accident reporting and investigation program

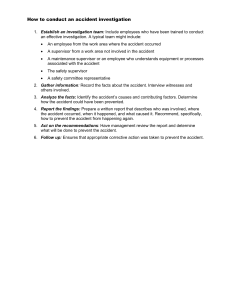

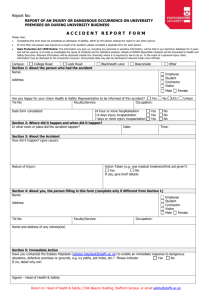

advertisement

ACCIDENT/INCIDENT REPORTING AND INVESTIGATION PROGRAM Environmental Health and Safety The University of South Carolina Columbia Campus Safety and Health Training A key factor for the safe conduct of work is safety and health training. It is also important to note that safety training should be accomplished for all levels of employees (i.e. worker, supervisor, middle management, top management) so that everyone knows the nature and extent of the hazards they work with and their roles and responsibilities for establishing and maintaining safe work conditions. Training is an especially important aspect of safety and health programs since one of the most common causes of unsafe acts is a lack of knowledge or information. Accident prevention must involve everyone in the Environmental Health and Safety department. The two absolutely essential elements of accident prevention are management commitment and training. An example of this idea is listed below with the underlying accident causes (real reasons) indicated in parentheses after each accident investigation statement: • Didn't follow instructions (Training). • Blundered ahead when he didn't know how to do the job (Training). • By-passed a safety rule to save time (Training and Supervision). • Failed to wear required personal protective equipment (Training and Supervision). • Didn't think ahead to possible consequences (Training and Job Safety Analysis). • Used the wrong equipment for the job (Training). • Used the correct equipment improperly (Training). • Used equipment that needed repair or replacement (Management). • Failed to use equipment guards or protective devices (Management). Management involvement would require, among other things, quality assessment of training programs and enforcement of safety rules. If safety is not recognized as a management responsibility, then it will not be perceived by employees as an important part of their job. In some cases, behavior modification of all individuals involved may be required to ensure this emphasis. Accident Reporting Policy It is necessary to report every accident in order to learn the cause and adopt proper methods to prevent any similar accident. Any accident that requires more than minor EHS-M-36 Destroy Previous Revisions Page 2 Issue Date: 8/18/10 Approved By: BH first aid at the work site or that results in lost work time must be recorded in the OSHA 300 log. It is the policy of the Environmental Health and Safety that all employees follow the established accident reporting procedures as follows: • Employees will report all accidents, injuries, near misses and property damage immediately to their supervisor. • The supervisor, upon report of an accident, will immediately administer appropriate first aid or ensure employee(s) receives the necessary medical attention. • The supervisor will assure the area and/or equipment in the accident environment is properly secured until the accident investigation has been completed. Accident Investigation Policy Although the Environmental Health and Safety department strives to be a safe and healthy environment, it is impossible to prevent every accident from occurring. Accident investigations are made to determine how and why these failures in the system happen, not to place blame on any one person or department. By using information found during an investigation, a similar or perhaps more serious accident may be prevented. It is the duty of the immediate supervisor to perform accident and incident investigations. Accident Investigation Accidents should be investigated as soon as possible after their occurrence (except when it delays medical treatment or the person involved is distraught). The longer the period of delay in the investigation, the more likely is the chance of witnesses not remembering the facts of the accident. Normally, the immediate supervisor should be the one to do the initial investigation because of his or her knowledge of the employees, equipment, and work practices in the area. There are five main methods of gathering accident information: (1) interviewing the accident victim, (2) interviewing accident witnesses, (3) investigation of the accident scene, (4) re-enactment of the accident, and (5) reconstruction of the accident. Interviewing the accident victim Interviewing the employee that has the accident will probably be the most important means of getting the facts on the accident that occurred. It is extremely important that the interviewer not attempt to assign blame or create a negative feeling in the employee that had the accident. The interview should be conducted in a positive fashion otherwise the "facts" of the case may become very biased or unclear as the employee senses that the interview is "looking for someone to blame." It is suggested that the interviewer not complete the accident report until after the investigation is finished. It is also suggested that the interviewer take notes and review the accident facts as known with the accident victim. The employee should be asked if the facts that have been recorded are correct. If the accident facts do not appear to be clear or reasonable, consider a second interview EHS-M-36 Destroy Previous Revisions Page 3 Issue Date: 8/18/10 Approved By: BH with the employee after a reasonable time for the employee to think about the occurrences. Finally, the interviewer should ask the accident victim his/her opinions concerning measures that should be taken to prevent a recurrence of the accident. Interviewing accident witnesses Many accidents will require the interviewing of witnesses to the accident. The accuracy of a fatality report, for example, relies heavily on the ability to gather information from witnesses. Witnesses need not be limited to those persons actually at the scene of the accident when it occurred, but should include others who might know of the circumstances relating to the accident. Most of the principles for interviewing the witnesses are the same as those for the accident victim. They are: • Interview the witnesses as promptly as possible after the accident. • Interview the witnesses separately. • Reassure the witnesses of the positive nature of the investigation and the desire to conduct the investigation to prevent a recurrence of the accident. • Do not interrupt the witnesses unless specific clarification is needed and, again, do not assign blame. • Ask the witnesses for their opinions on ways to prevent a recurrence of the accident. Investigation of the accident scene It is important for the accident scene to remain untouched until after the accident investigation. If this is not possible, photographs or video can be taken of the area to attempt to record physical conditions immediately after the accident. It is also recommended that the victim and witnesses be interviewed (separately) at the scene of the accident if possible. Areas of special attention when investigating the scene of the accident are the lighting, condition of the working and walking areas, machinery guards, etc. Re-enactment of the accident Under some circumstances, it may be desirable to re-enact the accident, especially if the causes for the accident are not clear. This can involve the employee or witnesses if appropriate. Obviously, it is very important that precautions be taken to prevent the accident from being repeated. Reconstruction of the accident If the accident victim cannot be interviewed and there are no witnesses, it will be necessary to attempt to reconstruct the accident based on the information available. This EHS-M-36 Destroy Previous Revisions Page 4 Issue Date: 8/18/10 Approved By: BH situation may require the assistance of expert help from an outside consultant. It may also involve a regulatory agency, such as OSHA. Information obtained in the accident investigation should be used to develop plans and to change operations to prevent a more serious recurrence. The findings from the accident investigation should be recorded on an accident report form. Additionally, a serious injury or fatality will require a more detailed investigation than indicated by the one page supervisor's report form although the overall approach should be the same. Completing the Accident Report Form Description of the injury or illness Provide a brief description of the injury or illness and the body part(s) involved. State briefly the facts of the accident including the location, time of occurrence, equipment involved, etc… Include the estimate of the lost work time caused by the accident. (For example: Broken leg and cracked ribs. Estimate of three months off the job. Employee being treated at the Palmetto Baptist Hospital in Columbia by Dr. Smith.) Employee's remarks This section is intended for the employee to provide his/her description and analysis of the accident. This should include suggestions for eliminating the cause(s) of the accident. If the employee is unable to complete this section because of the accident, all other sections should be completed and the section left blank until the employee is able to provide this information. A separate sheet with typed or hand written remarks may also be attached for this purpose. Unsafe acts/conditions causing the accident/illness This section should be completed by the supervisor listing all the factors that may have contributed to the accident/illness. Corrective actions taken Identify the specific actions that need to be completed and the estimated schedule for completion. The person responsible for the action should also be listed. Many times the corrective action will include formal or on-the-job training for the employee. EHS-M-36 Destroy Previous Revisions Page 5 Issue Date: 8/18/10 Approved By: BH Corrective Actions The accident investigation will usually yield a cause or causes for the accident and measures that will reduce the likelihood of a recurrence. Accident reports that include such statements as, "...caused by carelessness---accident prone employee---caused by a stupid employee mistake---not paying attention when he/she should have been..." should not be accepted since they indicate an incomplete investigation and a lack of understanding of the causes of accidents. While it is true that most accidents are caused by an unsafe employee act, it is equally true that measures can be taken to lessen the chance of these acts recurring. Correction of conditions that lead to an accident the responsibility of the department supervisor, the Director of Environmental Health and Safety and the EMS Core Group. These individuals will also be used for the actual accident investigation. One copy of the supervisor's accident report must be sent to the Human Resources Department in accordance with OSHA regulations. EHS-M-36 Destroy Previous Revisions Page 6 Issue Date: 8/18/10 Approved By: BH 1. Employee Information Employee Name Type (Check box) Department Date Job Title Supervisor 2. Related Specific Information Time Location / Work Area Shift Near Miss First Aid Medical Treatment Fatality Other 3. Visible Surface Cause – What caused the incident / accident to occur? 4. Root Cause Analysis (check all that apply) Unsafe Acts Unsafe Conditions System Deficiency(ies) Improper work technique Poor workstation design or layout Lack of written procedures Safety policy violation Congested work area Safety policies not enforced Improper PPE / PPE not used Hazardous substances Hazards not identified Operating without permit Fire or explosion hazard PPE unavailable Failure to warn or secure Inadequate ventilation Insufficient worker training Operating at improper speeds Improper material storage Insufficient supervisor training By-passing safety devices Improper tool or equipment Improper maintenance Guards not used Insufficient knowledge of job Inadequate supervision Improper loading or placement Slippery conditions Inadequate job planning Improper lifting Poor housekeeping Inadequate hiring practices Servicing machinery in motion Excessive noise Inadequate workplace inspection Horseplay Inadequate guarding of hazards Inadequate equipment Drug or alcohol use Defective tools/equipment Unsafe design or construction Unnecessary haste Insufficient lighting Unrealistic scheduling Unsafe act of others Inadequate fall protection Poor process design Other (specify): Other (specify): Other (specify): 5. Analysis – Why did this occur? (Answer the question of why five times) Why Why Why Why Why 6. Required Corrective / Preventative Actions Action Item Detail Title 7. Required Concurrences Print Name Signature Responsible Party Target Date Date Investigator / Supervisor Department Manager Department Safety Manager EHS-F-140 EHS-M-36 Page 1 Destroy Previous Revisions Destroy Previous Revisions Page 7 Issue Date: 8/18/10 Approved by: BH Issue Date: 8/18/10 Approved By: BH Determine The Root Cause: 5 Whys Asking "Why?" may be a favorite technique of your three year old child in driving you crazy, but it could teach you a valuable Six Sigma quality lesson. The 5 Whys is a technique used in the Analyze phase of the Six Sigma DMAIC methodology. It's a great Six Sigma tool that doesn't involve data segmentation, hypothesis testing, regression or other advanced statistical tools, and in many cases can be completed without a data collection plan. By repeatedly asking the question "Why" (five is a good rule of thumb), you can peel away the layers of symptoms which can lead to the root cause of a problem. Very often the ostensible reason for a problem will lead you to another question. Although this technique is called "5 Whys," you may find that you will need to ask the question fewer or more times than five before you find the issue related to a problem. Benefits Of The 5 Whys Help identify the root cause of a problem. Determine the relationship between different root causes of a problem. One of the simplest tools; easy to complete without statistical analysis. When Is 5 Whys Most Useful? When problems involve human factors or interactions. In day-to-day business life; can be used within or without a Six Sigma project. How To Complete The 5 Whys 1. Write down the specific problem. Writing the issue helps you formalize the problem and describe it completely. It also helps a team focus on the same problem. 2. Ask Why the problem happens and write the answer down below the problem. 3. If the answer you just provided doesn't identify the root cause of the problem that you wrote down in step 1, ask Why again and write that answer down. 4. Loop back to step 3 until the team is in agreement that the problem's root cause is identified. Again, this may take fewer or more times than five Whys. 5 Whys Examples Problem Statement: Customers are unhappy because they are being shipped products that don't meet their specifications. 1. Why are customers being shipped bad products? - Because manufacturing built the products to a specification that is different from what the customer and the sales person agreed to. 2. Why did manufacturing build the products to a different specification than that of sales? - Because the sales person expedites work on the shop floor by calling the head of manufacturing directly to begin work. An error happened when the specifications were being communicated or written down. 3. Why does the sales person call the head of manufacturing directly to start work instead of following the procedure established in the company? - Because the "start work" form requires the sales director's approval before work can begin and slows the manufacturing process (or stops it when the director is out of the office). 4. Why does the form contain an approval for the sales director? EHS-M-36 Destroy Previous Revisions Page 8 Issue Date: 8/18/10 Approved By: BH - Because the sales director needs to be continually updated on sales for discussions with the CEO. In this case only four Whys were required to find out that a non-value added signature authority is helping to cause a process breakdown. Let's take a look at a slightly more humorous example modified from Marc R.'s posting of 5 Whys in the iSixSigma Dictionary. Problem Statement: You are on your way home from work and your car stops in the middle of the road. 1. Why did your car stop? - Because it ran out of gas. 2. Why did it run out of gas? - Because I didn't buy any gas on my way to work. 3. Why didn't you buy any gas this morning? - Because I didn't have any money. 4. Why didn't you have any money? - Because I lost it all last night in a poker game. 5. Why did you lose your money in last night's poker game? - Because I'm not very good at "bluffing" when I don't have a good hand. As you can see, in both examples the final Why leads the team to a statement (root cause) that the team can take action upon. It is much quicker to come up with a system that keeps the sales director updated on recent sales or teach a person to "bluff" a hand than it is to try to directly solve the stated problems above without further investigation. 5 Whys And The Fishbone Diagram The 5 Whys can be used individually or as a part of the fishbone (also known as the cause and effect or Ishikawa) diagram. The fishbone diagram helps you explore all potential or real causes that result in a single defect or failure. Once all inputs are established on the fishbone, you can use the 5 Whys technique to drill down to the root causes. Take-Away Quotation "If you don't ask the right questions, you don't get the right answers. A question asked in the right way often points to its own answer. Asking questions is the ABC of diagnosis. Only the inquiring mind solves problems." -- Edward Hodnett Root Cause An identified reason for the presence of a defect or problem. The most basic reason, which if eliminated, would prevent recurrence. The source or origin of an event. ---------A root cause of a consequence is any basic underlying cause that was not in turn caused by more important underlying causes. (If the cause being considered was caused by more important underlying causes, those are candidates for being root causes.) EHS-M-36 Destroy Previous Revisions Page 9 Issue Date: 8/18/10 Approved By: BH