we all thought it sounded pretty interesting. Only now that it is complete can we fathom how important and educational the whole process has been. We can now look back on all our initial expectations and worries take pride in the fact that we were able to design a complete solution to the problem assigned. 19 BUDGET: The final budget report for the project is as follows: Materials (Wood, Hardware) Lift fan, Skirt, Hub 8hp Lift Engine Thrust Fan 3.5hp Thrust Engine TOTAL: $ 734.45 $ 361.22 $ 358.70 $ 157.00 $ 167.99 $1779.36 The estimated cost for production of a similar craft is the Projected Production Cost and is as follows: Total Material Costs: - $1779.36 Estimated Production Hours: - 200 hours - $25/hr Projected Cost = $5000 + $1779.36 = $6779.36 20 Appendix A: Shapes of Footprint and Sample Calculation Sample Calculation for rectangle: Area = length x width = 10 x 6 = 60 ft2 = 8640 in2 Weight = 2000 lbs. (Weight from metrics with a factor of safety of 2) Cushion Pressure = Weight/Area = 2000 lbs./8640 in2 = 0.231 lbs./in2 21 Appendix B: Educational Poster Double click on Title Screen to view 22 Appendix C: Lab Demonstration of Lift System for AntiGravity Vehicles Purpose: It is important to understand the scientific principle of lift in any vehicle that is freefloating or built specifically to defy gravity. The purpose of this experiment is to learn about how a free floating vehicle actually “defies” gravity. It will be important to understand the relationship between surface area of the vehicle, the weight of the vehicle and the air pressure developed between the vehicle and the ground. This experiment will provide the information necessary to understand the concept of lift. Theory and Background: Anti-gravity vehicles have become an area of great interest recently. Some people build them at home as a hobby much like go-carts. There are also important scientific uses for hovercrafts and other free-floating vehicles. The present level of scientific technology is so advanced that NASA and separate state space programs and space camps would have very important uses for an anti-gravity hovercraft. One of the uses is to use a hovercraft to explore unknown places on a planet. Astronauts that land on a planet for the first time would not be able to completely know what the terrain is like before they land. Because of this fact, a vehicle that hovers off of the ground is the best way to explore that planet in case it is not easy to drive a vehicle with wheels. The Delaware Aerospace Academy will demonstrate a life size hovercraft that was designed for the purpose of showing how planetary exploration would take place. By performing this experiment before viewing the demonstration, you will better understand how the hovercraft actually lifts off the ground and how it works. The equation that is important in figuring out if a hovercraft will actually hover is F = (P) X (A). In this equation, F = weight of the hovercraft plus passengers (the force needed to lift the hovercraft). A = the surface area on the bottom of the hovercraft (in this experiment the hovercraft is a rectangle and its A = length X width. And the P = air pressure between the hovercraft and the ground. Its units are pounds per square inch. You will construct hovercrafts of different weight (F) and area (A) and find the air pressure needed to cause lift. 23 Necessary Equipment: - Two standard 3” computer cooling fans (12VDC, .13Amps, 1.60Watts) - One 12 Volt DC battery - Two pieces of polystyrene poster-board 9” X 16” - Eight strips of pre-cut plastic (trash bag material) - Four 16” strips, two 9” strips, and two 18” strips - Masking Tape - A set of small weights totaling about 4 lbs. Procedure: 1) Using the piece of poster-board with the computer fans attached (holes will be precut in the poster-board with computer fans taped into them), tape one 9” piece of plastic to each shorter edge of the poster-board. Then, use the two 16” strips of plastic and tape those to the longer edges of the poster-board. Turn the poster-board over and use one piece of tape at each corner to attach the plastic strips as shown in figure 1 on the next page. 2) Before you turn the fans on, you must make sure the hovercraft is right-side up and all the loose ends of plastic are tucked under the craft. Then, hook the red wires on the fans to the positive (+) terminal of the battery. Then hook the black wires to the negative (-) terminal. Observe what happens. Does the hovercraft lift off the table? If it lifts, try putting some small weights on the poster-board away from the fans. If it lifts, write down the largest amount of weight it can hold up (and add this value to the weight of the hovercraft which is 1 lb.). The area A = 16” X 9” = 144 inches squared. With this weight (F) and area (A), use the equation F = P X A to calculate the air pressure. If it does not lift at all, move on to the next part. 3) Take the pieces of plastic off and tape the other piece of poster board onto the first one. Now use the two 18” pieces of plastic on the edges you used the 9” pieces on before and put the two 16” pieces on the other two edges as in figure 2. Then tape the corners as before and use the fans to try and lift the new set up. Again, add different weights to the hovercraft away from the fans. Does this one lift? Does this hovercraft lift better than the first one? Write down the largest amount of weight it can lift this time (remember to add the weight of this craft which is 1.25 lbs.). The area for this craft is A = 288 inches squared. Calculate the value of air pressure for this hovercraft. 4) Based on what you saw for the two hovercrafts, which one seemed to work better? Which one had a lower value of air pressure (P)? What can you say about the relationship between the value of P and how well the hovercraft works? 24 FIGURE 1 Top View Bottom View FIGURE 2 Top View 25 Appendix D: Theoretical Work and Graphs Equations Used And Derivation of Power Equation: Conservation of Energy and Conservation of Mass from the fluid mechanics perspective is used throughout. P3 V 23 V 22 gz 2 gz3 2 2 V 21 P 2 V 22 gz1 gz 2 ws 2 2 P2 P1 Steady-Flow Energy Equation 1 – 2 Bernoulli’s Equation 2 – 3 26 ws From Energy Equation: weight A From Bernoulli’s Equation: V3 2P2 A lw m Q Other useful Equations: Final Relevant Equations: P Wweight A Wweight lw Q V3 Aperimeter 2(l w) 2Wweight lw 3 Wweight W w s m 2(l w) (lw)3 Thrust Equations & Calculations: F Ma W M go W = 1000lbs. (from Metrics) a = 1.5 ft/s2 (from Metrics) go = 32.2 ft/s2 (from Metrics) Thrust Force Required = 60lbs. 27 Figure 1 : Gap Height = 1.0cm Figure 2 : Gap Height = 1.5cm Figure 3 : HP = 8 Figure 5 : HP = 6 Figure 4 : HP = 7 28 APPENDIX E: Hovercraft Safety and Operations Manual 29 Safety Suggestions: Please use caution when operating or standing close to the hovercraft. It is suggested that safety glasses and hearing protection be worn during operation for all pilots and adult spotters. Please use in a flat open area with adult supervision at all times. A fire extinguisher is located at the back right corner of the craft in the case of an emergency. The hovercraft’s direction can change depending on terrain, for this reason we suggest that an adult stay close to the hovercraft and act as a spotter. Because of the little force required to move the craft, an adult near the hovercraft can simply hold the side of the hovercraft to steady its position and allow the pilots to recover. All stopping mechanisms are located near the sides of the craft to allow the engines to be shut down easily in the event of a problem. Operation: The craft is designed to hold two pilots: one to control the lift and throttle and one to control the direction. These two pilots should be close to the same weight and the total weight should be less than 300 lbs. for optimal performance. Starting the hovercraft: 1) Enter the craft from the sides, stepping only on the panels labeled ‘step’. 2) Make sure both pilots are seated and familiar with the operation of the craft. 3) Do an inspection check of the craft including: a) Both engines and fans b) All screens. To be sure they are in place and secure. c) The wiring to be sure all wires are connected. d) The skirt for tears and holes. 4) Starting the thrust engine: Set the bottom lever to choke and the top lever to fast. Pull the cord to start the engine, once started move the bottom lever to run and the top to slow. 30 5) Starting the lift engine: Pull the throttle one half inch from its base; then, turn the key to the right. Once the engine starts to run, pull the throttle level up slightly. Then adjust until you can here the engine run at its highest speed. Caution. Pushing the throttle all the way forward will shut the engine off. Note: Turning the key to the off position will always shut the engine off. 6) Once hovering set the thrust engine to desired speed (top lever). 7) Steering is accomplished through the moving of the rudder stick located in the dash. Remember: Moving the rudder to the left will make the craft’s rear travel to the right. Centering the controls will then move the craft it the desired direction. This it also true for the reverse direction. Shutting down the hovercraft: 1) Shut down thrust engine by moving the top lever to the stop position. Do not move the lever to choke to shut the engine off. 2) Shut down the lift engine by turning the key to the off position (turning to the left). 3) Once both the lift and thrust fans have stopped it is safe to exit the craft. 4) Exit the craft be standing and then stepping on the panel labeled “step”. Gas and Oil: Both the lift and thrust engines can be filled with regular unleaded gas. Both the lift and thrust engines run on SAE 30 motor oil, which is available at most auto-part stores and gas stations. Both gas and oil levels should be checked frequently. Both engines should have their oil changed after the first 5hrs. of use. Thereafter, follow the maintenance suggested in the manuals located at the end of this document. Maintenance: A) Tools possibly needed: ½" open ended wrench ½" socket drive 31 Flat head screwdriver Phillips head screwdriver Staple Gun with staples B) Both the lift and thrust engine manuals are located at the end of this manual. These contain the maintenance schedules and also a trouble-shooting guide for each engine. If there are any problems with the engine that can not be solved by consulting these manuals, contact Charlie’s Equipment Service at the below address. Charlie’s Equipment Service 14-B2 Albe Drive Newark DE 19702 (302) 738-5664 C) The battery for the electric start is located at the front of the craft just inside the access panels. Wiring diagrams are provided at the end of this manual. D) All bolts used on the hovercraft are 5/16" in diameter. The length varies with location, however all are equipped with two washers, a single lock washer and one nut. Should one be lost or broken any hardware store will carry replacements. E) Frequently check all protective screens to ensure they are properly secured. If any area is unsecured re-staple the screen in place. If it becomes necessary to replace a screen the grid spacing is ¼" x ¼". F) If the body of the hovercraft is damaged in anyway it can be repaired with joint compound or Bondo. Simply fill the damaged area, and once dry sand smooth. Clean the area prior to painting with a semi-gloss black paint. G) Should the skirt become torn or damaged it can be repaired with an inner tube patch kit in most cases. If the tear is large, take extra skirt material and sew and glue a patch in place. This may require the removal of a portion of the skirt. Remove the screws that hold the skirt in place to do this. After the repair is made replace the 32 screws and skirt as close to the original position as possible, this will ensure the skirt remains efficient. Extra skirt material can be obtained from: Universal Hovercraft Box 281 Cordova, IL 61242 Phone: (309) 654 – 2588 H) Periodically check the location of the lift and thrust fans. For the lift make sure the ductwork is in place and no parts have worked loose. Check the attachment of the fan hub to the shaft, make sure that no parts are rubbing or in danger of binding. For the thrust fan, check to make sure the fan is not hitting the protective screens. 33 APPENDIX F: ENGINEERING DRAWINGS 35 36 37 38 39 40 41 42