policy - School of Design

advertisement

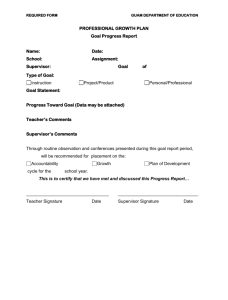

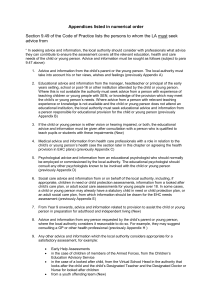

FACULTY OF PERFORMANCE, VISUAL ARTS AND COMMUNICATIONS HEALTH AND SAFETY STATEMENT SCHOOL OF DESIGN 2013 Postgraduate students please print and sign a copy of the certificate of compliance form located on page 19 of this document, when you have read all of our rule and policies. This must be returned to the general office before you commence any work. November2013 1 SCHOOL OF DESIGN DEPARTMENTAL HEALTH AND SAFETY POLICY STATEMENT 1 INTRODUCTION AND MISSION STATEMENT 2 GENERAL POLICY 3 HEALTH AND SAFETY RESPONSIBILITIES 3.1 KEY POSTHOLDERS AND RESPONSIBILITIES 3.2 HEAD OF DEPARTMENT 3.3 DEPARTMENTAL SAFETY SUPERVISOR 3.4 STAFF 3.5 STUDENTS 4 STANDARDS AND PROCEDURES APPENDIX 1: APPENDIX 2: APPENDIX 3: APPENDIX 4: APPENDIX 5: APPENDIX 6: APPENDIX 7: APPENDIX 8: APPENDIX 9: APPENDIX 10: APPENDIX 11: APPENDIX 12: APPENDIX 13: APPENDIX 14: APPENDIX 15: APPENDIX 16: APPENDIX 17: DEPARTMENTAL INFORMATION ON KEY POSTHOLDERS AND RESPONSIBILITIES SAFETY STANDARDS AND POLICIES SPECIFIC TO THE SCHOOL OF DESIGN SAMPLE CERTIFICATES OF COMPLIANCE FOR STUDENTS PEOPLE MATTERS FIRE SAFETY ELECTRICAL SAFETY RISK ASSESSMENTS CHEMICAL SAFETY AND COSHH REQUIREMENTS MANUAL HANDLING WORKING AT HEIGHT SLPIS AND TRIPS WASTE MANAGEMENT STUDENT FIELD TRIPS STAFF AND STUDENT MOTOR INSURANCE COMPLIANCE FORMS ABSENCE FROM WORK, HOLIDAYS AND WORKING FROM HOME CONTACT TELEPHONE NUMBERS RECORDS OF AMENDMENTS/UPDATES TO SAFETY POLICY November 2013 2 HEALTH AND SAFETY POLICY STATEMENT SCHOOL OF DESIGN 1. MISSION STATEMENT The School of Design endeavours to achieve a safe working environment recognising the demands of the multi-disciplinary activities within the School. Our aim is to provide a place of work where risks are eliminated/properly controlled for the benefit of the health and safety of all its students, staff and visitors. This safe environment will be achieved by monitoring and assessing equipment and facilities, working practices, and developments in Health and Safety legislation. 2. GENERAL POLICY This statement recognises the department’s obligations under the Health and Safety at Work Act 1974 Etc. and the department will so far as is reasonably practicable: Set standards that comply with all relevant statutory requirements so that the health and safety of staff, students, visitors and the general public are not adversely affected by the activities of the department. Provide and maintain equipment and a working environment that are, so far as is reasonably practicable, without risks to health and safety. Train all staff to be aware of their own responsibilities for and to provide information, instruction and training on, the particular hazards and risks which exists within the department. Ensure that these objectives are being fulfilled through the department’s monitoring procedures. These include ♦ Issues (i.e. Hazards) raised by staff on ad-hoc basis ♦ Routine safety inspection of the department (at least once per year) and ♦ Raising of safety issues at regular internal meetings of the health and safety committee, and ♦ Review of existing arrangements for safety at these meetings. ♦ Annual review of post holders and 4 yearly review of whole policy. ♦ Ensure that health and safety training offered to staff is in line with the requirements of the department and current best practice. November2013 3 3. HEALTH AND SAFETY RESPONSIBILITIES 3.1 For Key Post holders and Responsibilities see Appendix 1. 3.2 HEAD OF DEPARTMENT Overall responsibility for safety in the department lies with the Head of Department. The Head of Department is responsible for: Ensuring that the safety policy is effectively communicated to all staff; that the implementation of the policy is monitored; and reviewed on an annual basis. Ensuring that buildings/premises where the activities are under the direct control of the department are inspected at least annually. Safeguarding the health, safety and welfare of all persons working or visiting the department both with regard to safe condition of premises and with regard to provision of equipment which is mechanically and electrically safe. Ensuring that there are sufficient resources allocated to deal with health and safety issues in the department and that staff receive such instruction, information and training as is required to enable them to carry out their duties without undue risks to their health and safety. There is also a need to ensure that all information on health and safety hazards is provided to visiting researchers, contractors and maintenance engineers etc., who undertake work in the department. Where appropriate, training should be extended to include students. Ensuring that procedures are in place for the testing of all portable electrical equipment in the department whether owned by the individual, the department or another organisation (if on loan), and that records of these tests are kept. Ensuring that all accidents are reported on the University Sentinel online system and those incidents of any significance, even where no injury occurs, are suitably investigated. Records of these are also kept on an accident report form. For on line accident reporting please report the incident to Les Johnson or Azim Abadi. Ensuring that statutorily required assessments e.g. for Visual Display Units, for Manual Handling, or general risk assessments are carried out, kept under review, and that records of these are kept available for inspection. Referring matters of general concern with regard to health and safety not only to the Head of Faculty, Head of School etc., but also to the Pro Vice Chancellor who chairs the Management Committee for the Safety Services, via the University Safety Adviser. In practice certain of these duties may be delegated to other staff such as the Departmental Safety Supervisors, Fire Wardens, and First Aider's, who then have the full authority to act on behalf of the Head of Department in specific capacities. November2013 4 A list of staff with specific health and safety responsibilities is given at Appendix 1. Of these positions the departmental safety supervisor has an important co-ordinating role and a fuller list of the duties of this post are outlined below. 3.3 DEPARTMENT SAFETY SUPERVISOR Specific duties have been delegated to Departmental Safety Supervisor and these are as follows: To advise and assist the Head of Department in fulfilling the health and safety responsibilities of the department and in ensuring that guidance on health and safety issued by the department or issued by the University Safety Service is adhered to, and distributed to staff/students as appropriate. To act as a focal point for day-to-day issues e.g. providing advice to deal with problems, queries, accident reporting and investigation, training, assessments. To organise and conduct relevant departmental safety inspections with other staff. To maintain a record of such inspections on University Inspection Report Forms (Report Form and risk assessment procedure for prioritising remedial action included in Office Safety Manual). To ensure that all portable electrical equipment in the department, whether owned by the individual, the department or another organisation (if on loan) is subjected to electrical safety checks at appropriate intervals. To ensure that appropriate safety training is undertaken by staff. To provide new members of staff with information and/or induction training outlining local safety policy; accident and incident reporting procedures; information on means of escape in event of fire; fire evacuation procedures; first aid facilities; and names of staff with specific responsibilities for safety etc. To advise students re the items referred to in induction training above. To arrange for the prompt reporting of accidents, incidents and cases of occupational ill health in accordance with University procedures. To investigate these to identify appropriate remedial action. To ensure that first aid boxes in the department are checked regularly by a suitable member of staff and that any deficiencies are reported and made good; and similarly to ensure that fire extinguishers and means of escape are inspected on a monthly basis and deficiencies dealt with. In matters of urgency to act with the delegated authority of the Head of Department and where appropriate to liaise with University Safety Adviser on these. November2013 5 To refer promptly to the Head of Department or University Safety Adviser any health and safety problems where there is uncertainty as to the standards to apply or which cannot be resolved in a timescale appropriate to the risk. Items of general concern re resources, policies etc. can also be referred to the Management Committee for the Safety Services via the Head of Department. ♦ To periodically review health and safety policy, health and safety procedures in department. (A log for updates/amendments to the Safety Policy is given in Annex 2). 3.4 STAFF School staffs are responsible for: Observing all safety rules, procedures and instructions and relevant codes of practice. Making proper use of all work items, and equipment, provided. Not intentionally or recklessly interfering with or misusing anything provided in the interests of health and safety. Reporting to their immediate supervisor/line manager any observed defects or damage to property or equipment. Reporting to their immediate supervisor/line manager any hazards that come to their attention. Discussing any concerns over health and safety with their supervisor/line manager. Referring any important issues to the Health and Safety Committee, or their Supervisor/line manager. Co-operating with any departmental and/or University safety rules. Discussing their safety training needs with their supervisor/line manager. 3.5 STUDENTS 3.51 Undergraduate Health and Safety Statement Undergraduate students in the Department of Design are required to share the responsibility for achieving a safe working environment. All students must follow Health and Safety procedures, and understand the implications of these procedures on all activities within their programme of study. The following points should be considered at all times: Observe all safety rules, procedures and instructions and relevant codes of practice. Use facilities and equipment only for their intended purpose. Do not to interfere with, or misuse, anything provided in the interests of Health and Safety. (Goggles, masks, guards etc.) November2013 6 Discuss any concerns over health and safety with a member of staff or the Module Manager. Do not work in studios, laboratories or workshops on your own. Do not work in studios, laboratories or workshops outside normal teaching hours. (9am-5pm Monday to Friday during teaching weeks.) Where appropriate, at the commencement of a module, Module Managers will bring relevant Health and Safety issues to the attention of students and obtain student signatures that they are aware of the risks. Certificates of Compliance must be signed and returned to the Module Manger before any student is allowed to commence practical work using University facilities. See Appendix 3 for sample Certificates of Compliance. POSTGRADUATES 3.52 Post Graduate Health and Safety Statement Post Graduate students in the Department of Design are required to take an active and responsible role in achieving a safe working environment. All students must follow Health and Safety procedures, and understand the implications of these procedures on all activities within their programme of study and research. The following points should be considered at all times: Apply the departmental policies and procedures detailed in the Health and Safety Handbook. Be fully conversant with all safety rules, procedures and codes of practice relevant to your specialism. Use facilities and equipment only for their intended purpose. Do not to interfere with, or misuse, anything provided in the interests of health and safety. (Goggles, masks, guards etc.) Bring any concerns over health and safety to the attention of your project supervisor or the departmental health and safety supervisor. Do not work in studios, laboratories or workshops on your own, or without means of attracting attention, in case you are involved in an incident. Be an advocate for best practice in health and safety within your chosen field of study. Make sure all samples are labelled stating clearly what the contents are, dated and displaying all correct hazard symbols. November2013 7 • Make sure all work in progress, i.e. any chemicals and solutions that are stored in bottles, flasks, containers etc are labelled stating clearly what the contents are, dated and displaying all correct hazard symbols. At the beginning of a project the student must explore, with your supervisor(s) all health and safety issues. Risk Assessments must be discussed with your supervisor and written before any work commences. All suitable precautions and control measures must be put in to practice before any work commences. The risk assessments written for your work must be continually updated and reviewed as your project develops and new equipment, materials, chemicals and processes are used. You might find that a generic risk assessment and also a safe operating procedure has been written for the equipment you want to use, if so use the information contained in these to undertake your specific risk assP.ssm<>nt Again consult with your supervisor(s). COSHH assessments must be carried out, where appropriate, when chemicals are used or purchased, this must be done before any work commences. Certificates of Compliance must be signed and returned to the Department Office before any student is allowed to commence practical work using University facilities. See Appendix 3 for sample Certificates of Compliance. 4. STANDARDS AND PROCEDURES Specific advice on the standards to be achieved and the procedures for carrying out the various risk assessments required by law are given in the appropriate section of the Office Safety Manual. The University of Leeds Health and Safety Policy can be consulted on: www.leeds.ac.uk/safety The organisation and arrangements for dealing with departmental safety issues including the details of individuals with specific responsibilities - are given in Appendices. Signed Dated 24/11/13 Professor Chris Carr Head of School of Design November2013 November2013 8 8 SCHOOL SAFETY MANUAL APPENDICES TO THE HEALTH AND SAFETY POLICY STATEMENT APPENDIX 1: APPENDIX 2: APPENDIX 3: APPENDIX 4: APPENDIX 5: APPENDIX 6: APPENDIX 7: APPENDIX 8: APPENDIX 9: APPENDIX 10: APPENDIX 11: APPENDIX 12: APPENDIX 13: APPENDIX 14: APPENDIX 15: APPENDIX 16: APPENDIX 17: November2013 DEPARTMENTAL INFORMATION ON KEY POSTHOLDERS AND RESPONSIBILITIES SAFETY STANDARDS AND POLICIES SPECIFIC TO THE SCHOOL OF DESIGN SAMPLE CERTIFICATES OF COMPLIANCE FOR STUDENTS PEOPLE MATTERS FIRE SAFETY ELECTRICAL SAFETY RISK ASSESSMENTS CHEMICAL SAFETY AND COSHH REQUIREMENTS MANUAL HANDLING WORKING AT HEIGHT SLPIS AND TRIPS WASTE MANAGEMENT STUDENT FIELD TRIPS STAFF AND STUDENT MOTOR INSURANCE COMPLIANCE FORMS ABSENCE FROM WORK, HOLIDAYS AND WORKING FROM HOME CONTACT TELEPHONE NUMBERS RECORDS OF AMENDMENTS/UPDATES TO SAFETY POLICY 9 APPENDIX 1 DEPARTMENTAL INFORMATION ON ORGANISATION AND ARRANGEMENTS FOR DEALING WITH SAFETY ISSUES HEAD OF SCHOOL Professor Chris Carr SCHOOL SAFETY SUPERVISOR Mr Les Johnson DEPUTY SAFETY SUPERVISOR Mr Azim Abadi SAFETY COMMITTEE ORGANISATIONAL STRUCTURE Head of School and chair of committee Safety Supervisor Pressure Systems, Extraction Systems safety, Technical Staff Rep School Manager and Deputy Safety Supervisor Electrical, Mechanical, Office safety Security Chemical Safety Fire Safety Fashion Safety Graphics Safety Studio Safety Structured Textiles Safety Printed Textiles Safety Non-woven Safety Testing and Analysis Safety First Aid Senior Academic VDU Safety manual Online accident reporting CAP Professor Chris Carr c.carr@leeds.ac.uk Mr L Johnson l.johnson@leeds.ac.uk Mr A Abadi a.abadi@leeds.ac.uk Mr M Brookes Dr R S Blackburn Mr M Anderson Ms E Evans Mr M Anderson Ms L Clements Dr B Carnie Ms L Clements, Ms J Anderson Mr M Rathod Mr M Brookes Dr Vien Cheung Professor Chris Carr Dr Vien Cheung Mr L Johnson Mr L Johnson, Mr A Abadi Professor K Hay m.a.brookes@leeds.ac.uk r.s.blackburn@leeds.ac.uk m.anderson@leeds.ac.uk e.l.glover@leeds.ac.uk m.anderson@leeds.ac.uk l.m.clements@leeds.ac.uk b.w.carnie@leeds.ac.uk texlmc@leeds.ac.uk m.k.rathod@leeds.ac.uk texmab@leeds.ac.uk t.l.v.cheung@leeds.ac.uk c.carr@leeds.ac.uk t.l.v.cheung@leeds.ac.uk l.johnson@leeds.ac.uk fin6kgh@leeds.ac.uk School of Design FIRST AIDER(S) November2013 10 Michael Brookes, Azim Abadi, Gareth Griffiths, Elaine Evans, and Lynda Howarth. Health and Safety flow chart Vice Chancellor Prof Michael Arthur Health and Safety Services Dean of Faculty Prof David Cooper Health and Safety Services Faculty Manager PVAC Faculty, Health And Safety Meetings Head of School of Design Prof Chris Carr School of Design, Health And Safety Meetings School Safety Supervisor Mr Les Johnson Deputy Safety Supervisor Mr Azim Abadi Fire safety Mr Mike Anderson First Aid Officer Mr Terry Smith Fire Wardens First Aider's Electrical Safety Mr Azim Abadi Chemical Safety Dr Richard Blackburn APPENDIX 2 November2013 11 SPECIFIC ISSUES RELATING TO THE SCHOOL OF DESIGN Safety Inspections The School undertakes planned and unplanned safety inspections on a regular basis. The inspection team will consist of the head of School or senior member of staff, School safety supervisor, School manager and a senior member from the area being inspected. Where appropriate, members of the trades unions along with the faculty health and safety supervisor will be invited to join the inspection team. One way to monitor the standard of work and safety in which the Health and Safety Committee monitors’ standards in the School of Design is by formal risk assessments on an annual basis. These will be carried out by a trained member of the Health and Safety Committee and a senior member of staff for each area. The results will be brought to the attention of the Health and Safety Committee and appropriate action will be taken. Safety inspections will be carried out by the School Safety Supervisor or by other designated staff who have been appropriately trained, so as to cover all sections of the school over a one year period. Action in Case of an Accident The School Safety Supervisor or his deputies must be informed of all accidents, not just those that cause personal injury. It must be stressed that the reporting of a near miss is just as important as reporting an accident. All such accidents must be recorded on the universities online Sentinel accident reporting system. The school has two trained members of staff who have access to the reporting system, Azim Abadi and Les Johnson. Ensure that you know the location of the FIRST AID BOXES. A list of First Aid boxes is given in the beginning of this booklet. Obtain advice and help from one of the members of staff trained in First Aid. Absence from work, due to accident, for more than three days or from certain specified major injuries, diseases or poisoning, must also be notified to the local Inspector of the Health and Safety Executive, via the University Safety Adviser. Working Outside of Normal Hours It is essential that you enter your name in the log book provided, if you are in the school on weekends, holidays or weekdays after 6.30pm. This is located by the disabled doors in the Clothworkers South building. You should also sign out before leaving the building. In general, machinery must only be operated between 09.00 and 17.00. Experiments that require running overnight are not normally permitted. On the rare occasion when this cannot be avoided, permission must be sought from the School Safety Supervisor (the Academic Supervisor in the case of P/G Students) and notices are required to be posted November2013 12 both at the location of the experiment and at the door of the room containing the experiment. Appropriate forms for this are available from the Safety Supervisor. Declaration of instruments disabilities affecting working with equipment and All new staff and students should make a declaration of any disability that may affect their own or others safety in the laboratories and the workshop, e.g. epilepsy, diabetes. This can be made to their line manager, Safety Supervisor or Head of School. Any information received will be treated confidentially. They should also be aware that they will not be allowed to operate equipment or instruments if they are rendered unfit to work due to illness / effects of medication or other drugs / consumption of intoxicating liquor. Workshop Only qualified workshop staff are allowed to operate machinery in the Workshop. Under no circumstances will anyone else be allowed access to this machinery. Requests by students for work to be carried out in the Workshop should be approved by their supervisor. Requests by research workers for work to be carried out in the Workshop should be approved by research grant holders. Dr Bandara has been given special dispensation to operate certain machinery in the workshop. Fire Extinguishers If any fire extinguisher has been used, or you note that one of the plastic tags has been broken report this to the School Safety Supervisor, or the School Fire officer. Do not use a water extinguisher (red) on any electrical fire, burning liquids/chemicals (including petrol) or burning metals. When using a CO2 (black) extinguisher, do not hold the horn, as this becomes very cold in operation and could impart low temperature burns. The Fire Wardens will check all fire extinguishers once a month on a rota basis. Any use of, or damage to, a fire extinguisher must be reported to the School Safety Supervisor. It is School policy to periodically carry out evacuation drills. Everyone should make themselves aware of the safe routes out of the School. In the event of a fire or fire alarm sounding, do not use a lift. Hose Reels Where provided, all staff should be shown how to operate the hose reels. The hose should be pulled from the reel and the appropriate valves operated. November2013 13 Lasers Contact the School Laser Supervisor if the use of lasers is planned. Almost all lasers require safety rules to be observed. The only laser systems that do not require approval for use are those which are totally enclosed and where the laser beam is permanently inaccessible, e.g. laser printer. Compressed Air Compressed air supplies in workshops and laboratories should be treated with respect. It is supplied from a compressor in the plant room at a pressure of up to 7bar. Warning: never direct a jet of compressed air against another person (or yourself). Practical jokes with compressed air have caused horrific injuries and death. Always follow “Good Laboratory Practice” ♦ Work should be carried out in a clean and orderly manner and work areas should be kept clean. ♦ Broken glass must be placed in special containers provided, never in any other waste bin. ♦ Experiments which could compromise safety in the School, or experiments which use running water which could cause flooding and subsequent damage within the School, must not be left unattended, and they must not be allowed to continue overnight. ♦ Communal work areas such as fume cupboards and balance areas must be kept clean. Any substance that is spilled must be correctly cleaned up and disposed of following to procedures documented by the COSHH assessment using the information in the MSDS. ♦ The importance of eye protection should not be underestimated. Safety glasses must be worn in laboratories at all times. ♦ All samples/bottles should be labelled with the contents name and not just it’s formula, user’s name and date in bold. Appropriate hazard warning symbols must be attached. ♦ In the event of an accident resulting in flood or spillage, it is the responsibility of the research student in question to clean up the mess. Mops and buckets can be obtained from the Laboratory staff. Protective Clothing Appropriate protective clothing must be worn in laboratories and workshops. Dirty or contaminated overalls and coats should not be used. Laboratory coats should be worn buttoned up; unbuttoned coats are ineffective and could be dangerous. Eye protection should be worn when there is danger of splashing by chemicals, or glass apparatus is used under pressure. November2013 14 Fume cupboards Anyone intending to use fume cupboards must be instructed by the Pressure Systems Officer in the operational procedure. Fume cupboards are controlled by adjacent stop/start buttons. Where separately controlled fans are fitted in laboratories, it is the user’s responsibility to switch them off when not required. Where an extractor fan from a fume cupboard is interlocked electrically with other fume cupboards, the following procedure must be used in order to have control over your fume cupboard: Users should check the operation of fume cupboards weekly. Fume cupboards should be kept clean and not used as a store for equipment or Chemicals. Any spillages must be cleaned immediately so the fume cupboard is left safe for others to use. Breathing equipment The school is equipped with two SAVER SETS – compressed air breathing apparatus. These sets are extremely easy to use and provide approximately ten minutes of air, sufficient to deal with an emergency. The cylinder should be slung from the shoulder by means of the orange strap and the mask drawn over the face. As soon as the mask is on the face, the normal action of breathing draws air into the mask from the demand valve. There are no valves to operate. A small pressure gauge is incorporated into the cylinder head. SAVER SETS should not be used when tackling a fire. Users are required to attend a course in the use of breathing equipment, and each set should have two designated users. Current designated users are listed in the section on Organisational Details of this Manual. SAVER SETS are positioned in the corridor outside Lab 2.09 Use of Vacuum equipment When using vacuum equipment, always wear eye protection. Check that any glassware to be used is of the correct type and free from any cracks or scratches. Use a trap between the vacuum pump and the vessel to condense any volatiles. Gas Cylinders All gas cylinders must be securely clamped. They must never be left freestanding. Cylinders are stored behind the workshop in locked cages. The key is obtainable from the General Office. For instructions on fitting a pressure regulator, see the Pressure Systems Officer. Notices must be exhibited outside rooms containing pressurised gas cylinders, stating the type of gas contained. November2013 15 Water Supply to Apparatus The water supply pressure increases when there is less use of water (i.e. evenings, overnight). This can lead to burst tubing and flooding which could do damage to very expensive equipment situated on lower floors. It is essential therefore to ensure that no equipment uses running water overnight, or is left unattended during the day. Asbestos Safety Policy The University has published a policy for departments on ‘Asbestos in the Building Environment’. A copy of the University’s policy and may also be viewed on the web www.leeds.ac.uk/safety. The Introductory Sections build upon a variety of issues connected with asbestos in the building environment, but in addition you attention is drawn to: ♦ Appendix 1, which reproduces the PVC’s letter regarding prior authorisation for minor building work, and ♦ Appendix 2, which contains the pro-forma to be used when seeking authorisation for minor building work. Staff should therefore ensure that any minor work is first discussed with Les Johnson who will liaise with estates. Completion of Research Work, and Before Leaving the School All research workers are responsible for clearing up their effects (in consultation, where appropriate, with their supervisors) so that unidentifiable chemicals and equipment are not left behind, creating a potential hazard. ♦ Glassware must be left in a clean, safe state by the research worker. ♦ Capital equipment, borrowed from whatever source, should be returned in good working order by the research worker. ♦ Samples prepared in the course of research, which are to be retained, should be sealed in tubes or bottles. Each bottle must be labelled with the full name of the contents, name of researcher, date and the correct hazard labels. These must be given to the supervisor. Samples no longer required must be either destroyed (see COSHH or MSDS) or sent for disposal as a waste chemical. ♦ All unused chemical reagents should be returned to school safety supervisor for disposal. ♦ All keys must be returned to the General Office. ♦ A forwarding address should be left with the General Office. November2013 16 APPENDIX 3 School of Design Health and Safety Policy Under Graduate Certificate of Compliance Module No: Page of Training given by: By signing this certificate I agree that: I have attended the health and safety introduction and read any documents provided by the module manager. I understand the risks and safety issues relevant to this module. I will share the responsibility for the health and safety of myself, other students and members of staff by working in a responsible manner. I agree to wear and use any safety apparatus as directed by a member of staff. I agree to comply with all health and safety procedures detailed as part of this module and the Under Graduate Health and Safety Statement in the Programme Handbook. Student No. November2013 Student Name Signature Date 17 Health and Safety Policy Under Graduate Certificate of Compliance Notes to Staff Students should sign a Certificate of Compliance when taking a module where a Health and Safety Audit has indicated that training should be provided before equipment is used or processes undertaken. This certificate is documentary evidence that the appropriate training has been given to each student on a module. Certificates should be prepared in advance of any training or introduction: ♦ One copy of this certificate must be used for every 15th student make sure the rubric appears at the head of each signatory page so the student can clearly see what they are agreeing to. ♦ You may copy and paste the name and student number into the table from ‘Web for Faculty’– this will give you a clear indication of who should have attended your safety introduction, and who has not. ♦ Make sure the module number and the name of the member of staff giving the training is filled in, along with the page number (e.g. Page 1 of 3). ♦ Pass the certificate around the group after your talk, giving them sufficient time to read any additional health and safety documents provided (for longer documents, talk through the content.) ♦ Lodge a copy of the certificate with the Department Office. ♦ Make a note of anyone who missed your briefing and make him or her aware of the health and safety issues at the next session. Ask them to sign the Health and Safety Certificate in the Department Office before they use any equipment. November2013 18 School of Design Health and Safety Policy Post Graduate Certificate of Compliance Student’s Name: Programme of Study / Research: Project Description: To Cover the Period: - to - Supervisor: By signing this certificate I agree that: I agree to comply with all health and safety procedures detailed as part of this project and in the Post Graduate Statement in the Department Health and Safety Handbook. I have assessed the potential risks presented by the project I am to undertake I will share the responsibility for the health and safety of myself, other students and members of staff by working in a responsible manner. I agree that it is my responsibility to wear and use any safety apparatus in line with the risk to bystanders and myself. Additionally, I agree to wear and use any safety apparatus as directed by a member of staff. I understand that this procedure must be on going as my project develops and new equipment, materials, chemicals* and processes are used: new Risk Assessments must be undertaken, COSHH certificates obtained and Post Graduate Certificates of Compliance renewed. Signed: Date: Note: It is the Post Graduate Student’s responsibility to lodge a copy of this Certificate with the Department Office. Lack of a current Certificate of Compliance will result in the student’s permission to use University facilities being withdrawn. *This certificate does not replace COSHH risk assessment forms; these must be completed for each chemical used. For office Use Only Comment: November2013 Received: 19 APPENDIX 4 People Matters Stress at work The Department will promote a well-managed work environment that will protect staff from undue stress arising from the conditions in their workplace. The Department will seek to prevent work-related stress, and where this is not realistic, policies and practices should be implemented to mitigate the consequences of stress that remains. The Department will increase awareness of the causes and symptoms of stress and implement support, training and monitoring in line with University of Leeds Policy on Stress at Work. (http://www.leeds.ac.uk/hr/policy/documents/I(28).DOC) Counselling Services include: University Staff Counsellor – John Adams 0113 237 0309 The staff counselling service is open all year round except weekends and Bank Holidays. Your concerns do not have to be work related as advice and support can be provided on any personal, emotional, physiological or work related issue. Manager's/Supervisor's Advice-line - 8am and 9pm - 0800 085 3805 The Managerial Advice-line takes calls from any staff member who has managerial or supervisory responsibilities for others. It provides an opportunity to explore complex and challenging work situations and to devise strategies for managing them. Counselling in Companies - 0800 917 8452 In addition the University offers access to a 24hour Employee Advice line administered by Counselling in Companies. This provides a wide range of confidential advice and support to members of Staff and their immediate families who may be having difficulty balancing problems at work or home. Student Counselling Service – 0113 3434107 Nightline – 0113 3801381 (listening) 0113 3801380 (information) The Student Counselling Service is available through the Student Support Network. Advice may also be sought from the University Chaplaincy and Trade Unions. Occupational Health The University Occupational Health Service - 0113-233-2997 November2013 20 The Department will implement procedures and best practice as recommended by the University Occupational Health Service. This includes surveillance, assessment and prevention initiatives in relation to: ♦ Protecting health at work ♦ Promoting healthy working conditions ♦ Helping recovery and return to work after illness or injury ♦ Improving health and fitness The range of services offered by the Occupational Health includes advice on maternity provision, staff counselling, advice on resettling and rehabilitation for people with disabilities, accident prevention and first-aid training and advice on personal health issues such as stopping smoking and leading a healthier lifestyle. Sport and Fitness University Sports Facilities – www. leeds.ac.uk/sport/index.html To promote the basic health and fitness, members of the Department are encouraged to make use of the University Sports Facilities. A range of sports and gym facilities are provided on campus with organised classes taking place every day during term time. Student and Staff membership runs from October 1st each year, though facilities can be used by payment on an ad-hoc basis. VDU Safety policy ASSESSMENT EYE AND EYESIGHT TEST November2013 HOD to arrange for suitable and sufficient assessments of EQUIPMENT and ENVIRONMENTAL factors. To be carried out using pro-forma supplied by Health and Safety Services. Assessments can be organised by a co-coordinator (Dr Vien Cheung) done by individuals and forwarded to co-ordinator Overview sheet to be forwarded to HOD when significant action items from assessment. HOD to address issues found to be below standard or with recommendation for improvements (resource implications etc). Assessments to be stored centrally. (Office, Safety Supervisor or Health and Safety Services) Assessments to be reviewed when workstation relocated or substantially reorganised at regular intervals (say every 3/4 years). To carry out preliminary screening by requesting software package from Health and Safety Services. Applications for this to be made to Health and Safety Services by departmental co-ordinator. Departmental co-ordinator is to verify that application 21 involves an employee one who uses VDU for 2½ hours per day to forward VDU assessment and eye test application form to Health and Safety Services will issue voucher to individual for eye test at Vision (Appendix 3 refers) return assessment to individual be invoiced for cost of eye test and if appropriate for a contribution to the cost of VDU glasses, but not for glasses required for other use. DEPARTMENTAL INFORMATION November2013 Dr Vien Cheung – t.l.v.cheung@leeds.ac.uk or Phone: 38082 22 APPENDIX 5 Fire Safety Action in the case of Fire or Explosion On Hearing the Alarm: ♦ Evacuate the building by the shortest possible route. Do not use any lifts and report to the assembly point. ♦ Assembly Point for School of Design: The grass by Education- Opposite the Union Building. ♦ Fire wardens: When leaving the building check your area is clear and report to the fire officer or safety supervisor at the assembly point. They will then assign fire wardens to the school exits to stop re-entry. ♦ Any return to the building is prohibited until the Chief Fire Officer, School Safety Supervisor or Security Staff declares it safe to do so. If a fire is discovered: Common sense and discretion should be used on the discovery of a fire: ♦ If a fire is very small and one is confident that it can be easily extinguished, the nearest appropriate fire extinguisher should be used. ♦ Do not attempt to attack the fire if it is dangerous to do so, e.g. the risk of explosion; difficulty in breathing, your escape route is cut off, etc. ♦ If this action has no immediate effect on the fire, raise the nearest fire alarm. ♦ Activation of the alarm will contact security who will then contact the fire brigade. After activation of the alarm, security should then be called on 32222 with details of the fire. This information should include: a) The exact location of the fire b) The location of any trapped persons c) The type of fire- i.e. the fuel involved d) Report any hazardous substance that may be involved. November2013 23 Fire Wardens School of Design Azim Mike Abadi Anderson Palitha Bandara Richard Elaine Blackburn Evans Les Catherine Johnson Malkin Stephen Russell November2013 a.abadi@leeds.ac.uk m.anderson@leeds.ac.uk MMF 1.12 Wool Division 1.75 m.p.u.bandara@leeds.ac.uk Link Building 133 r.s.blackburn@leeds.ac.uk MMF 2.10 texelg@leeds.ac.uk Wool Division G.75 l.johnson@leeds.ac.uk MMF 2.07 c.malkin@leeds.ac.uk Wool Division G.75 s.j.russell@leeds.ac.uk Wool Division G.78g 24 APPENDIX 6 Electrical safety 3 pin plugged items All electrical equipment, including any items of personal equipment, or new equipment introduced to the school, either ‘new’ or ‘used’, must be examined and cleared for use by the School Electrical Safety Supervisor, Mr A Abadi. Details of every new electrical item must be passed on to Azim Abadi when they arrive in the School. The School Electrical Safety Officer must approve all existing portable electrical appliances, including items such as kettles and computers, for use. Appliances approved for use are recognised by the label ‘Tested for Electrical Safety’ affixed by the School Electrical Safety Officer. 3 Phase Equipment Do not attempt to install three-phase equipment yourself. Installation has to be arranged through Estates Services contact Richard Creaser. Only certified and approved electricians are allowed access to the 3-phase electrical supply and hardwired machine isolators. Advice must be sought from the School Electrical Safety Officer on procedures to be followed when three-phase equipment is involved. Use of Equipment and Test Instruments Do not attempt to repair or disengage a jammed instrument. Research students should inform the Mechanical Safety Officer in cases of difficulty. Certain testing instruments may also need booking, while others can only be operated if a second person is present at all times. You should therefore, in the first instance, contact the Mechanical Safety Officer, to clarify whether the machines can be operated on its own. Experimental Rigs All experimental rigs must be cleared for use by the Mechanical Safety Officer to ensure that the rig has proper safety guards and if appropriate safety interlocks. The Experimental Rig Safety Approval Form must be completed and displayed on or near the experimental machine. Permission must also be sought for any changes that may be required to mechanical guards or electrical connections. After any electrical changes, rewiring, refit etc the item must be tested for electrical safety and passed as safe to use. November2013 25 APPENDIX 7 Risk Assessments The risk assessment is a tool that when used correctly allows you to identify hazards and risks in tasks and then shows how to reduce these hazards and risk by applying control measures. A continual review (normally every year) of each risk assessment shows if the control measures incorporated are sufficient or not. Definitions Hazard means “anything that can, or has a potential to cause harm” (e.g. chemicals, electricity, machinery, workplace environment, etc) Risk is the chance that someone will be harmed by the hazard. Who has responsibility for writing risk assessments? It is yours, your supervisor’s or your managers responsibility to make sure that risk assessments are carried out on all specific tasks that have a risk or possess a hazard that you are involved in. As a School it is our duty to have in place risk assessments of all machinery, workplace, environment, chemical and fire safety. The chemical safety is mainly covered in the COSHH regulations but this needs to be referred to in risk assessments. The fire safety is also covered in a separate fire risk assessment carried out by the School ever year but this needs to be referred to in risk assessments. Risk assessments need to take in to account the following sets of regulations, 1. Management of Health and Safety at Work Regulations 2. Manual Handling Operations Regulations. 3. Personal Protective Equipment at Works Regulations. 4. Workplace (Health, Safety and Welfare) Regulations. 5. Provision on Use of Work Equipment Regulations. These must be incorporated where ever possible, especially the manual handling regulations, in to the risk assessments. November2013 26 Help with undertaking risk assessments Health and Safety Services run training courses on how to do risk assessment and on their web site they also have written guidelines on how to do this. http://www.leeds.ac.uk/safety/riskassess/introduction.htm The Health and Safety Executive also publish guidelines and this link below takes you to theirs. http://www.hse.gov.uk/pubns/indg163.pdf The pdf file can be printed out. Finally if you still have problems please see the School’s safety supervisor. November2013 27 SAFETY POLICY STATEMENT Appendix 8 Chemical safety and COSHH requirements No work can be carried out with any substance that it governed by the COSHH regulations until an assessment has been written and signed by one of the School’s approved personnel. Use of Chemicals Members of the School are advised that regulations concerning ‘Control of Substances Hazardous to Health Regulations’ (COSHH) are now in force. The effects of these regulations, on work in the School, are very widereaching. Safety assessments for laboratory work must also be discussed with research AND PROJECT STUDENTS before work commences and recorded on School forms. Standard Risk Assessment forms for all chemicals used must be completed by all UG and PG students and signed by the Chemical Safety Officer before any practical work with those substances is allowed to commence. Further advice may be sought from the School Safety Supervisor. The COSHH regulations also relate to such matters as assessment of risk and safe working. For example, use of fume cupboards and use of personal protective equipment, particularly gloves when handling dyestuffs (or the building blocks of dyestuffs). Disposal procedures for toxic chemicals should be followed, and appropriate recordkeeping maintained. For more details, see the University Safety Handbook, Section 9 Information regarding the potential hazards of chemicals may be found, for example, in the BDH Hazard Data Sheet Book (copies available from the Chemical Safety Officer), or the Aldrich Chemical Catalogue. Carcinogens can be normally identified as R45 in the ‘Risk and Safety’ phases in the chemical catalogues. A regulation governing the use of suspected carcinogens is given in the University Safety Handbook, Section 7.4 to 7.9. It may be necessary in some instances to tailor the advice therein to the particular activity being undertaken. In the first instance, students should contact the Chemical Safety Officer regarding their use. No work with carcinogens is to be undertaken without the formal, written permission from the School Safety Supervisor. Solvents Never leave bottles of flammable solvents or waste solvent on the bench or open shelves. They must always be kept properly sealed in the approved `University’ solvent cupboard. Keep the door closed. Make sure all bottles are correctly labelled. Winchester bottles must only be transported in proper Winchester carriers; they must never be picked up by their necks. Carriers are available in the Research Laboratory. November 2013 28 SAFETY POLICY STATEMENT Waste Solvents Strict control is required for the disposal of solid toxic chemicals or other noxious materials, since these substances must never be disposed of through the drains. Arrangements for their removal from the premises may be made by contacting the Chemical Safety Officer. Methods of waste disposal must be decided before work commences. Waste solvents must not be disposed of down the drains, but put in the appropriate waste solvent bottle (available from the Chemical Safety Officer). Make sure the waste solvents are compatible with each other before mixing. Never mix non compatible waste. This is dangerous. For non compatible waste solvent use a separate waste solvent bottle and label it appropriately. Waste containing chlorinated or any other halogenated solvent must be kept in a separate bottle labelled chlorinated waste solvent. The contents and approximate quantities of each component should be listed on the label of all bottles. The bottles should be kept in solvent cupboards and, when full, returned to the Chemical Safety Officer. Do not overfill the bottle. Acids, alkalis or aqueous solutions should not be put into the waste bottles except when it is unavoidable (i.e. already mixed with the solvent). All waste solvents should be neutralised before being placed in waste solvent bottles, this reduces the potential for gas formation. Chemicals or solvents handed in for disposal must be in a safe condition, i.e. not leaking or liable to build up pressure by the slow evolution of gas. All bottles containing waste materials must be correctly and fully labelled. All original labelling must be removed from the bottle so there is no confusion regarding the contents. November 2013 29 SAFETY POLICY STATEMENT APPENDIX 9 Manual Handling What is meant by the term manual handling? According to the Manual Handling Operations Regulations (as amended) 1992 (MHOR) manual handling is defined as “...any transporting or supporting of a load (including the lifting, putting down, pushing, pulling, carrying or moving thereof) by hand or bodily force” Training courses for manual handling available from SAS The School of Design actively encourages its entire staff to attend manual handling training courses provided by Safety Advisory Services. They run 2 manual handling types of courses, an office and a technical based course. Further details of when these courses are run can be obtained from Les Johnson. These courses can be beneficial to you also in your life outside the university. Injuries that can be caused from manual handling Musculoskeletal Disorders (MSDs) and other injuries from manual handling affect more than 1 million people every year. Here is a brief list of possible injuries:- death, fractures, dislocations, prolapsed disk, slipped disk, strains, pulled muscles cuts, excessive wear and tear to the body. General information on manual handling There are ways to eliminate or reduce the manual handling operations, so when faced with a manual handling task stop and think. Can we eliminate it, if not then we need to risk assess the task, can we reduce the risk of injury e.g. by splitting the load or purchasing the goods in small sized containers, take in to account all relevant information e.g. how much does it weigh, monitor and review all manual handling tasks. Learn how to lift correctly, all the necessary information on how to lift correctly can be obtained either on the training courses or from the HSE website. They have produced a manual handling tool called MAC, manual handling assessment chart, which takes you through how to lift correctly and finally has a section which allows you to produce a risk assessment on a particular task. The link to it is http://www.hse.gov.uk/pubns/indg383.pdf Copies of the MAC tool can also be obtained from the safety folder in reception and the link to HSE can also be found on the School of Design’s Health and Safety web site. November 2013 30 SAFETY POLICY STATEMENT Manual handling tips Get help; do not try to lift on your own. Split loads; possible. making the load more manageable when Make sure the load is safe; not slide for example with filing cabinet the draws will out. Check the surroundings; make sure there are no trip hazards when moving objects and that the floor is not slippery. Use appropriate footwear; flat heels or PPE footwear where necessary. People who are especially at risk from manual handling Workers who are especially at risk from manual handling include new or expectant worker, anyone below 18 years of age people with health problems and people who already have manual handling injuries. Any of these groups of people need to be individually risk assessed if they have to carry out any manual handling duties according to their circumstance. Use of manual handling aids The School of Design has provided manual handling aids for its staff. These can only be used by staff after they had read the risk assessment and safe operating procedure written about the manual handling aids. Copies of these should be either fixed on the tools or made available in the area they are stored in. CHECK LIST Below is a brief manual handling checklist form, which needs to be filled in by everyone involved in manual handling. Any major issues highlighted in this will have to have a full risk assessment carried out on it. November 2013 31 SAFETY POLICY STATEMENT MANUAL HANDLING OF LOADS: ASSESSMENT CHECKLIST Section A - Preliminary Job description: * Circle as appropriate Is an assessment needed? (I.e. is there a potential risk for injury and are the factors beyond the limits of the guidelines?) Factors beyond the limits of the guidelines? Yes/No* If "Yes" continue. If "No", the assessment need go no further. Operations covered by this assessment (detailed description): Locations: Diagrams (other information): Personnel involved: Date of assessment: Section B - see overleaf for detailed analysis Section C - overall assessment of the risk of injury? Low/Med/High* Section D - remedial action to be taken: Remedial steps that should be taken, in order of priority: 1 2 3 4 5 6 7 8 Date by which action should be taken: Date for re-assessment: Assessor’s name: Signature: TAKE ACTION --- AND CHECK THAT IT HAS THE DESIRED EFFECT November 2013 32 SAFETY POLICY STATEMENT Section B - More detailed assessment, where necessary: Section C Questions to consider: If yes tick the appropriate level of risk Low Med The tasks - do they involve: • holding loads away from the trunk? • twisting? • stooping? • reaching upwards? • Large vertical movement? • Long carrying distances? • Strenuous pushing or pulling? • Unpredictable movement of loads? • Repetitive handling? • Insufficient rest or recovery? • a work rate imposed by a process? The loads - are they: • Heavy? • Bulky/unwieldy? • Difficult to grasp? • Unstable/unpredictable? • Intrinsically harmful (e.g. sharp/hot)? The working environment - are there: • Constraints on posture? • Poor floors? • Variations in levels? • Hot/cold/humid conditions? • Strong air movements? • Poor lighting conditions? Individual capability - does the job: • require unusual capability? • hazard those with a health problem? • hazard those who are pregnant? • call for special information training? Other factors: Is movement or posture hindered by clothing or personal protective equipment? Section D Problems occurring from the task. (Make rough notes in this column in preparation for the possible remedial action to be taken). High Yes/No November 2013 33 Possible remedial action. (Possible changes to be made to system/task load, workplace/space, environment. Communication that is needed). SAFETY POLICY STATEMENT APPENDIX 10 Working at height It is now university policy that any staff needing to work at height must have attended a safe use of ladders course. It has been decided that students who occasionally use step ladders to access yarn bins for example, can be trained by a staff member, who has attended the safe use of ladders course, using the tool box power point presentation provided by Health and Safety Services. General rules for working at height The definition of “working at height” is that a place is at height if a person could be injured falling from it. Please remember that chairs, stools, tables, desks, bookcases etc are not designed for you to stand on them. Only the staff and students who have attended the safe use of ladders and steps training course and have a certificate to prove this can use ladders or steps in the School of Design. General tips for the people who are trained to use ladders Do you need to work at height? Can we eliminate the need to work at height by a reorganisation of the work space or by using some sort of tool to eliminate it? Always think about your own personal safety. Take a moment to assess the risks involved in you working at height. If you feel that the equipment you are using is poorly maintained or not correct for the work required, please report this fact to the Safety Supervisor. University Estate Services employees can bring their own ladders/step ladders in to our School to use. It is their responsibility to make sure that any “working at height” has been fully assessed and that all members of staffs who need it is fully trained in the use of ladder/step ladders. On no account must a member of staff or student use their ladders. External contractor must comply with the health and safety regulation. It is their responsibility to make sure that any “working at height” has been fully assessed and that they are fully trained in this. On no account must a member of staff or student use their ladders. The School must set up an annual inspection routine of all step ladders. This must include the numbering each set of step ladders we use, doing a yearly inspection of these against a set of standard checks and then certificating November 2013 34 SAFETY POLICY STATEMENT each set for use for the following year. Records of these inspections dated and signed must be kept by the School. Staff or students must not use any step ladders that have not been inspected. Guidelines for the use of step-ladders The guidelines below just refer to the use of step ladders only in the School of Design. Do a daily check of the step ladders. Ensure that there is space to open them full and that they are fully open in use. Always use any locking devices that are available. Get some one else to hold the step ladders if possible when you climb them. The floor should be clean not slippery, firm and level. Do not carry any weights of over 10kg up step ladders. Use for short periods of time only, no longer than 30 minutes at any one time. If you have to, use the top step as a hand hold. When using the steps do not stand above the top 2 steps unless you have a safe hand hold. Keep both feet on the same steps when working, do not over reach. Do not work “side on” to the steps. Do not jump from the step ladders. Do not slide down the edge of the step ladders. Do not have one foot on the steps and one foot on another surface. Do don’t wear loose or slippery footwear when using the step ladders. A simple guideline of the use of step ladders must be presented to all students who you allow to or expect to use them. Student use of step ladders Staff must do a risk assessment on “the use of step ladders in their area”, looking in particular to restricting their use when possible. Staff must give full training in the use of step ladders to all students prior to the step ladders being used. This can be written or verbal but must include the above points. A warning sign should be attached to or next to the step ladders referring to this. Make sure the students carefully listen to the safety advice given and get them to sign a certificate of compliance to that effect. Keep this record in case of accidents. November 2013 35 SAFETY POLICY STATEMENT APPENDIX 11 Slips and trips Over a third of all major injuries reported each year are caused as a result of a slip or trip (the single most common cause of injuries at work). This is area of health and safety that is quite often overlooked and is of concern to the Health and Safety executive as well as the university and School of Design. The School of Design requests that all staff and students are vigilant when going about their business around the School. If you see any problem, report it. Report it to the lecturer, supervisor, general office in the wool division room 1-63, Head of School of Design etc, by phone or email. It is most important that if you see a problem you report it rather than assuming some one else has already done so. What to look out for with regards to slips and trips* Spillage of wet and dry substances: Clean spills up immediately, if a liquid is greasy, make sure a suitable cleaning agent is used. If the spill is chemical check your spillage control on your COSHH assessment and clean it up. After cleaning the floor can be wet for some time; dry it where possible. Use appropriate barriers to tell people the floor is still wet and arrange alternative bypass routes. Put up warning signs for mopped floor after a spill e.g. caution wet floor. Trailing cables: Position equipment to avoid cables crossing pedestrian routes, use cable covers to securely fix to surfaces, restrict access to prevent contact. Remember that contractors will also need to be managed. If you see a problem, resolve or report it. Miscellaneous rubbish, e.g. plastic bags: Keep areas clear, remove rubbish on a continual basis and do not allow it to build up. Do not obstruct corridors of fire exits. Rugs/mats: Ensure mats are securely fixed and do not have curling edges. Ensure the mats are doing the job they were laid down for i.e. that they are not worn or breaking up. If rain water is being brought in from outside then the mat is not working correctly in absorbing it from shoes. Report this! Poor lighting: Report any areas that you think have poor lighting. Slippery surfaces: Assess the cause and treat accordingly, for example always keep them dry if wet causes the problem. Change from wet to dry floor surface: Provide suitable footwear, warn of risks by using signs and locate doormats where these changes are likely. November 2013 36 SAFETY POLICY STATEMENT Changes of level: Try to avoid. If you can’t, improve lighting, add high visible edgings to the step. Slopes: Improve visibility, provide hand rails, and use floor markings. Smoke/steam obscuring view: Eliminate or control it by redirecting it away from risk areas; improve ventilation and warn of it. Unsuitable footwear: Ensure you choose suitable footwear, particularly with the correct type of sole. If the type of work requires special protective footwear, the employer is required by law to provide it free of charge. * Preventing slips and trips at work. Health and Safety Executive (indg225.pdf) November 2013 37 SAFETY POLICY STATEMENT APPENDIX 12 Waste Management As a School we have taken on board the Universities scheme for recycling items. Around the School specific bins can be found to take paper, plastic bottles and tin cans for recycling organizing this is the PVAC faculty environmental coordinator, Mr. Michael Brooks. The latest information from the university regarding general and specific waste can be found by following this link. If anyone has any difficulty in accessing this site please contact Mr. Michael Brooks and he will be able to provide a paper copy for you. http://www.leeds.ac.uk/safety/waste/wstindex.htm In particular please read this section ../../My Pictures http://www.leeds.ac.uk/safety/waste/general/office.htm This lists the separate classes of waste and how to dispose of them. Please note now any electrical item with or without a plug (including simple printed circuit boards) should where possible be disposed of through this route. Contact details can be found here. Hazardous waste If you or your staff/students are producers any hazardous waste, think about what types of waste you are going to produce before you start on any work. Plan how you are going to handle the different classes of waste. Use the correct processes to handle the waste in a safe manner. Always refer to your COSHH assessment you have carried out on it and any MSDS that are available. Pack it appropriately, label the package with all the necessary hazard symbols and then arrange for its disposal through Mr Les Johnson. We have to pay to have the hazardous waste removed from the School. Chemicals and unknown materials If you find any chemicals or unknown materials also please contact the Schools safety supervisor who can then arrange for its disposal. We have to pay for the disposal of any unknown materials found in the school. November 2013 38 SAFETY POLICY STATEMENT Ordering chemicals Please think about waste disposal before placing an order. Only order what is required, therefore reducing the disposal needs. This helps both the safety and storage issues. It is better to have as small an amount of hazardous material as possible in the School at any one time. The chemical companies Fisher, Aldrich etc are very prompt with deliveries and in some cases they will deliver the next day if the substance is in stock. Chemicals have to be stored. They can be stored either on the shelves in laboratory 2-09, in flammable solvent cupboards, acid cupboard and toxic cupboard or in the outside flammable solvent store. In any case there is a finite amount of space available for the storage. We have to pay for the disposal of any unused chemicals or chemicals that are past their safe use by date from the school. Free samples The same philosophy needs to be applied to acquisition of so called “free samples”. The School has recently spent more on the disposal of these free samples than any other waste. Check with the company supplying you with the free sample and advise them of the quantity you need. If you do not tell them they sometimes find it easier to send out a standard commercial package that they have in stock which might be 25kg for example when you only need 50g of a sample. We have to pay for the disposal of any unused chemicals or chemicals that are past their safe use by date from the school. November 2013 39 SAFETY POLICY STATEMENT APPENDIX 13 Student field trips, visit to another institution Risk assessments for field trips need to be carried out by the team leader. This means any member of staff who instructs a student or students to work off campus has the responsibility of filling out a risk assessment. For example working off campus can be an organized visit to an institution, factory or any other site. This can be with organized transport or with them making their own way there. It can be for a few minutes, hours or days. As discussed in a PVAC Faculty Health and Safety Committee meeting the definition of working off campus would even apply if you give direction to a student to gather information for a project. An example of this would be if lecturer A tells student B that there is a very interesting tree at Hyde Park Moor and it would be useful for student B to sketch or photograph it for their course work then the lecturer is directing the student. Therefore a risk assessment is needed. If the student, without being give any direction, said look at this sketch of a tree I saw the other day I will use it for my work, then obviously this can not be risk assessed. But it would be appropriate to give a general warning to students who you know are inspired to work in this way. Field trip risk assessments can be written as a separate exercise or you can use the University tick box types. Links to the files for the different types of field trips are below, Visit to Institutions http://www.leeds.ac.uk/safety/ul_only/fieldw/visitpf.doc Visit to Rural sites http://www.leeds.ac.uk/safety/ul_only/fieldw/ruralpf.doc Visit to Urban sites http://www.leeds.ac.uk/safety/ul_only/fieldw/urbanpf.doc Forms are also available from the Schools safety supervisor. November 2013 40 SAFETY POLICY STATEMENT APPENDIX 14 Use of private cars for Leeds University business Staff, Please be aware that when you use your own vehicle for university business it is your responsibility to inform your insurance company of the fact. The mileage allowance received from the university takes this in to account. Advice for students. It is the student’s responsibility for arranging that the appropriate motor insurance when using private transport for University business. Please print out and fill in the form below. Confirmation of Adequate Motor Insurance To be completed when using private transport for University of Leeds business, including travel to and from coursework assignments. This form has to be filled in at the start of each semester. The department must be informed of any changes in details which may affect your insurance. Name of driver ……………………………………………………………….. Course………………………………………………………………………… Contact number……………………………………………………………….. Type of licence held…………………………………………………………… Car details Make…………………………. Model………………… Reg……………….. Policy details Insurance company…………………………………………………………………. Type of cover (comprehensive, Third party/Fire/Theft etc)……………………… Policy number………………………………………………………………………… Name of policy holder………………………………………………………………… Declaration I confirm that I have checked with my Insurance Company to ensure that I have sufficient cover, especially with regards to travel on University assignments, which some companies deem as business use. I confirm that any passengers are covered also under this policy. I further declare that I am licensed to drive the above vehicle and it satisfies Road Tax/MOT requirements. I also confirm that I will inform the department if any of my details change. I have read and understood this statement and accept all liabilities. Signed (student) Date Details checked by (supervisor) Date November 2013 41 SAFETY POLICY STATEMENT APPENDIX 15 Absence from work, holidays and working from home Here are the procedure for reporting absence from work due to sickness, booking holidays and working from home/off campus. It is essential that everyone observes these for health and safety, insurance purposes and for the school to be aware of the staff where about during working days. Regrettably, due to the above reasons the school manager will have no option but to report any unreported or unauthorised absence to HR. Absence from Work due to Sickness Members of staff should notify the School Office (tele: 0113 3433700 ) of any sickness absences before 10am, indicating when the illness began (including Saturdays and Sundays) the nature of illness and the probable date of return. Members of Staff should then contact their Line Manager or their Supervisor to ensure that they are aware of the absence. Members of staff who have lectures pending during their absence must ask staff in the School Office to post appropriate notes for the cancellation of lectures/tutorials etc. Any long term absence must also be brought to the attention of the Director of Learning and Teaching in order that alternative teaching arrangements may be considered. If the absence exceeds your estimated return date you must notify the School Office and your Line Manager or Supervisor as soon as possible. If the absence from work exceeds 7 days the member of staff should send a doctor’s sick note (to cover the whole period of absence) to Mrs. Jean Mitchell at the earliest opportunity. Please note that if you have been signed off sick by a doctor you must not return to work earlier than the date specified on the sick note. If you recover earlier than expected you need to go back to your doctor and obtain a return to work note so that the University is insured. Members of Staff will need to complete a ‘Personal Sickness Notification’ form on the day they return to work. It is essential that this form is completed following any period of absence, even if it only lasts for one day. It is also essential that this form is completed on the first day back at work following a period of absence. Failure to complete the form on your first day back at work may affect the payment of your salary. If Mrs. Jean Mitchell is not available please report your absence/return to work to Azim Abadi (0113 343 3712). November 2013 42 SAFETY POLICY STATEMENT Procedures for booking holidays Ensure you have someone to cover your role for the period of absence Complete the blue holiday book (a copy of this book resides in HR files, please see/email Mrs. Jean Mitchell about this) Request will be authorised by Line Manager and Head of School Annual leave entitlement will not normally be carried forward to succeeding years, but, subject to a discussion with the Head of Department, in individual cases the equivalent of one week’s annual leave entitlement may be carried forward, provided that it is taken by 31st March (Support staff) / 31st December (Academic and related staff). If you book a holiday and then find your circumstances have changed and the holiday is not going to be taken you must then cancel what you have booked to ensure that the holiday days are carried over. Failure to do so will result in HR assuming that this holiday has been taken. Staffs are requested to try to use up any annual leave if they have handed in their notice. In the event that there is some annual leave left over when leaving the University, this will be paid in the final salary. Mrs. Jean Mitchell will confirm the number of days left and then notify Payroll so that the payment can be processed. Where the termination arises on the expiry of a fixed-term appointment or on retirement, however, all due leave should be taken before the termination date. Working from Home/Off Campus Academic staff planning to work from home/off campus should contact Mrs. Jean Mitchell or the School office in advance and confirm the best way to contact them if the School needs to do so. If staff cannot be located, and they have not booked holidays or are absent from work due to sickness Jean / Azim will contact them. Health and Safety whilst working at home Human resources have produced guidelines for staff that need to work at home, here is the link http://www.leeds.ac.uk/hr/policy/documents/I(30).doc It contains essential information on risk assessments, electrical and other equipment workplace safety, first aid, stress, hazardous substances, vdu equipment at home and how to help your self. If anyone can not get access to this document see the School’s safety supervisor for a copy. November 2013 43 SAFETY POLICY STATEMENT APPENDIX 16 Contact telephone numbers For any emergency Security 32222 Non emergencies Security control 35494 Health and Safety Safety Advisory Services 34201 Health matters Occupational Health 32997 Staff Matters Human Resources 34146 University Staff Counsellor John Adams 0113 237 0309 Student Counselling Service 0113 3434107 Nightline (listening) 0113 3801381 Nightline for information 0113 3801380 School of Design Head Prof Chris Carr 33094 Safety Supervisor Mr Les Johnson 33702 School Manager Mr Azim Abadi 33712 Fire Officer Mr Mike Anderson 36335 November 2013 44 SAFETY POLICY STATEMENT APPENDIX 17 HEALTH AND SAFETY POLICY STATEMENT AMENDMENT RECORD Date Issue Amended By March 2003 2 Miss K Ledgerwood, Miss E Glover, Miss C Malkin, Mr D Bromilow September 2006 3 Mr Les Johnson September 2007 4 Mr Les Johnson October 5 Mr Les Johnson 6 Mr Les Johnson Comments/Details 2010 November 2013 Acknowledgements This manual was originally complied with the assistance of a number of colleagues, in particular Mr Les Johnson, Mrs Sandra Hassell, Dr Margaret Wilkinson and Mr John Pattinson. We would also like to thank the Department of Biochemistry & Molecular Biology, the School of Chemistry, and the Department of Electronic & Electrical Engineering, who’s Safety Manuals, form the basis of certain sections of this Manual. Also we would also like to thank to the Department of Food Science for the section on declaration of disability. This document was amended in March 2003 by Miss K Ledgerwood, Miss E Glover, Miss C Malkin and Mr D Bromilow. November 2013 45