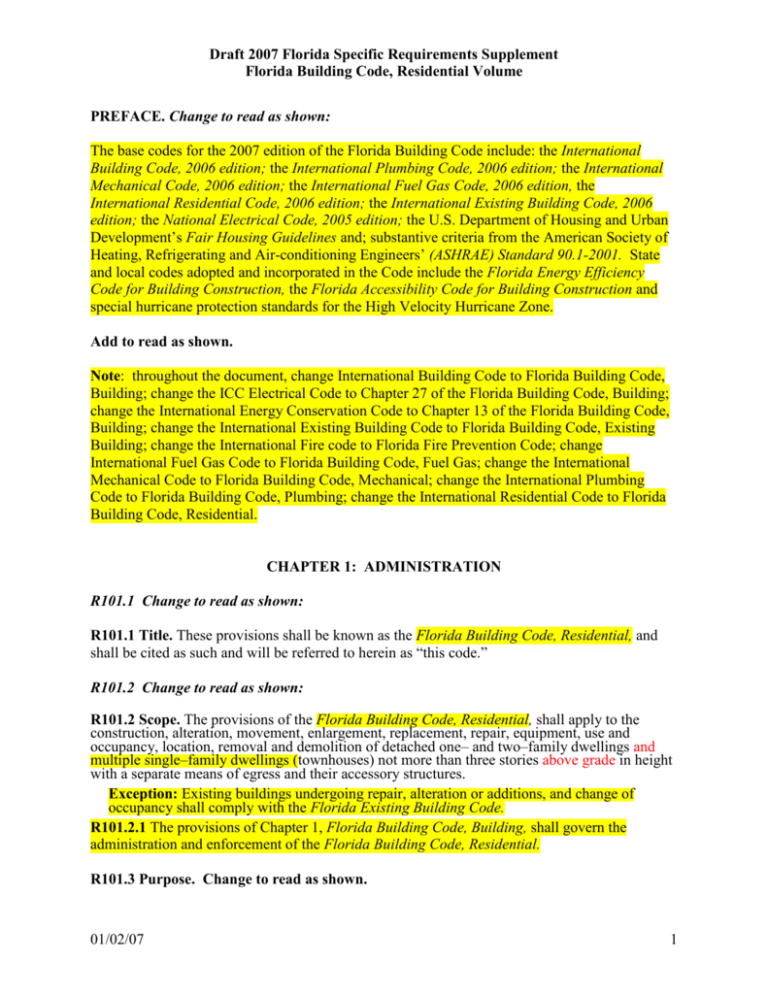

Florida Building Code 2007 Residential Supplement

advertisement