Masonry - Inmetro

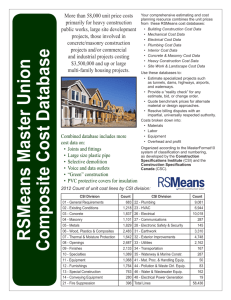

advertisement

1. ------IND- 2006 0432 FIN EN- ------ 20060821 --- --- PROJET Proposal 7 August 2006 B8 THE FINNISH BUILDING REGULATIONS Brick Structures Instructions 2006 Ministry of the Environment Decree on brick structures Adopted in Helsinki on the of 2006 In accordance with the Ministry of the Environment Decision, the following instructions for brick structures, applicable to construction, shall be enacted under Section 13 of the Land Use and Building Act (132/1999) adopted on the 5th of February 1999. This Decree shall enter into force on the of 2006 and it shall repeal the Ministry of the Environment Decision of 28 October 1988 on brick structures. Previous instructions may be applied to permit applications initiated before this Decree entered into force. In Helsinki on the of 2006 Ministry of the Environment Senior Advisor for Building and Planning 1 B8 THE FINNISH BUILDING REGULATIONS MINISTRY OF THE ENVIRONMENT, Department of Housing and Building Brick Structures Instructions 2006 Contents 1 1.1 1.2 1.3 1.4 GENERAL INSTRUCTIONS Scope Definitions Standards and symbols Mutual recognition 2 2.1 2.2 2.3 2.4 2.5 MASONRY MATERIALS Burnt bricks or lime sand bricks and blocks Building mortars Reinforcement elements Masonry ties Lintels 3 3.1 3.2 3.2.1 3.2.2 3.2.3 3.2.4 3.2.5 3.2.6 3.3 3.3.1 3.3.2 3.3.3 3.3.4 3.3.5 3.3.6 3.4 3.4.1 3.4.2 3.4.3 3.4.4 3.4.5 3.4.6 DESIGN OF STRUCTURES Plans Design criteria Methods of dimensioning General design criteria Loads Material characteristics of masonry wall Safety of structures Environmental stresses Structural instructions Joints and bonding Framework External walls Non-loadbearing partition walls Reinforced structures Deformation of structures Dimensioning of structures Loadbearing vertical structures Local compression strength Bracing walls Laterally loaded walls Masonry ties Reinforced masonry 4 4.1 4.2 4.3 PRODUCTION OF STRUCTURES General Management of bricklaying Storage of masonry materials on site 2 4.4 4.4.1 4.4.2 4.4.3 4.4.4 4.4.5 4.4.6 4.4.7 4.4.8 Bricklaying Bonding Joints Location of masonry ties and reinforcement elements in structures Accuracy of work Details of bricklaying Bricklaying in winter Temporary protection of structures Loading of structures 5 5.1 5.2 5.3 QUALITY CONTROL General Quality control of materials and supplies Supervision of production of structures 6 ACCEPTABILITY OF STRUCTURES 7 TESTS 7.1 7.2 7.3 7.4 DETERMINING THE STRENGTH PROPERTIES OF MASONRY WALL BY WAY OF 8 8.1 8.2 FIRE TECHNICAL DIMENSIONING Dimensioning criteria Table dimensions for fire resistance General Number of tests Test arrangements Review of test results Appendix 1 References Appendix 2 Symbols used Appendix 3 Categories of environmental conditions 3 1 General instructions 1.1 Scope These instructions apply to the strength, weather-resistance, long-term durability and fire resistance of structures produced by laying burnt bricks as well as lime sand bricks and blocks using building mortar or made in a similar way. 1.2 Definitions Brick structure refers to a structural element laid of bricks using building mortar Blockwork refers to a structural element laid of blocks using building mortar Burnt brick refers to a masonry piece made of clay or other materials with clay content, possibly also of sand, firing material or other additional materials and burnt at a sufficiently high temperature to achieve ceramic bond LD brick refers to a burnt brick used for protected masonry with the maximum gross dry density of 1000 kg/m3 HD brick refers to a burnt brick used for unprotected masonry and/or with the minimum gross dry density of 1000 kg/m3 Lime sand brick and block refers to a masonry piece mainly made of lime and quartziferous materials hardened at a high steam pressure Building mortar refers to a mixture of one or more inorganic binders, aggregate, water and sometimes blend components and/or additives used for laying of masonry, pointing and jointing General-purpose mortar refers to building mortar for traditional bricklaying Thin-joint mortar refers to building mortar intended for thin pointing with a maximum size of aggregate of 2 mm Light-weight mortar refers to building mortar with a maximum dry and hardened density of 1300 kg/m3 4 Compression strength class of building mortar refers to a class marked with an M after which the average compression strength given for mortar is stated as N/mm2 Masonry refers to a building component formed of bricks or blocks and mortar Masonry wall refers to a structure formed of bricks or blocks and mortar used to determine the characteristic strength of masonry wall (e.g. 1 m high masonry for characteristic compression strength of masonry wall) External leaf refers to external surface masonry in an external wall attached to building frame Cavity wall refers to a wall structure formed of masonry walls tied to each other Lintel refers to a beam used above openings in masonry which can also act as a sandwich structure with masonry; it is made of steel, masonry pieces, mortar, concrete or light-weight concrete or of a combination of these; reinforcement element may also be made of prestressing steel 1.3 Standards and symbols The standards and other documents referred to in these instructions are listed in Appendix 1. The symbols used in these instructions are given in Appendix 2. 1.4 Mutual recognition Whenever these instructions refer to SFS Standards or quality control procedures, an EN Standard or another standard or a quality control procedure with the corresponding level of safety, valid in another country of the European Economic Area, may also be used in accordance with the principle of mutual recognition. 2 Masonry materials 2.1 Burns bricks or lime sand bricks and blocks Burnt LD and HD bricks in accordance with the SFS manual XXXX, and lime sand bricks and blocks in accordance with the SFS manual XXXX are used for structures. Explanatory note: The SFS manual XXXX sets out as to how the Standards SFS-EN 771-1 and SFS-EN 7712 are applied when using these instructions until such time when the use of the Standard EN 1996 in the design of masonry is taken up. The national implementing standard SFS-YYYY sets out the recommendations of the business community of national standardisation as requirements in different uses, for instance, for product characteristics conforming to the Standards SFS-EN 771-1 and SFS-EN 771-2 as well as to the SFS manual XXXX. 2.2 Building mortars Building mortars conforming to the SFS manual XXXX are used for structures. 5 Building mortar is selected so that, when it hardens, it will bind the masonry pieces into a uniform structure. Mortars used for reinforced structures should provide the reinforcement with sufficient protection from corrosion. Explanatory note: The SFS manual XXXX sets out as to how the Standard SFS-EN 998-2 is applied when using these instructions until such time when the use of the Standard EN 1996 in the design of masonry is taken up. The national implementing standard SFS-YYYY sets out the recommendations of the business community of national standardisation as requirements in different uses, for instance, for product characteristics conforming to the Standard SFS-EN 998-2 as well as to the SFS manual XXXX. 2.3 Reinforcement elements Concrete reinforcing bars conforming to the Standard SFS 1215 or stainless steel bars conforming to the Standard SFS 1259, certified by an inspection body and approved by the Ministry of the Environment, are used to receive tensile stresses directed at the structures. Reinforcement elements may also consist of thin-jointed reinforcement elements in accordance with the Standard SFS-EN 845-3 provided that their tensile strength at break, their bond and long-term durability have been clarified. 2.4 Masonry ties Products used to tie and support an external leaf are made of corrosion resistant materials. They must withstand deformations and other stresses due to temperature changes without losing their acceptability. Ties bent from stainless steel wire, or nails made from stainless steel are used to tie an external leaf. Steel ties coated with a hot galvanized layer of at least 50 m may also be used for under 5 m high external leaves. To tie an external leaf, masonry ties conforming to the Standard SFS-EN 845-1 may be used provided that their compression strength, tensile strength, buckling strength/bending stiffness and long-term durability have been clarified. 2.5 Lintels Prefabricated lintels conforming to the certified product declaration are used for structures. Prefabricated lintels conforming to the Standard SFS-EN 845-2 may also be used for structures provided that their loadbearing capacity, deflection, corrosion resistance of reinforcement elements and, if necessary, frost resistance and fire resistance have been clarified. Explanatory note: In addition to prefabricated lintels, prefabricated steel beams, concrete beams and lightweight concrete beams may also be used above the openings in masonry dimensioned to function without the composite effect of masonry, lintels made on site and non-reinforced natural stone pieces when they are dimensioned as loadbearing structures. 6 3 Design of structures 3.1 Plans The plans set out the bricks/blocks and building mortar used, observing the CE marks or the marks conforming to the appropriate SFS manuals. In addition to usual information on structures, such as structural dimensions, location of the structures and useful loads, the plans set out, to the necessary extent, the following: - reinforcement, its protection and anchoring - quality, form, quantity and location of masonry ties - waterproofing and damp-proofing and drainage - expansion joints, their location and structure - bonding of bricks/blocks - type of a joint and thickness of a joint - support of walls - grooves, chases, recesses and holes - working openings and working joints - category of environmental conditions - additional instructions concerning special conditions, such as bricklaying in winter - construction loads and support 3.2 Design criteria 3.2.1 Methods of dimensioning Structures are dimensioned using a limit state design method observing the structural instructions set out in paragraph 3.3. Structures are designed taking into account both the ultimate limit states and the service limit states. 3.2.2 General design criteria Nominal sizes are used as dimensions in the calculations. However, the structure width, in the lateral direction of the structure, may be assumed as the dimension of a joint that meets the limit dimensions of a slot joint and a recessed joint in accordance with paragraph 3.3.1. When the recess of the joint is greater or the dimensions of the slot joint are different from those in paragraph 3.3.1, the thickness measured at the joint is used as the thickness of masonry in the calculations. The distances of support centres are assumed as span lengths of the structures and their clearance height as the height of walls and pillars. However, there is no need to assume a greater value than the clearance of supports multiplied with a coefficient of 1.05 as span lengths. 3.2.3 Loads Design loads of the structures are calculated in accordance with the regulations concerning them. 7 It may be assumed that the vertical loads in masonry walls are distributed and transferred in accordance with Fig. 1. Fig. 1. Distribution of vertical loads in a wall. When the structures receive the horizontal force of arch, the effect of arch may be taken into account above the openings in the distribution of loads, and assume that part of the vertical load is transferred directly onto the supports in accordance with Fig. 2. Fig. 2. Distribution of vertical loads at an opening. It may be assumed that the loads are evenly distributed onto the entire supporting surface on the supports of horizontal structures and at the lower ends of walls and pillars. When horizontal structures transfer horizontal loads onto more than one bracing wall, it may be assumed that the loads are distributed onto bracing walls in proportion to their rigidity. If necessary, the asymmetrical location of bracing walls is taken into account in the distribution of horizontal loads. Distribution of bending moments and shear forces in structures are calculated in accordance with the elasticity theory or using approximate methods set out in this instruction. When wall structures are dimensioned for wind loads, masonry may be calculated using the broken line 8 theory. If necessary, cracking of the structure and stresses due to constraint action are taken into account. No more than 20 % may be deviated from the distribution of bending moments conforming to the elasticity theory in continuous structures when other quantities of force are corrected to correspond to the altered distribution. 3.2.4 Material characteristics of masonry wall The strength characteristics of masonry wall are determined by way of tests in accordance with paragraph 7, or specific values determined for masonry wall from strength classes/characteristic values set out for masonry pieces and mortars conforming to the SFS manual XXXX with their use requiring that the joints and bonds meet the requirements set out in paragraph 3.3.1, are used in the design. The bond strength between a masonry piece and building mortar should conform at least to the requirement set out in the SFS manual XXXX. Values in Table 1 are used as characteristic values of compression strength of masonry wall built of burnt LD bricks and HD bricks using general-purpose mortar or thin-joint mortar. Values in Table 2 are used as characteristic values of compression strength of masonry wall built of lime sand bricks and blocks using general-purpose mortar or thin-joint mortar. Table 1. Characteristic values fck of compression strength of masonry wall built of burnt LD bricks and HD bricks using general-purpose mortar, given as N/mm2 Strength class of masonry piece 5 10 15 20 25 30 35 45 55 Compression strength class of building mortar M2.5 M5 M7.5 M10 M15 2.0 3.0 4.0 4.5 5.5 6.0 6.5 7.0 7.0 2.5 3.5 4.5 5.5 6.5 7.0 8.0 9.0 9.5 3.0 4.0 5.5 6.5 8.0 9.0 10.0 11.5 12.5 3.0 4.0 5.5 7.0 8.5 9.5 10.5 12.5 13.5 3.0 4.5 6.0 7.5 9.0 10.0 11.5 13.5 14.5 Note 1: Values in-between may be interpolated. Note 2: Characteristic values set out in Table 1 apply to burnt bricks in the opening group of 1 and 2 of the SFS manual when the compression strength of the masonry piece is determined with a test conforming to Appendix I.C of the said SFS manual using, as a test piece, two brick halves bedded together with cement mortar. Table 2. Characteristic values fck of compression strength of masonry wall built of lime sand bricks and blocks using general-purpose mortar, given as N/mm2. Strength class of masonry piece 10 15 20 25 30 Compression strength class of building mortar M2.5 M5 M7.5 M10 M15 2.0 3.0 4.0 4.5 5.5 2.5 3.5 4.5 5.5 6.5 3.0 4.0 5.5 6.5 8.0 3.0 4.0 5.5 7.0 8.5 3.0 4.5 6.0 7.5 9.0 Note 1: Values in-between may be interpolated. Note 2: If a structure is made by laying bricks/blocks with thin joints when the maximum thickness of joints is 3 mm, a value of M15 may be used as the strength class for building mortar. 9 Note 3: Characteristic values set out in Table 2 apply to lime sand bricks and blocks in the opening group of 1 and 2 of the SFS manual XXXX when the compression strength of the masonry piece is determined with a test conforming to the Standard EN 772-1 using a masonry piece conforming to the said opening group as a test piece. When the compression is in the vertical direction against the end of the masonry piece, the effect of the holes in masonry built of masonry pieces with holes, are taken into account as a reduction in strength by using a reduction coefficient of 0.5. When no mortar is used in vertical joints in bricklaying, the characteristic values in Tables 1 and 2 may be used except when the compression is in the vertical direction against the end of the masonry piece in which case the effect of vertical joints without mortar is taken into account using a reduction coefficient of 0.5. Characteristic values of bending strength of masonry wall, built of burnt LD bricks and HD bricks as well as of lime sand bricks and blocks using general-purpose mortar or thin-joint mortar in the fracture plane in the direction of horizontal joints (see Fig. 3, case 1), are obtained from Table 3a, and the characteristic values of bending strength of a masonry piece against the direction of horizontal joints in the vertical plane (see Fig. 3, case 2) are obtained from Table 3b. Table 3a. Characteristic values fxk1 of bending strength of masonry wall built of burnt LD bricks and HD bricks as well as of lime sand bricks and blocks using general-purpose mortar or thin-joint mortar in the fracture plane in the direction of horizontal joints, given as N/mm2. Strength class of masonry piece 5 15 20 25 35 45 55 Compression strength class of building mortar M10 ≤ M5 0.20 0.20 0.20 0.25 0.35 0.35 0.35 0.15 0.15 0.15 0.20 0.20 0.20 0.20 Note 1: Values in-between may be interpolated. Table 3b. Characteristic values fxk2 of bending strength of masonry wall built of burnt LD bricks and HD bricks as well as of lime sand bricks and blocks using general-purpose mortar or thin-joint mortar against the direction of horizontal joints in the vertical plane, given as N/mm2. Strength class of masonry piece 5 15 20 25 35 45 55 Compression strength class of building mortar M10 ≤ M5 0.60 0.60 0.60 0.75 1.05 1.05 1.05 0.45 0.45 0.45 0.60 0.60 0.60 0.60 Note 1: Values in-between may be interpolated. When no mortar is used in vertical joints in bricklaying, the characteristic values in Table 3a may be used. The effect of vertical joints without mortar against the direction of horizontal joints in the vertical plane is taken into account by multiplying the characteristic values in Table 3b with a reduction coefficient of 0.7. 10 Fig. 3. Bending strength of masonry wall in different directions. Case 1: Bending strength in the fracture plane in the direction of horizontal joints. Case 2: Bending strength in the vertical fracture plane against the direction of horizontal joints. Characteristic value of shearing bond strength in the direction of horizontal joints is calculated from the equation fvk = fvko + 0.4 c ≤ 1.0 N/mm2 (3.1) where fvk fvko c is the characteristic value of shearing bond strength; is obtained from Table 4; is the vertical compression stress against the joint plane calculated from permanent loads multiplied with a safety figure of 0.9. Table 4. Characteristic value of shearing bond strength of masonry wall built of burnt LD bricks and HD bricks as well as of lime sand bricks and blocks using general-purpose mortar without the effect of vertical compression stress against the joint plane f vko, N/mm2. Strength class of masonry piece 5 - 20 > 20 Compression strength class of building mortar M10 ≤ M5 0.2 0.3 0.16 0.2 Note 1: Values in-between may be interpolated. Characteristic value of shearing bond strength of masonry wall built of burnt LD bricks and HD bricks as well as of lime sand bricks and blocks using thin-joint mortar without the effect of vertical compression stress against the joint plane fvko = 0.31 N/mm2. When no mortar is used in vertical joints in masonry wall, the characteristic value of shearing bond strength is fvko = 0.07 N/mm2. The characteristic value of shear strength of masonry wall in vertical cross-section may be calculated by using, in the cross-section, a value of 1.5 N/mm2 for shear strength of a masonry 11 piece for burnt HD bricks as well as for lime sand bricks and blocks. When using the said values, the part of vertical joints is not taken into account. Values in Table 4 are used as a characteristic value of shear strength of reinforced masonry fvk. When calculating deformations due to short-term loading, the value below is used for the coefficient of elasticity in masonry Ec = 800 fck (3.2) where fck is the characteristic value of compression strength. When calculating deformations due to long-term loading, the value below is used for the coefficient of elasticity in masonry Ecc = Ec/(1 + ) (3.3) where = 0.75 with burnt bricks; = 1.50 with lime sand bricks and blocks. A value of 0.1 mm/m for shrinkage after brick laying and for moisture deformation, due to masonry wall getting wet and drying, is used for both with burnt bricks, and a value of 0.2 mm/m with lime sand bricks. A value of 6 x 10-6 °C-1 for the thermal expansion coefficient of the length of masonry may be used for burnt bricks and a value of 8 x 10-6 °C-1 for lime sand bricks and blocks. A lower yield limit or a limit of 0.2 is used as the characteristic strength of reinforcement, and the coefficient of elasticity of the said steel grade as the coefficient of elasticity. 3.2.5 Safety of structures When surveying the ultimate limit state of loadbearing structures, the design strength is obtained by dividing the characteristic strength of masonry wall/material with the partial safety figure of material conforming to Table 5. Table 5. Partial safety figures for materials Material Masonry from masonry pieces in category I of the applicable SFS manual Masonry from masonry pieces in category II of the applicable SFS manual Reinforcement Partial safety figure for material in ultimate limit state 2.0 3.0 1.2 The safety figure of reinforcement is used as the partial safety figure for material in steel masonry ties and the safety figure of masonry as the partial safety figure for anchoring. 12 If necessary, the surveys of service limit state show that deformations and cracks do not exceed the requirements imposed on usability of a structure nor are they otherwise detrimental. A value of 1.0 is used as the partial safety figure for material in the surveys of service state limit. 3.2.6 Environmental stresses When designing structures located next to the open air, the environmental stresses including deformations due to changes in temperature and moisture, rain and wind pressure as well as frost attack due to repeated freezing, should be taken into account. External stresses depend on the climate, on the location, form and height of the building as well as on the details of the structure. The diagonal rain stress depends primarily on the wind pressure directed at the wall. Particular attention to rain tightness should be paid when the building has no guttering, is high or located in an exposed place. Joints of the external leaf are made as tight as possible. When designing a wall, it should be remembered that water may seep through the external leaf, and care should be taken to conduct water away. Frost attack is directed most strongly at structures which are exposed to extensive moisture and where the temperature changes quickly follow the temperature changes outdoors. Frost attack is taken into account when selecting masonry materials and when designing a structure. Masonry pieces and mortar and any structures built from them and used outdoors should be weatherproof. Structures are designed so that no water from other building elements can adversely accumulate in them and that they are proofed from ground moisture. Structural reinforcement used in reinforced masonry should meet the following requirements for corrosion protection in different classes of environmental conditions (see Appendix 3): MX1: No requirements for corrosion protection MX2 and MX3: Stainless steel conforming to Standard SFS 1259 or hot-galvanized steel meeting the requirements concerning coating in at least Class ZnE of Standard SFS 1266. MX4: Stainless steel conforming to Standard SFS 1259 or hot-galvanized steel meeting the requirements concerning coating in at least Class ZnB of Standard SFS 1266. MX5: Requirement for corrosion protection set by the designer. 3.3 Structural instructions 3.3.1 Joints and bonding The strength and deformation characteristics set out in paragraph 3.2.4 apply to stretcher bonded masonry wall built using full joints (Fig. 4 a) or slot joints (meeting the requirements in Fig. 4 b) with the average joint thickness of no more than 15 mm. When using thin-joint mortar, the average joint thickness is no more than 3 mm. Masonry where staggering of overlapping masonry pieces is at least 1/4 of the length of the masonry piece and 1/2 of the height of the masonry piece is regarded as stretcher bonded (Fig. 5). A joint may be recessed from the plane of the masonry piece at the most in accordance with Fig. 4 c. When using other methods of bonding, thicker joints or racked or post-pointed joints, the weakening of masonry is taken into account in the plans. Wall structures may be laid using vertical joints without mortar if the reduction in the strength of the structure is taken into account, as set out in paragraph 3.2.4, and the structure is sealed with a surface layer as required by the object of use. 13 Fig. 4. Full joint and slot joint. täysi sauma – full joint rakosauma – slot joint sauman sisäänveto – recessed joint Fig. 5. Stretcher bonded masonry. 3.3.2 Framework The building frame and the associated masonry are designed so that sufficient total stability and construction stability are achieved. Dimensioning of masonry elements conforming to paragraph 3.4 requires that the joints between the structural elements transfer all horizontal forces onto the bracing structures. The bracing structures and joints should be checked on each plane at least for horizontal loads which are 0.5 % of the vertical load transferred from the plane. Generally, floors and roofs and transverse walls or lattice structures and framed structures functioning as plates are used as bracing structures. Walls which are included in the frame are bonded or tied to each other using reinforcement. 14 The minimum nominal thickness of a loadbearing or bracing wall is 85 mm in buildings with a maximum of two storeys, and 120 mm in buildings with several storeys. The minimum crosssectional area of a pillar is 50,000 mm2. The maximum design slenderness d of a loadbearing vertical structure, conforming to paragraph 3.4.1.4, is 30. 3.3.3 External walls The external leaf is braced and tied to the building frame so that deformations due to changes in temperature and moisture cause no damage to the structure. The external leaf is distributed with expansion joints into sections so that deformations cause no adverse cracks. Expansion joints are located in places where free movement of masonry wall is prevented, such as corners or in places where cracking is likely, for instance, due to changes in cross-section or to rejections. Cracking may also be restricted locally with reinforcement. Sections of the external leaf supported at different heights or braced to non-continuous structures are separated with expansion joints in a vertical direction. The external leaf is tied to the building frame with masonry ties. If the bracing effect of the external leaf is utilized in dimensioning of loadbearing walls or if the external leaf is dimensioned for wind loads by distributing some load on both leaves, the minimum quantity of ties is 4 kpl/m2 for the entire wall surface. If tying does not apply to the entire wall surface, the areas between the ties are dimensioned for wind loads in accordance with paragraph 3.4.4. External walls are designed so that no rainwater can adversely penetrate the wall or through the wall. The reveals of openings, joining to other structural elements and ventilation openings are designed so that no water can penetrate the walls through them. Joining of external walls to window and door openings, to floors and roofs and to the foundations is designed so that water, possibly penetrated through the external leaf, is carried away without causing damage. The maximum nominal thickness of the external leaf is 85 mm. 3.3.4 Non-loadbearing partition walls Non-loadbearing partition walls are supported so that sufficient stability is achieved for horizontal loads. When designing the walls, possible deflections of horizontal structures are taken into account. 3.3.5 Reinforced structures Reinforcement elements are positioned in joints or in channels formed from special masonry pieces. The minimum thickness of a joint should be 1.5-fold in comparison to the thickness of a reinforcement element. The compression strength class of mortar should be at least M 7.5 in structures outdoors and at least M 5 indoors. The minimum distance of a reinforcement element from the surface of a structure should be 15 mm indoors or, when reinforcement elements made of stainless steel are used, otherwise 30 mm. The minimum clearance of reinforcement bars should be 20 mm. The effective height of cross-section in beam structures is no more than 1 /2 of the span length and no more than 10 times the beam width. The maximum distance between reinforcement bars in panel structures is 400 mm. With beam structures, care should be taken to tie the masonry pieces underneath the reinforcement. 3.3.6 Deformation of structures 15 Masonry, joints and expansion joints are designed so that deformations and cracks due to loads and changes in temperature and moisture are not detrimental to the functioning of the structure or do not damage the associated structures. 3.4 Dimensioning of structures 3.4.1 Loadbearing vertical structures 3.4.1.1 General Loadbearing vertical structures are loaded with loads in the direction of their vertical axis and with possible horizontal loads. Masonry walls and pillars are dimensioned homogeneous and non-resistant to tension. Non-reinforced masonry walls and pillars may be dimensioned by assuming that they are only resistant to bending when dimensioning them for wind loads or similar short-term loads. Eccentricity of loads and slenderness of structures are taken into account in dimensioning. Walls and pillars are surveyed as separate structural elements by assuming that the method of bracing is articulated or by assuming that the method of bracing is secure, partly or in full (e.g. as parts of framed structures). When walls and pillars are fastened to horizontal structures, they may also be surveyed as part of a framed structure, and methods of calculation, more accurate than the approximate methods set out in this instruction, may be used for dimensioning of structures. In this case, eccentricity of vertical loads is calculated with the help of restraint moments and, generally, the clearance height of the structure of at least 0.75-fold is used as the effective length Ho. 3.4.1.2 Compression strength Compression strength Nu of a masonry wall or pillar is calculated using the equation: Nu = ks Ac fcd (3.4) where Ac fcd ks is the cross-sectional area; is the design value of compression strength of masonry wall; is the reduction coefficient which takes into account the eccentricity of load and slenderness of structure, obtained from Fig. 6. 16 Fig. 6. Coefficient ks. 3.4.1.3 Eccentricity of load The compression strength of a structure is calculated by using the design eccentricity ed: ed = 0.6 e1 + 0.4 e2 + ew 0.05 t + ew (3.5) where e1 e2 ew t is, in its absolute value, the greater of the eccentricities of the ends; is, in its absolute value, the smaller of the eccentricities of the ends, i.e. zero if the eccentricities are unlike; is the eccentricity due to horizontal load; is the thickness of the structure. The eccentricity of vertical loads is determined in accordance with Fig. 7. It is assumed that the support reaction on the supports of horizontal structures is distributed over the supporting surface so that it has an effect at the third of the point of the supporting surface. It is assumed that the support reaction of loads that are transferred on both sides of the wall over the supports of continuous horizontal structures has an effect at the third of the points of the supporting surface. It is assumed that the load is evenly distributed over the supporting surface at the lower end of the structure when the resultant of the load has an effect at the centre point of the supporting surface. 17 Fig. 7. Eccentricity of vertical load. Eccentricity ew due to vertical loads is calculated from the equation: ew = Md/Nd (3.6) where Md Nd is the design value of bending moment due to horizontal load; is the design value of normal force. If a horizontal structure rests on the cross-section of an entire vertical structure, the bending moment due to horizontal loads may be calculated by assuming that the support is partly fixed and that the support moment is 75 % of the support moment of a fully fixed structure. 3.4.1.4 Slenderness of structure The compression strength of a structure is calculated by using the design slenderness: d = Ho/te (3.7) where Ho te is the effective length; is the effective thickness of the structure. When the lateral shift of a structure is prevented, the clearance height of the wall or pillar may be used as effective length Ho. When the wall is supported, for instance, with a transverse wall on one side or both sides, the effective length Ho is calculated by multiplying the clearance height H with the coefficient kh obtained from Table 6 where L is the horizontal length of the wall. Table 6. Coefficient kh. L/H 0.3 0.5 1.0 kh Both sides supported1) 0.2 0.3 0.6 18 One side supported2) 0.5 0.7 0.9 1.5 2.0 1) 2) 0.8 0.9 1.0 1.0 L ≤ 30 to L ≤ 15 to Fig. 8. Support of wall. The effective thickness te with a single wall is its nominal thickness and with a pillar its smaller side measurement. With cavity walls, tied to each other with masonry ties evenly distributed over the entire wall surface transferring the horizontal forces due to deflection of the wall, the effective thickness is calculated from the equation: te = 3√(t13 + t23) (3.8) where t1 and t2 are the thicknesses of the cavity wall leaves The effective thickness te for arbitrary cross-section is calculated using the equation: te = √(12 i) (3.9) where i is the radius of gyration in the direction to be surveyed. 3.4.2 Local compression strength When the compressing force only loads part of the cross-section of a structure, the local compression strength NRu is calculated using the equation: NRu = Ao ∙ fcd (1 + 0.1 (t ∙ ao)/Ao) ≤ 1.5 Ao ∙ fcd (3.10) where Ao fcd ao t is the area of loaded surface which is no more than 2 t2 and where the minimum distance of the centre of gravity from the edge of the structure is t/4, is the design value of compression strength of masonry wall; is the distance of the loaded surface edge from the end of the wall; is the thickness of the structure. 19 Fig. 9. Local compression strength. 3.4.3 Bracing walls Bracing walls are loaded with a horizontal load in the direction of their plane and with a possible vertical load. Walls are dimensioned for shearing due to horizontal loads and for vertical load in accordance with Fig. 10. Shear strength Vu of masonry in the plane of horizontal joints is calculated using the equation: Vu = An fvd (3.11) where An fvd is the area of compressed cross-section; is the design value of shearing bond strength, see equation 3.1. Fig. 10. Dimensioning of bracing wall for shearing and for vertical load. If necessary, sliding of walls over damp-proof course is taken into account. Compression strength of a bracing wall is calculated in accordance with paragraph 3.4.1 by taking into account the eccentricity of load in the direction of the wall plane. 3.4.4 Laterally loaded walls When a wall is mainly loaded with lateral load vertically against its plane, the distribution of bending moments may be calculated by applying the elasticity theory of orthotropic plate or the 20 broken line theory. Walls are dimensioned so that the bending moments due to design loads do not exceed the bending strength in the direction to be surveyed. When masonry is loaded with horizontal load due to wind, the bending strength of the structure is calculated from the equation: Mu = (fxd1 + c) W (3.12) where fxd1 c W is the design value of bending tensile strength in the fracture plane in the direction of horizontal joints; is the compression stress due to vertical load (calculated from permanent loads using a partial safety coefficient of 0.9 for load); is the bending strength for cross-section. Bending strength in the horizontal direction is calculated from the equation: Mu = fxd2 W (3.13) where fxk2 W is the design value of bending tensile strength in the fracture plane vertically against horizontal joints; is the bending strength for cross-section. It may be assumed that with cavity walls, wind load is distributed for walls in proportion to their rigidity when masonry ties are divided for the entire wall surface and dimensioned for wind pressure and suction. When a wall structure in the horizontal direction is continuous and the maximum ratio L/t of the wall length and thickness is 30, it is assumed that it can function as a horizontal arch. Bending strength of the wall may be calculated using the equation: Mu = 0.07 fcd t2 H where fcd t H (3.14) is the design value of compression strength of masonry wall; is the wall thickness; is the height of the wall section to be surveyed. When the entire upper and lower level of the wall structure is supported, the maximum slenderness H/t of the wall is 20 and when the wall is loaded with a simultaneous vertical load, it is assumed that it can function as a vertical arch. If the maximum compression stress over the entire cross-sectional area, calculated from the design value of normal force, is a 0.2-fold design compression strength, the bending strength of the wall may be calculated using the equation: Mu = 0.3 t Nd where t Nd (3.15) is the wall thickness; is the design value of normal force (calculated from permanent loads using a partial safety coefficient of load of 0.9). 3.4.5 Masonry ties Masonry ties of the external leaf are dimensioned for compression and tension due to wind pressure and tension. A design value of 0.8 kN is used as tensile strength in masonry ties with a diameter of 4 mm, made of stainless or hot-galvanized steel and anchored in accordance with 21 Fig. 11, and a design value of 0.4 kN as compression strength when the minimum compression strength class of mortar is M 5. Fig. 11. An example of a masonry tie of an external leaf. Tensile and compression strength of other types of masonry ties is determined in accordance with Standard SFS-EN 845-1. Anchoring of masonry ties to structures other than masonry is designed in accordance with the instructions concerning the said structures and the type of ties. When designing masonry ties, any recurring thermal and moisture movements of the external leaf are taken into account. It is thought that steel ties fixed from both ends endure deformation stresses if their clearance length is: l √(0.2 Ød H) (3.16) where l Ød H is the clearance length of masonry tie; is the diameter of masonry tie; is the height of external leaf. If the length of a masonry tie is shorter than this, fastening which allows vertical movement is used. 3.4.6 Reinforced masonry 3.4.6.1 Dimensioning criteria Bending and tensile strength of masonry may be increased and brittle fracture of the structure prevented with reinforcement. In addition to the material characteristics of blocks, mortar and reinforcement, the functioning of reinforcement and the characteristics of a reinforced structure depend on bonding between these and on corrosion protection of reinforcement. Reinforcement is generally used in beam structures above the masonry wall openings and in laterally loaded walls functioning as a panel. In this case, the structures are dimensioned for bending moment, shear force and anchoring force of reinforcement due to these. 3.4.6.2 Bending strength 22 Bending strength of a reinforced structure is calculated from the equation: Mu = 0.8 As d fyd ≤ 0.3 fcd b d2 (3.17) where As b d fcd fyd is the cross-sectional area of tensile reinforcement; is the width of cross-section; is the effective height of cross-section; is the design value of compression strength of masonry wall in the direction to be surveyed; is the design strength of steel. 3.4.6.3 Shear strength Shear strength of a reinforced structure is calculated using the equation: Vu = fvd b d (3.18) where b d fvd is the width of cross-section; is the effective height of cross-section; is the design value of shear strength of reinforced structure, see Chapter 3.2.4. When checking the shear strength, the design loads with their distance from the support edge less than 2d, may be multiplied with 0.5 ∙ a/d. 3.4.6.4 Anchor strength Tensile stress of reinforcement in the cross-section to be surveyed is the sum of stresses due to bending moment and shear force at the point to be surveyed, and this is checked using the equation: Fbu Vd + Md/(0.8 d) (3.19) where Vd Md d is the design value of shearing force of cross-section; is the design value of bending moment of cross-section; is the effective height of cross-section. However, it is not necessary to assume that the tensile strength is greater than the values occurring in cross-sections dominant in respect of the bending moment. Anchor strength Fbu of a straight deformed bar is calculated using the equation: Fbu = fbu us lb ≤ 2 fvd b lb (3.20) where fbu us is the design value of anchor strength which is with the deformed bars (A500HW and B600KX) 1.5 N/mm2 using building mortar with a compression strength class of at least M 7.5 and 0.8 N/mm2 using building mortar with a compression strength class of at least M 5; is the circumference of reinforcement bar; 23 lb fvd b is the anchoring length; is the design value of the shearing bond strength in the direction of the horizontal joint, is the width of the joint. 4 Production of structures 4.1 General Masonry is built in accordance with the drawings and other construction documents observing working methods known to be good. 4.2 Management of bricklaying A person responsible for bricklaying should have training, skills and experience sufficient for the job. He/she takes care of compliance with the plans and with the quality of work at different stages of the building work. 4.3 Storage of masonry materials on site Masonry materials are stored so that they remain usable. They are protected from rain, soil moisture, dirt and other adverse effects. In addition, care is taken so that different types are not mixed with each other. 4.4 Bricklaying 4.4.1 Bonding Unless otherwise stated in the plans, bricks on top of the other are bonded to each other over a distance of at least 1/4 of the length of the masonry piece and at least 1/2 of the height of the masonry piece. 4.4.2 Joints Structures are built using full joints (Fig. 4 a) or slot joints (Fig. 4 b) or using special joints in accordance with the plans. A joint may be recessed at the most from the surface of a masonry piece in accordance with Fig. 4 c unless otherwise stated in the drawings. When using generalpurpose mortar, the nominal thickness of horizontal and vertical joints is 12…15 mm, and 2 mm when using thin-joint mortar, unless otherwise stated in the plans. Particular attention is paid to the tightness of the joints in structures exposed to weather stress and in structures included in framework. 4.4.3 Location of masonry ties and reinforcement elements in structures Masonry ties and reinforcement elements are located in structures as indicated so that the requirements in paragraphs 3.3.5 and 3.4.4 are met. Unless otherwise stated in the plans, the minimum number of masonry ties for the external leaf is 4 kpl/m2. 4.4.4 Accuracy of work The connecting line of the centres of top and bottom ends of the wall and pillar may deviate from vertical by no more than H/200 and the curvature measured from the connecting line may be no more than H/250 where H is the clearance height of the structure. 24 With supports, the maximum horizontal deviation of a wall and pillar from the planned centre line may be 8 mm. When using general-purpose mortar and light-weight mortar, the thickness of horizontal joints may deviate from the nominal thickness by no more than 3 mm and the thickness of vertical joints by no more than 8 mm. 4.4.5 Details of bricklaying Generally, any grooves, chases, recesses and holes may only be made in accordance with the plans. Vertical grooves with the maximum depth of 25 mm and the maximum width of 50 mm and vertical chases with the maximum width of 1/3 of the wall thickness and the length no more than the wall thickness, with their combined cross-sectional area of no more than 5 % of the cross-sectional area of the wall inside wall structures, may be made on the surface of loadbearing wall structures without structural reports. The grooves, chases and recesses are made either by cutting or by laying of special masonry pieces. Working openings and joints may be made if their effect on the structural strength is taken into account. 4.4.6 Bricklaying in winter Winter conditions are deemed to prevail when the air temperature goes below 0 °C, even intermittently. Then, particular attention is paid to the execution of work, to keeping and storage of building materials, to organisation of work and to protection of masonry. Masonry pieces must not be wet, frozen or covered in snow. If necessary, they may be heated. Building mortars, intended for winter conditions, are used in the winter conditions. Building mortar must not contain pieces of ice or icy components. If necessary, warm water is used to mix building mortar. When using warm building mortars, rapid stiffening of mortar should be taken into account. The temperature of building mortar must not exceed +40 °C. In the winter conditions, bricklaying work is carried out and the structure protected so that the temperature of building mortar remains above 0 °C so long that freezing of water no longer damages the mortar or the bond between the mortar and masonry piece. Building mortar must not freeze until the water content in mortar is reduced sufficiently low by masonry pieces absorbing the water or until mortar has hardened so long that it has achieved sufficient strength before freezing. 6 % of the dry weight may be regarded as a sufficiently low water content in respect of freezing for cement-lime mortars with at least 65 percentage by weight of their binding agent being Portland cement and for building cement mortars. Absorption of water from building mortar by masonry pieces is clarified by way of tests or in some other reliable way. When the structure thaws, it may be assumed that the maximum strength of masonry wall is 40 % of the design strength. Cement-lime mortars, with at least 65 percentage by weight of their binding agent being Portland cement, and building cement mortars may be deemed as having achieved sufficient strength in respect of freezing, regardless of the amount of water, after they have hardened at a temperature of over 0°C for at least 2 days. The temperature of building mortar is controlled in a reliable way. When the structure thaws, it may be assumed that the maximum strength of masonry wall is 60 % of the design strength. Reinforced masonry is made so that the temperature of the structure remains above 0 °C for 2 days. 4.4.7 Temporary protection of structures 25 Masonry is protected from temporary adverse stresses and contamination. Adverse stress may be, for instance, freshly laid structure getting wet from the effects of rain, snow and thaw water as well as of casting and water spraying of concrete structures, or too rapid or uneven drying and warming up. 4.4.8 Loading of structures Moulds and supports are made so that no adverse deformations take place in masonry. Support structures may not be dismantled and the structure loaded until masonry has achieved sufficient strength. The strength of a structure may be assessed on the basis of development of the strength of the mortar. The speed of hardening depends on the absorption of water by masonry pieces or on the temperature. Particular attention should be paid to the development of sufficient strength in the winter conditions. 5 Quality control 5.1 General To ensure the acceptability of masonry, the quality of the structures and of the construction materials used in them is controlled. 5.2 Quality control of materials and supplies Quality control of materials and supplies consists of quality control by the manufacturer and the user of masonry pieces, building mortars and their components as well as of reinforcement elements and other materials. The manufacturer of materials and supplies controls the quality of the products in accordance with the SFS manual XXXX or the instructions by an inspection body approved by the Ministry of the Environment. Building materials are visually inspected on site and they are checked to make sure that they correspond to the plans and that their acceptability is met in accordance with section 6. Manufacturing markings in the products and packages are taken into safekeeping. 5.3 Supervision of production of structures The supervision of production of structures consists of work supervision and possible preliminary tests and temporary tests. A person responsible for bricklaying monitors that bricklaying is carried out with sufficient workmanship in accordance with the instructions in section 4 and the instructions by the designer. Strength characteristics of masonry are clarified using preliminary tests, if the used masonry pieces or building mortars or additives in mortars with unknown properties are different from those in the SFS manual XXXX or the used dimensioning values in dimensioning of structures are different from those in this instruction. Preliminary tests are also carried out in accordance with section 7. If necessary, other characteristics of masonry, such as weather resistance and moisture technical function, are also clarified in advance. Test pieces for preliminary tests are made of building materials intended for use. If necessary, preliminary tests are supplemented with temporary tests. 26 6 Acceptability of structures Acceptability of masonry is demonstrated on the basis of the data required in these instructions regarding materials and supplies, design and production of structures. Demonstration of acceptability may also be based on the data available from preliminary tests and temporary tests supplementing these. Generally, acceptability of materials and supplies is deemed acceptable if - they conform to the requirements in Chapter 2 and - there appears no reason to suspect the quality of the materials and supplies. Otherwise, acceptability is assessed from the samples taken on site on the basis of the tests carried out in an approved testing centre. Samples are taken and tests carried out as required by the SFS manual XXXX to the extent it is considered appropriate in respect of the structure to be made. In respect of masonry ties used in structures, it is generally sufficient that they are checked visually and they are verified to meet the requirements in accordance with paragraph 2.4. 7 Determining the strength properties of masonry wall by way of tests 7.1 General The strength properties of masonry used in the design of structures may be determined using masonry test pieces. Tests may be carried out in respect of one composition of mortar, type of masonry piece and method of bricklaying or as more extensive suitability tests. 7.2 Number of tests The number of tests depends on the desired accuracy of the results and on the extent of the scope of the results. At least three tests for each combination of materials to be surveyed are carried out to determine the properties. At least six similar tests are required for a statistical review of the test results. 7.3 Test arrangements Test arrangements are made so that the stress placed on test pieces corresponds with sufficient accuracy to the stress of masonry wall in the structure. Tests are carried out in accordance with the standards relating to them. The characteristics of masonry pieces and building mortars used are determined to the necessary extent in connection with structural tests. 7.4 Review of test results The characteristic strengths are calculated from the test results by using fractile defective of 5 % and operating characteristic of 50 %. If the number of test results corresponds to that required by statistical examination, the characteristic strength is calculated from the test results using the specified mean value and standard deviation. If the number of test results is not enough to determine the standard deviation, it may generally be assumed that the deviation of strength is 15 27 % of the mean value. However, in this case, the characteristic strength must not be assumed to be greater than the smallest individual test result. The deformation characteristics of a masonry wall are determined as the mean value of test results. The characteristics of masonry pieces and building mortars required in their quality control are determined on the basis of the test results produced in connection with structural tests. 8 Fire technical dimensioning 8.1 Dimensioning criteria Loadbearing and separating elements are distributed into classes on the grounds how they resist fire. The requirements concerning building elements are described with the following markings: R loadbearing capacity E tightness I insulation capacity A marking may be supplemented with a code: M impact resistance in a fire situation Conformity of a building element is shown by way of tests, with calculatory methods or by means of table dimensions in paragraph 8.2. Building elements are made of building materials which meet the class requirements set for materials in each use. Explanatory note: The requirements for fire resistance and the requirements for class concerning building elements are set out in Parts E1, E2, E4 and E9 of the Finnish Building Regulations. 8.2 Table dimensions for fire resistance The minimum dimensions corresponding to different fire resistance classes of walls laid of burnt bricks as well as of lime sand bricks and blocks included in groups 1 or 2 for openings are set out in Table 7. Masonry pillars should meet, in different fire resistance classes, the requirement concerning the smallest side dimension set out in Table 8. The design slenderness d calculated using the equation (3.7) must not exceed the value 27 for loadbearing masonry and the value 40 for non-loadbearing masonry. Table 7. Minimum thickness (mm) of a masonry wall in different fire resistance classes EI (separating non-loadbearing structure), REI (separating, loadbearing structure) and R (loadbearing structure inside compartment). Minimum thickness (mm) of a masonry wall Fire resistance class, fire-resistance period (in minutes) EI REI R1 1 30 60 90 120 180 240 70 110 110 85 110 120 110 110 135 110 110 200 130 180 235 160 235 300 Minimum length of wall 1 m. Table 8. 28 Smallest side dimension (mm) of a masonry pillar in different fire resistance classes R (loadbearing structure). Smallest side dimension (mm) of a masonry pillar Fire resistance class, fire-resistance period (in minutes) R 30 60 90 120 180 240 250 250 250 250 280 350 29 Appendix 1 References SFS manual XXXX Masonry products SFS-YYYY Characteristics required for masonry products in different uses, and standards set for them SFS-EN 1996 Eurocode 6 – Design of masonry (Parts 1-1, 1-2, 2 and 3) SFS-EN 771-1 Specifications for masonry pieces – Part 1: Burnt bricks SFS-EN 771-2 Specifications for masonry pieces – Part 2: Lime sand bricks and blocks SFS-EN 998-2 Specifications for mortars – Part 2: Building mortars SFS-EN 845-1 Specifications for products supplementing masonry – Part 1: Masonry ties, fixings, supports and consoles SFS-EN 845-3 Specifications for products supplementing masonry – Part 3: Reinforcement steel wire nets for block joints SFS 1215 Concrete reinforcing bars. Welded, hot-rolled, deformed bar A500HW SFS 1259 Concrete reinforcing bars. Cold-worked, stainless, deformed bar B600KX SFS 1266 Hot-galvanized concrete reinforcement elements. Requirements for coatings 30 Appendix 2 Symbols used Ac Ao An As Ec Ecc Fbu H Ho Mu Md Nu Nd NRu Vu Vd W a ao b d ed e1 e2 ew fck fcd fbu fxk1 fxd1 fxk2 fxd2 fvk fvd fvko fyd i ka kh l is the net cross-sectional area of structure; is the area of loaded surface; is the area of compressed cross-section; is the cross-sectional area of tensile reinforcement; is the elasticity coefficient of masonry for short-term loads; is the elasticity coefficient of masonry for long-term loads; is the anchor strength of straight deformed bar; is the height of wall section to be surveyed; is the effective length; is the bending strength of structure; is the design value of bending moment; is the compression strength of masonry; is the design value of normal force; is the local compression strength; is the shearing strength of masonry; is the design value of shear force; is the bending strength of cross-section; is the distance of load from support; is the distance of the edge of loaded surface from the end of the wall; is the width of cross-section, the width of joint; is the effective height of cross-section; is the design eccentricity of load; is, in its absolute value, the greater of the eccentricities of the ends; is, in its absolute value, the smaller of the eccentricities of the ends, i.e. zero if the eccentricities are unlike; is the eccentricity due to horizontal load; is the characteristic value of compression strength of masonry wall; is the design value of compression strength of masonry wall; is the anchor strength; is the characteristic value of bending tensile strength in the fracture plane in the direction of horizontal joints; is the design value of bending tensile strength in the fracture plane in the direction of horizontal joints; is the characteristic value of bending tensile strength in the fracture plane vertically against horizontal joints; is the design value of bending tensile strength in the fracture plane vertically against horizontal joints; is the characteristic value of shearing bond strength; is the design value of shearing bond strength; is the characteristic value of shearing bond strength without the effect of vertical compression stress against the joint plane; is the design strength of steel; is the radius of gyration in the direction to be surveyed; is the reduction coefficient which takes into account the eccentricity of load and slenderness of structure; is the reduction coefficient of clearance height when the wall is supported, for instance, with a transverse wall; is the clearance length of masonry tie; 31 lb t te t1 and t2 us c d Ø Ød is the anchoring length; is the thickness of structure; is the effective thickness of structure; are the thicknesses of cavity wall leaves; is the circumference of reinforcement bar; is the vertical compression stress against the joint plane; is the design slenderness creep number; is the diameter of reinforcement bar; is the diameter of masonry tie; 32 Appendix 3 Categories of environmental conditions The categories of the environmental conditions of masonry are: MX1 Dry conditions MX2 Conditions exposed to damp and moisture MX3 Conditions exposed to damp and freezing-thawing stress MX4 Conditions exposed to salt impregnated air, sea water or de-icing with salt MX5 Conditions exposed to aggressive chemicals The classification of environmental conditions of masonry is explained in more detail in Appendix A of the Standard SFS-EN 1996-21. SFS-EN 1996-2 ’Eurocode 6: Dimensioning of masonry – Part 2: Design, selection of materials and workmanship of masonry 1 33