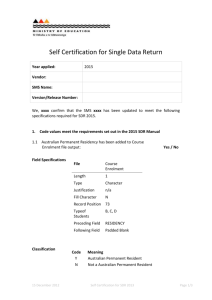

NTSB Survey VS SDRs

advertisement