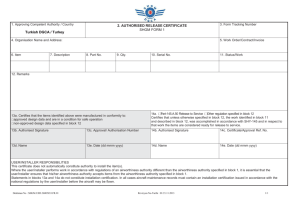

Design Organisation Approval Handbook - Malaysia DCA

advertisement