EML2322L -- Design Report Template

advertisement

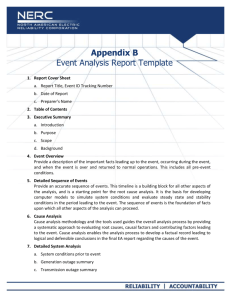

EML2322L – Design Report Template Table of Contents (for this report template, not for the submitted design reports) Cover Page ……………………………………………………………………………………….…..… 3 Introduction / Problem Statement ……………………………………………………………….……... 4 Background Information ……………………………………………………………………………..… 5 Conceptual Design Generation …………………………………………………………………….…... 8 Design Report 1 Submission Instructions ……………………………………………………………… 11 Selection of Design Concept …………………………………………………………………………… 13 Peer Evaluation for Design Report 2 ……………………………………………..…………................. 18 Design Report 2 Submission Instructions ……………………………………………………………… 20 Detailed Design …………………………………………………………..…………………………….. 16 Peer Evaluation for Design Report 3 ……………………………………………..…………................. 18 Design Report 3 Submission Instructions ……………………………………………………………… 20 Design Review Instructions ………………………………………………………….………………… 22 Design Report 3 Resubmission Instructions …………………………………………………………… 23 Competition Paperwork Submission Instructions ……..……………………………………………..… 25 Prototype Development and Testing …………………………………………………………………… 26 Discussion / Conclusion ………………………………………………………………………………... 27 Design Report 4 Submission Instructions ……………………………………………………………… 28 Report Appendices ………………………………………………………………………………..……. 29 Common Report Errors and Weaknesses ……………………………………………………………… 31 Links to Project Templates and Reference Documents ……..……………………………..….…….…. 33 NOTE: All instructions in red (and hyperlinks) should be deleted from this template after reading and prior to printing the report for submission. EML2322L – Design and Manufacturing Laboratory Design Report 1, 2, 3, 3 Resubmission, or 4 (denote appropriately for each submission) Team Number Team Member Name (1) (i.e. Mike Braddock (1)) Team Member Name (2) Team Member Name (3) Team Member Name (4) Team Member Name (5) (List in alphabetic order by last name and retain number in parenthesis) Instructor: Mike Braddock Semester Date NOTE: do not change any formatting on this page or in any part of the template Introduction / Problem Statement Give the reader a professional, objective introduction to the design problem. Provide a detailed description of the problem in a clear and organized manner. Present a clearly drawn (and labeled) illustration of the arena (the drawing(s) from the Design Project description can be copied, if printed clearly and labeled with figure numbers which are referenced in the report body). Include all design specifications (i.e. objectives & constraints). Explain exactly how the design will be evaluated (40% for …, 20% for …, time penalties, bonuses, etcetera) There are many points to mention in this section, so organize them well using paragraphs with sentences that flow together, and clear, concise terminology. To reduce the time required to complete this section so you can focus on your conceptual designs, simply print the Design Project description and Design Project Schedule in color and neatly highlight the following: 1. project design specifications (i.e. objectives and constraints) in yellow (including important dimensions in the description body and on the accompanying drawings) 2. evaluation criteria in blue 3. project deliverable dates in orange 4. underline in red ink any other information you feel may be important for the project’s success Note: Only one Introduction / Problem Statement is submitted for each group. Background Information (Team Member Name (1)) To assist in this important phase of the project, relevant research has been assembled on the topics listed below. INDIVIDUALLY answer the following questions based on the background information provided on the course website. If other sources are used, they must be cited. ANSWERS MUST BE IN YOUR OWN WORDS AND SHOULD SHOW CLEAR UNDERSTANDING OF THE MATERIAL PRESENTED. Copying off the course website or any other source is PLAGIARISM and will be treated as such. Leave subheadings and questions in your printed responses and use complete sentences and paragraphs to present your answers in an organized manner. This is the only chance you will have to do background research, so please take the exercise seriously and use the Internet to perform image and knowledge searches on relevant topics to improve your understanding of how each may influence your design choices. Electric DC motors What type of power supply is used for this project? What are the pros and cons of brush-type versus brushless-type DC motors? If cost is an important factor for the project, which type of motor would be the better choice? Change font color to black and type your response here. Robot controllers Summarize the difference between relay and proportional control. For what type of function on the project might each type of control be used? How many control channels of each type (relay and proportional) do the new laboratory controllers provide? Change font color to black and type your response here. Mobile robotic platforms Summarize three commonly used mobile platform types for robotic applications and explain the pros and cons of each. Which type of mobile platform did you select for your conceptual design and why did you select it over the other options? Change font color to black and type your response here. Steering mechanisms Summarize three common methods of steering for robotic applications and explain the pros and cons of each. Which steering method did you select for your design and why did you choose it over the other options? Would front or rear steering more desirable for your design and why? Change font color to black and type your response here. Wheels and tires What are the differences between regular wheels and caster wheels? When would each type of wheel be used? What are the pros and cons of pneumatic versus semi-rigid versus solid tires/wheels? Which type(s) of wheel(s) do you believe would be most beneficial for the project and why? Change font color to black and type your response here. Friction coefficients Why are friction coefficients important for this project? What are typical static friction coefficient ranges for common wheel materials (plastic and rubber) in contact with concrete surfaces? Change font color to black and type your response here. Bucket and ball lifting mechanisms / manipulators Summarize and graphically illustrate (by hand or by including downloaded images which clearly help explain the concepts) common types of manipulator mechanisms and explain the pros and cons of each. What type of manipulator does your conceptual design use to grab the buckets/balls for this project? (Do not feel limited to the two types of manipulators noted above.) Change font color to black and type your response here. Ball hoppers Summarize and graphically illustrate (by hand or by including downloaded images which clearly help explain the concepts) common options for ball hoppers and explain the pros and cons of each. Change font color to black and type your response here. Ball sorting mechanisms / strategies Summarize and graphically illustrate (by hand or by including downloaded images which clearly help explain the concepts) common options for sorting balls and explain the pros and cons of each. If not applicable for the current semester’s project, write “N/A” in the response area. Change font color to black and type your response here. Ball dispensing mechanisms / strategies Summarize and graphically illustrate (by hand or by including downloaded images which clearly help explain the concepts) three methods for dispensing balls. Change font color to black and type your response here. Gears / gearing What are gears? What is the purpose of gearing? List five types of gearing, a common application for each, and explain why a particular type of gearing is useful in each application (perform additional research to answer this last part). Will gears be beneficial on this project? Change font color to black and type your response here. Materials / material selection List the pros and cons of steel, aluminum, plastic, wood and 80-20, as well as three common applications of each. What materials will be best suited for which parts of the project? Change font color to black and type your response here. Material properties Define the following material properties and explain why each might be important for this project: cost, density, ductility, machinability, stiffness, strength and weldability. Change font color to black and type your response here. Balls What information about balls is useful for the project and why? Be specific (i.e. quantify size(s), weight(s), material(s), coefficient(s) of restitution, etcetera, with actual numbers). Change font color to black and type your response here. [section length is typically 5-7 pages depending on writing style] Conceptual Design Generation (Team Member Name (1)) At this point background research was performed on topics pertinent to the design problem; now brainstorm ideas to solve the problem. Good sketches are essential for explaining concepts. Each group member shall submit one set of neatly drawn hand sketches which clearly illustrate a complete design solution. Each sketch view should be on its own page, as large as possible and possess a unique and sequential figure number (i.e. 1A, 1B, etc. for team member 1). Include substantial detail in the required orthographic (front, side and top) and isometric views of the entire robot and separate detailed views of the ball manipulator, hopper/sorter & release mechanism(s). Include explicit dimensions showing overall size of robot, frame, control box, motors, wheels, hubs, object manipulator(s), hopper, release mechanism(s), and attachment brackets (note: some designs will not have all of these components and may include others). Show bucket/goal and balls in relation to the rest of the design in each view. Draw all parts true scale. Use leaders to clearly label components and materials, and to describe different functions. Ensure design satisfies all project constraints. Place your name on each sketch and in each report section, as shown in this template. Include a typed written description referencing your sketches by figure number to explain the concepts and material selections for each part of the design. Include the maximum robot velocity for the selected motor speed and wheel size using this reference chart (these components can be changed in the future after performing calculations to decide which combination will work best for your conceptual designs). Note this is NOT a rough draft, but rather a detailed presentation of the best and most complete solution you can come up with based on your research. This is the only opportunity you will have individually to generate a real solution to the design problem, so take this assignment seriously, as it sets the stage for the rest of the project. Do not submit stick drawings lacking detail that show you invested no serious effort synthesizing a real solution, but rather sketch actual components that will be used on the project, such as the control box, 80-20 extrusion (unless you choose otherwise), medium size lab motors and wheels (show their detail), the actual balls and bucket(s), etc. Using real parts in your conceptual design will result in a design that has significantly more potential of solving the problem than a rough illustration that contributes little to the project. This is NOT a rough draft, despite what you might infer from the phrase conceptual design. In this case, conceptual design means design of the concept you feel best achieves the objectives listed in the project description. The first two weeks of the semester are the time to research and compare different ideas; this assignment presents the idea you conclude is best after doing so. Design Report Examples former students submitted for this assignment can be found on the course webpage under the Design Project menu; however, pay more attention to the instructions listed in this template. After taking EML2023 everyone should know what proper sketches looks like, so invest time to create them. Unclear, messy, small, incomplete, and improperly scaled sketches lacking significant detail will be harshly graded. Hand drawn sketches are an important communication skill that only improves through practice, so leverage this opportunity to improve your drawing ability. Hand drawings usually take a significant amount of time, so plan to spend 12 - 15 hours on this assignment. It typically helps to begin drawing using light line weights that are easy to erase or ignore, and after the sketch contains all desired components, darken line segments as appropriate to show depth and detail. At the conclusion of this report, each group should have as many possible solutions as it has members, giving the team a variety of ideas to evaluate when selecting the final design to refine and prototype during the remainder of the course. The following checklist details everything required for each student’s Conceptual Design Generation submitted in Design Report 1. (Individual) Conceptual Design Generation Checklist CONCEPT QUESTIONS (ANSWER WHILE STILL IN THE BRAINSTORMING PHASE): 1. Does the design satisfy all constraints noted in the project description? 2. Have realistic materials been selected for each part of the design, such as the frame, lifting arm(s), object manipulator(s) and release mechanism? If not, conduct more research and talk to course TAs. 3. Can all mechanisms and components used in the proposed design be purchased for the allowable budget or manufactured using laboratory resources? If not, you need to do more research and speak with course TAs or the instructor prior to D.R.1 submission. ORTHOGRAPHIC & ISOMETRIC VIEWS: 1. Are front, side, top and iso views of entire design neatly drawn as large as possible and on separate pages? If more space is needed than an 8.5x11” sheet provides, use multiple pages or an 11x17” sheet folded to fit inside the 3-ring binder. Use unique & sequential figure numbers and place drawer’s name on each sketch and in each report section, as shown in this template. Always hole-punch landscape-oriented pages at the top of the page, not at the bottom. 2. Does each view show clear and substantial detail of the entire design, including the frame, control box, motors, wheels, hubs, attachment brackets, manipulator(s), hopper and release mechanism(s)? Use lighter line weights to make closer components “transparent” while still including them in all sketch views. 3. Are manipulated items (balls, buckets, etc.) shown in relation to the design? For example, if balls are released into a bucket via a ramp, is the bucket shown in all views to ensure it fits under the ramp? If balls are collected in a hopper, are they visible in all views showing the hopper? 4. Are all parts drawn true scale (i.e. with accurate scaling) and clearly dimensioned? Include explicit dimensions showing overall size of robot, frame, control box, motors, wheels, hubs, object manipulator(s), hopper, release mechanism(s), attachment brackets, and release bucket. 5. Are leaders included to clearly label components and proposed material selections, and to explain functions? If you haven’t talked to other students or TAs about your material choices, you haven’t finished your research; this is the stage at which you investigate material choices. DETAILED VIEWS OF OTHER MECHANISMS (MANIPULATORS, HOPPERS, DISPENSERS, ETC.): 1. Is each mechanism neatly drawn as large as possible and on separate pages? If more space is needed, use multiple pages or an 11x17” sheet folded to fit inside the 3-ring binder. Use unique & sequential figure numbers and place drawer’s name on each sketch and in each report section, as shown in this template. 2. Does each view show clear and substantial detail of the mechanism, including attachment method/bracket(s) and proposed material selections? Include at least two orthographic views and an isometric view of each mechanism. 3. Are all parts drawn true scale (i.e. with accurate scaling) and clearly dimensioned? 4. Are leaders included to clearly label components and proposed material selections, and to explain functions? If you haven’t talked to other students or TAs about your material choices, you haven’t finished your research; this is the stage at which you investigate material choices. WRITTEN DESCRIPTION: 1. Is the description typed and placed at the beginning of your Conceptual Design Generation report section? 2. Does the description clearly explain how each part of the design works and why certain materials have been selected for each part based on your background research? If you are unsure about material selections after completing the background research, speak with course TAs or instructors during office hours. 3. Does the description reference each sketch by figure number? Each sketch should be explained in the written description. If you have nothing to say about a sketch, it should not be included in your report. 4. Does the description include the maximum robot velocity estimation for your selected drive wheels and motors? Pay attention to the units noted on the robot velocity chart and make sure your wheel and motor combination offer an appropriate balance of controllability and speed by testing the example mobile platforms found in lab during office hours. 5. Is the description well written? Does the content of each sentence flows logically with the next? Are paragraphs used to clearly organize thoughts? Is the description clear and concise, like all good technical writing? No one is going to give your ideas the consideration they might deserve if you can’t explain them effectively. [section length is typically 9-12 pages depending on the complexity of the concept] Design Report 1 Submission Instructions Submit the first design report in one CLEAN, WHITE 1” three ring binder with a clear cover in which the cover page is placed. Begin each report section on a new page (as shown in this template). Use page lifters at the front and back of the notebook and page dividers with computer-generated labels to organize each report section for the grader. Glue page divider labels in place so they can’t fall out as the notebook is transported and jostled. Do not use page protectors, as they make it difficult to leave feedback while grading. Hole punch consistently when assembling the report as a group and do not staple pages. Order report sections in the following sequence: Cover Page (one per group inside the clear notebook cover) Introduction (one per group) Background Information (Team Member Name (1), i.e. Mike Braddock (1))) Conceptual Design Generation (Team Member Name (1)) Background Information (Team Member Name (2)) Conceptual Design Generation (Team Member Name (2)) Etcetera Important Notes Regarding D.R.1 Submission: 1. The appearance of your work is a reflection of the effort invested; therefore before submitting your report, ask yourself if the content is something you would be proud showing in an interview or submitting to a boss. Incomplete or poor quality work on D.R.1 is an indication you are unable or unwilling to commit the necessary time to the course and you should seriously consider dropping the class. Students who receive lower than 60% on D.R.1 will be dropped from the course due to their inability to meet the ABET objectives listed in the course syllabus and the burden they will subsequently place on rest of their teammates. 2. Make high quality copies of your final conceptual sketches to show your group while D.R.1 is being graded (keep the copies and submit the originals). Failure to copy sketches results in an individual grade penalty of 10% on D.R.1 because you will be unable to share your ideas with your teammates. 3. If any teammate(s) does not communicate with your group or equally contribute to preparing the report, hand-write “DNC” (did not contribute) next to his/her/their name(s) on the cover page before submission in lab. If you don’t flag this behavior now, it will only get worse moving into the much more demanding D.R.2. 4. Assemble the report BEFORE lab. If any member’s content is not in the design report notebook for prompt submission at the start of lab, hand-write “LATE” next to the member’s name on the cover page before submission. Failure to do so will result in the entire group receiving a LATE penalty. From this point onward, this option will not exist: the entire team will be penalized for any work not submitted on time. [This is the end of Design Report 1; however please review the Common Report Errors and Weaknesses section of this Design Report Template before printing your report sections for submission] Selection of Design Concept Note: Only one submission of this section is required for each group and it must be worked on as a team. Review the decision matrix example and provide the same level of clarity and assessment justification. Divide your designs into logical subsystems (i.e. mobile platform, ball manipulator, ball hopper/sorter, ball release mechanism, etc. (these are just examples)) and evaluate each separately to select the best overall solution. Create decision matrices for each subsystem to allow your group to unbiasedly select the best concepts. For each matrix, list the objectives/criteria used in evaluating the concepts. Accurately define all objectives, as they have different meanings for different groups. Explain in detail how the objectives are chosen and how the relative weighting factors are assigned. Sample criteria may include velocity (or time), controllability, size, simplicity, modularity, manufacturing time and material cost. Do not limit yourselves to these criteria; decide what design considerations are important for each subsystem and use those criteria (typically five or six) for each matrix. You can also review the crane hook example from the design process lecture notes. Include detailed justifications explaining how magnitudes and scores are assigned for different concepts in each evaluation matrix. For example, if your group uses velocity as an objective for the mobile platform, explain how the scores are computed (include all calculations with units in the appendices) and for qualitative assessments explain why Concept A scores higher than Concept B and why Concepts C and D score lower than Concept B. THIS SECTION REQUIRES SIGNIFICANT DETAIL TO CLEARLY JUSTIFY HOW THE SCORES ARE ASSIGNED. When evaluating quantitative parameters like cost or manufacturing time, include price or time justifications for each concept showing how every value is determined for the magnitudes listed in the matrices. Use the material price list on the course website to create accurate cost summaries and use the experience obtained in lab making parts and the time estimation guides for the manufacturing time summaries. TAs will gladly provide assistance if asked specific questions. When organizing the report, compare all concepts with respect to each objective as opposed to discussing all objectives for each concept. At this stage in the design process it is common for a new idea to arise which the team concludes is best after comparing it to the previously submitted concepts; in this case, simply add this new concept to the decision matrix (or matrices) and explain why it achieves a higher score. This could be an entirely new concept or a combination of the group’s individual concepts submitted in the first report. This is a common and good occurrence in the design process. Just evaluate the new idea against the other conceptual designs to decide which one is the best. In other words, if there are four members in your group and you came up with a new combined design, your comparison matrix will now have five concepts evaluated according to the predetermined objectives. Adding a new concept to one matrix does not require you to add a new concept to the others. You are not required to include hand drawings of this new design, because if it achieves the highest score it will be shown in detail in the CAD drawings generated for the next portion of the design project. Use Excel for all calculations included in the appendices and think about the number of significant figures reported for each. For example, if you are computing estimated robot speed, think about how precise you believe your estimate to be and use the appropriate number of significant figures (i.e. 2.3 versus 2.3456 ft/sec; the later boasts much higher precision and makes us look foolish). [section length is typically 40-60 pages including appendices] Design Report 2 Submission Instructions Submit D.R.2 in a CLEAN, WHITE 2” three ring binder with a clear cover in which the updated cover page is placed. Begin each report section on a new page (as shown). Use page lifters at the front and back of the notebook and page dividers with computer-generated labels to organize each report section for the grader. Glue page divider labels in place so they can’t fall out as the notebook is transported and jostled. Do not use page protectors, as they make it difficult to leave feedback while grading. Hole punch consistently when assembling the report as a group and do not staple pages. Order report sections in the following sequence: New Cover Page (with updated report number and date) Design Report 1 Grade Sheet (original copy completed by TA or instructor) Design Report 1 (complete and untouched from original submission and grading) Concept Selection Checklist (original copy completed by TA for first two evaluation matrices) Selection of Design Concept (original copy submitted for review by TA; contains all comments made by the TA regarding the first two evaluation matrices and is used to assess what feedback is heeded) Selection of Design Concept (update with TA feedback & assemble in the following sequence:) 1. decision matrices (print in landscape orientation like the template) 2. objective definitions, weighting factor justifications, and detailed magnitude and score assignment explanations 3. decision matrix calculations and quantitative assessment data should be neatly organized in tabular format in Appendix A (follow the formatting in the manufacturing time estimation guides) Appendix A: Decision Matrix Calculations / Justifications Appendix B: Robot Path Illustration, Speed & Time Calculations Appendix C: Wheel and Lifting Motor Torque Calculations Appendix I: Group Meeting Minutes (compilation of all members’ completed meeting minutes) Refer to Appendices section of template for details about the report appendices. D.R.2 GRADING NOTE: as stated at the beginning of the semester, the ideal number of group members is four. To compensate individual effort, report submissions by groups with five members which are not of excellent quality will be penalized and reports submitted by groups with three members will be graded more leniently. [This is the end of Design Report 2; however please review the Common Report Errors and Weaknesses section of this Design Report Template before printing your report sections for submission] Detailed Design Note: Only one submission of this section is required for each group; however all work should be distributed equally among team members and computer-generated. Provide a detailed description of how the final design accomplishes the goals stated in the project description. In other words, explain how each subsystem works and why the design was chosen based on the information learned from the project research. Finally, explain what materials are used for each part of the design and why each was selected. Present analyses and calculations in report appendices. Analysis for this project should include calculations of motor torques (amount required to move your robot and raise any lifting arms / doors) and robot speed and estimated task completion times (object manipulation, sorting, and/or release times, etc.). Show a clear sample calculation with units for each computed value. Include a top view of the arena showing the exact (dimensioned) path the robot will follow when navigating the course (use arrows and/or different line types to show the robot’s planned path in and out of the arena, label each path segment’s distance and estimated velocity, and include a summary table showing the estimated total driving distance). Present complete CAD generated part and assembly drawings. Use consistent title blocks for all drawings (required drawing templates are available on the course webpage). Include detail drawings of ALL components (manufactured and off the shelf (OTS)) used on the project with the exception of fasteners (since these are specified completely in the bill of materials (BOM)). Include dimensions, tolerances, units, material specifications, surface finish specifications, appropriate hole & thread notes, part quantities, (unique) part names & numbers, designer and drawer names and part deburring notes where appropriate. Use the provided detail drawings for common OTS parts (motors, wheels, 80/20 accessories, etc.). Assembly drawings must contain a BOM clearly labeling all parts of the assembly with sequential and uniquely numbered leaders and balloons; this typically requires multiple views/pages for clarity. Stated another way, each part has a unique balloon number which, when shown in the assembly drawings and BOM, appears sequentially with those of other parts. If a part is present in multiple assemblies, it maintains the same balloon number. In this case, the BOM containing a subsequent appearance of this part will have a jump in the number sequence. Include subassembly drawings of the mobile platform (here is a good example for reference), frame, drivetrain (i.e. drive motors, motor mounts, wheel hubs and wheels), ball and/or bucket manipulator(s), ball hopper/sorter and ball release mechanism that show necessary assembly dimensions (in the proper orthographic views). Provide a project schedule showing intermediate deadlines and responsibilities. The schedule shows who is responsible for each task and when each task should be complete based on the time estimates created previously for the concept selection matrices (update if necessary). In addition to scheduling for each manufactured part, include time for assembly of each subsystem, preliminary testing, design changes, final testing, and competition. The project schedule allows equal allocation of responsibility and effort, and creates accountability within your group. Note: pairing up group members on tasks is not an efficient use of resources; everyone receives the same training and should be capable of performing the same manufacturing tasks; if anyone needs additional help, ask one of the TAs, who will be happy to assist. When creating the schedule, keep in mind that failing to plan is planning to fail. Provide a project budget showing the costs for all materials and components used on your project. Purchased items must not exceed the $50 limit. Items provided by the team and components provided at no charge by the lab (i.e. the pre-allocated amount of unmodified 80-20, wheels, motors and fasteners) should be noted as such (as explained in the budget template). Budget should include all items in the final BOM. Include your team’s number on both sides of the robot using characters which are at least 3 inches high. Color, font, and background shade is at the team’s discretion, but please ensure the team number can be easily read for scoring purposes. [section length is typically 35-50 pages depending on the complexity of the design] (OPTIONAL) Peer Evaluation for Design Report 2, 3, or 4 Group Number: _____ TA: _____________________ The second report is the hardest part of this course, requiring by far the largest amount of effort. If any member(s) in your group did NOT do an equal amount of work on the second design report, this is your opportunity to inform me so the proper corrective action can be taken. Examples include students who repeatedly failed to complete their weekly project assignments, didn’t show up for scheduled team meetings (or weren’t prepared when they did), repeatedly made excuses why he/she couldn’t do their work, didn’t have the proper software installed on their computer, claimed they “weren’t good at CAD” (or writing, or calculations, or …), submitted work that was subpar and required other members to redo it, waited until last minute to submit their work to the rest of team for feedback and editing, etcetera. Realize that everyone occasionally has a bad week, so I’m not asking to hear about the one time someone didn’t show up prepared or complete an assignment; but rather I’m asking to hear about the member(s) who offered more excuses than results while working on this assignment. Please be specific in explaining why you feel the following member(s) did not contribute their part to the second design report. Attach additional pages as necessary, as well as your group meeting summaries I asked all groups to use. I will assume any group not submitting this peer evaluation sheet was completely satisfied with their teammates’ performance on this assignment. Submission of this evaluation is NOT a requirement for the second design report. Example: Michael did not perform an equal amount of work on this second design report. He rarely attended our group’s design meetings and when he did, he always arrived late, would only stay for about 30 minutes and rarely contributed anything helpful. He refused to work on CAD drawings because he claimed he wasn’t good at SolidWorks, that he learned AutoCAD at the last school he attended and that he would “do more of the group’s manufacturing during that phase of the project” (which was not helpful for this part of the project and only an empty excuse, since logically one person can only do the work of one person once manufacturing commences). The work Michael did on the decision matrices showed little effort, did not follow the guidelines or formatting in the design report template and had to be redone by the rest of the group. Specifically, objectives were not clearly defined, magnitudes were computed incorrectly and magnitude justifications were poorly explained, if at all and did not use the provided cost or time estimation templates. Michael repeatedly failed to submit his assignments to the rest of the team in time for proofreading, and consequently those sections show low effort and will now reflect poorly on the rest of our team. Michael was asked to complete the illustration of the robot’s trajectory, but claimed he didn’t know how to make it the day before it was due. Michael was also asked to create the team’s budget but failed to use the provided template for material costs, didn’t include all necessary items, and once again did not complete it in time for anyone to proof it. As a group we feel Michael only contributed about 20% of what he should have as an equal member of this group. Each week he was assigned clear tasks, but acted helpless, offered excuse after excuse and refused to attend the TA hours for assistance on his assignments. To explain how the work was divided for the second report we are including a breakdown of what tasks were performed by which team members: Selection of Matrix Objectives: Josh 40%, Sam 30%, Robert 30%, Michael 0% Definition of Matrix Objectives: Sam 60%, Robert 40%, Michael 0% Weighting Factor Justifications: Josh 80%, Michael 20% Magnitude Assignments / Justifications: Josh 30%, Sam 30%, Robert 30%, Michael 10% Robot Speed Calculations: Josh 50%, Robert 50% Robot Path Illustration: Sam 80%, Michael 20% Wheel & Lifting Motor Torque Calculations: Josh 50%, Robert 50% Detailed Written Description: Sam 10%, Robert 90% CAD Models (Custom Designed Parts): Josh 20%, Sam 60%, Robert 20%, Michael 0% Main Assembly Model: Josh 20%, Sam 60%, Robert 20%, Michael 0% Subassembly Models: Josh 20%, Sam 60%, Robert 20%, Michael 0% Detail Drawings (Off the Shelf Parts): Josh 20%, Sam 20%, Robert 60%, Michael 0% Detail Drawings (Custom Designed Parts): Josh 20%, Sam 20%, Robert 60%, Michael 0% Assembly Drawings: Josh 20%, Sam 20%, Robert 60%, Michael 0% Subassembly Drawings: Josh 20%, Sam 20%, Robert 60%, Michael 0% Bill of Materials: Sam 75%, Josh 25% Project Schedule: Josh 80%, Michael 20% Project Budget: Robert 80%, Michael 20% Final Report Assembly & Printing: Josh 20%, Sam 60%, Robert 20% Note: estimations accurate to approx. ± 10% All the members who sign below agree to these statements and hope you can have a talk with Michael so he will be more helpful during the prototyping phase of this project. Josh X Josh X Sam Y Sam Y Robert Z Robert Z Please submit this page to Mike personally the day your group submits their second report in lab. Design Report 3 Submission Instructions Submit D.R.3 in a CLEAN, WHITE 2” three ring binder with a clear cover in which the updated cover page is placed. Begin each report section on a new page (as shown). Use page lifters at the front and back of the notebook and page dividers with computer-generated labels to organize each report section for the grader. Glue page divider labels in place so they can’t fall out as the notebook is transported and jostled. Do not use page protectors, as they make it difficult to leave feedback while grading. Hole punch consistently when assembling the report as a group and do not staple pages. Order report sections in the following sequence: New Cover Page (with updated report number and date) Design Report 1 Grade Sheet (original copy completed by TA or instructor) Design Report 1 (complete and untouched from original submission and grading) Design Report 2 Grade Sheet (original copy completed by TA) Design Report 2 (complete and untouched from original submission and grading (including appendices)) Detail Design (assemble in the following sequence:) 1. written description and project schedule 2. full BOM table containing every item / balloon number used on the entire project (for quick reference by TAs when checking your BOM against your final prototyped assembly) 3. assembly drawings of entire robot with BOM containing smaller subassemblies 4. assembly drawings and BOM of subassembly 1 5. detail drawings of all parts in subassembly 1 6. assembly drawings and BOM of subassembly 2 7. detail drawings of all parts in subassembly 2 8. repeat for remaining subassemblies Appendix D: Estimated Project Budget Appendix I: Group Meeting Minutes (updated compilation of members’ completed meeting minutes) Refer to Appendices section of template for details about the report appendices. [This is the end of Design Report 3; however please review the Common Report Errors and Weaknesses section of this Design Report Template before printing your report sections for submission] Design Review Instructions The purpose of the formal (graded) design review is to allow the TAs to provide valuable feedback on each group’s design selection, final design, engineering drawings, and other project details. Each group will receive a grade using the Final Design Review Checklist / Grade Sheet distributed in lab and linked on the course website. Since each group is given a copy of the checklist, the expectation is that each group takes advantage of the TA hours and comes to the design review with all “YES” marks on the checklist; anything else is foolish and will adversely affect your group’s performance. Tips for good design reviews: 1. Arrive prepared with a COMPLETE and printed D.R.3 your group is proud of; the alternative not only wastes everyone’s time and achieves a poor grade, but incomplete assignments riddled with avoidable mistakes and poor organization hampers the TA’s ability to provide valuable feedback. 2. Write down all TA feedback, so your group can review the comments outside lab and the TA can examine and critique more of the report; the more writing you do (as opposed to the TA), the more feedback the TA will be able to provide. 3. Ask TAs to explain anything you don’t understand, but don’t argue with them, as doing so wastes everyone’s time, makes you look disrespectful, and only hurts your grade; every TA is invested in their group’s success and the feedback offered is done so with three goals in mind: (1) to improve designs, (2) to make designs easier to manufacture, and (3) to improve your D.R.3 grade. 4. During the design review the TA will likely catch several weaknesses and mistakes, since (s)he is knowledgeable about the requirements for each assignment. The feedback provided by a course TA during the two-period design review can typically improve a group’s performance and grade 10-15%, if heeded. 5. Realize the design review is the last chance for a TA to help improve your team’s design; if you bring poor or incomplete work to the design review, do not expect a TA to give you a second review. The goal of the design review is to leave each group with a list of changes which will help improve your chance of success and D.R.3 grade upon re-submission the following week. Although groups are not required to implement TA feedback, mistakes and weaknesses noted on the Concept Selection and Design Review Grade Sheets which are not corrected will be doubly penalized when the re-submission is graded. All drawings updated after the formal design review should contain updated revision letters (i.e. update from “Rev. A” to “Rev. B”, or from “Rev B” to “Rev. C”, etcetera). Design Report 3 RESUBMISSION Instructions Submit D.R.3 resubmission in a CLEAN, WHITE 2” or 3” three ring binder with a clear cover in which the updated cover page is placed (use the THINNEST binder necessary to NEATLY organize the material). Begin each report section on a new page (as shown). Use page lifters at the front and back of the notebook and page dividers with computer-generated labels to organize each report section for the grader. Glue page divider labels in place so they can’t fall out as the notebook is transported and jostled. Do not use page protectors, as they make it difficult to leave feedback while grading. Hole punch consistently when assembling the report as a group and do not staple pages. Order report sections in the following sequence: Cover Page (with updated report number and date) Design Report 1 Grade Sheet (original copy completed by TA or instructor) Design Report 1 (complete and untouched from original submission and grading) Design Report 2 Grade Sheet (original copy completed by TA) Design Report 2 (complete and untouched from original submission and grading (including appendices)) Final Design Review Checklist / Grade Sheet (original copy completed by TA) Design Report 3 Original Submission (complete and untouched with TA comments from design review and page dividers included with original submission) Detail Design Resubmission (revised and reprinted with updated drawing revision letters for all drawings edited/modified after the first D.R.3 submission) Appendix D: Estimated Project Budget (revised and reprinted) Appendix I: Group Meeting Minutes (updated compilation of members’ completed meeting minutes) Deductions will be assessed for the following mistakes: 1. 2. 3. 4. 5. 6. 7. Reports not submitted in clean white notebooks with updated cover sheets Reports missing page lifters between front and rear notebook covers Reports missing individually labeled page dividers for FIRST and second D.R.3 submissions Reports submitted without completed Concept Selection and Final Design Review Grade Sheets Reports not submitted in proper sequence Reports deviating from DRT formatting Reports possessing grammar, organization, and print quality issues [This is the end of D.R.3 Resubmission; however please review the Common Report Errors and Weaknesses section of this Design Report Template before printing your report sections for submission] Competition Paperwork Submission Instructions The following documentation must be submitted in appendices F thru I in your group’s design report notebook at the beginning of lab the day of competition: Appendix E: Final Budget & Purchase Orders (accurately account for all materials used on the final prototype) Appendix F: Engineering Change Notice Forms (properly completed and signed by your group’s TA) Appendix G: Robot Wiring Schematic (use template off course webpage; this schematic is used to wire your prototype during the competition) Appendix H: Final Assembly Drawings & BOM (should accurately match final prototype) Appendix I: Group Meeting Minutes (updated compilation of members’ completed meeting minutes) Prototype Development and Testing Show photographs of the prototype and close-ups of key design details. Highlight focus-areas with leaders or circles using photo editing software. Reference photos by figure number in the report body. Discuss the results of the manufacturing and testing and identify deficiencies in the design and improvements that were made. Did everything work as intended the first time or were adjustments and component modifications required? Be honest, as redesigns will not affect your grade, but rather provide opportunities to learn. Remember that design improvements are an important aspect of any successful prototype and should be viewed as exactly that: improvements. It is wrong to feel unforeseen changes are indicative of poor design skills. Experience greatly enhances your design and manufacturing skills! In other words, it only gets easier from this point forward ! OPTIONAL NOTE for groups which failed to complete the project in time for the course competition or whose project performance was subpar: Use D.R.4 as an opportunity to provide an honest and detailed analysis of what went wrong (ignore the typical page length noted below). Include new detail and assembly drawings showing how you would modify the design to make it better. For groups that failed, this is your chance to earn some of the points lost in the dynamic evaluation of your project’s performance, so don’t waste it. Note: Only one Prototype Development and Testing section is required for each group. [section length is typically 5-7 pages with photos containing highlights] Discussion / Conclusion Objectively review the strong and weak points of your design. Discuss how well your design solved the problem and what you would do differently if you tackled this problem again. Be objective and thorough. Pointing out weaknesses will help you learn what to do better next time and will help your final grade. Include a group photo showing all team members with names in the caption. Note: Only one Discussion / Conclusion section is required for each group. [section length is typically 1-2 pages] Design Report 4 Submission Instructions Submit D.R.4 in a CLEAN, WHITE 2” or 3” three ring binder with a clear cover in which the updated cover page is placed (use the THINNEST binder necessary to NEATLY organize the material). Begin each report section on a new page (as shown). Use page lifters at the front and back of the notebook and page dividers with computer-generated labels to organize each report section for the grader. Glue page divider labels in place so they can’t fall out as the notebook is transported and jostled. Do not use page protectors, as they make it difficult to leave feedback while grading. Hole punch consistently when assembling the report as a group and do not staple pages. Order report sections in the following sequence: Cover Page (with updated report number and date) Everything in Design Report 3 Resubmission (complete and untouched after grading, but insert the following two new sections between the Detailed Design section and the Report Appendices) Prototype Development and Testing (labeled with a new page divider and inserted at the back of the design report notebook (before the D.R.3 Resubmission appendices)) Discussion / Conclusion (labeled with a new page divider and inserted after the Prototype Development and Testing section) Appendix I: Group Meeting Minutes (compilation of all members’ completed meeting minutes) Note: Groups are not required to submit any updated part detail drawings with the third report since they were submitted with the individual ECN forms filled out during the prototyping phase of the project and contained in Appendix G. The only exception is groups which are using D.R.4 as an opportunity to provide new detail and assembly drawings showing how you would modify your design to make it better. [This is the end of D.R.4; if you haven’t reviewed the Common Report Errors and Weaknesses section of this D.R.T. already, don’t bother doing so now ] Appendices Appendices are used to organize your reports by placing calculations, purchase orders, etcetera in one centralized location. Group separate required items in sequential appendices as listed below: Appendix A: Decision Matrix Calculations / Justifications Appendix B: Robot Path Illustration, Speed & Time Calculations Appendix C: Wheel and Lifting Motor Torque Calculations Appendix D: Estimated Project Budget Appendix E: Final Budget & Purchase Orders (*) Appendix F: Engineering Change Notice Forms (*) Appendix G: Robot Wiring Schematic (*) Appendix H: Final Assembly Drawings & BOM (*) Appendix I: Group Meeting Minutes (*) NOTE: Include four additional appendix cover pages/place holders for final budget & POs, ECNs, robot wiring schematic and final assembly drawings & BOM; these items will be added to the report after prototyping begins and must be submitted with the report the day of the competition. Explain the analysis and calculations performed during the design process. Include all notes, calculations and units necessary to reproduce the logic behind the design decisions made during the project. Present notes and calculations in a neat and logical manner and use proper grammar so the reader can easily follow along. Use complete sentences to “tell the story”. For example “The torque on the lifting arm motor was calculated by ...”. Appendices should be placed at the back of the report. Each appendix should have its own separate cover page with the appendix title centered at the top of the page and the rest of the page blank. An example appendix cover page is included on the following page. Separate each appendix with a labeled page divider. Groups can add additional appendices if necessary to organize your second design report. Appendix A: Decision Matrix Calculations / Justifications LEAVE THE REST OF EACH APPENDIX COVER PAGE BLANK Common Report Errors & Weaknesses (REVIEW BEFORE DELETING!) 1. Background questions not answered adequately. If you answer a question and state something is better than something else, explain why, or your answer doesn’t show understanding. Be explicit and thorough, yet concise when answering background research questions. If you make general statements like steel is very heavy or aluminum is very light, re-read the background research and pay attention this time around. 2. Poorly presented conceptual designs. Remember, you’re training to become an engineer, not a cartoonist. Do not present a quick sketch of an idea that has not been thought through. Will the wheel orientation allow the design to turn if it has no casters? Are wheels just sketched in position without motors to drive them? (Although you don’t yet know which motors you will use for different parts of your robot, take measurements off one of the medium-sized lab motors and use those for your concept. If you’ve never seen how an electric motor attaches to a plastic robot wheel, research it.) Are motors just floating in space, or are they attached to some type of mounting bracket? Are all components in each sketch labeled to clearly communicate your design ideas? Are all components drawn to scale (if not, your concept is of little value.) What materials will you use for different parts of your robot, such as the frame, lifting arm, object manipulator(s) and release mechanism? (Materials are a topic of background research.) The instructor and TAs will answer specific questions regarding these topics. 3. Weak conceptual design selection criteria. Give good, unbiased reasons how your group selected its best concept; don’t just present the final selection. Explain why you chose certain objectives for the different comparison matrices, how you selected their weighting factors and how you assigned the scores. Every single magnitude assignment in your group’s evaluation matrices must be justified using logical data. (Yes, this is a lot of work to do well.) 4. Poorly thought out design. Is the design realizable? Can the design be assembled? How will specific parts be manufactured and attached to one another? (If you don’t know how a part will be produced, you have not done enough design work/manufacturing research.) Have part tolerances been reviewed to find a good balance between part function and manufacturing time? In other words, precise tolerances might ensure part function, but result in the part requiring much more time for manufacturing; if more liberal tolerances still allow the part to function properly, the part can be produced considerably faster. Are the required part tolerances obtainable using processes covered in class? Have cost issues been considered? If you don’t know the answers to these questions, you need to do more work. Engage your group members and the laboratory staff with questions. 5. Poorly detailed parts. Detailed part drawings must (by definition) be detailed. When necessary, use multiple pages to print separate views so there is adequate room to show a high level of detail. For each detail drawing in the second report, include all part features, dimensions necessary for manufacturing each feature, appropriate tolerances for every dimension (based on what you’ve learned in lab), proper thread notes, material and surface finish specifications (never specify “finish all surfaces”), quantity, part name, designer/drawer name. Engage the lab staff with questions about your drawings, part tolerances, material choices and surface finish specifications. 6. Figures / tables not labeled properly or not referred to in the report body. All figures and tables must be labeled with captions. Figure captions should be placed below figures; table captions should be placed above tables. Reference each figure and table in the text by number; otherwise, the material is superfluous and should not be included. Do not capitalize references to figures and tables, such as fig. 1A and table 2 unless they are the first word of a sentence. Number figures sequentially according to each member’s group number and capitalize figure and table captions (i.e. Fig. 1A, Fig. 1B for team member 1; Table 1, Table 2 for the main report body or appendices; etcetera). 7. Formatting. Although every person in the group contributes their own work to the design report, formatting should be consistent throughout; therefore all reports must use this template. Do NOT change the formatting within (i.e. page margins, font style/size/color, line spacing, etc.). Use provided subheadings to separate material in major sections. Print all report sections single sided and orient notebook rings at the TOP of all pages printed in landscape orientation (i.e. drawings, decision matrices, speed calculations, etcetera). Do not assemble reports last minute with poor print quality, mismatched hole-punching, or misspelled team members’ names, as these mistakes will receive grade deductions. If you invested serious effort into the design project, the design report should show it. 8. Calculation Reporting Errors. Always use appropriate significant figures relative to the accuracy of the measured or computed value. For example, if estimating manufacturing times for parts on the project, do not report times as 3.50 hr or 4.702 hr unless you are confident your estimates are accurate to a hundredth or a thousandth of an hour (which they aren’t); instead, report the values as 3.5 hr and 4.7 hr if you think your estimates are accurate to within a tenth of an hour (which they should be). Alternatively, you can report the estimated manufacturing times as 3.5 or 4.75 with a note in the table footer saying manufacturing times are reported to the nearest 0.25 hour (if you think that’s an appropriate estimation accuracy). Similarly, when computing parameters like motor torques or wheel speeds, never report final values as 1.28369 lb-ft or 3.14159 ft/sec, because that level of accuracy is absurd for what are supposed to be estimations; instead, report the final values as 1.3 lb-ft or 3.1ft/sec. The only common exception to this rule is US currency, which is traditionally reported as $XX.XX. In this example, reporting an estimated cost to the nearest cent seems unreasonable, since this is (as the name implies) an estimation. On the other hand, rounding each reported value to the nearest integer dollar seems inaccurate, as rounding errors can accumulate into something significant. Therefore it usually makes sense to report currency to the nearest half or quarter dollar with a note in the table footer saying costs reported to the nearest quarter or half dollar. 9. Organization. Take time to clearly organize your thoughts. Sections should be well written so the content of each sentence flows logically with the next. Don’t just throw disconnected sentences together and call them paragraphs. Write to the point, using as few words as necessary. Use paragraphs to separate your thoughts or points. You’ve received a lot of education to get to this point and you are expected to use it in this course. If your writing isn’t easy to read, don’t complain about the low grade you receive on it. 10. Grammar / Style. Proper grammar and spelling are vital. Reports with grammar mistakes will be harshly penalized. Your writing, spelling and grammar will be evaluated to ensure they are at a collegiate level. Final drafts should be well proofed. As for style, write in third person without exception. Place two spaces between sentences and a blank line between paragraphs to reduce eye fatigue by more easily denoting sentence and paragraph breaks. Finally, every sentence in the design reports should apply to this particular project, as opposed to just being a generality. 11. Examples of Common Grammar Problems. Never use trite words or phrases such as: usage, utilize, in order to, or very. Check homonyms. Ensure subject/verb agreement. Understand what a proper noun is and isn’t. Understand the difference between commas, semicolons and colons, and use each appropriately. Review the difference between apostrophes used to make nouns possessive and to form contractions. Do you know the difference between affect (a verb) and effect (a noun)? What about farther and further? Watch out for comma splices, run-on sentences and dangling participles. Always include a referent with “this”, such as “this type of steering”; with no referent, “this” only confuses the reader. The same applies for “it”, so use it sparingly. “Very” is an unspecific determinate. If you ask 10 people how big “very large” is, you would get 9 different answers. As engineers, we must do a better job quantifying something than by using “very”. Never end a sentence with a preposition. This might seem overly picky; however, covering the basics will greatly improve your ability to communicate effectively, which is a key element of a good engineer. Solid grammar and spelling skills will also keep us from quickly losing credibility with a customer who might not be capable of understanding what we do technically, but who can understand our inability to write at an eighth grade level. In short, avoid these ignorant mistakes. Links to Project Templates and Reference Documents All of the following documents are on the course website; these links are simply provided in this design report template for convenience to help you find the documents quickly. I’ve tried to group related documents together and list all the documents in chronological order for the course. MAIN PROJECT DOCUMENTS Design Project Description (explains the design project for this semester and the rules governing it) Design Project Schedule (presents the project schedule everyone should follow week-to-week) CONCEPTUAL DESIGN GENERATION (Design Report #1) Background Information Research (13 topics that should be pertinent to solving the design project) Design Report Example Reports (a collection of good and bad conceptual design drawing examples with clear feedback explaining what I’m looking for; pay attention to exactly what I ask for this semester in the Design Report Template (i.e. this document), but these examples should provide helpful feedback so you know what I’m looking for in your drawings) TIPS FOR WORKING EFFICIENTLY Tips on Working Effectively in Groups (very helpful document for making everyone participate equally) Project Meeting Template (template to use for group meetings so you can track individual responsibilities and track teammates who are not doing their part of the work) Individual Evaluations (peer evaluations filled out at the end of the project/semester) Project Tips (tips to help your group work more efficiently on the project once prototyping commences) SELECTION OF DESIGN CONCEPT & DETAILED DESIGN (Design Report #2) Decision Matrix Example (Crane Hook; Adobe pdf format with digital comments) Project Decision Matrix Example (Mobile Platform; Adobe pdf format) Project Decision Matrix Template (Mobile Platform; Excel format) Electric Motors and Drives (lecture notes explaining how to calculate estimated robot speeds using specific motors and wheel sizes) Robot Speed & Time Calculations (use and modify this spreadsheet to calculate the estimated speeds of your conceptual designs so you can decide how fast the final robot design should be to complete the task; remember faster robots are less controllable (and vise-versa), so it’s important to find a prudent balance that suits the current project description) Drive Wheel Motor Torque Calculations (use this example to compute the torque required for your drive motors to move your robot and then compare to the actual torque values published by the manufacturer in the Motor Specifications listed on the website.) Time Estimation Guide for Parts Manufacturing (since manufacturing time should be an objective in each of your evaluation matrices, this document provides time estimates for the parts you manufactured earlier in the semester, as well as typical motor mounts, sheetmetal parts and most any other operation you will need to perform in the lab during robot prototyping; you should provide similar estimates for your group’s different conceptual designs) Material Price List (prices for common materials found in the lab; since cost is likely to be an objective in your evaluation matrices, these prices allow you to easily create cost summaries for your group’s different conceptual designs) Concept Selection Checklist / Grade Sheet (used by your TA to evaluate your conceptual selection; this is a good checklist for your team to use as well) Mechanical Power Transmission (lecture notes explaining different ways to transmit torque which are applicable for the design of your group’s wheel hubs) Motor Mount Design Guide (tips for designing motor mounting brackets) Wheel Hub Design Guide (tips for designing wheel mounting hubs) Sheetmetal Design Guide (tips for designing sheetmetal parts) Sheetmetal Demonstration (if you’re thinking of making parts for your project out of sheetmetal, watch this informative video, which covers basic sheetmetal operations as well as important personal safety) Motor Specifications (dimensions, output torques, etc. for electric motors provided in class) Part CAD Models (SolidWorks CAD models of all the motors, control box, 80-20 accessories, etc.) SolidWorks Part Drawing Templates (links to templates with must be used for this course) Lab Material Sizes (table showing common material sizes stocked in the design lab) Lab Fastener Sizes (table showing common fastener sizes stock in the design lab) Dimensioning Rules (rules that will greatly improve your drawings) Design & Manufacturing Tips (LOTS of helpful tips that will improve your designs and your drawings, allow you to select better tolerances, and empower you to ask the instructor or TAs better questions) Design For Manufacturing Examples (great examples showing how to apply the tips presented above to design parts which are easier to manufacture, saving valuable time and allowing your group to have more time for testing and improving your design) Final Design Review Checklist / Grade Sheet (used by your TA to evaluate your Design Report #2 submission; this is a great checklist for your team to use when completing D.R. #2) Project Schedule Template (Excel template to use for presenting your team’s schedule) Project Budget Template (Excel template to use for presenting your project’s budget) HELPFUL DOCUMENTS ONCE PROTOTYPING COMMENCES Purchase Orders (once robot construction commences, these are used to purchase parts) Engineering Change Notice Form (used to track any changes made to your design after Design Report #3 is submitted for the second (and final) time) Wiring Schematic Template (once you wire your robot successfully the first time, use this wiring schematic to do it correctly every other time; this should also be submitted the day of the competition) -