BUSINESS PLAN PROPOSAL

advertisement

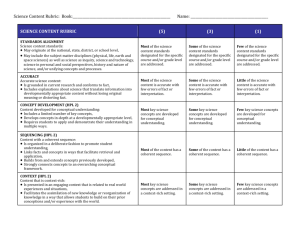

Mid-Term Case Analysis Arborite STRATEGY 669 Winter 2007 Group 15 Jiji George Gilles Monniaux Taro Nagao Nanda Rajanala Sharad Srivastava Q1. What do Porter’s forces say about the industry? The analysis has been conducted for the Canadian HPL market only as that was the focus of this case. Based on our analysis of this industry using the five forces framework, we concluded that this industry was not attractive. The detailed analysis used for this conclusion is presented in Exhibit 1 of this paper. The reasoning behind our diagnosis is given below. Barrier to Entry (High): The market for the HPL in Canada is about 100 Million dollars. Assuming a high net margin of 20%, the total profits of the industry will be about 20M. The investment for a new plant is 70 million dollars. If an entrant company has about 10% of the share (compared to the incumbent share of 35%) the profit for the company will be about 2 M. Ignoring the discount rate, it will take about 35 years to recover the cost of the new plant. This shows that the industry is capital intensive and it will be not an easy decision for a company to enter this industry. Additionally the plants are a scale intensive investment. For a 250 million sq ft plant the rate per square feet comes to 0.25 whereas for an 80 million sq ft facility this rate is 0.43. The variable cost of this smaller plant is also about 150% of the bigger plant. So a new player trying to enter the industry with a smaller plant faces huge cost disadvantages. The other individual processes also seem to be scale intensive as evident from the importance of MES at each level of value chain. The government duties also make it difficult for small players to enter Canadian market. WilsonArt and Formica are able to overcome these barriers as they had attained a certain scale in manufacturing and procurement. The product differentiation in this market is mainly based on delivery service and it might be difficult for a new entrant to make easy inroads. Industrial Rivalry (High): The industry growth rate in Canada is very low, about 2% and there are three large companies competing for this market. These three companies have about 82% of the market share. HPL is more of a commodity than a differentiated product as exhibited by the fact that architects and OEM can change the brands of the HPL very easily in the job driven sales. In the inventory driven market the most important factor is the price. As a result of the rivalry in this industry, HPL prices have been decreasing continuously since 1971. Supplier Power (High): The three main inputs to the industry are resins, cover paper and core stack paper. Resins are commoditized, the prices are decreasing over the years and the suppliers have to resort to value added activities for the buyers in order the get the business. So we can conclude that the resin suppliers have low power. Cover paper and core stack paper account for 33% of the cost of the HPL. The core stack industry consists of two players and they did not offer any discounts to the HPL manufacturers. Although three players dominated the cover stack market, they gave about 50% discount on volume. A possible explanation is that the changeover process or delivery in the industry is scale intensive. This discount gives huge cost advantage to the big players in the HPL industry. There is also no clear substitute for the papers for the HPL industry and the quality of the input makes a difference to the final product. Hence we conclude that the paper suppliers have power over the HPL manufacturers. Threat of Substitute (High): There are five substitutes available for HPL in the market. Of the six market segments, HPL has a clear advantage in the post forming segment and that too because of the lack of competition there. In the kitchen cabinets and custom designed segments, the HPL advantage over the substitutes is not significant. All substitutes other than Veneer are lower in price and this might put a downward pressure on HPL manufactures if they want to capture market share in different segments. The total usage of HPL also is much lower than other substitutes. Buyer Power (High): The two distinct buyers in this industry are the job driven buyers and the inventory driven buyers. The job driven purchases are driven by OEMs and architects who are not price conscious. The choice of the HPL was made more on the appearance. The architects contracted with OEMs. Architects selected HPL based on appearance, reputation of the manufacturers for product availability, performance and the delivery times. However a failure to meet these criteria led to the OEMs switching between different brands. This switching seems to be easy and a common practice. For the inventory driven buyers, price was the most important factor in choosing HPL. The post formers don’t seem to be doing that well as an industry resulting in further price pressure on the HPL manufactures. Moreover, the 1 dealers and the distributors have limited shelf space and keep only one brand and popular colors with them. This way they will have a lot of power in terms of bargaining with the HPL manufactures, putting another pressure in terms of prices. Q2. In order to understand what value HPL create for buyers, we must first define what we mean by value. Value here means the difference between the HPL and the next best alternative. The next step is therefore to understand the needs of these buyers and then analyze how HPL and their substitutes perform on the fulfillment of those needs. The HPL buyers can be put in two main categories: job driven buyers and inventory driven buyers. Since these two groups differ in many of their needs, it is necessary to look at each sub-group individually. In fact, the only need that all those buyers have in common is “product performance” which could be defined as a mix of durability, reparability, pliability and delivery without chipping or breaking. Inside the job-driven group itself, there are two distinct decision makes and each has its own criteria (See Exhibit 2A). On the one hand, the architects and designers are the ones who specify the use of HPL (they play the role of a gatekeeper between the HPL industry and the end-customer). As the cost of HPL is not relevant for them and they are not directly responsible for the finishing the project, they only care about emotional attributes, namely the product variety and the product appearance as reflected in its color, texture, design. On the other hand, OEMs have to buy the HPL to use it in a time sensitive projects. As a consequence, they are mainly concerned about the “product availability” as a low availability could lead to delays. Inside the inventory-driven group, there are three different buyers. The dealers who buy HPL or HPLmade objects are mainly concerned about prices as the activities in their HPL value chain are simply “buy, store and sell”. On the other hand, distributors are in the business of delivering HPL and OEMs are in the business of transforming them, two activities that need reliable supply of HPLs. Consequently availability is their main concern. Having identified the five attributes buyers are looking for in HPL-like products (variety, appearance, availability, performance and price), one can compare how HPL and their substitutes perform on those attributes (see Exhibit 2B). One of the results is that the main attributes on which HPL and non-HPL compete are appearance, performance and price. Plotting the positioning of each material along the first two criteria (see Exhibit 2C) allows one to see that HPL have a very distinct positioning: higher prices but market-leading performance and very reasonable appearance (see Exhibit 2D). This unique differentiation is what allows HPL to create value for those buyers who have the mix of needs on which they are positioned. Q3. A comparison of the strategic positioning of the three companies is presented in Exhibit 3A. In summary, Arborite has a strong presence in the inventory-driven segment, WilsonArt focuses in job-driven segment, and Formica is in the middle of the other two, targeting both segments. Each company’s strategy and sustainability of its competitive advantage are discussed below. Arborite Product-market domain: With its basic and relatively undifferentiated products, Arborite has a strong presence in the inventory-driven segment in Canada. Customers in this segment are characterized as follows. First, their needs are concentrated in basic products (“bread and butter colors”). Second, their purchase amount is highly predictable every month. Third, they are not willing to pay premium for better appearance, high quality, or quick delivery. Finally, they are highly price sensitive. 2 Value proposition: Arborite provides value to customers by offering its products for low prices; it keeps product costs low by eliminating attributes that are unnecessary to the target segment. Set of activities: This strategy is well-implemented in Arborite’s marketing activities: it does not advertise its products, does not spend much on distribution of samples, and stays away from investing in “innovative” products. Consequently, Arborite enjoys significant cost advantage in marketing (See Exhibits 3B and 3C for the detailed comparison). On the other hand, Arborite fails to achieve any cost advantage in the other areas: operations, outbound logistics, and firm infrastructure. Operation costs are inflated mainly because 1) Arborite lacks scale on purchasing 2) both Toronto and Montreal plants operate at low capacity utilization, and 3) Montreal plant is equipped with old, inefficient technologies. Outbound logistics costs are inflated by producing large number of colors and grades, which may be unnecessary for target customers. Two-layer management structure brings an additional cost disadvantage to Arborite. These activities are not consistent with Arborite’s strategy of cost focus. Sustainability of competitive advantage: Arborite’s operating costs are 9% higher than Formica, even though Arborite is considered lower quality. For the reasons discussed above, Arborite is not located on the efficient frontier; it does not have a competitive advantage in the industry. Formica Product-market domain: As a largest producer of HPL in the world, Formica targets both job-driven and inventory-driven segments in Canada. Value proposition: Formica provides value to customer through its extensive marketing capabilities (customer focus, innovative products, frequent sales call). Set of activities: In marketing, Formica leads the industry in such areas as customer relationship management (210 sales representatives make frequent calls), marketing research (sophisticated customer preference transmission system), and promotion (regularly distribute samples and pamphlets). The company reduces operation costs by fully utilizing economies of scale both at the corporate level (coordinated purchases of materials) and at the plant level (high capacity utilization). In addition, Formica’s operations are highly automated with cutting-edge technologies, further diminishing costs. Sustainability of competitive advantage: The strengths mentioned above are, however, highly vulnerable. First of all, operation procedures can be easily imitated. Indeed, WilsonArt operates more efficiently than Formica (38.7 vs. 39.9 cents per square feet), and Arborite’s new Toronto plant (45.1) is almost as efficient absent the difference in scale on purchasing. Secondly, Formica’s marketing activities are not tightly linked to each other (compared to WilsonArt, discussed below) and are relatively easy to imitate. Therefore, the competitive advantage of Formica is not sustainable in the long run. WilsonArt Product-market domain: WilsonArt concentrates in the job-driven segment in Canada. Customers in this segment are characterized as follows. First, availability of products is critical to them. Sometimes OEMs requires products to be delivered in two to three days. Second, their buying decision is affected by wide range of product attributes, such as colors, patterns, textures and grades. Third, they are less price sensitive than inventory-driven buyers. 3 Value proposition: WilsonArt provides value to customer by committing to extensive service and shorter shipping time. Set of activities: WilsonArt put significant resource on development and maintenance of distribution capabilities. The exclusive relationship gives dealers incentive to carry high level/variety of inventories, making quick deliveries possible. In addition, the customer service and support standards can be followed more rigorously in the exclusive dealership, which is aligned with needs of job-driven customers. Although the distribution strategy significantly increases WTP of the job-driven segment, it also brings significant costs. To offset the cost increase, WilsonArt is involved in various cost-cutting efforts in operations and marketing (“WTP-arbitrage”). In operations, the company fully utilizes economies of scale both at the corporate level (coordinated purchases of materials) and at the plant level (high capacity utilization). Its plants employ current, efficient technologies, and use cheaper materials when possible (e.g. thicker core stock, only one separate sheet). In marketing, WilsonArt does not invest in innovation. Instead, it copies what Formica developed. Consequently, its products cost less than competitors’ (net of tariffs). Sustainability of competitive advantage: For competitors, WilsonArt’s strategy is hard to imitate for the following reasons. First, WilsonArt’s activities are reinforcing each other in a complex way. For example, its quick delivery capabilities are enabled by maintaining exclusive dealership network, employing sophisticated order processing system, carrying high level of inventory, and owning its fleet of trucks. Copying one or two of these activities will not help competitors achieve the same level of service. Second, competitors have been locked-in to certain types of activities such as non-exclusive, large distribution network, and it is difficult to reverse them and redevelop new activities. For the reasons mentioned above, WilsonArt has a sustainable competitive advantage in the job-driven segment. Q4. Arborite should concentrate in the inventory-driven segment because 1) the needs of the segment fit with Arborite’s capabilities (old technologies, no marketing), 2) the segment is not yet preempted by either WilsonArt or Formica, and 3) significant demand (42% of HPL buyers) is identified. To obtain a sustainable competitive advantage in the segment, we recommend Arborite to take the following actions. First, Arborite should close its Montreal plant because operation costs in Toronto are significantly lower (45.1 vs. 51.5 cents per square feet). This will increase the capacity utilization of Toronto plant from 30% to 52%, further reducing unit costs. Resulting potential increase in delivery time will not be a problem, since inventory-driven buyers are typically willing to wait 3 to 4 weeks. Second, Arborite should seek to export its products to the U.S. to further increase capacity utilization and diminish the scale disadvantage on purchasing. Third, Arborite should use cheaper materials wherever possible, because use of high-quality materials does not increase WTP of inventory-driven buyers. This includes uses of thicker paper (0.3 cents per square feet) and only one separate sheet per press (0.3 cents). Fourth, Arborite should reduce variety of products offered, as most inventory-driven buyers purchase only basic "bread and butter" on a regular basis. By focusing on core products, Arborite will be able to reduce costs in pressing and outbound logistics while maintaining WTP. Focusing on core products also makes demand more predictable, improving efficiency of plant operations. Fifth, Arborite should reduce the fixed cost in the West (where its scale is less than MES) by outsourcing the warehousing operations. Finally, Arborite should simplify its management structure. Simplified operations (only one plant) will reduce the number of management layers and functions needed. These activities are complementary to each other and hard to imitate for competitors. For example, it is difficult for Formica to reverse its commitment to the innovation and cut number of products. Similarly, it is difficult for WilsonArt to intentionally reduce its perception of high performance, availability and service. Therefore, the strategy developed above is likely to give a sustainable competitive advantage to Arborite. 4 Exhibit 1 Industry Analysis STRUCTURE Number of firms Rate of growth of industry Nature of Product Switching Costs Cost Structure Diverse Business Exit Barriers Number and concentration of Suppliers Substitutes available FACTORS EFFECT and CAUSAL LOGIC INDUSTRY RIVALRY (HIGH) Fewer firms - Arborite, Formica, and Positive effect on Revenues Wilson Art control 80% of market Smaller number of firms makes price Fairly consolidated industry wars less likely (tacit collusion argument) Slow – roughly less than 2% growth Negative effect on Revenues Lack of growth means only way to grow revenues in by increasing market share. This in turns leads to price wars and revenues reduction. Market not attractive Largely commodity based (Specialty in Negative effect on Revenues some cases depending on buyer) Low product differentiation means competition largely based on price, leading to lower price of products Low for the most part – buyers had Negative effect on Revenues choice to select different HPL Increases the value of the next best manufacturers based on quality or alternative (which is reduced by delivery speed switching costs) and therefore reduces value of HPL and buyers’ WTP – affects ability to price or sell products leading to reduced revenues High variable costs – labor intensive Positive effect on Revenues: no one can processes, volume based production price above MC which is high due to variable/fixed artio Volume determines extent of revenue generated Except for Wilson Art, diversity of Lesser category of products to sell business is absent leading to lower revenues Capital intensive business Decision to sell assets may not be easy SUPPLIER POWER (HIGH) Two main raw materials – resin and Negative effect on Costs paper Resin: Low bargaining power of For chemicals used in resins or presupplier – lower costs for HPL mixed resins—supplier power is low; manufacturers low prices or bulk prices were offered. Cover Paper: greater bargaining power Paper was the main driver of the of supplier over HPL manufacturers – demand for resin costs will be high for HPL Paper – Cover paper and core stock manufacturers; however volume paper. Cover paper – monopolized by discounts are given to them three suppliers, high cost item Core Stock: High bargaining power Core Stock – Heavily monopolized, over HPL manufacturers – costs will be only two players, strong bargaining very high for HPL manufacturers power with high prices and no volume discounts No substitutes for raw materials Negative effect on Costs provided by suppliers Lower bargaining power for HPL Resin and paper manufacturers serve manufacturers leading to high costs of 5 HPL manufacturers among several other industries Valuable Materiality of product to your value chain (criticality of input) Threat of forward None integration Initial Capital Requirements Economies of Scale Government Influence Negative effect on Costs Raw materials provided are vital link in value chain, hence cannot be eliminated – higher costs of raw materials Positive effect on Costs HPL manufacturers have lesser competition as threat of new entrants is not present from suppliers – higher revenues possible due to lesser players in market BARRIERS TO ENTRY (MEDIUM) Highly capital intensive process Positive effect on Profits High investments for new comers - $70 New entrants have high costs of entry million investment (compare to in turn discouraging them from entering expected annual profit) the industry – better market position for incumbents Extensive distribution network is difficult to replicate Volume driven processes led to greater Positive effect on Profits emphasis on scale economies in Scale comes here from bargaining industry position rather than from allocation of Economies of scale inconsistent among fixed costs different players – Wilson Art was There is some challenge to new better compared to Arborite entrants in matching the scale (Operations cost was 38.7 compared to economies of some incumbents – as 48.5 for Arborite) HPL products cannot necessarily be sold at a premium price, new entrants will find it difficult to gain revenues Incumbents with scale economies will have lower operational costs and better profits Mostly no government interference Positive effect on Profits except for some trade tariffs between Trade tariffs reduce incentives for new US and Canada (4% for Canada to US comers to enter the Canadian market – and 13.5% from US to Canada) higher costs involved in carrying out operations Greater revenues through better share of the Canadian market for incumbents There is some absolute cost advantage - Positive effect on Profits experience in the production process Difficult for new comers to achieve leading to greater volume production, scale in production, so high costs especially in labor intensive lay up and finishing processes Absolute Cost Advantage Patents or Proprietary knowledge/Exper ience Product Low Differentiation Number and raw materials Negative effect on Profits Easy for new entrant to create product. Less price margins and hence lower revenues for incumbents BUYER POWER (HIGH) High and with specialized needs, Buyers have the upper hand in setting 6 concentration of buyers multiple processes define different price points leading to reduced buyer segments revenues for HPL manufacturers Fragmented Criticality of input Most buyers need HPL as only a part of Negative effect on Revenues their bigger projects Less reliance to some extent on HPL Not dependent on any particular HPL products – greater choice of substitutes manufacturer - certain products do not and bargaining power on price leading require sophistication and hence can be to lower revenues for HPL obtained anywhere manufacturers Exception is that HPL is 35% of costs for post formers, but they are performing poorly or exiting the business How well Good for the most part – job driven Negative effect on Revenues informed are buyers used network of architects and Greater information discounts the they? distributors advantage HPL manufacturers may have in raising prices or gaining other cost benefits that will not be passed on to the buyer Ease of switching High Negative effect on Revenues Buyers switching between suppliers puts a pressure on price and the revenues that HPL manufacturers can gain Ability to High – Some buyers such as specialized Negative effect on Revenues purchase manufacturers constituted 49% of the Greater bargaining power leading to significant sales for HPL manufacturers price discounts on bulk purchasing proportion of leading to lower revenues for HPL output manufacturers Product Mostly a commodity based product Negative effect on Revenues Differentiation Buyer has no incentive to pay higher price for such products resulting in lower revenues for HPL manufacturers Threat of None - HPL manufacturing is not an Positive effect on Revenues backward attractive investment for them. Some concession for HPL integration manufacturers to have control over their market share and existence in the industry – hence better revenues THREAT OF SUBSTITUTES (HIGH) Number and High – there were 5 different substitute Negative effect on Quantity concentration of products each with their own share of More substitutes leads to greater choice substitutes the HPL markets for buyer to select between products – lesser power in raising prices and hence lower revenues for HPL manufacturers Demand for High for products such as Vinyl, Negative effect on Quantity substitutes Veneer and Paper in some applications Greater demand for substitutes makes such as office furniture and custom buyers price elastic to HPL and would design office interiors tend to switch to other substitutes if prices for HPL products are raised 7 Exhibit 2A Needs of Various HPL Buyers Exhibit 2B Comparison of HPL and non-HPL on Attributes Exhibit 2C Positioning of HPL and non-HPL on Attributes Exhibit 2D HPL and non-HPL on the WTP-Cost Efficiency Frontier 8 Exhibit 3A Comparison of Strategic Positioning Exhibit 3B Comparison of Critical Value Chain Activities The critical value chain activities for this industry are firm infrastructure, operations, outbound logistics and marketing and sales. Activity Firm Infrastructure Operations Outbound Logistics Arborite Costs included charge for management at Arborite and allocations for two layers of corporate overhead Formica Expenditure for quality control at plant level declined due to a recent leveraged buy-out of the firm. Infrastructure costs consists of one layers of management overhead 2 Canadian factoriesSeveral manufacturing Montreal: Older factory, facilities overseas, North produced 42% of firm’s America and in St. Jean HPL production by Montreal. 100% capacity volume, 25% capacity utilization at St. Jean. utilization Investments made to Toronto: Newer automate most of the old factory, 58% of firm’s plant at St. Jean HPL production by volume, 30% capacity 156 lb basis weight paper utilization core stock 115 lb basis weight paper core stock 3 warehouses in Montreal, Toronto and Vancouver 75% firm inventory held in Toronto and 20% in Regional warehouses at Toronto and St. Jean and contracted with independent firms to warehouse inventory in Vancouver and 9 WilsonArt Costs supported 2 levels of organizational infrastructure above the plant level Three US manufacturing facilities. Capacity utilization of 90%. Not integrated into resin mixing 156 lb basis weight paper core stock 14 warehouses in the US, 3 servicing Canada Distributed 5% of products direct to OEMs and 95% Marketing & Sales Montreal Edmonton 28% of volume sold to OEMs and 72% through independent distributors and building supply dealers 40% of Canadian volume shipped to OEMs and 60% to distributors and building supply dealers Distributors carry 120 colors and grade of HPL Distributors carry 100 colors and grade of HPL on average Does not own a fleet of trucks Does not own a fleet of trucks 20 sales representatives covering territories in Canada who call on both distributors and dealers and were directed to provide high levels of service No advertisements and widespread distribution of samples Firm trains field sales representatives and does not provide incentive based compensation Worldwide marketing and sales organization of 215 representatives who call on architects, designers, OEMS and distributors and dealers Sophisticated system for transmitting information on customers’ preference for fashionable, innovative HPL back to management No advertisements, distributed samples and pamphlets to architects, designers and OEMs 10 through distributors. Each distributor received a commitment that the firm would not sell to any other distributor or dealer in the local area Distributors carried 210 colors/grades of HPL Owns a fleet of trucks Shipped stock items within 3 days and nonstock items within 10 days of receipt of order Most sophisticated order processing system 45 sales representatives across North America who call on WilsonArt’s exclusive distributorships. Circulated samples to designers and architects in greater quantities than either Arborite and Formica Exhibit 3C Detailed Comparison of Value Chain Activities (costs: cents per square feet) 11