Truck Midterm Exam

advertisement

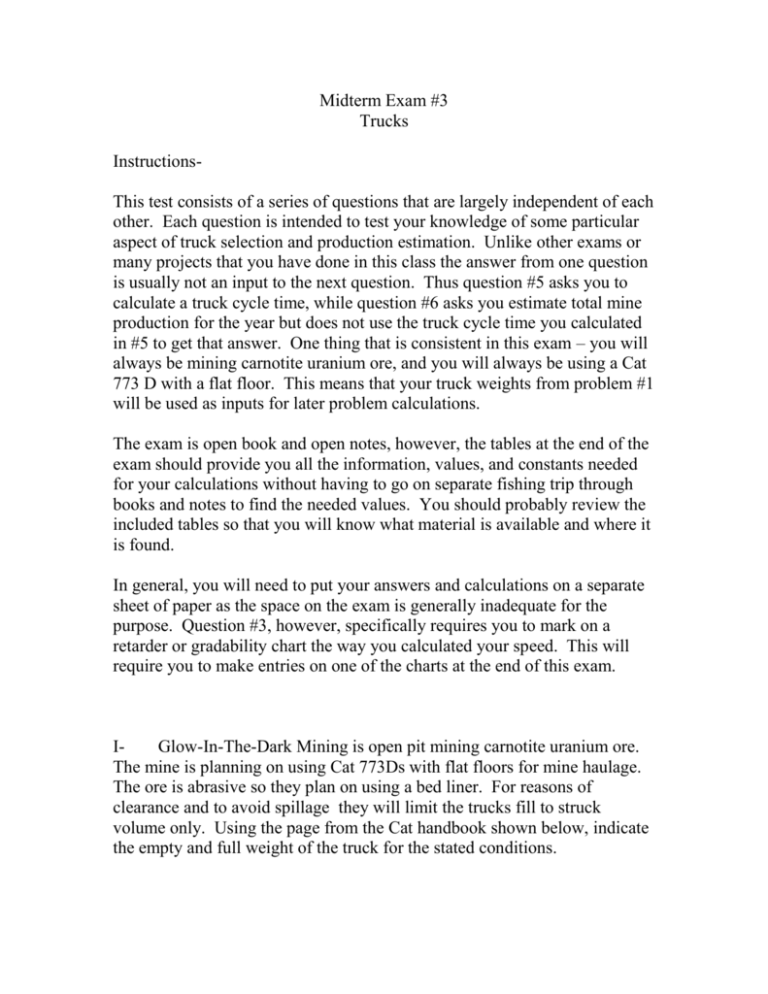

Midterm Exam #3 Trucks InstructionsThis test consists of a series of questions that are largely independent of each other. Each question is intended to test your knowledge of some particular aspect of truck selection and production estimation. Unlike other exams or many projects that you have done in this class the answer from one question is usually not an input to the next question. Thus question #5 asks you to calculate a truck cycle time, while question #6 asks you estimate total mine production for the year but does not use the truck cycle time you calculated in #5 to get that answer. One thing that is consistent in this exam – you will always be mining carnotite uranium ore, and you will always be using a Cat 773 D with a flat floor. This means that your truck weights from problem #1 will be used as inputs for later problem calculations. The exam is open book and open notes, however, the tables at the end of the exam should provide you all the information, values, and constants needed for your calculations without having to go on separate fishing trip through books and notes to find the needed values. You should probably review the included tables so that you will know what material is available and where it is found. In general, you will need to put your answers and calculations on a separate sheet of paper as the space on the exam is generally inadequate for the purpose. Question #3, however, specifically requires you to mark on a retarder or gradability chart the way you calculated your speed. This will require you to make entries on one of the charts at the end of this exam. IGlow-In-The-Dark Mining is open pit mining carnotite uranium ore. The mine is planning on using Cat 773Ds with flat floors for mine haulage. The ore is abrasive so they plan on using a bed liner. For reasons of clearance and to avoid spillage they will limit the trucks fill to struck volume only. Using the page from the Cat handbook shown below, indicate the empty and full weight of the truck for the stated conditions. (Note – Other problems depend on these empty and full truck weights – if you do not do this problem then substitute 48 tons empty and 96 tons loaded for the weight of the truck). IIRandy Reject just got a Mining Engineering degree from Missouri Rolla. For the 773Ds hauling carnotite uranium ore as above he proposes the trucks should be loaded using Cat 980G front end loaders with 6 cubic yard bolt on edge general purpose buckets (See Cat handbook page attatched). The 6 cubic yard buckets are expected to actually hold 5 cubic yards of swelled material. Aside from the fact that Randy obviously graduated from the wrong school can you give any concretely defensible reasons why his proposed loader size should be rejected? What specifically are the reasons if you believe it should be rejected if that is in fact your opinion? If you believe the loader is acceptable indicate which checks for compatibility that you have performed and found to be satisfactory. III- On one segment of the road that the Cat 773D trucks will encounter, they will be required to carry a full load of material up a 7% grade through loose dry sand for a distance of 1200 feet. The material included at the back of the test includes tables of rolling resistances, friction factors, gradability, and retarder charts. Use these tables to calculate the total effective grade for this road segment, then use either a retarder or gradability chart (which ever one you think is appropriate) to calculate the maximum possible speed that the trucks engine and drive train are mechanically built to sustain (there may be all sorts of field conditions where a driver would not or could not go this fast but this question pertains only to mechanical capabilities of the truck). Mark on the chart how you got the answer. IV- Using the information provided in the tables and charts at the end of the test, together with your superior knowledge and mastery of truck cycle time calculations determine the amount of time the Cat 773 will take to go over the 1200 foot road segment from #3 if the truck enters the segment already going 20 miles per hour. VNow assume that your fleet of cat 773 trucks will follow this loading cycle (Please note that this question is disregarding any speed capabilities or times you calculated in questions #3 and #4). Haulage Segment #1 - Following being loaded the truck will drive 200 feet through a congested area (trucks coming in and out from loading). The mechanical maximum speed capabilities on this segment are 25 miles per hour. Haulage Segment #2 - The trucks will then drive over 2700 ft of road while loaded at maximum speeds of 25 mph. Haulage Segment #3 - The truck will then drive 150 ft, spot, and dump the material. Entering the 150 ft section, spotting and dumping will take 2 minutes (Note that I included all your travel time through haulage segment #3 in the dump cycle time). Haulage Segment #4 - The truck will then pull away through the 150 ft congested area. The truck is mechanically capable of traveling 40 mph on this short segment (although you may not want your driver to even try to go that fast). Haulage Segment #5 - The truck will then travel the 2700 ft return road at up to 40 mph. Haulage Segment #6 - The truck will then enter a 200 ft congested loading area. Again the truck could go at 40 miles per hour but you probably will not want the driver to go that fast. The truck will take 2.5 minutes to load before beginning the cycle over again. The mine works with 10 hour shifts under hot conditions where the ton mile per hour rating of the tires is 225. A- Using the tables at the end of the test and your own judgment indicate any haulage segments where you wish to impose a speed limit less than the maximum speed the truck is mechanically capable of reaching. Indicate what speed you wish to limit to. (Remember for haulage segment #3 your moving cycle time was included with your dump time and therefore you will not do any moving cycle time calculations on haulage segment #3). B- Using the tables at the end of the test select appropriate speed factors for each segment of the haulage route (except haulage segment #3). C- Calculate the cycle time for one haulage cycle with the truck under the stated conditions. (Note – Since Question D depends on the answer to C, if you do not complete problem C substitute 9 minutes for the cycle time from C). D- Given the hot conditions at the mine, will you have to slow the trucks down or impose rest times on the trucks to prevent the tires from overheating during those 10 hour shifts? Show supporting calculations for your answer. VI- Suppose the uranium mine will have 5 trucks and that each truck could produce 500,000 tons of ore if it were running all the time the mine was operating. Suppose there is one loader available to service these trucks and that the loader is available 90% of the time. Suppose also that the truck cycle time is 13 minutes and the loader takes 2.5 minutes of that time to load the truck. Under these conditions, how many tons of ore would you expect to be able to produce from the mine? Show your calculations that support your answer. Speed Restrictions Suggested by Surface Mining (1rst Ed) Congested Area Guideline Down-Hill Grade Guideline Loaded Truck Speed Factors Empty Truck Speed Factors Caterpillar Match Factor and Bunching Tables