Rust Vs Corrosion What is the difference between Corrosion and

advertisement

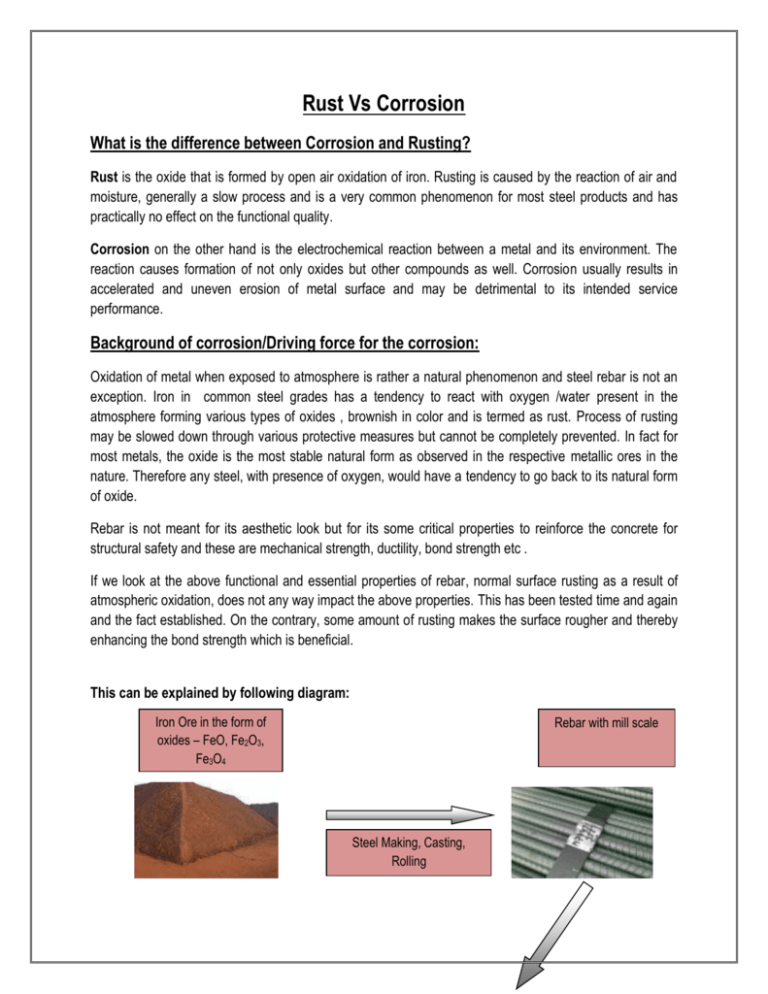

Rust Vs Corrosion What is the difference between Corrosion and Rusting? Rust is the oxide that is formed by open air oxidation of iron. Rusting is caused by the reaction of air and moisture, generally a slow process and is a very common phenomenon for most steel products and has practically no effect on the functional quality. Corrosion on the other hand is the electrochemical reaction between a metal and its environment. The reaction causes formation of not only oxides but other compounds as well. Corrosion usually results in accelerated and uneven erosion of metal surface and may be detrimental to its intended service performance. Background of corrosion/Driving force for the corrosion: Oxidation of metal when exposed to atmosphere is rather a natural phenomenon and steel rebar is not an exception. Iron in common steel grades has a tendency to react with oxygen /water present in the atmosphere forming various types of oxides , brownish in color and is termed as rust. Process of rusting may be slowed down through various protective measures but cannot be completely prevented. In fact for most metals, the oxide is the most stable natural form as observed in the respective metallic ores in the nature. Therefore any steel, with presence of oxygen, would have a tendency to go back to its natural form of oxide. Rebar is not meant for its aesthetic look but for its some critical properties to reinforce the concrete for structural safety and these are mechanical strength, ductility, bond strength etc . If we look at the above functional and essential properties of rebar, normal surface rusting as a result of atmospheric oxidation, does not any way impact the above properties. This has been tested time and again and the fact established. On the contrary, some amount of rusting makes the surface rougher and thereby enhancing the bond strength which is beneficial. This can be explained by following diagram: Iron Ore in the form of oxides – FeO, Fe2O3, Fe3O4 Rebar with mill scale Steel Making, Casting, Rolling Atmospheric rusting of rebar Rusting of Rebar – Myth vs. Reality: Myth- Rusted rebar will have weak bonding with concrete. Realty-Controlled rust improves bond strength. Surface rusting of rebar does not affect the performance of the rebar. In fact surface rusting can improve the bond of the rebar with the concrete. This is because of the fact that compared to a smooth surface of rebar which under load may have a tendency to slip out of the concrete, little rust increases the roughness, offer more frictional resistance against any force to dis bond the rebar . Myth-Rusting of rebar reduces its strength. Realty-Rusting has no effect on rebar strength. The strength of the rebar is achieved by the control of its chemistry and the thermal treatments through which it was produced and rusting does affect neither of them. Chemistry and inherent strength remains the same and so also its load bearing capacity. However, severe rusting and pitting corrosion which can result from prolonged exposure to open atmosphere/water and which reduces the section of the rebar heavily and create pits on the surface may reduce the load bearing capacity. The simple example is the difference in load bearing capacities of rebar of similar strength but of different sizes. Therefore prolonged exposure to open atmosphere which may result in corrosion needs to be avoided. Myth - Rust on rebar is not permitted as per rebar code/standard. Realty- The rebar standard indicates that rust is a common expected phenomenon on rebar and not a cause for concern. IS 1786: 2008-Indian Code for rebar , Clause 4.3.1 States-“ All bars/ wires shall be well and cleanly rolled and shall be sound and free from surface defects and pipe or other defects detrimental to its subsequent processing and to its end use. Rust, seams, surface irregularities or mill scale shall not be the cause for rejection provided a hard wire brushed test specimen fulfils all the requirement of this specification”. How to check rebar for its fitness for use? One of the easy way to check a rebar for its application worthiness is to clean the surface with a wire brush and observe whether there is any pit formation due to corrosion/over rusting which is not advisable to use. Pits look like small localized depression on the surface The other simple measure is to check whether the ribs on the surface has been washed out due to rusting or not. If it has not shown any rib wash out, it can be used safely. Severely rusted/pitted rebar is detrimental Did We Know? 1. In big construction projects like flyovers, high rise buildings, commercial complexes, and executed by leading construction organizations and generally is spread over a longer time of construction than a common house building, usage of rebar with reddish color is a very common phenomenon. Such rebar would never been used /allowed to be used if there could be any detrimental effect. 2.There are some countries, known for their technological excellence, the construction engineers , by design, do not use fresh rebar because they feel that it will not give the best bond strength with concrete. At the site the rebars are kept in open atmosphere till some rust appears on the surface and then only these are used. Placement of rebar in big projects Light coating of red rust is rather beneficial Protection of Rebar against Corrosion: While usage of little reddish rebar has its own advantages, it is important to protect it from progressive corrosion. Corrosion is mostly dependant on the environment which the rebar is exposed to. Any acidic atmosphere in presence of salts like chloride or gasses like C02 may promote corrosion .Corrosion can also be encouraged if water is logged in some portion of rebar for long time. A common example of such situation which may be created when a portion of rebar extends from already cast concrete members. This is generally done when there is a plan to extend the construction in future.In such cases, the minimum precaution to be taken is to cover such extended rebar with some coating like cement slurry. In absence of such protection, it may lead to accelerated rusting /corrosion and should be avoided. Protection of Rebar Protruding out of concrete for future construction: In case the building has to be extended vertically in future, it is general practice that reinforcement bars in columns are extended well above roof for lapping purpose. The reinforcement bars would eventually rust and then corrode if the bars are left unprotected for longer durations. If the extension of building is going to take place after some time , the following should be adopted: 1. Cleaning: Brushing with hard wired brush. 2. Cement Slurry Coating: Apply cement slurry by brush to the protruded reinforcement bars. Cement slurry can be made by mixing cement with water generally in a ratio of one part of cement with 2 parts of water. Extended rebar Rebars coated with cement slurry Roof/Slab Wall Column Similar method of applying cement slurry should be adopted for rebars extended from roof slab/beams etc If the extension of building is going to take place after longer time, the following should be adopted: Weak concrete Extended rebar for lapping 50mm cover Roof/Slab Wall Column Protect the Protruding rebar with weak concrete Weak Concrete: Weak concrete is a M10 grade of concrete where cement: sand: coarse aggregates have the ratio of 1:3:6 by weight proportion. This concrete cover can be broken before start of fres construction Storage of Rebar at Site: The actual location of stacking place of reinforcement bars depends on the site conditions but it should be such that it is protected against contact with water. In order to ensure that the reinforcement bars are kept in good condition they should not be left in direct contact with the ground but they should be stacked on top of dunnages made out of timber or say bricks and in particularly rainy season , should be covered. Where space is extremely limited, bars may also be stacked vertically with adequate support with additional care of handling during use. Whatever method of stacking is adopted the bars should be stacked in such a way that the various sections and lengths can be easily identified. Section mix up being so common , it is advisable to use rebar which marks the section in rebar clearly. With such simple measures and understanding, usage of rebar for better structural safety and durability can be ensured X Should not be stored in open yard Points to be note: Rusting of rebar to an extent does not affect any functional quality rather improves its bond strength. However severe rusting and corrosion is not desirable and should be avoided. Storage and protection of rebar from direct contact with water needs a conscious attention. Protruded part of rebar from an ongoing construction site requires specific protection to avoid accelerated rusting.