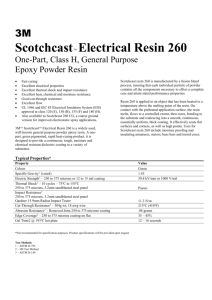

3M - Resin Technical Systems

advertisement

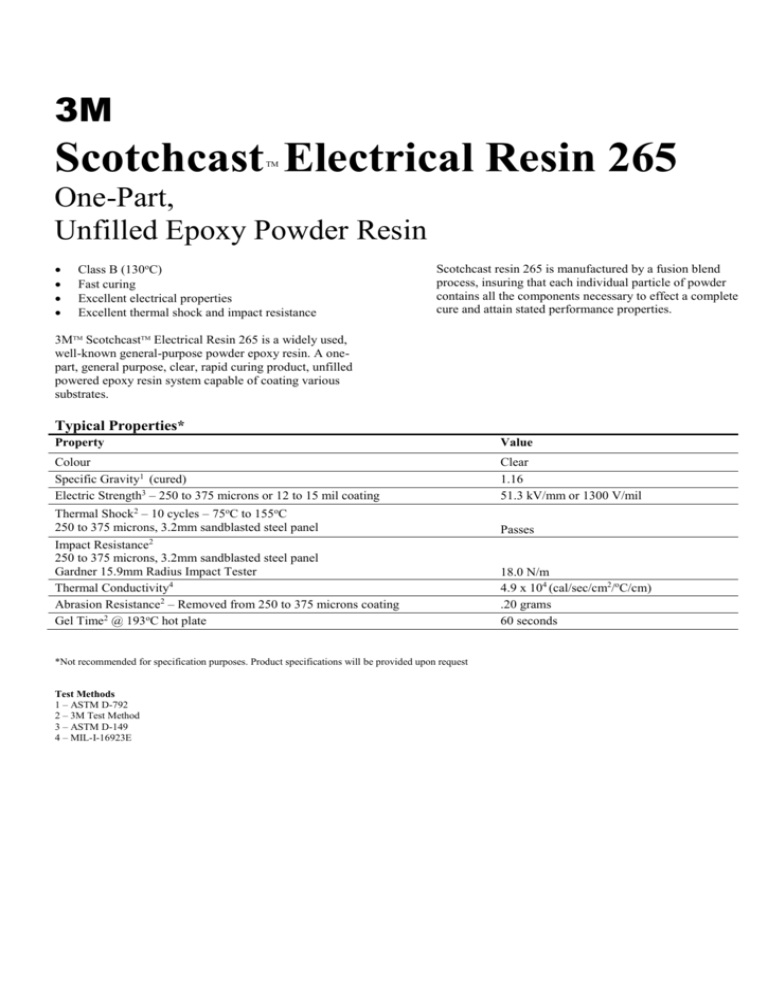

3M Scotchcast Electrical Resin 265 TM One-Part, Unfilled Epoxy Powder Resin Class B (130oC) Fast curing Excellent electrical properties Excellent thermal shock and impact resistance Scotchcast resin 265 is manufactured by a fusion blend process, insuring that each individual particle of powder contains all the components necessary to effect a complete cure and attain stated performance properties. 3MTM ScotchcastTM Electrical Resin 265 is a widely used, well-known general-purpose powder epoxy resin. A onepart, general purpose, clear, rapid curing product, unfilled powered epoxy resin system capable of coating various substrates. Typical Properties* Property Value Colour Specific Gravity1 (cured) Electric Strength3 – 250 to 375 microns or 12 to 15 mil coating Clear 1.16 51.3 kV/mm or 1300 V/mil Thermal Shock2 – 10 cycles – 75oC to 155oC 250 to 375 microns, 3.2mm sandblasted steel panel Impact Resistance2 250 to 375 microns, 3.2mm sandblasted steel panel Gardner 15.9mm Radius Impact Tester Thermal Conductivity4 Abrasion Resistance2 – Removed from 250 to 375 microns coating Gel Time2 @ 193oC hot plate *Not recommended for specification purposes. Product specifications will be provided upon request Test Methods 1 – ASTM D-792 2 – 3M Test Method 3 – ASTM D-149 4 – MIL-I-16923E Passes 18.0 N/m 4.9 x 104 (cal/sec/cm2/oC/cm) .20 grams 60 seconds Usage Information Method of Application Coating is accomplished by using either standard or electrostatic spraying or fluid bed techniques. Before application of the powder, the part to be coated must be heated to a temperature above the melting point of the resin. On contact with heated article, the resin melts, flows out and bonds to the substrate. The powder can be applied electrostaically to either a hot or cold part. A post cure is usually required to cure the product fully. Conventional varnish and trickle impregnation resins used for wire holding and anchoring of performed coil windings can be replaced by ScotchcastTM Resin 265 in applications where only impregnation of the outermost windings is required. Fluid bed dipping is the most common means of applying the powder in this type of application. Preheating of the coils can be accomplished by conventional means of by resistance heating. The latter allows for selective deposition of the powder on only the windings. Self-support coils can also be fabricated using this resin, thereby eliminating the need for bobbins, strapping and taping. In such a coil winding application, wire is run through a 15-20% solution of resin 265 in acetone. (In using solvents, care must be exercised as recommended by their supplier to prevent health of flammability hazards.) After a solvent flash, the individual laminations can be handled and stacked as if they were bare laminations. Completed stacks can then be bonding using only contact pressure and heat. Bonding of stator, rotor and transformer laminations is another use ScotchcastTM Resin 265. The advantages are the elimination of bolts, rivets, pins and welds and the reduction of eddy currents and operating noise. A 15-20% solution of resin 265 in acetone is applied to individual laminations before stacking. After a solvent flash, the individual laminations can be handled and stacked. Curing The cure of resin 260 to a thermoset condition involves a time/temperature relationship. The figures opposite indicate the temperature and time necessary to obtain the resin’s adhesion impact and chemical resistance characteristics. Time does not include that required to reach the cure temperature. The user must determine the time required for the coated substrate to reach listed temperatures. Preheated Temperature Range Prior to applying resin 265, the part must be preheated to a temperature ranging from 163oC (325oF) to 232oC (450oF). The optimum preheat temperature depends upon the size, heat capacity and configuration of the object to be coated, as well as the method of application. The ideal coating temperature will vary for each application and is best determined by experimentation. Handling and Safety Precautions Read all Health Hazard, Precautionary, and First Aid statements found in the Material Safety Data Sheet and/or product label of chemicals prior to handling or use. Storage Laboratory evaluation indicates that the usable shelf life of this product is twenty four months (24) from the date of manufacture when stored at temperatures not exceeding 27oC (80oF), providing the material is stored in its original container. Care should be taken when removing resin form the original shipping container to prevent inclusion of foreign material. After resin removal, the bag should be retired immediately. This will help to avoid agglomeration caused by excess moisture. For best results, store in a cool, dry place. Important Notice Technical information provided by 3M is based on experience and/or tests believed to be reliable but their accuracy is not guaranteed and the results may not be relevant to every user’s application. Cure Temperature 149oC (300oF) 177oC (350oF) 204oC (400oF) 232oC (450oF) Time 30 minutes 10 minutes 30 seconds 20 seconds For this reason 3M does not accept responsibility or liability, direct or consequential, arising from reliance upon any information provided and the user should determine the suitability of the products for their intended use. Nothing in this statement will be deemed to exclude or restrict 3M’s liability for death or personal injury arising from its negligence. All questions of liability relating to 3M products are governed by the seller’s terms of sale subject where applicable to the prevailing law. If any goods supplied or processed by or on behalf of 3M prove on inspection to be defective in material or workmanship, 3M will (at its option) replace the same of refund to the Buyer the price of the goods or services. Except as set out above, all warranties and conditions, whether express or implied, statutory or otherwise are excluded to the fullest extent permissible at law. 3M is a trademark. Printed in the UK. Copyright 3M United Kingdom PLC 3M Electronics & Insulation Group 3M United Kingdom PLC 3M HOUSE, P.O. Box 1 Market Place, Bracknell Berkshire RG12 1JU Tel: +44 1344 858000 Fax: *44 1344 858278 3M Ireland 3M House, Adelphi Centre Upper Georges Street Dun Laoghaire, Co. Dublin Tel: +353 1 2803555 Fax: +353 1 2803509 3M Belgium N.V.S.A. Hermeslaan 7 B-1831 Diegem Belgium Tel: +32 2 722 5276 Fax: +32 3 722 5012 3M Netherland B.V. P.O. Box 193 2300 AD Leiden The Netherlands Tel: +31 71 545 0364 Fax: +31 71 545 0378