SKF2711 - Faculty of Chemical Engineering, UTM

advertisement

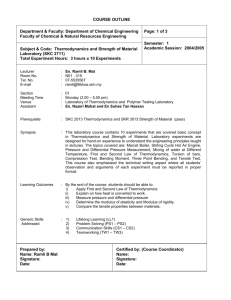

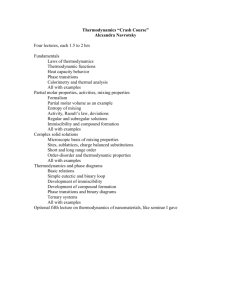

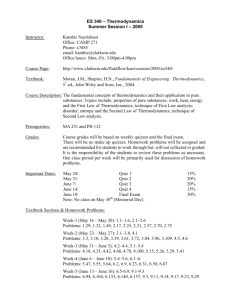

COURSE OUTLINE Department & Faculty: Department of Chemical Engineering Faculty of Chemical & Natural Resources Engineering Subject & Code: Thermodynamics and Material Engineering Laboratory (SKF 2711) Total Experiment Hours: 3 hours x 10 Experiments Page: 1 of 3 Semester: 2 Academic Session: 2005/2006 Lecturer Room No. Tel. No. E-mail : : : : Section Meeting Time Venue Assistant : : : : Prerequisite : SKC 2013 Thermodynamics and SKR 3013 Material Engineering (pass) Synopsis : This laboratory course contains 10 experiments that are covered basic concept in Thermodynamics and Strength of Material. Laboratory experiments are designed for hand-on experience to understand the engineering principles taught in lectures. The topics covered are: Marcet Boiler, Stirling Cycle Hot Air Engine, Pressure and Differential Pressure Measurement, Mixing of water at Different Temperature, First and Second Law of Thermodynamics, Torsion of bars, Compression Test, Bending Moment, Three Point Bending, and Tensile Test. This course also emphasized the technical writing aspect where all students’ observation and arguments of each experiment must be reported in proper format. Learning Outcomes : By the end of the course, students should be able to: i) Apply First and Second Law of Thermodynamics ii) Explain on how heat is converted to work. iii) Measure pressure and differential pressure iv) Determine the modulus of elasticity and Modulus of rigidity. v) Compare the tensile properties between materials. Generic Skills Addressed : Prepared by: Name: Signature: Date: 1) 2) 3) 4) Lifelong Learning (LL1) Problem Solving (PS1 – PS2) Communication Skills (CS1 – CS2) Teamworking (TW1 – TW3) Certified by: (Course Coordinator) Name: Signature: Date: COURSE OUTLINE Department & Faculty: Department of Chemical Engineering Faculty of Chemical & Natural Resources Engineering Subject & Code: Thermodynamics and Material Engineering Laboratory (SKF 2711) Total Experiment Hours: 3 hours x 10 Experiments Page: 1 2ofof3 3 Semester: 2 Academic Session: 2005/2006 Experiment Topic Learning Outcomes 1 Marcet Boiler It is expected that students will be able to: Study the relationship between the pressure and temperature of saturated steam Compare dT/dP measured with values calculated from data in steam tables. 2 Stirling Cycle Hot Air Engine It is expected that students will be able to: Study the effect of changing dynamometer load on engine speed Demonstrate on how heat is converted to work. 3 Pressure and Differential Pressure Measurement It is expected that students will be able to: Compare two methods of measuring pressure measure differential pressure using manometer. 4 Mixing of Water at Different Temperature It is expected that students will be able to: measure the final temperature of the mixing water at two different conditions demonstrate the energy balance (First Law of Thermodynamics). 5 First and Second Law of Thermodynamics It is expected that students will be able to: find the temperature changes of the hot and cold water. determine the amount of heat lost 6 Torsion of bars It is expected that students will be able to: investigate the relationship between torque (T) and the angle of twist () of a circular cross section specimen determine the (G) of materials Convert ladder diagram into program 7 Compression Test It is expected that students will be able to: determine the modulus of elasticity, E of materials in compression. To determine the ultimate strength in compression To compare the properties of materials in compression and in tension COURSE OUTLINE Department & Faculty: Department of Chemical Engineering Faculty of Chemical & Natural Resources Engineering Subject & Code: Thermodynamics and Material Engineering Laboratory (SKF 2711) Total Experiment Hours: 3 hours x 10 Experiments Module Topic Page: 13 of 3 Semester: 2 Academic Session: 2005/2006 Learning Outcomes 8 Bending Moment It is expected that students will be able to: comprehend the action of moment of resistance in a beam. measure the bending moment at a normal section of a loaded beam and to check its agreement with theory. 9 Three Point Bending It is expected that students will be able to: Determine the modulus of elasticity, E through bending. confirm the formula of simple beam theory observe the deflection of material subjected to pure bending Set proper simulation parameters Tensile Test It is expected that students will be able to: investigate the tensile properties of materials, such as yield stress, ultimate tensile strength, stress at failure, modulus of elasticity and also the percentage of elongation. compare the tensile properties between materials. 10 Teaching Methodology References Assessment : : Group Work and Discussion, Group Report 1. Wylen G.V. , Sonntag R.,and Borgnakke C., Fundamentals of Thermodynamics, 6th ed., John Wiley, New York, 2003 2. Yunus A. Çengel , Thermodynamics: An Engineering Approach, 4th ed, Mc Graw Hill, 2002. 30% exam and 70% group report. Students will be awarded points based on performance on their lab work as documented in their laboratory reports. Each group has to submit one Group Report for each module. Each lab report can earn a maximum score of 100 points broken down into the following categories: Abstract (10%), Introduction (10%), Theory (10%), Methodology (10%), Result and discussion (40%), Conclusion (10%) and Format (10%).