Chapter 8 - Institute for Research on World

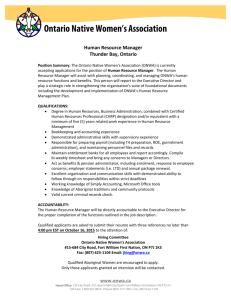

advertisement