NOTE: If the swing of the arc of any boom is within 100 ft. of any

advertisement

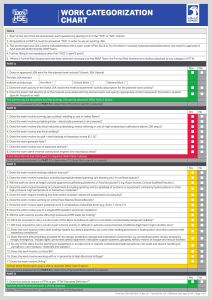

Opening Process Equipment - Tier 1 Best Practice Quick Reference List Site: Date: Level 1 Level 2 Completed By: Description of Work: Equipment and Tools Description 1) Are blinds or "double block & bleed" used as the preferred method of isolation for work? 2) Is an "Opening Process Equipment Permit" in place for the installation of blinds? 3) Are cutting/drilling tools & procedures appropriate for the work conditions? 4) Are isolation blinds suitable for the anticipated pressure? Yes No N/A Comments N/A Comments Systems Description 5) Is an "Opening Process Equipment Permit" in place? 6) Were the equipment isolation points "positively identified" including valves to be closed, blind locations and drains/bleeders? Each should be discretely tagged (i.e. numbered). 7) Was equipment containing hydrocarbon or hazardous/toxic material emptied, flushed clean and purged? 8) Are deadlegs & lowpoints appropriately considered with evidence that flushing/purging was effective? 9) For equipment that does not meet the 2 requirements above, is there a written procedure in place? For equipment that cannot be positively isolated, is there a "specific to this exact job" written procedure, risk assessment, JSA and approval to open? Using a standard site SOP or the checklist on an "Opening Process Equipment Permit" does not meet this test. For working behind a single block valve, is there a "specific to this exact job" written procedure, risk assessment, JSA and approval to open? Using a standard site SOP or the checklist on an "Opening Process Equipment Permit" does not meet this test. Is the exact location of the equipment/line break positively identified on the field (i.e. painted/numbered tag) and documented on the permits? Did the process technician verify that the equipment was positively isolated (i.e. no leakage) within 3 hours of the equipment break? Verify signatures. 10) 11) 12) 13) Yes No 14) Is the appropriate PPE identified on the permit and being used? 0302F49 February 2014 Page 1 of 2 Opening Process Equipment - Tier 1 Best Practice Quick Reference List People Description Yes No N/A Comments 15) Are nearby workers aware that process equipment is being opened? 16) Is safe egress from the work site provided? 17) Were specific exposures considered (benzene, acids/caustics, NORM, etc.)? 18) Is the equipment prepared in a way so as to minimize the required PP&E? If you answered “No” to any question, please provide details: 0302F49 February 2014 Page 2 of 2