Technical Requirements

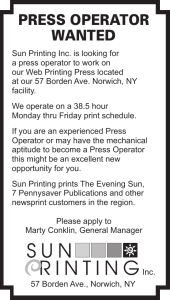

advertisement

Technical Terms of AS Printall November, 11, 2005 1. General 1.1 Technical terms are developed by AS Printall to ensure the print quality. 1.2 Technical terms are mandatory on preparing the printing material and in case of their neglect, the printing house shall not be responsible for the deviances in the quality of the printing result. 1.3 The valid technical terms are public and available at the address www.printall.ee and they are supplied with the last version date. 2. Printing Process 2.1 The newsprint is performed in cold set offset technology using the following paper makes: newsprint 38 g/m2 up to 48.8 g/m2 approved newsprint 49 g/m2 up to 60 g/m2 2.2 The permitted maximum deviance in registration of the newsprint is 0.3mm. 2.3 The permitted density deviance of the newsprint is 0.1 D. 2.4 The magazine print is performed: 2.4.1 in heat-set web-offset technology and using the following paper makes: coated paper 48 g/m2 up to 130 g/m2 uncoated paper 70 g/m2 up to 90 g/m2 approved newsprint 49 g/m2 up to 60 g/m2 2.4.2 in sheet-fed offset technology and using the following paper makes: coated paper 80 g/m2 up to 300 g/m2 uncoated paper 70 g/m2 up to 250 g/m2 2.5 Permitted register deviance in registration of the magazine print is 0.1 mm. 2.6 The permitted density deviance of the magazine print is 0.1 D. 3. File Naming 3.1 The files should be named according to the general rule: The page number_name of the work_reference to the customer_date of issue For example: 23. front page of the AED of Eesti Päevaleht issued on 23rd of September: 001_EPL_AED_0923.pdf Recommendation: use maximum of 5 character mark parts between the separators in the file name. 3.2 Underline character _ or dash - can be used as separators, but commas, slashes, brackets, etc are not be used. The language specific letters (õ, ä, ö, ü, E, E, å , etc) cannot be used in the name. 3.3 In case of the mistakes in naming the files, the printing house is not responsible for the correct layout of the pages. in the sheet fed assembly. Recommendation: As a rule, the file name should include the page number, the date and name of the issue (part). It is also necessary that the files of the same product are named according to the integral logic. 3.4 In case in the preparation procedure of the materials different settings are used, it should be reflected in the file name (contents pages are made in the editing office and advertisements come from the agency). For example: Contents part 42_YA_TM_juuli advertising part 47_YA_TM_juuli_CocaCola 4. Sending the Files 4.1 The files should be sent to the address ftp.printall.ee. Each customer receives a separate catalogue and separately agreed password. 4.2 The files should be sent on the basis of the date and time schedule. 4.3 The files may be brought to the printing house on CD-ROM, USB-memory stick and DVD media. 4.4 In case of the delay in submitting the materials, the printing house shall not be responsible for the timely printing schedule of the product. The deletion and renaming of the sent files in the ftp-server is allowed only for the Preparation Department and all the deficient files, corrected and renewed files should be sent with the changed name, supplying the file name with the word “new” and in repeated sending also with the relevant number of sending. For example: 001_EPL_AED_0923new; 001_EPL_AED_0923new2 4.5 In case of all possible delays, renamining or correction in submitting the material, the customer should give a prior information to the CSO or account manager to ensure the possible change in the schedule 5. File Format 5.1 AS Printall receives the files in composite pdf-format, versions 1.3, 1.4 and according to ISO standard 15930-1 pdf/x-1a: 2001 and ISO standard 15930-4 pdf/x-1a: 2003 and in Postscript-format level 2 and level 3. 5.2 All pages should be aligned and the crop marks and bleed should be used with the products to be trimmed into format. 5.3 Generally the file should include one full page. 5.4 According to the agreement with the Preparation Department the file may also include several full pages, whereas the sequence and volume of the pages should be separately agreed proceeding from the sheet fed assembly. 5.5 All used fonts should be embedded to the file. Recommendation: use Adobe programs in making the pdf-files. Avoid CorelDraw, Windows Office software packages. 6. Layout 6.1 The layout is in printing scale 1:1. 6.2 In product layouts (A3) not trimmed to the final format: blank margin of 12 mm from the upper, bottom and outer edge of the page should be left to the final format. 6.3 In product layouts of the approved newsprint the printing size (backgrounds and other dominating illustrative objects) should be performed as 90% raster. 6.4 In product layouts trimmed to the final format, critical objects (text, logos, and other illustrative elements) should be positioned 5 mm clear of the margins of the final format in addition the bleed of 5 mm from the upper, bottom and outer edge should be left. 6.5 In product layouts, the black and white objects should be in grayscale format. 6.6 In product layouts all the polychrome pictures and objects should be in the CMYK format. 6.7 When in product layout the "rich black" is required, the colour combination black 100%, Cyan 50% or 100% black, 50%Cyan, 40%M should be used in achieving the appropriate colour on the large black surfaces. 6.8 In product layout below 0.2 mm line width and below 10 pts in texts (headings, subheadings, body text) other colours cannot be used in black objects. 6.9 In product design the white fonts below 10 points and line width below 0.2 mm should not be used in coloured objects. 6.10 In product layout of the black framed objects (grid of the crosswords, grid of the table, picture frames or analogical design elements), other colours (Cyan, Magenta, Yellow) should not be used. 6.11 In processing the customer material, the Preparation Department shall ignore the different trapping mechanisms. 6.12 In processing the customer material, the overprint shall be retained unchangeable for all colours, but for 100% black colour the Preparation Department shall make the forced overprint in RIP process. Recommendation: do not use overprint in case of the white colour. 6.13 Screen density is defined by the Preparation Department during the RIP process and is 137 lpi in case of the magazine print and 85 lpi in case of the newsprint, in case of the approved white backing it is 112 lpi. Recommendation: in image processing the used image resolution should be double screen density (e.g. in newsprint the optimal resolution of the images is 170 dpi). On separate agreement it is possible to change the screen density on request of the customer. 6.14 Under the additional 5th (spot) color no CMYK color components are allowed. 7. Colour Management 7.1 In product layout it should be followed that in converting an image from RGB to CMYK the result will be flat CMYK , using the following ICC profiles: 7.2 Newsprint 45 g/m2: ISOnewspaper26v4.icc. 7.3 Coated paper: 7.3.1 in heatset weboffset ISOwebcoated.icc 7.3.2 in sheetfed ISOcoated.icc 7.4 Uncoated (and/or with approved white backing) paper: ISOuncoated.icc. 7.5 Relevant profiles and their description is available at the address www.printall.ee. The access to this page is separately agreed. Recommendation: in image processing the colour correction should be made in RGB. 7.6 In case the image processing is performed with using the integrated colour separation engine or Custom ICC, the following alignments should be used: 7.7 Newsprint 45 g/m2: 7.7.1 total ink limit 240% 7.7.2 maximum black 95 7.7.3 GCR colour separation type 7.7.4 Dot gain 26% 7.8 Coated paper print in heatset weboffset: 7.8.1 total ink limit 300% 7.8.2 maximum black 100 7.8.3 GCR colour separation type 7.8.4 Dot gain 16% 7.9 Coated paper print in sheetfed offset: 7.9.1 total ink limit 350% 7.9.2 maximum black 100 7.9.3 GCR colour separation type 7.9.4 Dot gain 15% Recommendation: in image processing use ICC profiles and avoid integrated colour separation engines and Custom ICC.