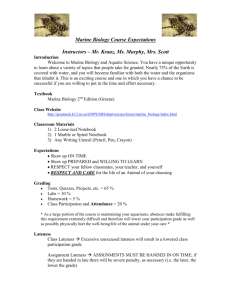

mt_f02_431_soln - University of Windsor

advertisement

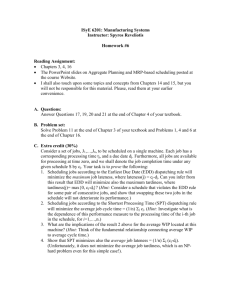

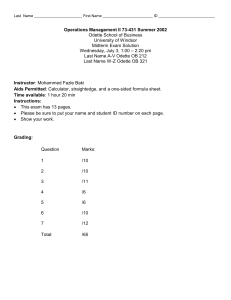

Last Name _______________________ First Name ________________________ ID ___________________________

Operations Management II 73-431 Fall 2002

Odette School of Business

University of Windsor

Midterm Exam Solution

Wednesday, October 23, 1:00 – 2:20 pm Odette B04

Instructor: Mohammed Fazle Baki

Aids Permitted: Calculator, straightedge, and a one-sided formula sheet.

Time available: 1 hour 20 min

Instructions:

This exam has 11 pages including this cover page.

Please be sure to put your name and student ID number on each page.

Show your work.

Grading:

Question

Marks:

1

/10

2

/8

3

/5

4

/6

5

/6

6

/8

7

/5

8

/8

9

/9

Total:

/65

Last Name _______________________ First Name ________________________ ID ___________________________

Question 1: (10 points)

1.1 In a job shop

a. Machines are grouped functionally

b. Machines are arranged in the sequence in which every job visits the machines

c. Production is initiated by the customer order

d. Production is initiated by the demand forecast

e. a and c

f. b and d

1.2 If the major concern of a production plant is utilities, a more appropriate scheduling objective is to

minimize

a. makespan

b. total completion time

c. average lateness

d. maximum lateness

e. average tardiness

f. maximum tardiness

1.3 In a static scheduling

a. the processing times are not known

b. the processing times are all 1

c. the arrival times are not known

d. the arrival times are all zero

e. for every job, flow time is the same as its completion time

f. d and e

1.4 If a schedule minimizes total completion time, the schedule also minimizes

a. mean completion time

b. total lateness

c. mean lateness

d. all of the above

e. b and c

f. none of the above

1.5 Which of the following is the most appropriate?

a. EDD rule minimizes total completion time

b. SPT rule minimizes maximum lateness

c. If a schedule minimizes maximum lateness, then the schedule also minimizes

maximum tardiness

d. If a schedule minimizes maximum tardiness, then the schedule also minimizes maximum

lateness

e. c and d

f. None of the above

1.6 Which of the following is the most appropriate?

a. A Gantt chart shows time on the y-axis and resources on the x-axis

2

Last Name _______________________ First Name ________________________ ID ___________________________

b.

c.

d.

e.

f.

In a Gantt chart the length of each rectangle is proportional to the processing time

Every rectangle in a Gantt chart corresponds to a worker, a machine, or a tool

All of the above

b and c

None of the above

1.7 For a three-machine flow-shop problem, makespan can be minimized by an extension of the

Johnson’s rule if

a. Machine 1 or Machine 2 dominates Machine 3

b. Machine 2 or Machine 3 dominates Machine 1

c. Machine 3 or Machine 1 dominates Machine 2

d. Machine 1 and Machine 2 dominate Machine 3

e. Machine 2 and Machine 3 dominate Machine 1

f. Machine 3 and Machine 1 dominate Machine 2

1.8 For a stochastic 2-machine parallel processing problem with processing time exponentially

distributed, the expected makespan is minimized by

a. shortest expected processing time rule

b. longest expected processing time rule

c. earliest expected due date rule

d. Johnson’s rule

e. Lawler’s rule

f. c rule

1.9 For a critical activity,

a. ES=LS

b. EF=LF

c. Slack=0

d. all of the above

e. a and b

f. none of the above

1.10

a.

b.

c.

d.

e.

f.

A supply chain comprises

suppliers

manufacturers

suppliers and their suppliers

manufacturers and their manufacturers

all the stages at which value is added in producing and delivering a product or service

a and b

3

Last Name _______________________ First Name ________________________ ID ___________________________

Question 2: (8 points)

Three trucks, 1, 2 and 3 will be unloaded at a loading dock at XYZ Company that has only a single

service bay. The trucks are labelled in the order that they are scheduled to arrive at the dock.

Assume that the current time is 2:00 pm. The times required to unload each truck and the times that

the goods they contain are due in the plant are given in the table below:

Truck

Scheduled Arrival Time

Unloading Time

Time Material is Due

1

2:00 pm

15 minutes

2:40 pm

2

2:05 pm

30 minutes

2:50 pm

3

2:10 pm

20 minutes

2:45 pm

Determine the schedule for the SPT rule and compute various performance measures as indicated

in the worksheet below.

Truck

Scheduled

Arrival

Time

(Minutes)

Processing

Time

(Minutes)

Due Date

(Minutes)

Completion

Time

(Minutes)

Flow

Time

(Minutes)

Lateness

(Minutes)

Tardiness

(Minutes)

1

0

15

40

0+15=15

15-0=15

15-40=-25

max(0,-25)=0

3

10

20

45

15+20=35

35-10=25

35-45=-10

max(0,-10)=0

2

5

30

50

35+30=65

65-5=60

65-50=15

max(0,15)=1

5

Total

115

100

-20

15

Maximum

65

60

15

15

Write the values of various performance measures in the space shown below:

a. (1 point) Makespan

65

b. (1 point) Total completion time

115

c. (1 point) Maximum flowtime

60

d. (1 point) Total flowtime

100

e. (1 point) Maximum lateness

15

f. (1 point) Maximum tardiness

15

g. (1 point) Total tardiness

15

h. (1 point) Number of tardy jobs

1

4

Last Name _______________________ First Name ________________________ ID ___________________________

Question 3: (5 points)

Three trucks, 1, 2 and 3 are waiting at a loading dock at XYZ Company that has only a single

service bay. Assume that the current time is 2:00 pm. The times required to unload each truck and

the times that the goods they contain are due in the plant are given in the table below:

Truck

Unloading Time

Time Material is Due

1

15 minutes

2:40 pm

2

30 minutes

2:50 pm

3

20 minutes

2:45 pm

Determine the schedule for the Critical Ratio (CR) rule.

Current Time

0

Truck

Unloading Time

(Minutes)

Due Date

(Minutes)

Critical Ratio

Assign?

1

15

40

(40-0)/15=2.67

No

2

30

50

(50-0)/30=1.67

Yes

3

20

45

(45-20)=2.25

No

Current Time

30

Truck

Unloading Time

(Minutes)

Due Date

(Minutes)

Critical Ratio

Assign?

1

15

40

(40-30)/15=0.67

Yes

3

20

45

(45-30)/20=0.75

No

Write your final CR sequence here: 2-1-3

Marking Scheme:

CR formula and computed values

2 points

Assignment rule (assign the job with the least CR to the beginning) 2 points

Final sequence

1 point

5

Last Name _______________________ First Name ________________________ ID ___________________________

Question 4: (6 points)

Irving Bonner, an independent computer programming consultant, has contracted to complete four

computer programming jobs.

Job

Time required (days)

Due date (days)

1

8

17

2

10

15

3

9

30

4

12

21

a. (4 points) Find a sequence in which he should be performing the jobs in order to minimize the

number of tardy jobs.

Step 1: Arrange the jobs in the EDD order. (1 point)

Job

(EDD order)

Processing

time (days)

Completion

time (days)

Due date

(days)

Lateness

(Days)

Tardy?

2

10

10

15

-5

No

1

8

18

17

1

Yes

4

12

30

21

9

Yes

3

9

39

30

9

Yes

Step 2: The first job tardy is Job 1. (1 point) Eliminate the longest job (Job 2) on or before the

first job tardy (Job 1). (1 point) Arrange the remaining jobs in the EDD order.

Job

(EDD order)

Processing

time (days)

Completion

time (days)

Due date

(days)

Lateness

(Days)

Tardy?

1

8

8

17

-9

No

4

12

20

21

-1

No

3

9

29

30

-1

No

Step 3: No job tardy. Stop. Append the previously eliminated job(s) in the end (in any order)

Final sequence: 1-4-3-2 (1 point)

b. (2 points) What is the minimum number of tardy jobs?

Only one job (Job 2) is eliminated in Part a. Hence one job is tardy. See below for detail.

Job

(EDD order)

Processing

time (days)

Completion

time (days)

Due date

(days)

Lateness

(Days)

Tardy?

1

8

8

17

-9

No

4

12

20

21

-1

No

3

9

29

30

-1

No

2

10

39

15

24

Yes

6

Last Name _______________________ First Name ________________________ ID ___________________________

Question 5: (6 points)

The following four jobs must be processed through a three-machine flow shop.

Machine

Job

A

B

C

1

5

4

9

2

6

5

9

3

6

1

10

4

8

2

6

a. (4 points) Find the optimal sequence of the jobs in order to minimize the makespan.

Step 1: Construct a fictitious 2-machine flow shop problem.

Job

Processing time on Machine 1

Processing time on Machine 2

1

5+4=9

4+9=13

2

6+5=11

5+9=14

3

6+1=7

1+10=11

4

8+2=10

2+6=8

Step 2: Find the optimal sequence for the fictitious 2-machine flow shop problem.

Among all operations, min processing time = 7 on M1 for J3. So, Assign Job 3 in the beginning.

3

Remove Job 3. Among the remaining operations, min processing time = 8 on Machine 2 for Job

4. So, Assign Job 4 in the end.

3

4

Remove Job 4. Among the remaining operations, min processing time = 9 on Machine 1 for Job

1. So, Assign Job 1 in the beginning.

3

1

4

Remove Job . Among the remaining operations, min processing time = 11 on Machine 1 for Job

2. So, Assign Job 2 in the end.

3

1

2

4

b. (2 points) What is the makespan of the resulting schedule? As shown below makespan is 41.

Job

Machine A

Machine B

Machine C

Start

Process

End

Start

Process

End

Start

Process

End

3

0

6

6

6

1

7

7

10

17

1

6

5

11

11

4

15

17

9

26

2

11

6

17

17

5

22

26

9

35

4

17

8

25

25

2

27

35

6

41

7

Last Name _______________________ First Name ________________________ ID ___________________________

Question 6: (8 points)

A production facility assembles inexpensive telephones on a production line. The assembly requires

5 tasks with precedence relationships and activity times in minutes are shown below:

17

D

E

10

A

B

C

12

11

8

a. (2 points) For each task compute positional weight and rank

Task

Positional Weight

Rank

A

12+11+8+10=41

1

B

11+8+10=29

2

C

10+8=18

4

D

10+17=27

3

E

10

5

b. (2 points) According to the ranked positional weight method what is the assembly line balancing

solution if the cycle time is 30 minutes?

Step 1: Assign A to Station 1: {A}12

Step 2: Assign B to Station 1: {A,B}12+11=23

Step 3: D does not fit in Station 1. Assign D to Station 2: {A,B}12+11=23 {D}17

Step 4: Assign C to Station 2: {A,B}12+11=23 {C,D}17+8=25

Step 5: E does not fit in Station 2. Assign E to Station 3: {A,B} 12+11=23 {C,D}17+8=25 {E}10

c. (2 points) If the cycle time is 30 minutes, what is the theoretical minimum number of station?

Theoretical minimum number of workstations

12 11 8 17 10 58

=

30 1.93 2

30

d. (2 points) Can you find a line balancing solution with the theoretical minimum number of stations

(assume 30 minute cycle time) by eye inspection? Is this solution better than the one obtained by

the ranked positional weight method?

Station 1: {A,D}12+17=29, Station 2:{B,C,E}11+8+10=29

For a cycle time of 30 min, the solution in part d is better as it has fewer workstations.

8

Last Name _______________________ First Name ________________________ ID ___________________________

Question 7: (5 points)

A project consisting of six activities satisfies the following precedence constraints:

Activity

Immediate Predecessors

A

-

B

-

C

A

D

A,B

E

B,C

Construct a network for the project. Use activity on arc method. Use maximum two pseudo (dummy)

activities.

A

2

C

4

1

B

3

D

E

5

Marking scheme:

1 point off for violation of each precedence constraint and network construction rule.

Note: 5 rules of network construction:

1. Start node

2. Finish node

3. Arc from node labelled low to node labelled high

4. Every activity represented by exactly one arc

5. Two nodes connected by at most one arc

9

Last Name _______________________ First Name ________________________ ID ___________________________

Question 8: (8 points)

a. (4 points) An activity-on-arc project network consisting of four activities is shown below. For each

activity, show the Earliest Start (ES), Earliest Finish (EF), Latest Start (LS), and Latest Finish

(LF). Show your computation. Use either the table below or the boxes adjacent to the activities.

0

2

4

6

4

8

2

C

A

4

6

1

B

0

0

9

13

4

6

4

D

6

6

6

6

3

Node 1 = starting node

Node 4 = finish node

13

13

ES EF

LS LF

Activity

ES

EF

LS

LF

A

0

4

2

6

B

0

6

0

6

C

4

9

8

13

D

6

13

6

13

b. (2 points) What is the critical path?

For each of the activity B and D, ES=LS and EF=LF. Moreover, B-D is the longest path from the

start node 1 to finish node 4. Hence the critical path is B-D.

c. (2 points) What is the length of the critical path?

The length of the critical path B-D is 6+7=13.

10

Last Name _______________________ First Name ________________________ ID ___________________________

Question 9: (9 points)

All weather Oil and Gas Company is planning delivery routes for five natural gas customers. The

customer locations are given below:

Customer

Location

1

(5,0)

2

(0,12)

3

(5,7)

4

(9,7)

5

(9,6)

Assume that the Depot (D) is located at the origin of the grid. Also assume that the cost of travel

between any two locations is the straight-line (Euclidean) distance between them.

a. (3 points) Compute the distance between Customers 1 and 2.

Distance (1,2) =

0 52 12 02

13

b. (3 points) Compute savings S(1,2) obtained by assigning Customers 1 and 2 to a single vehicle.

Dist (D,1) =

0 52 0 02

Dist (D,2) =

0 02 12 02

5

12

Savings (1,2) = Dist (D,1) + Dist (D,2) – Dist (1,2) = 5+12-13 = 4

c. (3 points) Improve the tour D-1-3-4-5-2-D. (Hint: plot the customer locations)

Step 1: Eliminate intersecting arcs (3,4) and (5,2)

2(0,12)

Step 2: There are two disjointed paths: 2-D-1-3

and 4-5. Reverse one of them, say 4-5 to get the

path 5-4.

Step 3: There is only one way to get a tour from

two paths 2-D-1-3 and 5-4. Add the arcs 3-5 and

4-2. The resulting tour is D-1-3-5-4-2-D.

3(5,7)

5(9,6)

Hence, an improved tour is D-1-3-5-4-2-D.

D(0,0)

11

4(9,7)

1(5,0)