Machine Design

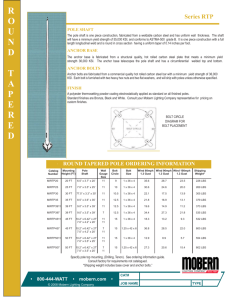

advertisement

ME 437 Notes on Machine Design Important Topics Power screws Bolt design Bolt clamping loads Bolt shear loads Bolt groups Bolts in fatigue loading Gears Kinematics Forces Stresses Belts Welds Welds subjected to shear Welds subjected to torsion Welds subjected to bending Clutches/Brakes Disk type / Drum type Flywheels Spring design Helical Roller/ball bearing design Journal bearings Shaft design Against fatigue Whirling Lateral vibration Machine Design Recommended Text: Fundamentals of Machine Component Design by Juvinall and Marshek – 3rd Edition Bolt Selections and Design You need Dimensions of standard threads (UNF/UNC) Strength specifications (grades) of bolts. Clamping forces Fe The bolt force is kb Fb Fi Fe kb kc Where Kb and KC are the bolt and the clamping material stiffness and Fi is the initial bolt tensioning. The clamping force is kc Fc Fi Fe kb k c Fb Fi Fc Fe Recommended initial tension : Fi = 0.90 SpAt where Sp is the proof strength and At is the tensile area of the bolt. Recommended tightening torque: T = 0.20 Fid Where d is the nominal bolt size. Design of bolts in tension Fb = At Sp Where At is the tensile area. Problem #M1a : Given: Two plates are bolted with initial clamping force of 2250 lbs. The bolt stiffness is twice the clamping material stiffness. Find: External separating load that would reduce the clamping force to 225 lbs. Find the maximum bolt force at minimum clamping force. Answers: 6075 lbs and 6300 lbs Problem #M1b :Select a bolt that would withstand 6300 lbs nominal load in direct tension. Apply a factor of safety of 2.5. Use a bolt with SAE strength grade of 2 (which has a proof strength of 55 ksi). Answer: ¾ “ 10-UNC Bolts under shear loading Problem #M1c: A 1”-12 UNF steel bolt of SAE grade 5 is under direct shear loading. The coefficient of friction between mating surfaces is 0.4. The bolt is tightened to its full proof strength. Tensile area is 0.663 in2 Proof strength is 85 kpsi, and yield strength is 92 kpsi a) What shear force would the friction carry? b) What shear load can the bolt withstand w/o yielding if the friction between clamped members is completely lost? Base the calculation on the thread root area. Approximate Answers: a) 22500 lbs, b)35300 lbs Bolt design under fatigue loading Analysis method: Root stress – Goodman Criteria Sy Sn 4 Sf a 3 2 1 Sy Su Example: Consider a ½ “ UNF Grade 7 bolt with an initial tension of 90% of its proof load. The clamping material is 4 times stiffer than the bolt. If a cyclic load of 0 to 6150 lbs is applied, what would be the factor of safety guarding against eventual fatigue failure? The tensile area and proof strength are At = 1599 in2 and Sp=105 ksi. The initial tension is: Fi = .9*(0.1599)(105) = 15.1 kips Under this initial load, the root of the thread yields – Point-1 in the figure. The additional fluctuation in the bolt load is: Fb Kb 1 Fe (6150) 1230 lbs Kb Kc 5 When the external load is applied, the additional stress at the bolt root is: ( Fb 1230 )K f ( )3 23000 psi At .1599 The root stress, however, remains at yield point as this additional stress is applied. The additional load is simply picked up by the cross-section that is stressed nominally (force divided by area). But when the load is removed, the stress backs off from the yield point and goes back into elastic region by exactly the same amount of stress that is removed. In this case, the stress goes back to (115-23)=92 ksi. This point is shown as Point 2 in the graph. On subsequent application and removal of the load, the stress point moves between Point 2 and Point 3 on a 45-degree line. The reason is that half of the stress adds to the mean stress and the other half becomes the amplitude of the alternating stress as shown below: 92 ksi As the alternating load is increased, Line2-3 moves left until it reaches Point-4 which is the eventual failure point. The margin or factor of safety is determined by the distance between a and Sf Endurance limit Sn 0.5SutCLCGCS 0.5(133)(1)(0.90)(1) 60 ksi The fatigue strength is Sf Su S y Su S n Sn 133 115 (60) 14.8 ksi 133 60 The factor of safety is: FS Sf a 14.8 1.3 11.5 Problem #M2 Solve the same problem as in the example above but for bolts ¾ “ UNF Grade 2 bolts (Sy=57 ksi, and Su=74 ksi). Create a scaled drawing of the Goodman graph and lable points 1,2,3, and 4 along with all the numerical values for stress labels in the graph. Answer: Factor of Safety is about 2.8 Design of Bolt Groups in Bending Assume bolted frame is rigid. Use geometry to determine bolt elongations. Assume load distribution proportional to elongations. Assume shear loads carried by friction. L F D d Problem #M3: Consider the bracket shown above. Assume the bracket is rigid and the shear loads are carried by friction. The bracket is bolted by four bolts. The following is known: F=5400 lbs, L=40 inches, D=12 inches, d=4 inches. Find appropriate UNC bolt specifications for bolts of 120 Ksi proof strength using a factor of safety of 4. Answer: ¾”- 10UNC Design of Bolt Groups in Torsion Assume bolted frame is rigid. Use geometry to determine bolt distortion. Assume torque distribution proportional to distortions. Assume bracket rotates around the bolt group C.G. Exclude direct shear if its magnitude is small. Use the bolt shank area for analysis of stresses. Example #M4 L The bolts are ½”-13UNC. The distance between bolts is 1.25”. The load is 2700 lbs and L=8”. Find the shear stress on each bolt. Answer: 44250 psi