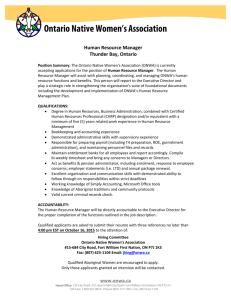

Green Industries

advertisement