485 LS Study Guide

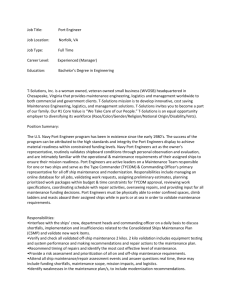

advertisement