thesis-2nd-rev

advertisement

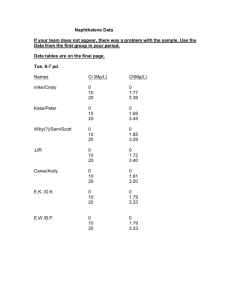

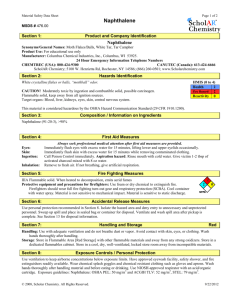

Directed ortho Metalation and Cross-Coupling of Naphthalene 1,8-bis(diethylamide): Research Towards Nerve Growth Inhibitors by John M.D. Stephenson jmdsdf@hotmail.com 410-1306 An undergraduate thesis presented to the Queen’s University Chemistry Department in fulfillment of the Chem 417 requirement for the degree of Engineering Chemistry in Applied Science Department of Chemistry Queen’s University Kingston, Ontario, Canada March 29, 2004 Copyright © John M.D. Stephenson John M.D. Stephenson March 29, 2004 Acknowledgements I would like to thank Professor Victor Snieckus for his guidance and supervision in my work in organic chemistry. It has been an honor to be a part of an excellent team of individuals as constituted by the members of the Snieckus group. In particular, I would like to especially thank Chris Jones for his patience, perseverance and direction in working on my undergraduate thesis. Todd Macklin has also been of particular help in showing me time saving techniques for getting work done quickly and efficiently without cutting any corners. Extra thanks to the entire Snieckus group as the entire experience with the team, both in the lab and the social dynamics outside of the lab, was thoroughly enjoyable. i John M.D. Stephenson March 29, 2004 Abstract Work in the synthesis of novel substituted naphthalene amides was motivated by interest in the preparation of new Nerve Growth Factor inhibitor candidates related to the treatment of arthritis. Work in our laboratories has recently demonstrated that the Directed ortho Metalation reaction may be applied to the synthesis of 2- and 2,7- substituted naphthalene 1,8-bis(diethylamide), 1 2 + 3. The aim of this study was to establish conditions for selective formation of 2 over 3 for E = I and TMS will be presented. In addition, the Suzuki-Miyaura cross-coupling reaction of 2 4, where R = phenyl and E=I, will presented. CONEt2 CONEt2 CONEt2 CONEt2 CONEt2 R E 1. s-BuLi -78°C/THF 2. E+ 1 RB(OH)2 base/Pd/DMF 2 4 CONEt2 CONEt2 E E 3 ii CONEt2 John M.D. Stephenson March 29, 2004 Table of Contents Acknowledgements .............................................................................................................. i Abstract ............................................................................................................................... ii 1.0 Background ................................................................................................................... 1 2.0 Introduction ................................................................................................................... 2 2.1 Directed ortho Metalation (DoM) ............................................................................. 2 2.2 Suzuki-Miyaura Cross-Coupling .............................................................................. 3 3.0 Synthesis of Naphthalenes ............................................................................................ 5 4.0 Results ........................................................................................................................... 6 5.0 Discussion ..................................................................................................................... 8 6.0 Conclusions ................................................................................................................... 9 7.0 Future Direction ............................................................................................................ 9 8.0 Experimental ............................................................................................................... 10 General Procedure A: Standard workup ................................................................... 12 General Procedure B: Directed ortho Metalation ..................................................... 12 General Procedure C: Suzuki-Miyaura Palladium-Catalyzed Cross Coupling ........ 13 naphthalene 1,8-bis(diethylamide) (1) ...................................................................... 13 2-trimethylsilanylnaphthalene 1,8-bis(diethylamide) (2a) ....................................... 14 2-iodonaphthalene 1,8-bis(diethylamide) (2b) ......................................................... 15 2-phenylnaphthalene 1,8-bis(diethylamide) (4) ........................................................ 15 9.0 References ................................................................................................................... 17 iii John M.D. Stephenson March 29, 2004 1.0 Background Work conducted in the Snieckus laboratories to form novel substituted naphthalene amides was motivated by the study of Ross and coworkers1 who were interested in testing new Nerve Growth Factor (NGF) inhibitor candidates for the management of pain caused by pathologies such as arthritis. NGF consists of two identical 119 subunit long amino acid sequences that form the proteins quanternary structure. Binding of the NGF occurs at transmembrane neurotrophin receptor and there exists interest to find novel compounds that bind to, but do not activate, the receptor. This class of compounds is of great interest as they have been shown to reduce suffering in patients afflicted with arthritis and NGF is implicated in other diseases such as Alzheimer’s, epilepsy and stroke.2 Previously identified NGF inhibitors consist of substituted naphthalene imide structures with an electron-withdrawing group such as a benzoic acid or ethanol moiety on the imide functionality as shown in Figure 1. Availability of compounds that could be screened was limited due to commercial availability of the precursors and ease of preparation of the inhibitor candidates.3 1 John M.D. Stephenson March 29, 2004 R O N O for NCP 205 R= O OH for ALE 540 R= OH O2N Figure 1: Previously identified NGF inhibitors Target naphthalene imides for synthesis are shown in Figure 2. These molecules, a challenge to prepare by classical methods, could potentially be prepared using Directed ortho Metelation (DoM) and Suzuki-Miyaura cross-coupling synthetic strategy developed in the Snieckus group. EWG R = H, SMe, I, O N R O , H O R Figure 2: Examples of new target NGF inhibitor candidates 2.0 Introduction 2.1 Directed ortho Metalation (DoM) Since the initial independent discoveries by Gilman4 and Wittig5 in the late 1930s that anisole (X) would form an ortho lithiated species, the DoM reaction has become an influential synthesis for regioselective electrophilic aromatic substitution. Gilman and 2 John M.D. Stephenson March 29, 2004 Wittig both showed that the lithiated species (Y) could be functionalized to yield orthoanisic acid (Z) by treatment with carbon dioxide as shown in Scheme 1. In the first published DoM reactions the lithium would coordinate to the methoxy group. The methoxy group functioned as what is now called a Directed Metalation Group (DMG). Since then many more DMGs including CONR2, OCONR2 and OCH2OCH3 have been discovered.6 All of the groups are able to coordinate a lithium ion using a heteroatom before deprotonation 7 , although recent research states that in some cases that deprotonation can occur through a one-step metal-hydrogen exchange when TMEDA is added.8,9 In addition a larger variety of electrophiles, such as TMSCl 10 , iodomethane, dimethylformamide, B(OiPr)3 11 and trifluoroiodoethane 12 have been successfully employed to introduce a variety of substituents ortho to the DMG. OMe OMe OMe n-BuLi CO2 CO2H Li X Y Z Scheme 1: First Directed ortho Metalation as performed by Gilman and Wittig 2.2 Suzuki-Miyaura Cross-Coupling Carbon-carbon bonds can be formed through a variety of transition metal catalyzed crosscoupling reactions including those using organomagnesiums, organozincs, organostannanes and organoborons. 13 Suzuki-Miyaura cross-coupling is a palladium catalyzed process involving organoboron compounds. Suzuki and Miyaura discovered this reaction in the late 1970s. 14 Original research took place with substituted aryl 3 John M.D. Stephenson March 29, 2004 bromides and phenylboronic acid in benzene with an equivalent of sodium carbonate using Pd(PPh3)4 as the catalyst.15 The reaction now includes the reaction of alkenyl16, aryl, alkynyl, benzyl, allyl or alkyl halides or triflates with an aryl, alkenyl or alkyl boronic acids or boronate esters in the presence of a base.17 Common palladium catalysts include the previously mentioned palladium(0) tetrakis(triphenylphosphine) and palladium(II) catalysts such as Pd(dppf)Cl2 (dppf = 1,1bis(diphenylphosphino)ferrocene), Pd(dba)2 (dba = dibenzylideneacetone) and Pd(OAc)2. The active species is Pd(0) and thus Pd(II) catalysts require reduction to Pd(0) before they can participate in the catalytic cycle. This reduction will occur in situ by alkylation with the substrate or by oxidation of the phophine ligands. The mechanism by which the reaction proceeds is thought to occur via oxidative addition, transmetalation and finally reductive elimination to give the products as shown in Scheme 2. Pd0 R1 R2 R1 X Oxidative Addition Reductive Elimination R1 Pd2+X R1 Pd2+R2 Transmetalation BX(OH)2 R2 B(OH)2 Scheme 2: Suzuki-Miyaura Cross-Coupling Mechanism 4 John M.D. Stephenson March 29, 2004 Oxidative elimination is the rate-determining step in the catalytic cycle. The reaction proceeds fastest and in highest yield in decreasing rate and yield for I>OTf>Br>>Cl. 18 Suzuki-Miyaura cross-coupling is widely used in organic synthesis as the organoboron compounds are generally not air or water sensitive and the metal byproduct generated is non-toxic boric acid. 3.0 Synthesis of Naphthalenes Substitution at the ortho positions in the naphthalene system is a challenge by conventional electrophilic aromatic substitution. Directed ortho Metalation of some naphthalene compounds has taken place. 19 Shimano and Meyers 20 used napththyloxazolines to form 1-[4’-tert-butyloxazolin-2’-yl]naphthalene through DoM. This intermediate was then used to produce novel β-amino acids. Furthermore, concurrent substitution at the 2- and 7- positions of the naphthalene system have been previously reported using DoM in the synthesis of 2,7-diformyl-1,8naphthalenediol 21 for use in forming trinucleating ligand systems. DoM has also previously been combined with a Suzuki cross-coupling strategy on the naphthalene system, for example the preparation of 1,8-dihydroxy-2,7-diphenylnaphthalene 22 , a polydentate ligand for TiCl4. A similar methodology is explored here in. The model compound selected to explore the DoM techniques of the naphthalene system was naphthalene 1,8-bis(diethylamide) containing diethylamide, an extensively explored 5 John M.D. Stephenson March 29, 2004 Directed Metalation Group (DMG). Previous work conducted in the Snieckus laboratories23 has determined conditions for the formation of 2,7-di- substituted products of this system. The focus of this research is to explore producing mono substitution patterns using DoM and Suzuki cross-coupling strategies. The target compounds are shown in Figure 3. This research has been part of ongoing studies to establish conditions for selective formation of 2-mono- substituted products over 2,7-di- substituted products. CONEt2 CONEt2 O R = H, Br, I, SMe, TMS, , H R Figure 3: 2-mono- substituted target molecules 4.0 Results Metalation of naphthalene 1,8-bis(diethylamide) (1) at –78°C in THF with TMEDA followed by quench with an electrophile led to the formation of 2,7-di (2) and 2-mono (3) as well as the recovery of (1) as isolated by flash chromatography (Scheme 3). 6 John M.D. Stephenson March 29, 2004 Table 1: Directed ortho Metalation Results Electrophile 1 (%) 2 (%) 3 (%) TMSCl 38 16 (2a) 25 (3a) CF3CH2I 18 24 (2b) 35 (3b) CONEt2 CONEt2 CONEt2 CONEt2 CONEt2 E 1. s-BuLi E CONEt2 E + -78°C/THF 2. E+ 3 1 2 Where E+ = TMSCl or CF3H2I and E = TMS or I Scheme 3: Directed ortho Metalation of 1 The Suzuki-Miyaura cross-coupling of the 2-iodo substituted naphthalene derivative (2b) with phenylboronic acid was performed to afford 2-phenylnaphthalene 1,8bis(diethylamide) (4) in quantitative yield (Scheme 4). CONEt2 CONEt2 CONEt2 CONEt2 I RB(OH)2 base/Pd/DMF 2b 4 Scheme 4: Suzuki-Miyaura cross-coupling reaction 7 John M.D. Stephenson March 29, 2004 5.0 Discussion 2-mono substituted naphthalene 1,8-bis(diethylamide) to form 2a and 2b was obtained in low yield using TMSCl and CF3H2I (38% and 18% respectively). Deuteration studies have been performed in the Snieckus laboratories on naphthalene 1,8bis(diethylamide) as shown in Figure 4. These results show that a mixture of starting material (4%), 2-mono- (33%) and 2,7-di- (63%) substituted products are formed when 1.1eq of base, TMEDA and electrophile are used. Figure 4: MS results of deuterating 1 with 1.1eq of s-BuLi, TMEDA and CD3OD. The results presented for the introduction of iodo and trimethylsilyl groups also show a mixture of 2-mono- products and starting material: a mixture consistent with the results obtained from the deuteration studies. Attempts at using dimethylformamide to introduce a single aldehyde group and dimethyl disulfide to introduce a single methylsulfide group proved difficult. The resulting products could not be separated via flash chromatography. Perhaps the differences in 8 John M.D. Stephenson March 29, 2004 polarities of the 2,7-di- and 2-mono- substituted compounds are too close to be separated by the standard 12” column chromatography used. The quantitative yield obtained for 2-phenylnaphthalene 1,8-bis(diethylamide) (4) is an excellent result compared to the previous preparation of the 2,7-diphenyl- substituted product, which took place in a moderate yield of 51%.23 6.0 Conclusions Mono ortho substituted naphthalene 1,8-bis(diethylamide) have been prepared with with TMS, iodo and phenyl functional groups using DoM techniques or a DoM/SuzukiMiyaura strategy. Similar to deuterium studies showing 33% 2-deuterated and 63% 2,7-dideuterated naphthalene derivatives with 1.1eq of s-BuLi and 1.1eq of TMEDA, the preceding results also show a mixture of mono- and di- substituted products in similar ratios. 7.0 Future Direction More work should be done in optimizing the reaction conditions that could be used to provide a higher yield of 2-mono- substituted products. 9 John M.D. Stephenson March 29, 2004 Directed Remote Metalation (DReM) has become an important synthetic utility for its ability to create five-membered ring systems, such as fluorenones24 and pharmaceuticals such as Raloxifene.25 Previously in the Snieckus laboratories a fluorenone derivative (X) has been obtained from the 2,7-diphenyl naphthalene (Y) in 39% yield23 (Scheme 5). O CONEt2 CONEt2 CONEt2 LDA X -10°C to rt 36h Y Scheme 5: Synthesis of a fluorenone In the future it would be interesting, as a proof of concept, to perform a similar DreM reaction on 4 (Scheme 6). O CONEt2 CONEt2 CONEt2 LDA 4 -10°C to rt 36h Scheme 6: Potential formation of a fluorenone using DReM Now that the methodology to create 2-mono- substituted products has been confirmed by the results presented in this work, it would be extremely exciting to go forward and attach imides to the naphthalene derivatives—to form potential, but untested, NGF inhibitors. 10 John M.D. Stephenson March 29, 2004 8.0 Experimental Uncorrected melting points were established using a Fischer Scientific hot stage apparatus. 1H NMR (300 MHz) spectra were obtained on a Bruker AV-300 machine in deuterated chloroform (CDCl3). 1H NMR (400 MHz) were obtained on a Bruker AV-400 machine using CDCl3. In reporting NMR spectra, the following acronyms were used to designate the multiplicity peaks: s=singlet, d=doublet, t=triplet, q=quartet, m=multiplet. Gas chromatography with mass spectroscopy (GC/MS) data was obtained on a Varian Chrompack Saturn GC/MS 2000 as well as a Agilent Technologies Network GC System coupled with a S973 inert MS detector using a 7683 series autosampler and injector. Thin Layer Chromatography (TLC) analysis was performed on SiliCycle aluminum backed ultra pure silica gel TLC plates. Whatman qualitative 150mm filter paper was employed for gravity filtration. A Büchi Rotavapor R-114 with a Büchi Waterbath B-480 was used prior to high-vacuum to fully remove solvents from the products. Tetrahydrofuran (THF) [CAS #109-99-9] was purified through distillation under an argon atmosphere from sodium benzophenone ketyl. All other dry solvents were purchased from Aldrich Chemical Company and were at least 99.9% pure and anhydrous. Secbutyllithium (s-BuLi) [CAS #598-30-1] as a solution of in cyclohexane was also purchased from Aldrich. The s-BuLi was stored in a sealed glass bottle using a rubber septum to prevent contact with the atmosphere. The concentration of the solution was periodically checked titrated using sec-butanol [CAS #78-92-2] using 1,10phenanthroline [CAS #12678-01-2] as an indicator. All reactions were carried out under an argon atmosphere in oven or flame dried borosilicate glassware using syringe-septum 11 John M.D. Stephenson March 29, 2004 techniques to transfer reagents where applicable. Using a dry-ice acetone bath to form a slurry, cryogenic temperatures of approximately -78°C were obtained to carry out the directed ortho metalation and the addition of electrophiles. Internal temperatures of the reaction flasks were determined using a Barnant Dual J stainless steel-sheathed thermocouple. N,N,N',N'-tetramethylethylenediamine (TMEDA) and dried over potassium hydroxide prior to use. All other commodity chemicals were also purchased from Aldrich unless otherwise mentioned. General Procedure A: Standard workup The phrase “standard workup” as referred to in the following experimental refers to extracting three times with an equal volume of ethyl acetate. The organic layer is then dried with anhydrous sodium sulfate, gravity filtered and concentrated on the rotary evaporator. General Procedure B: Directed ortho Metalation 1 was dissolved in anhydrous THF at a concentration of 0.1M in a flame-dried round bottom flask containing a magnetic stirbar. TMEDA [CAS #110-18-9] was then introduced, also at a concentration of 0.1M. The solution was cooled to -78°C and a thermocouple was used to monitor the internal temperature of the reaction. Magnetic stirring was started. Without allowing the solution to rise above a temperature of -70°C a solution of s-BuLi in cyclohexane was added dropwise. It continued to stir for 45mins before the addition of the appropriate electrophile, again ensuring that the temperature 12 John M.D. Stephenson March 29, 2004 did not rise above -70°C. The solution was then stirred for a further 45 minutes and the resulting post-reaction solution was allowed to warm to room temperature, followed by the addition of a saturated aqueous solution of ammonium chloride. Finally the product was concentrated via the “standard workup” as outlined in General Procedure A. General Procedure C: Suzuki-Miyaura Palladium-Catalyzed Cross Coupling To a Schlenk tube containing the halogenated compound, dimethylformamide, K3PO4 and the boronic acid was added Pd(PPh3)4 using glove bag techniques. The Schlenk tube was degassed at least 4x to remove any oxygen from the solvent. The reaction was heated to 150°C until the reaction was completed as monitored by GC/MS. The reaction was allowed to cool to room temperature and three equal parts of distilled water was added to the reaction mixture. The product was concentrated via the “standard workup” as outlined in General Procedure A. naphthalene 1,8-bis(diethylamide) (1) 1 was prepared by Jones23 through reacting diethylamine [CAS CONEt2 CONEt2 #109-89-7] with naphthalene-1,8-dicarbonyl chloride dissolved in dichloromethane and triethylamine. The naphthalene-1,8- dicarbonyl chloride, itself, was also prepared using a literature procedure26 via reacting commercially available 1,8-naphthalic anhydride [CAS #81-845] from Aldrich and phosphorus pentachloride [CAS #10026-13-8] using phosphorous oxychloride [CAS #10025-87-3] as a solvent. The product was purified using flash (1:1 13 John M.D. Stephenson March 29, 2004 EtOAc:hexanes) and its identity verified using IR, NMR and MS. The reaction scheme is shown below in Scheme 7.23 O O COCl O CONEt2 COCl PCl5 Et2NH POCl3 reflux 3 days NEt3 Stir overnight CONEt2 Scheme 7: Synthesis of bis(diethylamide) starting material 2-trimethylsilanylnaphthalene 1,8-bis(diethylamide) (2a) CONE t2 General Procedure B was conducted using the following CONE t2 TMS materials: 0.326g 1 (1mmol, 1eq), 0.86ml (1.1mmol, 1.1eq) 1.04M s-BuLi in cyclohexane, 0.14mL (1.1mmol, 1.1eq) chlorotrimethylsilane (TMSCl) [CAS #75-77-4] and 5ml THF. Flash chromatography (2:1 EtOAc:hexanes), gave 2a (0.0652g, 16%) as a white compound. NMR (300MHz, CDCl3) 7.86-7.84 (d, J=8.3 Hz, 2H), 7.71-7.69 (d, J=8.3 Hz, 1H), 7.52-7.47 (t, J=7.1 Hz, 1H), 7.38-7.35 (dd, J=1.3, 7.0 Hz, 1H), 3.95-3.73 (m, 2H), 3.47-3.18 (m, 2H), .99-2.91 (m, 4H),.33-1.28 (t, J=7.3 Hz, 6H),0.89-0.83 (m, 6H),0.37 (s, 9H). MS m/z (rel. intensity) 398 (M+, 6), 326 (62), 298 (36), 282 (42), 252 (100), 72 (41). 14 John M.D. Stephenson March 29, 2004 2-iodonaphthalene 1,8-bis(diethylamide) (2b) CONEt2 CONEt2 I General Procedure B was conducted using the following materials: 0.326g 1 (1mmol, 1eq), 0.83mL (1.1mmol, 1.1eq) 1.32M s-BuLi in cyclohexane, 0.11ml (1.1mmol, 1.1eq) 2-iodo-1,1,1-trifluoroethane [CAS #353-83-3] and 5ml THF. Flash chromatography (6:4 EtOAc:hexanes) gave 2b (0.1066g, 24%) as a white compound. NMR (400MHz, CDCl3) 7.90-7.88 (d, J=8.6 Hz, 1H), 7.82-7.80 (dd, J=1.3, 8.1 Hz, 1H), 7.52-7.48 (m, 2H), 7.34-7.32 (dd, J=1.3, 7.1 Hz, 1H), -3.98 (m, 1H), 3.86-3.78 (m, 1H), .33-3.24 (m, 1H), 3.19-3.07 (m, 5H), .38-1.34 (t, J=7.2 Hz, 3H),.33-1.29 (t, J=7.2 Hz, 3H),.18-1.15 (t, J=7.2 Hz, 3H),1.00-0.96 (t, J=7.2 Hz, 3H). MS m/z (rel. intensity) 452 (M+,18), 379 (36), 352 (48), 306 (37), 252 (100), 72 (55). 2-phenylnaphthalene 1,8-bis(diethylamide) (4) General Procedure C was conducted using the CONEt2 CONEt2 following materials: 0.117g 3 (0.259mmol, 1eq), 0.030g Pd(PPh3)4 (0.0259mmol, 0.1eq), 0.038g phenylboronic acid (0.311mmol, 1.2eq) [CAS #98-806], 0.158g K3PO4 (0.746mmol, 2.4eq), 5ml DMF. Flash chromatography (6:4 EtOAc:hexanes) gave 0.107g 4 (0.259mmol, 100%) as a colorless oil. NMR (400MHz, 15 John M.D. Stephenson March 29, 2004 CDCl3) 7.91-7.86 (t, J=9.7 Hz, 2H), 7.56-7.54 (d, J=6.7 Hz, 2H), 7.49-7.47 (d, J=8.9 Hz, 2H), 7.39-7.33 (d, J=7.4 Hz, 4H), 3.85-3.79 (q, J=6.7 Hz, 2H), 3.46-3.37 (q, J=7.5 Hz, 1H), 3.31-3.23 (m, 2H), 3.12-3.01 (m, 1H), 2.85-2.74 (q, J=6.9 Hz, 2H),1.33-1.30 (t, J=7.2 Hz, 3H), 1.14-1.11 (t, J=7.2 Hz, 3H),0.76-0.72 (t, J=7.2 Hz, 3H),0.69-0.65 (t, J=7.2 Hz, 3H). MS m/z (rel. intensity) 402 (M+,28), 330 (100), 302 (89), 258 (63), 202 (59), 72 (79). 16 John M.D. Stephenson March 29, 2004 9.0 References 1 Marone, S.; Ross, G. 2000, World Patent No. WO0069829. 2 Shamovsky, I.L.; Ross, G.M.; Riopelle, R.J.; Weaver, D.F.; J. Am. Chem. Soc. 1999, 121(42), 9797-9806. 3 Jones, C.; Ross, G. Personal communication. 4 Gilman, H.; Bebb, R. J. Am. Chem. Soc. 1939, 61, 109-112. 5 Wittig, G.; Fuhrmann, G. Chem. Ber. 1940, 73, 1197. 6 Snieckus, V. Chem. Rev. 1990, 90, 879-933. 7 Stratakis, M. J. Org. Chem. 1997, 62, 3024-3025. 8 Whisler, M.; MacNeil, S.; Snieckus, V.; Beak, P. Angew. Chem. Int. Ed. 2004, 43, 2-21. 9 Anderson, D.; Faibish, N.; Beak, P. J. Am. Chem. Soc. 1999, 121, 7553-7558. 10 MacNeil, S.; Familoni, O; Snieckus, V. J. Org. Chem. 2001, 66, 3662-3670. 11 Hartung, C.; Fecher, A.; Chapell, B.; Snieckus, V. Org. Lett. 2003, 5, 1899-1902. 12 Blackmore, I.; Boa, A.; Murray, E.; Michael, D.; Woodward, S. Tet. Lett. 1999, 40, 6671-6672. 13 Diederich, F. and Stang, P.J. Metal Catalyzed Cross-coupling Reactions. J. Wiley & Sons, Weinheim. 14 Miyaura, N.; Yamada, K., Suzuki, A. Tet. Lett. 1979, 20, 3437-3440. 15 Miyaura, N.; Suzuki, A. Chem. Commun. 1979, 866. 16 Chang, H.; Young, M. Bull. Korean Chem. Soc. 2002, 23, 663-664. 17 Suzuki, A. Pure Appl. Chem. 1991, 63, 419-422. 17 John M.D. Stephenson 18 March 29, 2004 Smith, G.B.; Dezeny, G.C.; Hughes, D.L.; King, A.O., Verhoeven, T.R.; J. Org. Chem. 1994, 59, 8151-8156. 19 Gant, T.G.; Meyers, A.I. Tetrahedron. 1994, 50, 2297-2360. 20 Shimano, M; Meyers, A.I. J. Am. Chem. Soc. 1994, 116, 6437-6438. 21 Glasser, T.; Liratzis, I. Synlett. 2004, 4, 735-737. 22 Poirier, M.; Simard, M.; Wuest, J. D. Organometallics. 1996, 15, 1296-1300. 23 Jones, C.; Snieckus, V. Unpublished results. 24 McCubbin, J.A.; Tong, X.; Wang, R.; Zhao, Y.; Snieckus, V.; Lemieux, R.P. J. Am. Chem. Soc. 2004, 126, 1161-1167. 25 Kalinin, A.V.; Reed, M.A.; Norman, B.H.; Snieckus, V. J. Org. Chem.; 2003, 68, 5992-5999. 26 Mason, J. J. Am. Chem. Soc. 1924, 37, 2116. 18