The Oxidation States of Tin

advertisement

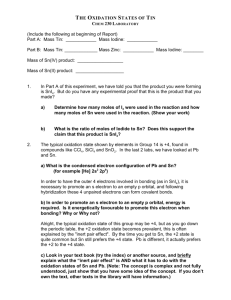

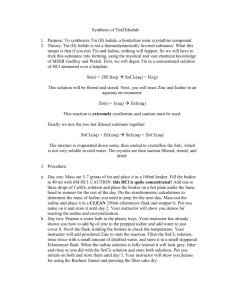

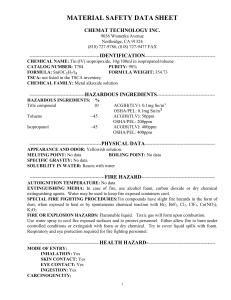

The Oxidation States of Tin Bobby Deimler Department of Chemistry and Physics, Georgia College and State University, Milledgeville, GA 31033 11/10/08 Abstract: Throughout the history of scientific study, scientists have always been interested in exploring and explaining different phenomenon that they observe during experimentation. One phenomenon that has caught the attention of the scientific community in the past is the fact that some elements have multiple oxidation states without being a member of the transition metal block. This has been observed in several compounds the most prominent of which are the two states that tin can possess when it reacts with iodine. This report documents the exploration of this phenomenon through the preparation of tin(IV) iodide and tin(II) iodide. These compounds were prepared separately in a two-part procedure that was obtained prior to the experimentation date. This procedure required the use of several chemical most importantly tin, iodine, zinc and hydrochloric acid. At the conclusion of this procedure, orange crystals were obtained for both compounds. The crystals for tin(IV) iodide weighed 0.4065 g and made up 73.8% of the total theoretical yield. The crystals from the tin(II) iodide experiment weighed 0.0293 g and made up 17.23% of the total theoretical yield. These crystals were meant to be differentiated from one another by their melting points. The melting point test revealed that both compounds that were prepared had the same melting point in the range of 145 – 150 C. This is significant because the two compounds are reported to have different melting points. This discrepancy is addressed at a later point in this report. This experiment is important because it presents a method by which multiple oxidation states are obtained by certain elements. This experiment also illustrates different kinds of reactions that can occur during a synthesis. An example of one of these reactions being the double decomposition reaction that occurs in the tin(II) iodide preparation. Introduction: This lab sought to prepare the compounds tin(IV) iodide and tin(II) iodide. This experiment was performed so that an unusual characteristic of certain metals could be demonstrated. Some metals have the ability to maintain two or more oxidation states even though they are not a part of the transition metal block. This quality is demonstrated in several compounds one of the most significant of which are the tin structures prepared in this experiment. At first glance this concept may seem rather confusing. How can a metal that is not a transition metal, act like one? To begin to understand this concept it is necessary to look at the way in which the electrons are arranged within the orbitals of the tin element. Tin is located on the right side of the periodic table in the rows that contain the 5s and 5p orbitals. The periodic table can also be used to determine that tin would have four valence electrons based on the column of the table that it resides in. These four electrons must find a way to orient themselves within the energy levels of the element. The configuration that would be the most obvious would have the s energy level completely filled with two electrons and the having the remaining two electrons occupy the p energy level. This configuration is based upon Hund’s Rule, which states that the lower energy levels must be filled completely before one can begin filling the higher orbitals. This arrangement creates the tin(II) oxidation state. In this state the compound tends to form bonds with two ligands. There is however, one more configuration that can be obtained under special conditions. If the tin were to absorb some energy from its surroundings, it would have enough force to promote one of the s electrons to the p energy level, thus half filling it. This arrangement creates the tin(IV) oxidation state. This state normally forms bonds with four ligands. The tin cannot hold onto this promotional energy forever though. In order to form these bonds it must release this energy. The awkward s energy level with one electron in it is compensated for more or less by the bonds that are formed (1). This awkward energy distribution is not really achieved frequently during experimental observation. The formation of this oxidation state is highly dependent on both the ease of promoting the electrons, and the bond strength contained in the atom itself (1). The second oxidation state would only be profitable if the cost of promoting the electron is equaled by the return from bond formation. In the case of tin this is true, the electron promotion cost and the bond formation return are relatively the same so both states occur. This would not be true in the case of other elements like lead. In this case the bond formation energy is much less than that which is used to promote the electron (1). For this reason lead tends to occur in the Pb(II) state. Now that the theory has been discussed it would be wise to see how this concept translates in a real reaction. As stated before both tin(II) iodide and tin(IV) iodide were produced in this experiment. Of the two compounds prepared tin(IV) iodide is the easiest, as it only requires one step in it’s reaction. (Figure 1) Sn + 2I2 SnI4 (Figure 1) The reaction above is a general redox reaction in which the elemental iodine is reduced from I2 to I-. Since the iodine now has a negative charge and the tin has a positive charge, the atoms are attracted to one another and the tin continues to attract the iodine molecules until the orbitals are completely full. In this case, the orbitals are completely filled after attracting four iodines. The process used to obtain tin(II) iodide is slightly more complicated and requires several reactions to complete. The first reaction that is utilized in this synthesis is between zinc and iodine. (Figure 2) Zn(s) + I2(s) Zn2+(aq) + 2I-(aq) (Figure 2) This reaction prepares one of the vital components in the creation of the tin solution, that of the zinc iodide solution. This solution is prepared through a redox reaction between Zn and I2. The iodine is the oxidizing agent and begins to oxidize the Zn to Zn2+ as soon as the two elements come into contact in the solvent. The solvent in this case is water. Because the iodine is the oxidizing the zinc, it is consequently reducing itself from I2 to 2I-. The other component that is necessary for this reaction to occur is the creation of the tin(II) chloride solution. (Figure 3) Sn(s) + 2HCl(aq) Sn2+(aq) + 2Cl-(aq) + H2(g) (Figure 3) This reaction illustrates chemically what is occurring when one dissolves elemental tin into solution using HCl. The hydrogens and the chlorines in the HCl compound are dissociated and the hydrogens go on to make hydrogen gas while the chlorines go through a redox reaction with the Sn in the same fashion that the iodine has in the prior reactions. The last step in this part of the experiment is to combine the Sn2+ and the 2Ifrom the prior reactions in order to create the final product. (Figure 4) Sn2+(aq) + 2I-(aq) SnI2(s) (Figure 4) In this reaction the ions or charges of the elements switch partners and go to the adjacent compound. This type of reaction is known as a metathesis reaction. (1) Upon completion of the metathesis reaction the final product for the second part of the experiment, tin(II) iodide was obtained. Experimental: This experiment was divided into two separate sections depending upon the type of complex that was going to be prepared. Part A of this experiment details the preparation of tin(IV) iodide while part B details the preparation of tin(II) iodide. The experiment began by preparing the tin(IV) iodide. First, .120 g of Sn and .466 g of I were placed into a round bottom flask with a boiling stone. This flask was added to a microreflux unit and placed in a water bath pre-prepared on a hot plate. A long stem pipette was used to add 6 mL of methylene chloride to the flask through the condenser. This addition caused the sample to turn a muddy purple color. The water bath the reflux unit was resting in was heated until the chemicals in the flask maintained a mild reflux. This reflux was allowed to continue for forty minutes. At the conclusion of this time, the solution was no longer purple and began to show signs of orange particles floating in solution. This solution was gravity filtered through a glass vial stuffed with cotton to remove any unreacted metal. The recovered solution was then cooled in an ice bath. This caused a large amount of orange crystals to fall out of solution. After cooling, the solution was filtered using a vacuum filtration system to recover the crystals. These crystals were collected and placed in a plastic vial to dry. It should be mentioned that the vial was weighed before placing any sample into it and found to weigh 6.8814 g. When the sample was placed into the container, it increased its weight to 6.9879 g. This means that the sample prepared must have a mass of 0.1065 g. While the crystals from part A were drying, the compound in part B was prepared. In this procedure two reagents needed to be made. To begin, the first reagent was prepared. A piece of tin foil that weighed 0.0797 g was torn into small pieces and placed in a flask with a stir bar. This was placed onto a hot plate in a hood. While in the hood, 1 mL of concentrated HCl and one drop of 0.1 M CuSO4 was added to the solution. This solution was heated jus under boiling and a watch glass was placed over the mouth of the beaker so the evaporated HCl could not escape. This solution was left to heat until all of the tin had dissolved into the HCl. While the experiment was waiting for this to occur, the second reagent required in this part was prepared. In this, .116 g of I, .115 g of Zn and 1 mL of deionized were added to another flask along with a stir bar. This mixture was stirred slowly in an ice bath, which caused the solution to turn brown. This reagent was stirred for roughly an hour, which caused the solution to turn from brown to a light yellow color. This color change indicated that the reaction was proceeding. The solution was transferred to another flask using a filter pipette. This solution was clear with no unreacted metal seen to be floating in it. To be sure all of the metal had been removed, the solution was washed with a few drops of water and transferred in the same way to the latter beaker. The condition of the beaker containing the first reagent was finished around this time as well. It was observed that all of the zinc had been dissolved into the acid. This solution was transferred into another flask using a different filter pipette for the same reason as before. This HCl reagent was then added dropwise to the second reagent that contained the zinc. As soon as the drop of the one solution contacted the other, orange crystals began to form. When all the solution had been added, the flask was soaked in an ice bath to be sure that all of the crystals had come out of solution. The crystals were isolated using a vacuum filtration system. An empty plastic vial was weighed and found to be 6.6142 g. After the sample was recovered from the filtration system and placed in the vial, it weighed 6.6435 g. This means that the sample prepared weighed 0.0293 g. At this time, the product from part A was dry so the characterization test could be performed on it. A small amount of product was taken and dissolved in 5 mL of acetone. This 5 mL was split into two separate flasks. To the first portion a few drops of water were added which caused no reaction to occur. The second portion then had a few drops of saturated KI solution added to it. This caused the solution to turn a yellow-orange color and for small solid particles to become visible in the solution. Besides this characterization it was also necessary to take the melting points and percentage yield of each of the products. When tested, both products, from part A and B, had a melting point of 145-150 C. The percentage yield for part A was 73.8% and for part B was 17.23 %. The details of these calculations are outlined in the results section. Results: Percent Yield = Part A: .4065 g .5502 g Part B: .0293 g .1700 g actual amount theoretical amount x 100 x 100 x 100 = 73.8% yield for tin(IV) iodide = 17.23% yield for tin(II) iodide Discussion: This procedure for this experiment was able to be performed successfully and both compounds were able to be prepared. The truth of this fact can be confirmed by several physical characteristics observed during the lab as well as two characterization tests performed after the lab was complete. One physical characteristic that was observed during the lab was the color change from the brown/muddy purple to yellow in both parts of the experiment following the oxidation of the metal compound by the iodine. This is significant because it shows that the reaction was proceeding in the predicted way. It also helps to support the fact that this was the iodine-metal redox reaction that was occurring. This was due to the fact that this color change occurred in the preparation of both the tin(II) iodide and the tin(IV) iodide. It is highly unlikely that such a color change would be identical in two separate syntheses unless the same reaction was specifically occurring in both. Another thing to consider is that in the second part of the experiment this reaction is performed with zinc rather than tin. In spite of this the same color change occurs helping to confirm the identity of the reaction that is happening. Another physical property that helps to identify the compound is the orange crystals that were produced. These colored crystals are commonly associated with this type of tin compounds. This is significant because it allows the person performing the experiment to have a benchmark by which to measure the success of the experiment. If the crystals produced had been brown or black, than it would have been evident that a problem had occurred. Since these crystals are bright and defined in color, it is fairly easy to identify them. When this reaction was complete several calculations and characterization tests were run to further identify and quantify the product. A percent yield was calculated for both products performed in the experiment. It was discovered that 73.8 % of the theoretical value had been produced for tin(IV) iodide and 17.23 % had been produced for tin(II) iodide. When one observes these values they can see that a fair amount of tin(IV) iodide was produced, more than enough to do the necessary tests required by the lab. Problems arise however, when one looks at the percent yield for the tin(II) iodide, as its yield is fairly low. The reason that this yield was low is mainly attributed to the iodine-zinc portion of this reaction. This part of the experiment required that the zinc and iodine be combined in a flask with water and allowed to sit in an ice bath for an extended amount of time. This reaction was performed five times with the flask being allowed to sit in the ice bath for varying amounts of time. These time variances were allowed because the reaction occurred at different rates depending on the attempt. In some attempts the reaction proceeded quickly with the reaction turning from brown to yellow in ten to twenty minutes while other did not have a color change for an hour. This discrepancy is mainly due to the zinc that was being used in this experiment. The zinc that was used in the reaction had been boiled in HCl acid earlier in the semester in order to remove the effects of oxidation. This batch of zinc was stored in a dessicator to prevent it from oxidizing again. This zinc was shared between many different lab groups and may have oxidized once again as it was taken in and out of the dessicator. This hypothesis is supported by the variances in time that were observed for the zinc iodine reaction. It would make sense to say that since the iodine is an oxidizing agent, its goal is to oxidize the zinc. If most of the zinc is already oxidized, than the reaction is going to take place really quickly because the iodine doesn’t have that much to oxidize. On the other hand, if a sample of zinc that is not oxidized was added to the solution then the reaction should take a good deal longer as the iodine has to react with the sample of zinc in its entirety. These two ideas give an account for why several of the attempts at this experiment had different time periods for this reaction. It also explains why the yield may have been lower than expected. The zinc that was used in the reaction that eventually yielded product could have had a portion that was oxidized and did not take part fully in the reaction. The larger amount of zinc oxidized would potentially lower the yield. Judging by the results of this experiment, it is evident that a large portion of the zinc used was oxidized leading to a smaller yield. Two characterization tests were also performed to further validate the results of the physical observations. These included a melting point test for both compounds and a KI spot test for the tin(IV) iodide. The first test that was done was the characterization test performed with the saturated KI solution. A literature search was performed and it was found that KI will turn a yellow color when it is introduced into a solution that contains tin(IV). (2) For this reason it is safe to conclude that since the solution containing the product from this reaction turned a yellowish-orange color, it did in fact contain the tin(IV) element. This further helps to prove that the compound produced in the reaction was what it was supposed to be. The other characterization test performed on the final products was a melting point test. A slight discrepancy was detected here as well, because when the melting points of both compounds were taken, they were determined to have the same melting point in the range of 145 – 150 C. This is a problem because although this matches the literature value for the tin(IV) iodide compound which is reported at 144.5 C (3) it is far from the melting point of tin(II) iodide which is reported at 320 C (4). This difference is due to a chemical property of tin(II) iodide that was not taken into account during the execution of the experiment. Tin(II) iodide easily oxidizes to tin(IV) iodide if it is left out in the open air for too long (5). So, when the product was being allowed to dry for the melting point analysis, it was actually being oxidized into tin(IV) iodide instead. This reaction would explain the reason why the compound from both reactions would yield the same melting point even though they were produced through different reactions. Conclusion: The goal of this experiment was to prepare crystals of both the tin(IV) iodide and tin(II) iodide complex. This was achieved successfully with a 73.8% yield of the tin(IV) iodide and a 17.23% yield of the tin(II) iodide. A discrepancy did arise when the melting points of the two compounds were taken and found to be in the same range. This however, was addressed through further research that suggested that the time that the tin(II) iodide was allowed to dry may have caused it to oxidize into tin(IV) iodide which would explain the similarity in melting points. This experiment further shows that elements such as tin have the ability to adopt the electron configuration for more than one oxidation state. These states allow for different structures as evidenced by the two types of crystals that can be prepared. A possible continuation of this experiment would be to test the complexes of the elements within the same row or column as tin and observe whether this ability to have more than one oxidation state translates to any other groups in the periodic table. If this ability does translate perhaps there is a group that can be used in this experiment that would not oxidize in the laboratory. This would help improve the successful synthesis and percent yield obtained in this kind of reaction. References: 1. Szafran, Zvi; Pike, Ronald M.; Singh, Mono M., Microscale Inorganic Chemistry: A Comprehensive Laboratory Experience; 1st Ed.; J. Wiley: 1991; pp. 248-251 2. West Virginia Academy of Science. Proceedings of the West Virginia Academy of Science; West Virginia Academy of Science: 1960; pp. 67 3. Sigma-Aldrich http://www.sigmaaldrich.com/catalog/search/ProductDetail/ALDRICH/466352 4. Perry, Dale L.; Phillips, Sydney L.; Handbook of Inorganic Compounds: An Electronic Database; CRC Press: 1995; pp. 383 5. Birk, James P. Tin, Sn2+, Sn4+ http://www.public.asu.edu/~jpbirk/qual/qualanal/tin.html Acknowledgements: I would like to acknowledge the Department of Chemistry and Physics for the opportunity to use the lab and the equipment necessary for this experiment to take place.