Nitration - Gravity Waves

advertisement

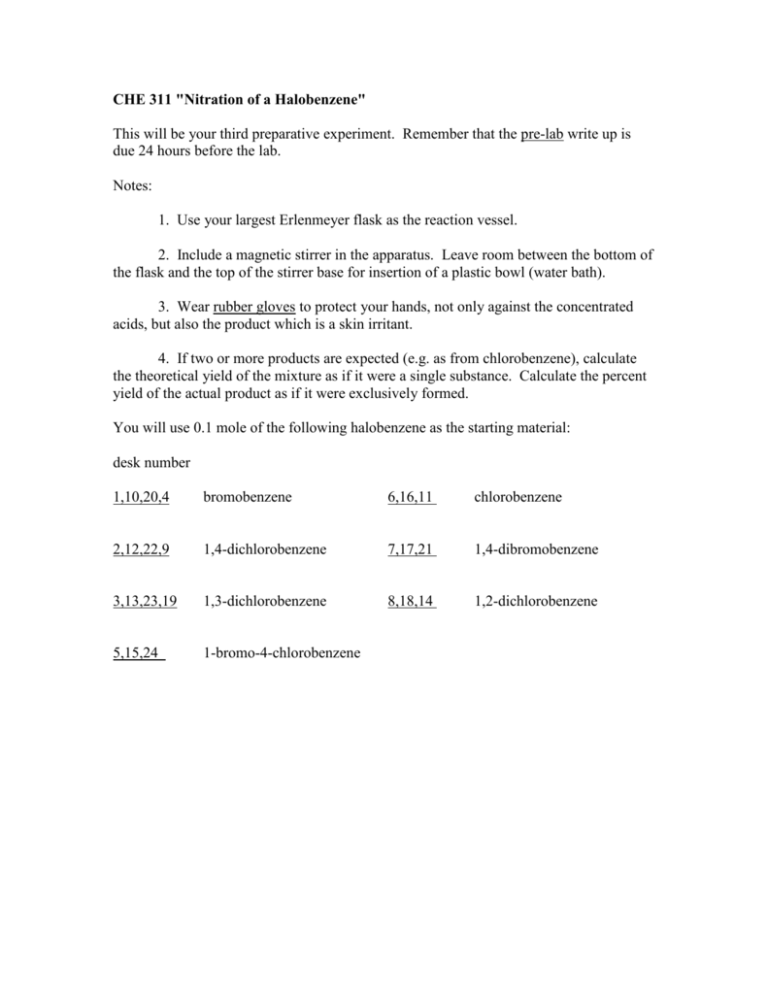

CHE 311 "Nitration of a Halobenzene" This will be your third preparative experiment. Remember that the pre-lab write up is due 24 hours before the lab. Notes: 1. Use your largest Erlenmeyer flask as the reaction vessel. 2. Include a magnetic stirrer in the apparatus. Leave room between the bottom of the flask and the top of the stirrer base for insertion of a plastic bowl (water bath). 3. Wear rubber gloves to protect your hands, not only against the concentrated acids, but also the product which is a skin irritant. 4. If two or more products are expected (e.g. as from chlorobenzene), calculate the theoretical yield of the mixture as if it were a single substance. Calculate the percent yield of the actual product as if it were exclusively formed. You will use 0.1 mole of the following halobenzene as the starting material: desk number 1,10,20,4 bromobenzene 6,16,11 chlorobenzene 2,12,22,9 1,4-dichlorobenzene 7,17,21 1,4-dibromobenzene 3,13,23,19 1,3-dichlorobenzene 8,18,14 1,2-dichlorobenzene 5,15,24 1-bromo-4-chlorobenzene Nitration of a Haloarene: Experimental Procedure The starting haloarenes for this synthesis are either liquid or solid, but the desired product in each case is a solid. For some, only one possible product may be formed; some may react to form a mixture of two products, one of which predominates. The remaining compounds may theoretically be converted to a mixture of two or more products. Included in your assignment is the isolation and determination of the identity of the major product. A. Apparatus The standard-taper assembly described below could be used for this preparation. However, it is also possible to carry out the procedure in an Erlenmeyer flask (which you will do) but it is necessary to carry out the reaction in a fume hood. 1. A 500-mL Erlenmeyer flask will serve as the reaction vessel. The thermometer is placed in the flask, with its bulb resting on the bottom. When you must stir or shake the reaction mixture, hold the thermometer in place by grasping the neck of the flask and the thermometer simultaneously with one hand. [alternatively: a. Fit a 250-mL two-neck flask with a Claisen adapter or use a 500-mL three-neck flask. If you are provided with a magnetic stirrer, place a magnetic stirring bar in the flask. b. Place a thermometer in the angled side neck of the flask and position the bulb so that it will be immersed in the reaction mixture. Attach a reflux condenser to the other side neck and connect the top opening of the condenser to a gas trop (oxides of nitrogen may be evolved). c. Attach a dropping funnel to the center neck if the compound to be nitrated is a liquid. If your starting material is a solid, the center neck is to be plugged with a glass stopper.] 2. Surround the flask with a plastic bowl containing some tap water. Obtain some crushed ice in a separate container and keep it handy for cooling the reaction mixture as needed. B. Reaction 3. Begin the preparation of the nitrating agent by pouring 20 mL (28.5 g; 0.32 mole) of concentrated nitric acid through a narrow-stem funnel into the flask. Do not use the addition funnel, if one is included in your assembly. Carefully add in small portions of 20 mL (37 g; 0.36 mole) of concentrated sulfuric acid. Stir the mixture mechanically or swirl the flask by hand while you are adding the sulfuric acid. When all of the sulfuric acid has been added, cool the mixture to 25-30oC by adding some ice to the water bath, if necessary. Do not cool the solution below 25oC. If the temperature of the nitrating agent is allowed to fall much below 25oC it is possible that insufficient energy will be available to initiate the reaction. Continued addition of the substance to be nitrated will permit the concentration of unreacted starting material to build up. when the reaction does begin, and heat is evolved, all of the aromatic compound present may interact with the nitrating agent and the reaction may get out of control because of the excessive evolution of heat. 4. Measure out a quantity equivalent to 0.1 mole of the starting material you were assigned. Add the aryl halide to the nitrating agent as directed below. Stir or swirl the reaction mixture to mix the reactants thoroughly. Use the cooling bath to control the temperature so that it does not rise above 60oC, but do not allow the temperature to fall below 30oC. If the temperature does get too low, remove the cooling bath temporarily and allow the reaction mixture to warm up before continuing the addition. 5. 6. Continue to add the starting material in the manner described above until all of it is consumed. When the temperature of the reaction mixture no longer rises spontaneously, heat the mixture on a steam bath or hot water bath for 30 minutes. A heating mantle may also be used, but be certain to wipe the outside of the flask first to remove any adhering water. Heat the mixture to a temperature between 60 and 100oC. 7. Remove the flask from the heat source and allow the mixture to cool to room temperature. You may help it along by using a cooling bath. C. Isolation and Preliminary Purification 8. Put a mixture of 150 mL of water and enough crushed ice to bring the volume to 200 mL into a 400- or 600-mL beaker. Carefully pour the contents of the flask into the cold water while stirring the mixture with a glass rod. Rinse the reaction flask with a small amount of ice water and add the rinsings to the beaker. The crude product should separate as a solid. If it does so, it can be isolated by suction filtration. If the crude product separates from the aqueous phase as an oil, the following measures may be taken. a. Carefully decent as much of the aqueous phase as possible, leaving the oily material behind. Add some crushed ice and vigorously stir the mixture with a glass rod. If this treatment does not effect solidification of the material, see step b (below). b. Dissolve the crude oily product in about 50 mL of diethyl ether or dichloromethane by adding the solvent directly to the beaker that contains the product-water mixture. Transfer the contents of the beaker to a separatory funnel and separate and discard the aqueous phase. After completing step 11, continue with step 12b. 9. 10. The reaction mixture contained a strongly acidic solution, some of which will remain admixed with the crude product. The product must therefore be washed thoroughly with water. A solid may be washed while it is in the Buchner funnel; a product in solution should be washed in a separatory funnel. D. Purification 11.a. The product is a solid, so a recrystallization is in order. Select a recrystallizing solvent from among those available to you in the laboratory. If the crude product was dissolved in an organic solvent, that solvent must be removed at this point. A rotary evaporator would be best for this purpose, but any other suitable means may be employed. If the residue is still liquid, it may still be subjected to a crystallization procedure, just as if it were solid. b. E. Verification of Identity and Purity 12. 13. Determine the melting range of your product. The product will be analyzed by thin-layer chromatography on silica gel, with the eluting solvent 9:1 (v:v) hexane:chloroform. Pure samples of most of the possible reaction products are available, you should attempt an identification by comparison of Rf values for the authentic material(s) run alongside the reaction 14. product on the same TLC strip. Package the product and turn it in.