Chapter 19

advertisement

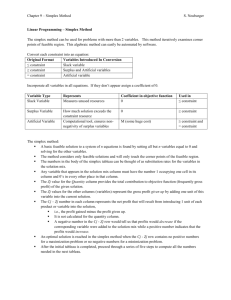

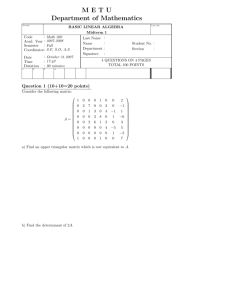

Supplement to Chapter 06 - Linear Programming SUPPLEMENT TO CHAPTER 6: LINEAR PROGRAMMING Answers to Discussion and Review Questions 1. 2. 3. 4. 5. 6. Linear programming is well-suited to an environment of certainty. The “area of feasibility,” or feasible solution space is the set of all combinations of values of the decision variables which satisfy the constraints. Hence, this area is determined by the constraints. Redundant constraints do not affect the feasible region for a linear programming problem. Therefore, they can be dropped from a linear programming problem without affecting the optimal solution. An iso-cost line represents the set of all possible combinations of two inputs that will result in a given cost. Likewise, an iso-profit line represents all of the possible combinations of two outputs which will yield a given profit. Sliding an objective function line towards the origin represents a decrease in its value (i.e., lower cost, profit, etc.). Sliding an objective function line away from the origin represents an increase in its value. a. Basic variable: In a linear programming solution, it is a variable not required to equal zero. b. Shadow price: It is the change in the value of the objective function per unit increase in a constraint right hand side. c. Range of feasibility: The range of values over which a constraint’s right hand side value may vary without changing the optimal basic feasible solution. d. Range of optimality: The range of values over which a variable’s objective function value may vary without changing the current optimal basic feasible solution. 6S-1 Supplement to Chapter 06 - Linear Programming Solution to Problems 1. a. 1. The optimal values of the decision variables are x1 = 2, x2 = 9 and the optimal objective function value = z = 35. 2. None of the constraints have any slack. Both constraints are binding. 3. Neither of the constraints have any surplus (there are no greater than or equal to constraints). 4. No, there are no redundant constraints. X2 18 16 14 12 Optimum 10 8 6 ProfitLine 4 Material Labor 2 2 4 6 8 10 12 Simultaneous solution: *2 (6x1 + 4 x2 = 48) *1 (4 x1 + 8 x2 = 80) (12x1 + 8x2 = 96) * –1 (4x1 + 8 x2 = 80) 6S-2 14 16 18 20 X1 Supplement to Chapter 06 - Linear Programming Solutions (continued) –12x1 – 8x2 = –96 4x1 + 8x2 = 80 4x1 + 8x2 = 80 4(2) + 8x2 = 80 8x2 = 72 x2 = 9 –8x1 = –16 x1 = 2 z = 4x1 + 3x2 = 4(2) + 3(9) = 35 b. 1. The optimal values of the decision variables are x1 = 1.5, x2 = 6.25 and the optimal objective function value z = 65.5. 2. None of the constraints have any slack. 3. The second constraint has a surplus of 15. (There are 15 lbs. of excess material). 4. No, there are no redundant constraints. *R & T (Optimum) 10x1 + 4x2 x1 + 2x2 10x1 + 4x2 –2x1 – 4x2 8x1 R & S** 10x1 + x1 + 10x1 + –10x1 – – = 40 = 14 = 40 = –28 = 12 x1 = 1.5 4x2 6x2 4x2 60x2 56x2 = 40 = 24 = 40 = –240 = –200 x2 = 3.57 1.5 + 2x2 = 14 2x2 = 12.5 x1 + 21.42 = 24 x2 = 6.25 x1 = 2.58 x1 = (1.5) (2), x2 = (6.25) (10) x1 = 3, x2 = 62.5 x1 + x2 = 65.5 S & T*** x1 + 6x2 = 24 x1 + 2x2 = 14 x1 + 6x2 = 24 –x1 – 2x2 = –14 4x2 = 10 x2 = 2.5 x1 + 5 = 14 x1 = 9 x1 = (9) (2) = x2 = (2.5) (10) x1 = 18 x2 = 25 * R = durability ** S = Strength *** T = Time 6S-3 x1 = (2.58) (2), x2 = (3.57) (10) x1 = 5.16, x2 = 35.7 x1 + x2 = 40.86 Supplement to Chapter 06 - Linear Programming Solutions (continued) X2 24 22 20 18 16 14 12 10 8 Optimum 6 4 2 R S T 0 0 2 4 6 8 10 12 14 16 18 20 22 24 X1 6S-4 Supplement to Chapter 06 - Linear Programming Solutions (continued) c. 1. The optimal values of the decision variables are A = 24, B = 20 and the optimal objective function value = z = 204. 2. The third constraint has a slack of 120. In other words, there are 120 hours of unutilized labor hours. 3. There are no greater than or equal to constraints, therefore no surplus is possible. 4. No, there are no redundant constraints. B 100 90 80 70 Material 60 50 40 Optimal Solution 30 20 Profit Line Labor 10 Machinery 10 20 30 40 50 60 70 80 90 100 A At the intersection of Machinery and Material constraints: *5 (20A + 6B = 600) *–4 (25A + 20B = 1000) 100A –100A + 30B = (Material) (Machinery) 3000 – 80B = –4000 –50B = –1000 B = 20 6S-5 Supplement to Chapter 06 - Linear Programming Solutions (continued) From the material constraint 2. 20A + 6B = 600 substituting B = 20 20A + 6(20) = 600 20A = 480 A = 24 a. 1. The optimal values of the decision variables are: S = 8 and T = 20. The optimal objective function value = z = 58.4. 2. Since all of the constraints are greater than or equal to type, none of the constraints have any slack. 3. The third and fourth constraints have surpluses of 92 grams and 10 grams respectively. 4. Yes, the third constraint is redundant. It does not affect the feasible region. b. 1. The optimal values of the decision variables are: x1 = 4.2 and x2 = 1.6. The optimal value of the objective function = z = 13.2. 2. Yes, the constraint F has a slack of 4.6. 3. No, there is no surplus. 4. No, there are no redundant constraints. X2 12 11 10 9 8 D 7 6 5 4 E 3 2 F Optimum 1 00 1 2 3 4 5 6S-6 6 7 8 9 10 11 12 X1 Supplement to Chapter 06 - Linear Programming Solutions (continued) D&E D&F 4x1 + 2x2 = 20 4x1 + 2x2 = 20 2x1 + 6x2 = 18 x1 + 2x2 = 12 4x1 + 2x2 = 20 4x1 + 2x2 = 20 –4x1 – 12x2 = –36 –x1 – 2x2 = –12 –10x2 = –16 3x1 x2 = 1.6 x1 = 4x1 + 3.2 = 20 8 2.67 2.67 + 2x2 = 12 4x1 = 16.8 3. = 2x2 = 9.33 x1 = 4.2 x2 = 4.67 x1 = (2) (4.2) = 8.4 x1 = (2) (2.67) = 5.34 x2 = (3) (1.6) = 4.8 x2 = (3) (4.67) = 14.01 Total = 13.2 Total = 19.35 Maximize: $40H + $30W Subject to: fabrication 4H + 2W 600 hours 300 250 assembly 2H + 6W 480 hours a. Optimum: H = 132 W = 36 Z = $6,360 W fabrication 200 150 b. 0,80: Z=$2,400 150,0: Z = $6,000 132,36: Z = $6,360 (optimum) 100 optimum 50 0 100 assembly 150 200 250 H 6S-7 Supplement to Chapter 06 - Linear Programming D = 110 Solutions (continued) 4. Peanuts cost $.60/lb. Deluxe revenue is $2.90/lb. Raisins cost $1.50/lb. Standard revenue is $2.55 /lb. Deluxe mix has 1/3 lb. peanuts, 2/3 lb. raisins. Hence, deluxe mix cost is 1 2 ($.60) + ($1.50) = $1.20/lb. 3 3 The standard mix has ½ lb. peanuts and ½ lb. raisins. Hence, the standard mix cost is ½ ($.60) + ½ ($1.50) = $1.05/lb. Profits are $2.90 – $1.20 = $1.70/lb. for deluxe and $2.55 – $1.05 = $1.50/lb. for the standard Standard mix. Thus, the objective function is: 220 Maximize: Z = $1.70D + $1.50S 200 Subject to: 180 2 1 raisins D + S 90 lb. 160 3 2 raisins 140 1 1 peanuts D + S 60 lb. 120 3 2 S = 110 D 110 lb. 100 S 110 lb. 80 Optimum: 60 40 D = 90 lb. peanuts 20 S = 60 lb. 0 Profit = $243 20 40 60 80 100 120 140 160 180 200 220 240 5. Maximize: $1.50A + $1.20G Deluxe Grape Subject to: 1200 sugar: 1.5A + 2.0G 1,200 cups flour: 3.0A + 3.0G 2,100 cups 1000 time: 6.0A + 3.0G 3,600 min. Optimum: 800 A = 500 pieces 600 G = 200 pieces Revenue = $990 400 200 0 200 400 sugar 600 flour time 800 1000 Apple 6S-8 Supplement to Chapter 06 - Linear Programming Solutions (continued) Unused supplies sugar: 1.5(500) + 2(200) = 1,150 cups used. Hence, 1,200 – 1,150 = 50 cups remaining. flour: 3.0(500) + 3.0(200) = 2,100 cups used. No flour remains. time: 6.0(500) + 3.0(200) = 3,000 minutes. No time remains. 6. a. The optimal value of the decision variables are: x1 = 4, x2 = 0, x3 = 18. The optimal value of the objective function value = z = 106. b. The optimal value of the decision variables are: x1 = 15, x2 = 10, x3 = 0. The optimal value of the objective function value = z = 210. 7. a. For problem 6a, the range of feasibility for the three constraints are as follows: Constraint 1: 22 to infinity () Constraint 2: 10 to 47.5 Constraint 3: 20 to 45 b. For problem 6a, the range of optimality for the three coefficients of the objective function are: Variable 1 (x1): 2.5 to 15 Variable 2 (x2): – to 10.6 Variable 3 (x3): 8. 1.333 to 8 a. For problem 6b, the range of feasibility for the three constraints are as follows: Constraint 1: 20 to 26.6667 Constraint 2: 35 to 50 Constraint 3: 35 to b. For problem 6b, the range of optimality for the three coefficients of the objective function are: 9. Variable 1 (X1): 6 to 12 Variable 2 (X2): 5 to 10 Variable 3 (X3): – to 20 The optimal value of the decision variables are: x1 = 0, x2 = 80, x3 = 50. The optimal value of the objective function is z = 350. The range of optimality for the profit coefficient of each variable is as follows: x1: – to 3.042 x2: 1.95 to 3.75 x3: 2 to 5 6S-9 Supplement to Chapter 06 - Linear Programming Solutions (continued) 10. x1 = number of containers of orange juice x2 = number of containers of grapefruit juice x3 = number of containers of pineapple juice x4 = number of containers of All-in-One Orange Juice Grapefruit Juice Revenue per qt. $1.00 $.90 Pineapple Juice $.80 All-in-One $1.10 Cost per qt. .50 .40 .35 .417 Profit per qt. $.50 $.50 $.45 $.683 Maximize .50x1 + .50x2 + .45x3 + .683x4 s.t. Orange juice: Grapefr. juice: Ratio: +.33x4 1200 qt. 1x2 Pineapple juice: Grapefr. cont.: +.33x4 1600 qt. 1x1 1x3 +.33x4 –.30x1 +.70x2 –.30x3 –.30x4 5x1 800 qt. 0 cont. 0 x1, x2, x3, x4 0 –7x3 The optimal values of the decision variables are: x1 = 800, x2 = 400, x4 = 2,424.24. The optimal value of the objective function coefficient: z = 2,255.78. 6S-10 Supplement to Chapter 06 - Linear Programming Solutions (continued) 11. x1 = qty. of chopping boards x2 = qty. of knife holders maximize 2x1 + 6x2 s.t. Cutting 1.4x1 + .8x2 Gluing 5x1 Finishing 12x1 + 3x2 56 minutes + 13x2 650 x1, x2 360 0 x2 Opt. is: x1 = 0 x2 = 50 z = 300 120 Slack: finishing Cutting 16 minutes Gluing 0 Finishing 210 minutes 70 50 Opt. gluing cutting 0 12. 30 40 130 x1 x1 = qty. ham spread x2 = qty. deli spread maximize 2x1 + 4x2 (profit) or minimize 3x1 + 3x2 (cost) s.t. x2 mayo 1.4x1 + 1.0x2 70 lb. mayo 1.4x1 + 1.0x2 112 lb. ham deli x1 112 20 pans x2 18 pans x1, x2 0 70 a. x1 = 37.14, x2 = 18, Cost = $165.42 b. x1 = 20, x2 = 84, Profit = $376. mayo = 112 mayo = 70 18 0 6S-11 x1 20 50 80 Supplement to Chapter 06 - Linear Programming Solutions (Continued) 13. A = quantity of product A B = quantity of product B C = quantity of product C A Revenue $80 Cost B $90 C $70 Mat’l #1 2 x $ 5 = $10 1 x $ 5 = $ 5 6 x $ 5 = $30 Mat’l #2 3 x $ 4 = $12 5 x $ 4 = $20 Labor 3.2 x $10 = $32 1.5 x $10 = $15 2 x $10 = $20 Total $54 $40 $50 Profit $26 $50 $20 Maximize 26A + 50B + 20C (profit) s.t. Mat’l #1 2A + 1B + 6C 200 lb. Mat’l #2 3A + 5B 300 lb. Labor 3.2A + 1.5B + 2.0C 150 hr. A output 2/3A – 1/3 B – 1/3C 0 2A – A/B A A 3B =0 5 A, B, C 0 Solution: Optimal values of the decision variables are: A = 18.75 B = 12.50 C = 25.00 Optimal value of the objective function is: z = $1,612.50 14. x1 = boxes of regular mix x2 = “mix” deluxe x3 = “mix” cashews x4 = “mix” raisins x5 = “mix” caramels x6 = “mix” chocolates 6S-12 Supplement to Chapter 06 - Linear Programming Solutions (continued) maximize .80x1 + .90x2 + .70x3 + .60x4 + .50x5 + .75x6 s.t. cashews .25x1 + .50x2 + raisins .25x1 caramels .25x1 chocolate .25x1 + .50x2 120 lb./day x3 + 200 lb./day x4 + 100 lb./day x5 + x6 160 lb./day boxes: regular 20 boxes x1 deluxe 20 boxes x2 cashews 20 boxes x3 raisins 20 boxes x4 caramels x5 20 boxes x6 20 boxes chocolates x1, x2, x3, x4, x5, x6 0 Solution: 15. x1 = 320 x4 = 120 x2 = 40 x5 = 20 x3 = 20 x6 = 60 Z = 433 a. The first constraint (machine) and the third constraint (material) are binding because S1 and S3 are not in the solution (are not basic variables). Therefore as nonbasic variables, they each have a value of zero. In other words, there are no excess machine hours or materials. b. The range of optimality for the objective function coefficient of product 3 is from 13.5 to 36. Therefore an increase from 15 to 22 would not change the value of the decision variables. However, the objective function value would increase from 792 to 792 + 48 (22 – 15). Therefore the new value of z = 1128. c. The range of optimality for the objective function coefficient of product 1 is from – to 22.2. Since 22 is within the range, the change would not affect the value of decision variables. Since x1 is not a basic variable, the objective function value will not be affected (we are not producing any units of product 1). d. We have a slack of 56 hours (S2 = 56), and the range of feasibility lower limit for the second constraint is 232. Therefore, reducing the available labor hours by 10 (288 – 10 = 278) will not affect the value of the decision variables. The objective function value will not change either. However, there will be 10 hours less slack. Thus, the new value of S2 = 56 – 10 = 46. 6S-13 Supplement to Chapter 06 - Linear Programming Solutions (continued) e. If no additional machine hours and materials are obtained, there would not be any change in the profit (z). No change is allowed in the objective function value because all machine hours and all materials are used (constraint 1 and constraint 3 are binding). f. To determine if the changes are within the range for multiple changes, we first compute the ratio of the amount of each change to the end of the range in the same direction. 1 1 For product 1, it is = = 9.8% 22.2 – 12 10.2 1 1 For product 2, it is = = 50% 20 – 18 2 1 1 For product 3, it is = = 4.76% 36 – 15 21 The sum of the ratios = .098 + .50 + .0476 = .646 Since .646 1.0, we conclude that these values are within the range. Therefore, the optimal values of the decision variables will not change (x1 = 0, x2 = 4, x3 = 48). However, the objective function value will change. The new objective function value = z = (19 x 4) + (16 x 48) = 844 or 792 + 4 + 48 = 844. 16. Instructor Note: The RHS of the machine constraint should be 660 minutes. a. The marginal value (shadow price) of a pound of bark is $1.50. This marginal value is in effect from 510 lbs. to 750 lbs. of bark (range of feasibility for the first constraint right hand side). b. 1.50 per pound. c. The marginal value (shadow price) of 1 labor hour is zero because we currently have 105 excess labor hours remaining. This marginal value is in effect from 375 hours to infinity. d. We can not use any additional machine hours because we currently have 135 minutes of excess machine time. e. Maximum possible increase for pine bark constraint is 150 lbs. (750 – 600). Maximum possible increase for storage constraint is 14.21 bags. (1.50) (150) = $225 (expected increase in profit for pine bark) (1.50) (14.21) = $21.32 (expected increase in profit for storage) Therefore, add 150 pounds of pine bark. f. The range of optimality for the objective function coefficient of chips (x3) is from 5.4 to 9. Therefore an increase from $6 to $7 would not change the value of the decision variables. However, the optimal objective function value (z) would increase from 1125 to 1125 + 1(75 units) = $1200. g. To determine if the changes are within the range for multiple changes, we first compute the ratio of the amount of each change to the end of the range in the same direction. 1 For chips (x3), it is = .333 9–6 6S-14 Supplement to Chapter 06 - Linear Programming Solutions (continued) .6 = .600 9–8 The sum of the ratios = .333 + .600 = .933 Since .933 1.0, we conclude that these values are within the range. Therefore, the optimal values of the decision variables will not change (x1 = 75, x2 = 0, x3 = 75). However, the optimal value of the objective function will change. The new z = (8.4 x 75) + (7 x 75) = $1,155. h. To determine if the changes are within the range for multiple changes, we first compute the ratio of the amount of each change to the end of the range in the same direction. 15 For pine barks (first constraint), it is = .10 750 – 600 27 For machine time (second constraint), it is = .36 600 – 525 5 For storage capacity (fourth constraint), it is = .352 164.21 – 150 The sum of the ratios = .10 + .36 + .352 = 1.112 Since 1.112> 1.0, we conclude that these values are not within the range. Therefore, the optimal values of the decision variables will not change (x1 = 75, x2 = 0, x3 = 75). The optimal value of the objective function (z) will change. For nuggets (x1), it is Solution to Son, Ltd. Case 1. Q = quantity of Product Q L = quantity of labor R = quantity of Product R W = quantity of Product W A = quantity of Material A B = quantity of Material B Maximize 122Q + 115R + 76W – 8L – 4A – 4B subject to Labor 5Q + 4R + 2W – L 0 hr. Material A 2Q + 2R + 1/2W – A 0 lb. Material B 1Q + 2W – B 0 lb. Product R Budget 85 units R 8L + 4A + $11,980 4B All variables Optimal: R = 85 0 Labor = 1,000 hr. W = 330 Mat A = 335 lb. Mat B = 660 lb. 6S-15 Contribution = $22,875 Supplement to Chapter 06 - Linear Programming 2. E = equal quantities of Q, R, and W [E contribution is 122 + 115 + 76 = 313] [An alternate approach would be T = total amount, with an average contribution of 313/3 = 104.333] Maximize 313E – 8L – 4A – 4B subject to Labor 11E –L 0 Mat’l A 4.5E –A 0 Mat’l B 3E –B 0 Product R E 85 Budget 8L + 4A + 4B $11,980 All variables 0 Optimal: E = 101.53 [i.e., Q = 101.53, R = 101.53, and W = 101.53.] Labor = 1,116.78 hr. Material A = 456.86 lb. Material B = 304.58 lb. Contribution = $19,798.89 The contribution is less by: $22,875 – $19,798.89 = $3,076.11 3. 5% waste on A: 4.5E – .95A 0 6S-16 Supplement to Chapter 06 - Linear Programming Case: Custom Cabinets, Inc. Problem Formulation: Semi-custom Cabinets A = quantity of Type A B = quantity of Type B C = quantity of Type C D = quantity of Type D Standard Cabinets S10 = quantity of Type S10 S20 = quantity of Type S20 S30 = quantity of Type S30 S40 = quantity of Type S40 Max Z = 325A + 575B + 257C + 275D +175S10 + 210S20 + 260S30 + 230S40 s.t. Wood: 125A + 160B + 140C + 200D + 60S10 + 110S20 + 200S30 + 180S40 < 400,000 Trim: 27A + 42B + 35C + 52D + 21S10 + 28S20 + 50S30 + 43S40 < 140,000 Granite: 175A + 243B < 45,000 Solid Surface: 160C + 140D + 112S10 < 150,000 Laminate: + 135S20 + 254S30 + 176S40 < 400,000 Assembly: 37A + 57B + 30C + 35D + 21S10 + 25S20 + 30S30 + 27S40 < 100,000 Finish: 7A + 12B + 5C + 7D + 3S10 + 5S20 + 7S30 + 5S40 < 25,000 A > 117 B > 92 C > 130 D > 150 S10 > 475 S10 < 875 S20 > 363 S20 < 713 S30 > 510 S30 < 960 S40 > 412 S40 < 887 All variables > 0 Optimal Values A = 117 B = 101 C = 193 D = 150 S10 = 875 S20 = 713 S30 = 535 S40 = 412 Z = $723,831.60 6S-17 Supplement to Chapter 06 - Linear Programming Sensitivity Analysis Both Assembly and Finishing have shadow prices equal to 0, so don’t work overtime. Laminate also has a shadow price of 0, so don’t purchase additional laminate. Wood has a shadow price of $1.30, and an allowable increase of 462,136.8 board feet. Purchase that amount (500,000 board feet is available) at a cost per board foot of $.50, for a net increase in profit of $.80 per board foot. Using the additional wood, all decision variables values remain the same except S30, which increases by 250 units to 849.6821. The revised profit increases by $260(250) = $65,000 to $776,617.36 Enrichment Module: The Simplex Method The simplex method is a general-purpose linear-programming algorithm widely used to solve largescale problems. Although it lacks the intuitive appeal of the graphical approach, its ability to handle problems with more than two decision variables makes it extremely valuable for solving problems often encountered in operations management. When teaching the simplex method, please consider the following points: 1. A computer package for simplex is highly desirable because it permits assigning a range of problems and concentrating on interpretation of solutions rather than on technique. 2. Students should solve a few problems manually to gain some knowledge of what is actually taking place during computations, and gain some insight as to why. 3. Insight receives a boost when simplex and graphical solutions are compared for the same problem. 4. Computations are best done without calculators; students should keep numbers in fractional form. 5. Minimization, artificial variables and ranging can be skipped without seriously impairing appreciation and understanding of the simplex method. The simplex technique involves a series of iterations; successive improvements are made until an optimal solution is achieved. The technique requires simple mathematical operations (addition, subtraction, multiplication, and division), but the computations are lengthy and tedious, and the slightest error can lead to a good deal of frustration. For these reasons, most users of the technique rely on computers to handle the computations while they concentrate on the solutions. Still, some familiarity with manual computations is helpful in understanding the simplex process. You will discover that it is better not to use your calculator in working through these problems because rounding can easily distort the results. Instead, it is better to work with numbers in fractional form. Even though simplex can readily handle three or more decision variables, you will gain considerable insight on the technique if we use a two-variable problem to illustrate it because you can compare what is happening in the simplex calculations with a graphical solution to the problem. Let’s consider the simplex solution to the following problem: 6S-18 Supplement to Chapter 06 - Linear Programming Maximize Subject to Z= 4x1 + 5x2 x1 + 3x2 12 4x1 + 3x2 24 x1, x2 0 The solution is shown graphically in Figure 1. Now let’s see how the simplex technique can be used to obtain the solution. Figure 1. Graphical Solution X2 10 8 6 4X1 + 3X2 = 24 Objective function Optimum 4 2 X1 + 3X2 = 12 4X1 + 5X2 = 20 0 2 4 6 8 10 12 X1 The simplex technique involves generating a series of solutions in tabular form, called tableaus. By inspecting the bottom row of each tableau, one can immediately tell if it represents the optimal solution. Each tableau corresponds to a corner point of the feasible solution space. The first tableau corresponds to the origin. Subsequent tableaus are developed by shifting to an adjacent corner point in the direction that yields the highest rate of profit. This process continues as long as a positive rate of profit exists. Thus, the process involves the following steps: 1. Set up the initial tableau. 2. Develop a revised tableau using the information contained in the first tableau. 3. Inspect to see if it is optimum. 4. Repeat steps 2 and 3 until no further improvement is possible. Setting Up the Initial Tableau Obtaining the initial tableau is a two-step process. First, we must rewrite the constraints to make them equalities and modify the objective function slightly. Then we put this information into a table and supply a few computations that are needed to complete the table. Rewriting the objective function and constraints involves the addition of slack variables, one for each constraint. Slack variables represent the amount of each resource that will not be used if the solution is implemented. In the initial solution, with each of the real variables equal to zero, the solution consists solely of slack. The constraints with slack added become equalities: 6S-19 Supplement to Chapter 06 - Linear Programming 1) x1 + 3x2 2) 4x1 + 3x2 + 1s1 = 12 + 1s2 = 24 It is useful in setting up the table to represent each slack variable in every equation. Hence, we can write these equations in an equivalent form: 1) x1 + 3x2 + 1s1 + 0s2 = 12 2) 4x1 + 3x2 + 0s1 + 1s2 = 24 The objective function can be written in similar form: Z = 4x1 + 5x2 + 0s1 + 0s2 The slack variables are given coefficients of zero in the objective function because they do not produce any contributions to profits. Thus, the information above can be summarized as: Maximize Z = 4x1 + 5x2 + 0s1 + 0s2 Subject to 1) x1 + 3x2 + 1s1 + 0s2 = 12 2) 4x1 + 3x2 + 0s1 + 1s2 = 24 This forms the basis of our initial tableau, which is shown in Table 5S–1. To complete the first tableau, we will need two additional rows, a Z row and a C – Z row. The Z row values indicate the reduction in profit that would occur if one unit of the variable in that column were added to the solution. The C – Z row shows the potential for increasing profit if one unit of the variable in that column were added to the solution. To compute the Z values, multiply the coefficients in each column by their respective row profit per unit amounts, and sum within columns. To begin with, all values are zero: C 0 x1 (1)0 x2 3(0) s1 1(0) s2 (0)0 Quantity (12)0 (1)0 (24)0 0 0 0 4(0) 3(0) 0(0) Z 0 0 0 The last value in the Z row indicates the total profit associated with a given solution (tableau). Since the initial solution always consists of the slack variables, it is not surprising that profit is 0. Values in the C – Z row are computed by subtracting the Z value in each column from the value of the objective row for that column. Thus, Variable row x1 x2 s1 s2 Objective row (C) 4 5 0 0 Z 0 0 0 0 C–Z 4 6S-20 5 0 0 Supplement to Chapter 06 - Linear Programming Table 1 Partial Initial Tableau Profit per unit for variables in solution C Variables in solution Decision Variables 4 5 0 0 Objective row x1 x2 s1 s2 Solution quantity 0 s1 1 3 1 0 12 0 s2 4 3 0 1 24 The completed tableau is shown in Table 2. The Test for Optimality If all the values in the C – Z row of any tableau are zero or negative, the optimal solution has been obtained. In this case, the C – Z row contains two positive values, 4 and 5, indicating that improvement is possible. Developing the Second Tableau Values in the C – Z row reflect the profit potential for each unit of the variable in a given column. For instance, the 4 indicates that each unit of variable x1 added to the solution will increase profits by $4. Similarly, the 5 indicates that each unit of x2 will contribute $5 to profits. Given a choice between $4 per unit and $5 per unit, we select the larger and focus on that column, which means that x2 will come into the solution. Now we must determine which variable will leave the solution. (At each tableau, one variable will come into the solution, and one will go out of solution, keeping the number of variables in the solution constant. Note that the number of variables in the solution must always equal the number of constraints. Thus, since this problem has two constraints, all solutions will have two variables.) To determine which variable will leave the solution, we use the numbers in the body of the table in the column of the entering variable (i.e., 3 and 3). These are called row pivot values. Divide each one into the corresponding solution quantity amount, as shown in Table 3. The smaller of these two ratios indicates the variable that will leave the solution. Thus, variable s1 will leave and be replaced with x2. In graphical terms, we have moved up the x2 axis to the next corner point. By determining the smallest ratio, we have found which constraint is the most limiting. In Figure 1, note that the two constraints intersect the x2 axis at 4 and 8, the two row ratios we have just computed. The second tableau will describe the corner point where x2 = 4 and x1 = 0; it will indicate the profits and quantities associated with that corner point. It will also reveal if the corner point is an optimum, or if we must develop another tableau. 6S-21 Supplement to Chapter 06 - Linear Programming Table 2 Completed Initial Tableau. C 4 5 0 0 0 Variables in solution s1 x1 1 x2 3 s1 1 s2 0 0 s2 4 3 0 1 24 Z 0 0 0 0 0 C–Z 4 5 0 0 C Solution quantity 12 4 5 0 0 0 Variables in solution s1 x1 1 x2 3 s1 1 s2 0 Solution quantity 12/3 = 4 0 s2 4 3 0 1 24/3 = 8 Z 0 0 0 0 0 C–Z 4 5 0 0 Smallest positive ratio Largest positive At this point we can begin to develop the second tableau. The row of the leaving variable will be transformed into the new pivot row of the second tableau. This will serve as a foundation on which to develop the other rows. To obtain this new pivot row, we simply divide each element in the s1 row by the row pivot value (intersection of the entering column and leaving row), which is 3. The resulting numbers are: Pivot-row value x1 x2 s1 s2 Solution quantity 1/3 1 1/3 0 4 These numbers become the new x2 row of the second tableau. The pivot-row numbers are used to compute the values for the other constraint rows (in this instance, the only other constraint row is the s2 row). The procedure is: 1. Find the value that is at the intersection of the constraint row (i.e., the s2 row) and the entering variable column. It is 3. 2. Multiply each value in the new pivot row by this value. 3. Subtract the resulting values, column by column, from the current row values. 6S-22 Supplement to Chapter 06 - Linear Programming x1 4 Current value: –3 x (pivot row) x2 3 –3(1/3) New row value s1 0 –3(1) 3 –3(1/3) –1 0 s2 1 Quantity 24 –3(0) –3(4) 1 12 The two new rows are shown in Table 4. The new Z row can now be computed. Multiply the row unit profits and the coefficients in each column for each row. Sum the results within each column. Thus, Row x2 Profit 5 s1 0 New Z row x1 5(1/3) x2 5(1) s1 5(1/3) s2 5(0) Quantity 5(4) 0(3) 0(0) 0(–1) 0(1) 0(12) 5/3 5 5/3 0 20 Next, we compute the C – Z row: C x1 4 x2 5 s1 0 s2 0 Z 5/3 5 5/3 0 C–Z 7/3 0 –5/3 0 Table 4 partially completed second tableau C 5 Variables in solution x2 0 s2 4 5 0 0 x1 1/3 x2 3 s1 1/3 s2 0 3 0 –1 1 4 5 0 0 x1 1/3 x2 1 s1 1/3 s2 0 Solution quantity 4 Solution quantity 4 12 Table 5 completed second tableau C 5 Variables in solution x2 0 s2 3 0 –1 1 12 Z 5/3 5 5/3 0 20 C–Z 7/3 0 –5/3 0 6S-23 Supplement to Chapter 06 - Linear Programming The completed second tableau is shown in Table 5. It tells us that at this point 4 units of variable x2 are the most we can make (see column Solution quantity, row x2) and that the profit associated with x2 = 4, x1= 0 is $20 (see row Z, column Solution quantity). The fact that there is a positive value in the C – Z row tells us that this is not the optimal solution. Consequently, we must develop another tableau. Developing the Third Tableau The third tableau will be developed in the same manner as the previous one. 1. Determine the entering variable: Find the column with the largest positive value in the C – Z row (7/3, in the x1 column). 2. Determine the leaving variable: Divide the solution quantity in each row by the row pivot. Hence, 4 = 12 12/3 = 4 1/3 The smaller ratio indicates the leaving variable, s2. See Table 5S–6. 3. Divide each value in the row of the leaving variable by the row pivot value (3) to obtain the new pivot-row values: Current value x1 3 x2 0 s1 –1 s2 1 Quantity 12 New pivot-row value 1 0/3 –1/3 1/3 12/3 = 4 5 0 Table 6 Leaving/Entering Variables C 4 Variables in solution 0 x1 x2 s1 s2 Solution quantity 5 x2 1/3 1 1/3 0 4 1/3 0 s2 3 0 –1 1 12/3 = 4 Z 5/3 5 5/3 0 20 C–Z 7/3 0 –5/3 0 Entering variable is x1 6S-24 = 12 Leaving variable is s2 Supplement to Chapter 06 - Linear Programming 4. Compute values for the x2 row: Multiply each new pivot-row value by the x2 row pivot value (i.e., 1/3) and subtract the product from corresponding current values. Thus, x1 1/3 Current value: –1/3 x (pivot row) x2 1 –1/3(1) New row value s1 Quantity 4 –1/3(1/3) –1/3(4) 1/3 –1/3(0) 0 s2 0 –1/3(–1/3) 1 –1/9 4/9 8/3 At this point, it will be useful to consider the tableaus in relation to a graph of the feasible solution space. This is shown in Figure 2. 5. Compute new Z row values. Note that now variable x1 has been added to the solution mix; that row’s unit profit is $4. Row x2 Profit $5 x1 5(0) x2 5(1) s1 5(4/9) s2 5(–1/9) x1 $4 4(1) 4(0) 4(–1/3) 4(1/3) 4(4) 4 5 8/9 7/9 88/3 New Z row 6. Compute the C – Z row values: C x1 4 x2 5 s1 0 s2 0 Z 4 5 8/9 7/9 C–Z 0 0 –8/9 –7/9 Figure 2 Graphical Solution and Simplex Tableaus X2 10 8 6 3rd tableau 4 2nd tableau 2 1st tableau 0 2 4 6 6S-25 8 10 12 X1 Quantity 5(8/3) Supplement to Chapter 06 - Linear Programming Table 7. Optimal Solution C 4 5 0 0 5 Variables in solution x2 x1 0 x2 1 s1 s2 4/9 –1/9 Solution quantity 8/3 4 x1 1 0 –1/3 1/3 4 Z 4 5 8/9 7/9 88/3 C–Z 0 0 –8/9 –7/9 The resulting values of the third tableau are shown in Table 7. Note that each of the C – Z values is either 0 or negative, indicating that this is the final solution. The optimal values of x1 and x2 are indicated in the quantity column: x2 = 8/3, or 2 2/3, and x1 = 4. (The x2 quantity is in the x2 row and the x1 quantity in the x1 row.) Total profit is 88/3, or 29.33 (quantity column, Z row). Handling and Constraints Up to this point, we have worked with constraints. Constraints that involve equalities and constraints are handled in a slightly different way. When an equality constraint is present, use of the simplex method requires addition of an artificial variable. The purpose of such variables is merely to permit development of an initial solution. For example, the equalities (1) 7x1 + 4x2 = 65 (2) 5x1 + 3x2 = 40 would be rewritten in the following manner using artificial variables a1 and a2: (1) 7x1 + 4x2 + 1a1 + 0a2 = 65 (2) 5x1 + 3x2 + 0a1 + 1a2 = 40 Slack variables would not be added. The objective function, say Z = 2x1 + 3x2, would be rewritten as: Z = 2x1 + 3x2 + Ma1 + Ma2 where M = A large number (e.g., 999) Since the artificial variables are not desired in the final solution, selecting a large value of M (much larger than the other objective coefficients) will insure their deletion during the solution process. For constraints, surplus variables must be subtracted instead of added to each constraint. For example, the constraints (1) 3x1 + 2x2 + 4x3 80 (2) 5x1 + 4x2 + x3 70 (3) 2x1 + 8x2 + 2x3 68 6S-26 Supplement to Chapter 06 - Linear Programming would be rewritten as equalities: (1) 3x1 + 2x2 + 4x3 – 1s1 – 0s2 – 0s3 80 (2) 5x1 + 4x2 + x3 – 0s1 – 1s2 – 0s3 70 (3) 2x1 + 8x2 + 2x3 – 0s1 – 0s2 – 1s3 68 As equalities, each constraint must then be adjusted by inclusion of an artificial variable. The final result looks like this: (1) 3x1 + 2x2 + 4x3 – 1s1 – 0s2 – 0s3 + 1a1 + 0a2 + 0a3 80 (2) 5x1 + 4x2 + x3 – 0s1 – 1s2 – 0s3 + 0a1 + 1a2 + 0a3 70 (3) 2x1 + 8x2 + 2x3 – 0s1 – 0s2 – 1s3 + 0a1 + 0a2 + 1a3 68 If the objective function happened to be 5x1 + 2x2 + 7x3 it would become 5x1 + 2x2 + 7x3 + 0s1 + 0s2 + 0s3 + Ma1 + Ma2 + Ma3 Summary of Maximization Procedure The main steps in solving a maximization problem with only constraints using the simplex algorithm are these: 1. Set up the initial tableau. a. Rewrite the constraints so that they become equalities; add a slack variable to each constraint. b. Rewrite the objective function to include the slack variables. Give slack variables coefficients of 0. c. Put the objective coefficients and constraint coefficients into tableau form. d. Compute values for the Z row; multiply the values in each constraint row by the row’s C value. Add the results within each column. e. Compute values for the C – Z row. 2. Set up subsequent tableaus. a. Determine the entering variable (the largest positive value in the C– Z row). If a tie exists, choose one column arbitrarily. b. Determine the leaving variable: Divide each constraint row’s solution quantity by the row’s pivot value; the smallest positive ratio indicates the leaving variable. If a tie occurs, divide the values in each row by the row pivot value, beginning with slack columns and then other columns, moving from left to right. The leaving variable is indicated by the lowest ratio in the first column with unequal ratios. c. Form the new pivot row of the next tableau: Divide each number in the leaving row by the row’s pivot value. Enter these values in the next tableau in the same row positions. d. Compute new values for remaining constraint rows: For each row, multiply the values in the new pivot row by the constraint row’s pivot value, and subtract the resulting values, column by column, from the original row values. Enter these in the new tableau in the same positions as the original row. e. Compute values for Z and C – Z rows. f. Check to see if any values in the C – Z row are positive; if they are, repeat 2a–2f. Otherwise, the optimal solution has been obtained. 6S-27 Supplement to Chapter 06 - Linear Programming Minimization Problems The simplex method handles minimization problems in essentially the same way it handles maximization problems. However, there are a few differences. One is the need to adjust for constraints, which requires both artificial variables and surplus variables. This tends to make manual solution more involved. A second major difference is the test for the optimum: A solution is optimal if there are no negative values in the C – Z row. Example Solve the following problem for the quantities of x1 and x2 that will minimize cost. Minimize Z = 12x1 + 10x2 x1 + 4x2 8 3x1 + 2x2 6 x1, x2 0 Subject to Solution to example 1. Rewrite the constraints so that they are in the proper form: x1 + 4x2 8 becomes x1 + 4x2 – 1s1 – 0s2 + 1a1 + 0a2 = 8 3x1 + 2x2 6 becomes 3x1 + 2x2 – 0s1 – 1s2 + 0a1 + 1a2 = 6 2. Rewrite the objective function (coefficients of C row): 12x1 + 10x2 + 0s1 + 0s2 + 999a1 + 999a2 3. Compute values for rows Z and C – Z: C 999 x1 1(999) x2 4(999) s1 –1(999) s2 0(999) a1 1(999) a2 0(999) Quantity 8(999) 999 3(999) 2(999) 0(999) –1(999) 0(999) 1(999) 6(999) Z 3,996 5,994 –999 –999 999 999 13,986 C–Z –3,984 –5,984 999 999 0 0 4. Set up the initial tableau. (Note that the initial solution has all artificial variables.) C 12 10 0 0 999 999 999 Variables in solution a1 x1 1 x2 4 s1 –1 s2 0 a1 1 a2 0 Solution Quantity 8 999 a2 3 2 0 –1 0 1 6 Z 3,996 5,994 999 999 13,986 0 0 C–Z –3,984 –5,984 –999 –999 999 999 5. Find the entering variable (largest negative C – Z value: x2 column) and leaving variable (smaller of 8/4 = 2 and 6/2 =3; hence, row a1). 6S-28 Supplement to Chapter 06 - Linear Programming 6. Divide each number in the leaving row by the pivot value (4, in this case) to obtain values for the new pivot row of the second tableau: 1/4 –1/4 4/4 = 1 0/4 1/4 0/4 8/4 = 2 7. Compute values for other rows; a2 is: x1 3 x2 2 –2 x (new pivot row) –2/4 New row 10/4 Current value s1 0 s2 –1 a1 0 a2 1 Quantity 6 –2 2/4 –0/4 –2/4 –0/4 –4 0 +2/4 –1 –2/4 1 2 8. Compute a new Z row: Row x2 Cost 10 x1 10(1/4) x2 10(1) s1 10(–1/4) s2 10(0) a1 10(1/4) a2 10(0) Quantity 10(2) a2 999 999(10/4) 999(0) 999(2/4) 999(–1) 999(–2/4) 999(1) 999(2) 2,500 10 497 –999 –497 999 2,018 Z 9. Compute the C – Z row: C x1 12 x2 10 Z 2,500 C–Z –2,488 s1 0 s2 0 a1 999 a2 999 10 497 –999 –497 999 0 –497 999 1,496 0 10. Set up the second tableau: C 10 12 10 0 0 999 999 Variables in solution a1 x1 1/4 x2 1 s1 –1/4 s2 0 a1 1/4 a2 0 Solution Quantity 2 a2 10/4 0 2/4 –1 –2/4 1 2 Z 2,500 10 497 –999 –497 999 2,018 C–Z –2,488 0 –497 999 999 1,496 0 11. Repeat the process. a. Check for optimality: It is not optimum because of negatives in C – Z row. b. Determine the entering variable: The largest negative is in column x1. c. Determine the leaving variable: 2/(1/4) = 8, 2/(10/4) = 0.8. Therefore, it is row a2. d. Find new pivot-row value using the pivot value of 10/4: 1 0 0.2 –0.4 –0.2 0.4 6S-29 0.8 Supplement to Chapter 06 - Linear Programming e. Determine values for new x2 row: 0 f. –0.3 1 0.1 –0.1 0.3 1.8 Determine new values for row Z: Row x2 Cost 10 x1 10(0) x2 10(1) s1 10(–0.3) s2 10(0.1) a1 10(0.3) a2 10(–0.1) Quantity 10(1.8) x1 12 12(1) 12(0) 12(0.2) 12(–0.4) 12(–0.2) 12(0.4) 12(0.8) 12 10 –0.6 –3.8 0.6 3.8 27.6 Z g. Determine values for the C – Z row: C x1 12 x2 10 s1 0 s2 0 a1 999 a2 999 Z 12 10 –0.6 –3.8 0.6 3.8 C–Z 0 0 0.6 3.8 998.4 995.2 h. Set up the next tableau. Since no C – Z values are negative, the solution is optimal. Hence, x1 = 0.8, x2 = 1.8, and minimum cost is 27.60. C 12 10 0 0 999 999 10 Variables in solution a1 x1 0 x2 1 s1 –0.3 s2 0.1 a1 0.3 a2 –0.1 Quantity 1.8 12 a2 1 0 0.2 –0.4 –0.2 0.4 0.8 Z 12 10 –0.6 –3.8 0.6 3.8 27.6 C–Z 0 0 0.6 3.8 6S-30 998.4 995.2 Supplement to Chapter 06 - Linear Programming Problems for the enrichment module (simplex) 1. Given this information: Maximize Z = 10.50x + 11.75y + 10.80z Subject to Cutting 5x + 12y + 8z 1,400 minutes Stapling 7x + 9y + 9z 1,250 minutes Wrapping 4x + 3y + 6z 720 minutes x, y, z 0 Solve for the quantities of products x, y, and z that will maximize revenue. 2. Use the simplex method to solve these problems: a. Minimize Z = 21x1 + 18x2 Subject to (1) 5x1 + 10x2 100 (2) 2x1 + 1x2 10 x1, x2 0 b. Minimize Subject to Z = 2x + 5y + 3z (1) 16x + 10y + 18z 340 (2) 11x + 12y + 13z 300 (3) 2x + 6y + 5z 120 x, y, z 0 3. Use the simplex method to solve the following problem. Minimize Z = 3x1 + 4x2 + 8x3 Subject to 2x1 + x2 6 x2 + 2x3 4 x1, x2, x3 0 4. Use the simplex method to solve the following problem. Maximize Z = 8x1 + 2x2 Subject to 4x1 + 5x2 20 2x1 + 6x2 18 x1, x2 0 Note: Row operations in problems 3 and 4 are computationally easy. 6S-31 Supplement to Chapter 06 - Linear Programming Solutions-Enrichment Module (SIMPLEX) 1. C 10.5 11.75 10.80 0 0 0 Var x y z S1 S2 S3 0 S1 5 12 8 1 0 0 1,400 116.67 0 S2 7 9 9 0 1 0 1,250 138.89 4 S3 4 3 6 0 0 1 720 0 10.80 0 0 0 0 0 0 0 Z C–Z C Var 0 10.5 0 11.75 x y z S1 S2 S3 bi bi 11.45 y 0 S2 5/12 13/4 1 0 2/3 3 1/12 –3/4 0 1 0 0 0 11/4 0 4 –1/4 0 1 0 0 0 0 1,370.83 S2 S3 bi S3 240 ratio 1,400/12 280 200 61.54 370 134.54 Z C–Z 4.896 11.75 5.604 0 Var x y z 11.75 y 0 1 11/39 7/39 –5/39 0 91.026 10.5 x 1 0 12/13 –3/13 4/13 0 61.54 0 S3 0 0 19/13 5/13 –11/13 1 2610/13 522 11.75 0 13.01 –0.314 1.724 –2.206 0.314 –1.724 0 0 1,715.73 C 7.833 0.979 2.967 –0.979 ratio S1 Z C–Z 10.5 0 C Var x y S1 S2 S3 bi 0 10.5 S1 x 0 1 39/7 9/7 11/7 117/91 1 0 –5/7 –1/7 0 0 507.14 178.57 0 S3 0 –15/7 78/91 0 –4/7 1 5.72 10.5 0 13.5 –1.75 13.5 –2.7 0 0 1.5 –1.5 0 0 1,874.99 Z C–Z z Optimal solution is x = 178.57, y = 0, z = 0, and optimal solution = 1874.9 6S-32 ratio 507.1 Supplement to Chapter 06 - Linear Programming Solutions (continued) 2. a. Minimize Z = 21x1 + 18x2 5x1 + 10x2 + A1 – S1 s.t. 2x1 + C I. II. = 100 + A2 – S2 = 10 1x2 21 18 M 0 M 0 C Var x1 x2 A1 S1 A2 S2 bi M A1 5 10 1 –1 0 0 100 10 M A2 2 1 0 0 1 –1 10 10 M –0 –M M M –0 –M M 110M M Z C–Z 7M 11M [21–7M] [18–11M] C ratio 21 18 M 0 M 0 C Var x1 x2 A1 S1 A2 S2 bi ratio 18 x2 0.5 1 0.1 –0.1 0 0 10 20 M A2 1.5 0 –0.1 0.1 1 –1 0 0 M –M –0 M 180 Z C–Z [1.5M+9] [12–1.5M] 18 0 C 21 18 0 III. C Var [1.8–0.1M] [0.1M–1.8] [1.1M–1.8] [1.8–.1M] x1 x2 18 x2 0 1 –0.1333 0.333 10 21 x1 1 0 +0.0667 –0.667 0 21 0 18 0 –0.99999 0.99999 –8.000 8.000 180 Z C–Z S1 0 S2 The optimal solution: x1 = 0; x2 = 10; Z = 180 6S-33 bi Supplement to Chapter 06 - Linear Programming Solutions (continued) 2. b. I. C 2 5 3 M 0 M 0 M 0 Var x y z A1 S1 A2 S2 A3 S3 bi M M A1 A2 16 11 10 12 18 13 1 0 –1 0 0 1 0 –1 0 0 0 0 340 300 M A3 2 6 5 0 0 0 0 +1 –1 120 M 0 –M M M 0 –M M M 0 –M M Z 29M 28M 36M C–Z [–29M+2] [–28M+5] [–36M+3] II. C Var x y z 3 M Z A2 .8889 –.5556 .5556 4.778 1 0 .0556 –.722 M A3 3.222* 0 –.2778 [8M+1.7] [–8M+3.3] 3 0 [–M+.17] [M–.17] [2M–47] [–M+.17] –2.444 Z [–3M+2.7] C–Z [+3M+.7] III. C Var x y z 3 M z A2 1.31 3.069* 0 0 1 0 5 Y –0.7586 1 5 0 Z [3M+.138] C–Z [–3.1M+1.86] IV. C V. A1 S1 S1 A2 S2 A3 S3 bi –.0556 .722 0 1 0 –1 0 0 0 0 18.89 54.44 .2778 0 0 1 –1 25.56 M 0 –M M M 0 –M M A2 S2 –.1034 .3103 0 1 0 –1 .1724 1.483 0 0.08621 0 0 –0.3103 3 0 [.3M+.121] [–.3M–.121] 0 –M M Var x y z S1 3 2 z x 0 1 0 0 1 0 –0.236 .1011 5 y 0 1 0 Z C–Z 2 0 5 0 3 0 S2 C Var x y z S1 3 0 z S1 2.333 9.889 0 0 1 0 0 1 5 y –1.611 1 0 0 Z C–Z –1.06 3.056 5 0 3 0 0 0 .1629 6S-34 S3 [1.5M–1.03] [–1.5M+1.03] S3 .427 –.3258 –.2472 –0.6067 0.6067 0.309 –0.309 760M –0.4607 .4831 .05618 –0.1348 0.1348 S2 S3 –0.3333 –3.222 .6667 4.778 .2778* +0.3889 –0.3889 –0.7222 –1.6111 1.6111 80M+56.7 bi 14.48 16.55 7.931 [16.55M+83.1] bi 7.416 5.393 12.02 93.15 bi 20 53.33 3.333 76.67 Supplement to Chapter 06 - Linear Programming Solutions (continued) VI. C Var x y z S1 S2 S3 bi 3 z .4 1.2 1 0 0 –0.200 24 0 S1 –8.8 11.6 0 1 0 –3.6 92 0 S2 –5.8 3.6 0 0 1 –2.6 23 1.2 3.6 3 0 0 –0.6 72 .8 1.4 0 0 0 .6 Z C–Z Optimal solution is: x = 0; y = 0; z = 24 and Z = 72.0 3. C M M 3 4 8 0 0 M M Var x1 x2 x3 S1 S2 A1 A2 A1 A2 2 0 1 1 0 2 –1 0 0 –1 1 0 0 1 6 4 Zj Cj–Zj 2M 3–2M 2M 4–2M 2M 8–2M –M M –M M M 0 M 0 10M 3 4 8 0 0 Var x1 x2 x3 S1 S2 x1 A2 1 0 ½ 1 0 2 –½ 0 0 –1 Zj Cj–Zj 3 0 2M 8–2M –3/2 3/2 C 3 M C 3 8 –M M 3 4 4 8 0 0 Var x1 x2 x3 S1 S2 x1 x3 1 0 ½ ½ 0 1 –½ 0 0 –½ 3 2 3 0 11/2 –3/2 8 0 –3/2 3/2 –4 4 25 3 4 8 0 0 Var x1 x2 x3 S1 S2 x1 x2 1 0 0 1 –1 2 –½ 0 ½ –1 1 4 3 0 4 0 5 3 –3/2 3/2 –5/2 5/2 19 C Zj Cj–Zj The optimal solution is: x1 = 1; x2 = 4; x3 = 0 and Z = 19. 6S-35 bi/aij 3½=6 41=4 4M+9 3 Zj Cj–Zj 3 4 M–3/2 5/2 –M bi bi bi bi bi/aij 3½=6 2½=4 bi/aij 6/2 = 3 – Supplement to Chapter 06 - Linear Programming Solutions (continued) 4. Cj 0 0 8 2 0 0 Var x1 x2 S1 S2 S1 S2 4 2 5 6 1 0 0 1 20 18 Zj Cj–Zj 0 8 0 2 0 0 0 0 0 Var x1 x2 S1 S2 x1 S2 1 0 Zj Cj–Zj 8 0 bi Cj 8 0 5/4 7/2 10 –8 bi ¼ –1/2 0 1 5 8 2 –2 0 0 40 Optimal solution is x1 = 5, x2 = 0, S1 = 0, S2 = 8 and Z = 40. 6S-36