a blind spot detection system based on ultrasonic sensing

advertisement

PSZ 19:16 (Pind. 1/07)

UNIVERSITI TEKNOLOGI MALAYSIA

DECLARATION OF THESIS / UNDERGRADUATE PROJECT REPORT AND COPYRIGHT

Author’s full name : MOHD RIDHUAN BIN SELAMAT

Date of Birth

Title

A BLIND

: 17 MARCH 1991

: A BLIND SPOTSYSTEM

DETECTION

SYSTEMON

BASED

ON ULTRASONIC

SPOT DETECTION

BASED

ULTRASONIC

SENSING

SENSING.

Academic Session : 2013/2014

I declare that this thesis is classified as:

CONFIDENTIAL

(Contains confidential information under the Official

Secret Act 1972)*

RESTRICTED

(Contains restricted information as specified by the

organization where research was done)*

MOHD RIDHUAN BIN SELAMAT

OPEN ACCESS

I agree that my thesis to be published as online open

access (full text)

I acknowledged that Universiti Teknologi Malaysia reserves the right as follows:

1. The thesis is the property of Universiti Teknologi Malaysia

2. The Library of Universiti Teknologi Malaysia has the right to make copies for the

purpose of research only.

3. The Library has the right to make copies of the thesis for academic exchange.

Certified by:

UNIVERSITI TEKNOLOGI MALAYSIA

NOTES:

SIGNATURE

SIGNATURE OF SUPERVISOR

910317-01-5271

DR. HERMAN BIN WAHID

(NEW IC NO/PASSPORT)

NAME OF SUPERVISOR

Date: 19 JUNE 2014

Date: 19 JUNE 2014

*

If the thesis is CONFIDENTAL or RESTRICTED, please attach with the letter from the

organization with period and reasons for confidentiality or restriction.

“I hereby declare that I have read this thesis and in my opinion this thesis is

sufficient in terms of scope and quality for the award of the degree of Bachelor

of Engineering (Electrical – Instrumentation and Control)”

Signature

: ……………………………..

Supervisor

: Dr. Herman Bin Wahid

Date

: 16th June 2014.

A BLIND SPOT DETECTION SYSTEM BASED ON ULTRASONIC SENSING

MOHD RIDHUAN BIN SELAMAT

A thesis submitted in fulfilment of the

requirements for the award of degree Bachelor of

Engineering (Electrical – Instrumentation and Control)

Faculty of Electrical Engineering

Universiti Teknologi Malaysia

JUNE 2014

iii

I declare that this thesis entitled “A Blind Spot Detection System based on Ultrasonic

Sensing” is the result of my own research except as cited in the references. The thesis

has not been accepted for any degree and is not concurrently submitted in

candidature of any other degree.

Signature

:

………………………………

Name

:

Mohd Ridhuan Bin Selamat

Date

:

16 June 2014

iv

Dedicated, in thankful appreciation for support, encouragement and

understanding to my beloved mother, father, sister, brothers and friends

v

ACKNOWLEDGEMENT

Alhamdulillah, Prise to Allah for His guidance and blessings that this project

has finally completed.

Firstly, I would like to express my greatest gratitude to my respected

supervisor Dr Herman Bin Wahid for his humble guidance, encouragement, patient

enthusiasm, invaluable support and motivation through the whole completion of this

project. This project would not be succeeded without her continuous support.

Secondly, I would like to drop my sincere appreciation to thank to my family

who have been tolerant, motivated me and support me all these year in

accomplishing this project. Thanks for their encouragement, love and emotional

supports that they had given to me.

Last but not least, I would like to express my heartiest appreciation to my

friends and SEI member’s batch 2010 and those whom involve directly or indirectly

with this project. There is no such meaningful word than. Thank You So Much.

vi

ABSTRACT

Driving a vehicle in modern traffic conditions is highly risky. In fact, if the

driver is not aware of the presence of a vehicle or obstacle in his blind spot, a crash

can easily occur. The goal of this work is to suggest a solution to improve a driver’s

safety when changing lanes on the highway, which focuses on the low-end vehicle.

The Blind Spot Detection (BSD) system based on wireless detecting technique is

proposed to monitor the blind spot region for the presence of obstacles, automobiles

or other objects, in vehicle application. Two parts of BSD system are mounted nearly

on the left side area at the flat surface body of car. Meanwhile, another two parts are

mounted on the right side at the flat surface body of the vehicle. The detection of cars

in the blind spot region is displayed by warning light indicators. The BSD system

algorithm proposed here is based on a distance calculation between the object. The

ultrasonic sensor is programmed at certain parameter or distance to detect upcoming

vehicle, object or obstacle to activate the warning light indicator circuitry. Upon the

detection, the device triggers the activation of light indicator circuitry for a certain

period of time, at the different alert zones. If the blind spot region of the vehicle can

be minimized, it is expected the accident cases could be reduced significantly.

vii

ABSTRAK

Memandu kenderaan di dalam keadaan trafik moden adalah sangat berisiko.

Malah, kemalangan boleh berlaku jika pemandu tidak sedar akan kehadiran

kenderaan atau halangan di tempat titk buta kenderaan. Matlamat kerja ini ialah

untuk mencadangkan jalan penyelesaian untuk meningkatkan keselamatan pemandu

kenderaan berteknologi rendah apabila menukar lorong di lebuh raya. Sistem

Pengesanan titik buta atau BSD system ini berdasarkan teknik pengesanan tanpa

wayar yang dicadangkan untuk memantau kawasan titik buta kenderaan seperti

kehadiran halangan , kereta atau objek lain. Dua bahagian BSD system dipasang di

cermin hampir sisi pada permukaan rata kenderaan. Sementara itu, dua bahagian lain

dipasang di belakang pada permukaan rata kenderaan. Pengesanan kereta di kawasan

titik buta kenderaan

dipaparkan dengan memberi amaran penunjuk cahaya.

Algoritma sistem BSD dicadangkan di sini adalah berdasarkan pengiraan jarak antara

objek. Penderian

ultrasonik diprogramkan pada jarak tertentu untuk mengesan

kenderaan, objek atau halangan yang akan datang bagi mengaktifkan litar penunjuk

lampu amaran, pada zon-zon yang berbeza. Sekiranya kawasan titik buta kenderaan

dapat dikurangkan, ia dijangka kes kemalangan boleh dikurangkan dengan ketara .

viii

TABLE OF CONTENTS

CHAPTER

1

2

TITLE

PAGE

DECLARATION OF THESIS

ii

DEDICATION

iv

ACKNOWLEDGEMENT

v

ABSTRACT

vi

ABSTRAK

vii

TABLE OF CONTENT

viii

LIST OF TABLES

xi

LIST OF FIGURES

xii

LIST OF ABBREVIATIONS

xv

LIST OF APPENDICES

xvi

INTRODUCTION

1.1

General Introduction

1

1.2

Problem Statement

2

1.3

Project Objectives

4

1.4

Project Scopes

4

1.4

Thesis Outline

5

LITERATURE REVIEW

2.1

Introduction

6

2.2

Blind spot detection system

6

2.3

The invention ideas of BSD system

9

2.3.1

9

A Wireless Sensor-Based Driving

ix

Assistant for Automobiles based on

ultrasonic sensing [8].

2.3.2

Ultrasonic sensor based blind spot

13

accident prevention system [10].

2.4

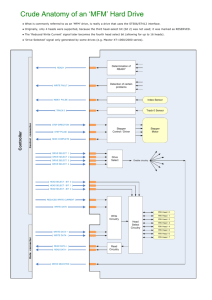

The concept of ultrasonic sensor

14

2.5

Advantages of ultrasonic sensing compare to

15

another system sensing in BSD system

3

METHODOLOGY

3.1

Project workflow

18

3.2

BSD system development

19

3.3

Hardware Development

19

3.3.1

20

Block diagram and Flowchart of BSD

system

3.3.2

Circuit design of BSD system

21

3.3.3

Main components in circuitry

23

3.3.4

Main components in the circuitry of

27

warning light indicator

3.3.5

Structure design and installation of BSD

31

system

3.4

Software implementation

33

3.4.1

34

Arduino UNO and Arduino Promini

Programming

3.5

System integration: interfacing hardware and

34

software BSD system

4

RESULTS AND DISCUSSION

4.1

Introduction

35

4.2

BSD position experiment

36

4.3

Activation of BSD system one the left side sensor

37

of small car.

4.4

Activation of BSD system on the right side sensor

of small car

39

x

4.5

5

6

Discussion

42

CONCLUSION AND RECOMMENDATION

5.1

Conclusion

43

5.2

Recommendation for Future Work

44

PROJECT MANAGEMENT

6.1

Introduction

46

6.2

Project Schedule

46

6.3

Cost Estimation

47

REFERENCES

51

APPENDIX A

53

APPENDIX B

55

xi

LIST OF TABLES

TABLE NO.

TITLE

PAGE

NO.

3.1

The specifications of HC-SRO4 ultrasonic sensor.

24

3.2

The Arduino Uno Specifications.

29

6.1

The Project Gantt chart for semester one

46

6.2

The Project Gantt chart for semester two.

47

6.3

The cost estimation for assembling the circuitry of

48

wireless ultrasonic sensor

6.4

The cost estimation for assembling the circuitry of

49

warning light indicator

6.5

The total cost estimation for BSD system.

50

xii

LIST OF FIGURES

FIGURE

TITLE

PAGE NO.

NO.

1.1

The blind spot definition

2

1.2

The ford car with Blind Spot Information System

3

(BLIS)

2.1

The model of BMW (5series) having BLIS system

8

2.2

The volvo model having BLIS system

8

2.3

The layout of the driving assistant

10

2.4

The responses of indicators in various scenarios

11

2.5

The placement of sensor.

12

2.6

The LED meter of this driving assistant

13

2.7

The basic concepts of „ping‟ and „pong‟

14

3.1

The flowchart of the project workflow.

18

3.2

The system setup block diagram of BSD system of

20

circuitry for warning light indicator

3.3

The system setup block diagram of BSD system of

circuitry for wireless ultrasonic sensor.

20

xiii

3.4

The flow chart of BSD system

21

3.5

The schematic diagram of the circuitry of warning

22

light indicator.

3.6

The Arduino Promini

23

3.7

The HC-SRO4 ultrasonic sensor

24

3.8

The block diagram of NRF24L01 transceiver.

25

3.9

The NRF24L01 transceiver module (Transmitter).

25

3.10

The battery supply 9v

26

3.11

The hardware development of BSD system of the

27

circuitry of wireless ultrasonic sensor

3.12

The Arduino UNO

28

3.13

The NRF24L01 transceiver module (Receiver).

29

3.14

The LED

30

3.15

The buzzer

30

3.16

The hardware development of BSD system of the

30

circuitry of warning light indicator

3.17

The drawing of installation BSD system on the car.

31

3.18

The prototype model of installation BSD system on

32

small car.

3.19

The prototype model of installation BSD system on

32

small car.

4.1

The installation of BSD system on prototype car.

36

4.2

The GREEN LED on the left side of the warning light

37

xiv

indicator was activated .

4.3

The rear left side sensor of BSD system was activated

38

4.4

The front left side sensor of BSD system was

38

activated.

4.5

The GREEN LED on the right side of the warning

39

light indicator was activated.

4.6

The rear right side sensor of BSD system was

40

activated.

4.7

The front right side sensor of BSD system was

40

activated.

4.8

The completed result of BSD system experiment.

41

5.1

XL-MaxSonar-EZL1Sensor.

44

xv

LIST OF ABBREVIATIONS

LED

Light Emitter Diode

BLIS

Blind information system

BSD

Blind spot detection

BSR

Blind spot region

CPU

central processing unit

PCB

printed circuit board

PWM

Pulse Width Modulation

AVR

Advanced Virtual RISC

USB

Universal Serial Bus

AC

Alternating Current

DC

Direct Current

I/O

Input/Output

CSN

Chip Select Not

xvi

LIST OF APPENDICES

APPENDIX

TITLE

PAGE

A

DATASHEET OF COMPONENTS

53

B

BSD SYSTEM CODING

55

CHAPTER 1

INTRODUCTION

1.1

General introduction

Driving a vehicle in modern traffic conditions is highly risky. The high risk

could occur if the driver watching the oncoming road hazards and at the same time

look backward in highways driving. It is essential to look both sideway and

backward before safely change the lanes. A problem that often concerned by the

driver is the areas cannot be seen by side view and rear view mirrors, which is called

as blind spot region of vehicle. In several accident cases it is happened because of a

driver’s inability to monitor the blind spots region well.

In Figure 1.1, the area almost commonly called to blind spot is the rear

quarter blind spots, area towards the back of the vehicle on both sides. Vehicles in

the adjacent lanes of the road may fall into these blind spots, and a driver may be

unable to see adjacent vehicle using only the car's mirrors. Other areas that are

sometimes called blind spots are those that are too low to see behind and in front of a

vehicle. Also, in cases where side vision is hindered, areas to the left or right can

become blind spots as well [1].

2

Figure 1.1: Blind spot definition

1.2

Problem Statement

Nowadays, technology in vehicles has been rapidly increasing to reduce the

risk of accident while driving vehicle. There are many research proposed based on

the driving assistance system focusing on the blind spot region [16]-[20]. The

modern technology based on sensors like camera, laser, ultrasonic and radar are most

likely applies in high-end and high-tech vehicle to monitor blind spot region. Volvo

vehicle was first introduced BLIS system that produced alert system if there any

vehicle enter blind spot region. Volvo vehicle implement two door mounted lenses to

check the blind spot area and functionally for driver to change lanes. After a decade,

Volvo vehicle improve their BLIS system by using radar-based detector to monitor

in blind spot region. Which the LED light on A-pillar will glow to detect the

presence entity vehicle [2][3].

3

Ford vehicle also implement the same BLIS system that Volvo developed. As

shown in Figure 1.2, Ford vehicle places radar-based detectors near the rear of the

car, but the light that flashes to warn driver of hidden vehicle is on the outside rear

view mirror. Audi vehicle also introduced Audi Side Assist that will detect cars

coming up from as far as 150 feet (45.7 meters) behind in adjoining lanes and flash a

light in external rear view mirror [3].

Figure 1.2: The ford car with Blind Spot Information System (BLIS)

All of the high-end and high-tech cars are most likely to have embedded

system of blind-spot detection and these active blind spot detection systems are not

available for low-end vehicle. This blind spot detection system in high-end vehicle is

also remade act as driving assistance system for driver and implement into low-end

vehicles. However, the high product price and installation cost and the capability of

the product functional are the some of the factor which do not attract the low end

users to use BLIS system. The driving assistance of blind spot detection or

monitoring system for vehicles is highly desirable to low-end vehicles to monitor

4

blind spot region. So the research of blind spot detection system with high ratio of

capability and more affordable price for low-end vehicle is an important task to

reduce collision among vehicle.

1.3

Project Objectives

The objectives of this project are:

1.

To design a portable and wirelessly controlled BSD system for low-end

vehicle

2.

To design suitable algorithm to calculate distance for detecting object when

vehicle enter the blind spot region.

3.

To design a hardware system for producing visible alert when a vehicle enter

the blind spot region.

1.4

Project Scopes

They a several scopes of work have been determined are as follows:

•

BSD system that focusing quarter blind spot region vehicle.

•

BSD system is suitable apply for car, van and small lorry.

The proposed system will use ultrasonic technology, hence some

limitations are expected such as:

5

•

The detection angle is only 15deg, thus the sensor need to be located

properly to cover the region of interest (BSR). Therefore a special tool

needs to be designed to fix the position of the sensors at certain angle.

•

The sensitivity of the sensors needs to be analyzed, as it may cause

some delay in the detection process. Hence, an algorithm will be used

to

compensate this delay.

1.5

Thesis Outline

This project involves six chapters. Chapter 1 consists of the introduction of

the project that explains the project in general. The problem statement will be

discussed based on some issues and problems that related to this project.

The

objectives of the project will be discussed and scope of the project is explained.

Chapter 2 contains literature review that related with this project. The explanation is

based on gathered information from the journal, thesis, internet, reference books and

relevant article. Chapter 3 contains research methodology that explains in detail the

overall project flow of BSD system. Chapter 4 contains hardware and software

implementation and in Chapter 5 the results and analysis are discussed. Finally,

Chapter 6 contains the conclusion and recommendation of the project.

CHAPTER 2

LITERATURE REVIEW

2.1

Introduction

Literature review was carried out throughout the whole project to gain

knowledge and improve skills needed to complete this project. The main sources for

this project are previous related projects, research thesis, books, journals and articles

which are mostly obtained from online databases provided by UTM and UTM

library. This chapter focuses on the basic concepts and all fundamental theories

which related to this project.

2.2

Blind spot detection system

Blind spot detection system is device that really essential to monitor blind

spot region while driving vehicle in modern traffic condition. Collision among

vehicle can often occur if the driver did not properly well check the blind spot region

during changing the lane. The surrounding area of the driver and the condition

7

current of situation for potential hazard need to be considered as driver want to

change the lanes. Situation awareness (SA) in the perception and recognition phases

is important when a person has time on hand such as when changing lanes. SA can

be classified into three levels [4][5]:

Level 1: Perception of elements in the environment

Level 2: Comprehension of current situation

Level 3: Projection of future status

Hence, approximately 75% of the accident during lane changes is due to

driver Situation Awareness failure [4][6]. Blind spot monitoring system is essential

to improve visibility and reduce the blind zone in order to implement safety driving.

Nowadays, blind spot monitoring system is implemented in several vehicles.

Normally, high-end and high-tech vehicle using embedded system of blind spot

monitoring. Meanwhile, low-end vehicle need driving assistance of blind spot

monitoring system. Either embedded system or driving assistance the aim is only one

to improve safety while driving a vehicle. For example, BMW (5series) model have

the active blind spot detection to alert driver if there any upcoming potential hazard

in blind spot zone.

From Figure 2.1, active blind spot detection system of BMW (5series) model

help to eliminate blind spots and actually allows drivers to avoid collisions when

changing lanes, literally keeping your gaze straight ahead. Using radar sensing to

detect entity vehicle and placed at the rear of the vehicle. This system alerts drivers if

a vehicle is in their blind spot region vehicle. The light display on their side-view

mirror housings begins to flash and also steering wheel vibrate [7].

8

Figure 2.1: Model of BMW (5series) having BLIS system

From Figure 2.2, another example of implementation of blind spot

monitoring system. The Volvo vehicle use based on radar sensing that informs the

driver about vehicles in the blind spots on both sides of the car. It is also detect and

alerts the driver to rapidly approaching vehicles up to 70 meter behind the car [2].

Figure 2.2: The Volvo model having BLIS system

9

2.3

The invention ideas of BSD system

The main purpose of invention ideas of BSD system is to understand method

used in previous research of blind spot monitoring system before applying to this

project. There are several ideas of invention that related to blind spot information

system:

2.3.1

A Wireless Sensor-Based Driving Assistant for Automobiles based on

ultrasonic sensing [8].

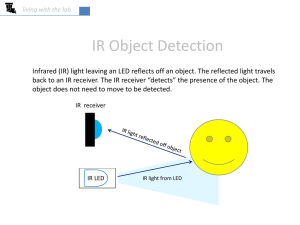

In this research paper, the system acts as a driving assistant for vehicles that

detects the obstacle or object within the monitored area and alert the driver via

tactile, audio and visual signal. This driving assistant is based on ultrasonic sensing

approach.

The system contains five separate components: four of them are the sensor

modules and the fifth one is the controller. The nodes are connected in the sequel that

attached to body of the car. Meanwhile, controller responsible for coordinating the

operation of the nodes and then process the data for presenting alerts to the driver.

The two front corners on both sides of the vehicle are covered by sensor modules.

While the blind spot areas are the most likely ones to be neglected by drivers, the two

front corners are found to produce the highest accident rates [8][9]. As shown in

Figure 2.3, it shows the correlation among the system components. All five modules

are makes around the same processing unit consisting of a microcontroller and radio

transceiver. The sensor modules consist of ultrasonic sensors in the same time the

controller connected to three types of indicators such as LEDs panel, buzzer, and the

vibrators mounted on the steering wheel [10].

10

Figure 2.3: Layout of the driving assistant

(adapted from: http://www.suurland.com/blueprints_archive.php)

Related to this research, there are four crucial parts need to be considered.

There are sensor, indicator, wireless communication and modules. The driving

assistant detect the object or obstacle via ultrasonic proximity sensor (PING))) TM

Ultrasonic Sensor, Parallax Inc). Another alternative for detection the object is via

infrared sensor but infrared sensors lack the accuracy of their ultrasonic counterparts

due to the ambient noise and infrared radiation [8].

According to Table 2.4, the indicator will be functional and alerts the driver if

object enter the blind spot region zone. Vehicle is classified safe and the all the

indicators deactivated if there are no obstacles or object are present in zone 1 and

11

zone 2. Meanwhile, LED indicators are turned on to provided alert to driver if the

objects enter in zone 1 and will be considered as “mildly threatened”. Hence, when

object enter zone 2, the vehicle is classified “threatened”. LED indicators, either the

vibrators or the buzzer are turned on [8].

Table 2.4: The responses of indicators in various conditions [10].

Sensor Number

0

1

2

3

Zone

Activated Indicator

0

None

1

LED 0

2

LED ),Left Vibrator

0

None

1

LED 1

2

LED1, Right Vibrator

0

None

1

LED 2

2

LED 2, Buzzer

0

None

1

LED 3

2

LED 3, Buzzer

The wireless communication is connected between the sensor and the

ultrasonic sensor. Advantage of using wireless connection is the easy installation. It

also did not need more space for wiring the blind spot detection system.

12

2.3.2

Ultrasonic sensor based blind spot accident prevention system [10].

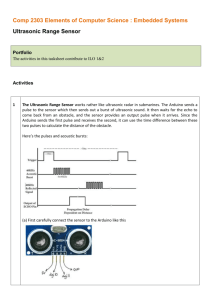

In this research paper, the system based on proximity detection device is

using radio frequency waves for detecting object. It includes three parts:

I.

Front sensor, left sensor and right sensor.

The front sensor is functional to detect seasonal black spots. This sensor will

monitor presence of any entity and warn the driver about the upcoming risk in cases

of temporary blind spot. In Figure 2.5, it shows the placement of sensor attach on

body of the car. The left and right sensor will cover the blind spot at rear of car.

Figure 2.5: The placement of sensor.

13

II

LED meter

As shown in Figure 2.6, the LED meter functional based on the sensor to alert

the driver about entity object or possible risk. The LED meter was divided into three

part activation. If the left sensor detect the object the left hand side LED meter will

be activated. While, if right sensor detect the object the right hand side LED meter

will be triggered. Hence, the front hand side LED meter indicate risk of front sensor.

Figure 2.6: The LED meter of this driving assistant

2.4

The concept of ultrasonic sensor

Ultrasonic signals are like audible sound waves, except the frequencies are

much higher. The ultrasonic transducers have piezoelectric crystals which resonate to

a preferred frequency and convert electric energy into acoustic energy and vice versa

[11][12].

14

The illustration in Figure 2.7 shows how sound waves, transmitted in the

shape of a cone, are reflected from a target back to the transducer. An output signal is

produced to perform some kind of indicating or control function. A minimum

distance from the sensor is required to provide a time delay so that the "echoes" can

be interpreted. Variables which can affect the operation of ultrasonic sensing include:

target surface angle, reflective surface roughness or changes in temperature or

humidity. The target can have any kind of reflective form - even round objects.

Figure 2.7: Basic concepts of „ping‟ and „pong‟

15

2.5

Advantages of ultrasonic sensing compare to another system sensing in

BSD system.

Several system sensing can be applied for monitoring blind spot region. For

example, there are three types of sensor systems onboard vehicle for lateral object

detection [13]:

I.

Ultrasonic sensor system

II.

Doppler radar system

III.

Vision system

The ultrasonic technique has unique advantages over conventional sensors

such as infrared or reverse sensor when used for sensing functions (Larson, 1960)

[12]:

Discrete distances to moving objects can be detected and measured.

Less affected by target materials and surfaces, and not affected by

color. Solid state units have virtually unlimited, maintenance free life.

Have ability to detect small objects over long operating distances.

Have resistance to external disturbances such as vibration, infrared

radiation, ambient noise, and EMI radiation

As reported by [13] ultrasonic sensor system offers the following advantages:

It is less expensive and will be suitable for general vehicle

applications.

It can easily obtain distance information immediate objects without

complex computation detection.

It has wide surface measurement, not just single point

16

For the Doppler radar systems, the system involved high manufacturing cost

and limited for high-end cars only [8]. Radar system is normally has blind spots and

a smaller view. The range of blind spots depends on the number of the installed

radars. Besides, due to the limited detection distance for radar system, it is difficult

for radars to detect an object moving in a large area [14].

Furthermore, radar sensor is complicated to use, because of the need of CPUintensive image processing techniques. In addition, the high of project cost need a

more complex processing platform, which would also increase the cost of their

encasing sensor modules [8].

In the vision system, there are several problems need to be considered. The

cost involved much computation time to extract useful information. Real-time

performance is a challenge issue for vision-based systems. At night, it would be

difficult to use because of lighting condition will also influence the image acquisition

[15].

`

Based on these three systems sensor, the ultrasonic sensor is better rather than

using Doppler radar system or vision system to apply in BSD system. It is because of

the cost to build this system sensing is much less expensive and it can easily obtain

the distance of the object without complex computation of detection process.

CHAPTER 3

METHODOLOGY

This chapter explains the methodology applied in this project to ensure the

successfulness of the project objectives. Starting from the overall workflow of the

project and followed by Hardware and Software development of BSD system. The

hardware and software system integration and testing will be described at the end of

this chapter

18

3.1

Project workflow

The overall workflow of the project is illustrated in Figure 3.1. Each stage of

the workflow is described below.

Figure 3.1: Flowchart of the project workflow.

19

3.2

BSD system development

BSD system is developed based on imitation and some improvements of

previous works done. Hardware and software development are two crucial parts

needs to be considered in this BSD system. The hardware development is more on

the components used, the designation of circuit and the real shape of BSD system.

Meanwhile, the software development is based on how to program the brain (i.e.

central processor) of the circuitry of wireless ultrasonic sensor and the circuitry of

warning light indicator

3.3

Hardware development

The project continues with the hardware development of BSD system. There

are two major parts in this hardware development of BSD system which are the

circuitry of wireless ultrasonic sensor and the circuitry of warning light indicator.

20

3.3.1

Block diagram and flowchart of BSD system

Figure 3.2: System setup block diagram of BSD system of circuitry of warning light

indicator.

Figure 3.3: System setup block diagram of BSD system for wireless ultrasonic

sensor circuit.

21

Figure 3.4: Flow chart of BSD detection system

3.3.2

Circuit design of BSD system

Designing the circuit is the crucial part for this project. This is important due

to the functional performance of the sensor depends on the quality of the designed.

The Frizing and Eagle software have been used to design the circuit of circuitry for

wireless ultrasonic sensor and circuitry for warning light indicator. As shown in

Figure 3.5, it is the schematic diagram of the circuitry of warning light indicator,

designed using Eagle software. After the design had been completed, the circuit is

then tested on proto-board. Proto-board is used to implement the components that

had been designed in circuit design step before implementing it on the PCB or donut

22

board for soldering the components. This is important to know whether the sensor

will be functioning as well as follow to the desired output of BSD system or not.

In this project, I had implemented the circuitry of wireless ultrasonic sensor

and the circuitry of warning light indicator first on the proto-board to test the

functionality of both circuits. The circuitry of wireless ultrasonic sensor will detect

the object or obstacles. After that, warning light indicator will respond the signal

from the circuitry of wireless ultrasonic sensor and activated the LED or buzzer

inside the warning light indicator. The programming will be discussed more on the

software implementation and in APPENDIX B.

Figure 3.5: The schematic diagram for the circuitry of warning light indicator.

23

3.3.3

Main components in the circuitry of wireless ultrasonic sensor

Figure 3.6 shows the hardware development of BSD system for the circuitry

of wireless ultrasonic sensor. It contains of four main components which are:

1. Arduino Promini

2. Ultrasonic sensor

3. NRF24L01 Transceiver module

4. Power supply 9v

In this project, Arduino Promini was chosen to act as a brain for the circuitry

of wireless ultrasonic sensor. It is because of its compact size dimension and also

more economic as compared to another microcontroller. Besides, the functionality of

input and output pins are the same with Arduino UNO. The Arduino Promini is

shown in Figure 3.6.

Figure 3.6: The Arduino Promini

Figure 3.7 shows the HC-SR04 ultrasonic sensor which is the main sensor

used in this project. The HC-SR04 ultrasonic sensor uses sonar to determine distance

to an object like bats or dolphins do. It offers excellent non-contact range detection

24

with high accuracy and stable readings. The sensor operation is also not effected by

sunlight. The detail of this sensor had been attached in the APPENDIX A.

Figure 3.7: HC-SRO4 ultrasonic sensor

The specifications of this HC-SR04 ultrasonic sensor are shown in Table 3.1.

It is described the principle of this sensor, the working current needed to operate this

sensor, the validation angle detected and the ranging distance to detect object.

Table 3.1: The specifications of HC-SRO4 ultrasonic sensor.

Power Supply

5 V DC

Quiescent Current

<2mA

Working Currnt

<15°

Effectual Angle:

15deg

Ranging Distance

2cm – 400 cm/1" - 13ft

Resolution

0.3 cm

Measuring Angle:

30 degree

Trigger Input Pulse width

10uS

Dimension:

45mm x 20mm x 15mm

25

The third element is NRF24L01 transceiver transmitter module. This element

functions by transferring the signal from the circuitry of wireless ultrasonic sensor to

the circuitry of warning light indicator. This element is important in this project due

to the BSD system circuit connection is based on wireless connection. Figure 3.8 and

Figure 3.9 illustrate NRF24L01 transceiver module and the block diagram of

NRF24L01 transceiver respectively. The details of this component had been attached

at the APPENDIX A.

Figure 3.8: The block diagram of NRF24L01 transceiver.

Figure 3.9: The NRF24L01 transceiver module (Transmitter).

26

Figure 3.10 shows the battery supply 9v that had been chosen for supply the

current and voltage in order to operate components in the circuitry of wireless

ultrasonic sensor.

Figure 3.10: The battery supply 9v

Figure 3.11 shows the complete hardware development of BSD system for

circuitry of wireless ultrasonic sensor. It consists of four circuitry of wireless

ultrasonic sensor and needs to be installed at certain of area vehicle’s body.

27

Figure 3.11: The hardware development of BSD system for the circuitry of

wireless ultrasonic sensor.

3.3.4

Main components in the circuitry of warning light indicator

The hardware development of BSD system for the circuitry of warning light

indicator contains of four main components which are:

a. Arduino UNO

b. NRF module for receiver

c. LED

d. Buzzer

Microcontroller acts as the main brain of this project. Without it, the system

cannot function as we expected. Arduino Uno was chosen for this project to act as a

brain of circuitry for warning light indicator as it is a single-board microcontroller for

28

multipurpose project discipline. As shown in Figure 3.12, Arduino UNO board

consists of an ATmega328 which is 28-bit AVR microcontroller with

complementary components to facilitate programming and incorporated into other

circuit.

It has 14 digital input and output pins of which 6 can be used as PWM

outputs, and 6 analogue inputs. For this project, I used digital and analogue pin as an

output which are three digital pins to make LED red activated, three analogue pins to

make LED orange activated, two digital pins to make LED green activated and five

digital pins to activate NRF24l01 module receiver.

Figure 3.12: The Arduino UNO.

The Arduino UNO can be powered by the universal serial bus (USB)

connection or with an external power supply such as battery, power band and AC-toDC adapter. In this project, I chose to use USB because as it is easily to make my

system portable and easily to power up it in the vehicle and during system test. Table

3.2 shows the Arduino UNO basic specifications

29

Table 3.2: Arduino Uno Specifications.

Microcontroller

Atmel ATmega328

Operating Voltage (logic level)

5V

Input Voltage (recommended)

7-12 V

Input Voltage (limits)

6-20 V

Digital I/O Pins

14 (of which 6 provide PWM

output)

Analog Input Pins

6

DC Current per I/O Pin

40 mA

Flash Memory

33 KB

SRAM

2 KB

EEPROM

1 KB

Clock Speed

16 MHz

Figure 3.13 shows the element called as NRF24L01 transceiver receiver

module. It is functioned by receiving the signal from the circuitry of wireless

ultrasonic sensor. This element is important in this project to make the LED and

buzzer in the circuitry of warning light indicator activated.

Figure 3.13: The NRF24L01 transceiver module (Receiver).

30

Figure 3.14 and Figure 3.15 are shows the output of the circuitry of warning

light indicator. It will be functioned depending on the instruction which is

programmed in the circuitry of warning light indicator. The programming instruction

had been described more detail in APPENDIX B.

Figure 3.14: LEDs

Figure 3.15: Buzzer

Figure 3.16 shows the completed hardware development of BSD system for the

circuitry of warning light indicator.

Figure 3.16: Hardware development of BSD system for circuitry of warning

light indicator

31

3.3.5

Structure design and installation of BSD system

This part will mention about the installation of BSD system on the car. The

Figure 3.17 shows the drawing of installation of BSD system on the car. Two parts of

the circuitry of wireless ultrasonic sensor are mounted on the left side at the flat

surface of the car. Meanwhile, another two parts are mounted on the right side at the

flat surface of the car. The detection of cars in the blind spot region is displayed by

warning light indicators that had been put on the dashboard of car.

Figure 3.17: The drawing of installation BSD system on the car.

32

Figure 3.18: BSD system.

As illustrates in Figure 3.19, it is the prototype model of installation BSD system on

a miniature (small) car.

Figure 3.19: Prototype model of installation BSD system on miniature (small) car.

33

3.4

Software implementation

The next step is software implementation which is designing the suitable

algorithm to calculate distance for detecting object when vehicle enter blind spot

region. To program the code of this BSD system, it must uses the Arduino software

version 1.5.4. It is the latest version that released by the Arduino company. The code

which is used in Aduino programming is based on C++ programming in Java.

3.4.1

Arduino UNO and Arduino Promini Programming

Arduino is an open-source physical computing platform based on a simple

input/output (I/O) board and development environment that implements the

processing/wiring language.

Both of Arduino UNO and Arduino Promini

programming are the same. This is one of the advantages when using the Arduino as

microcontroller.

To program and upload the code into the Arduino UNO and Arduino Promini

microcontroller, it must be connected to the computer with a USB A/B cable. USB

cable acts as a program connector between Arduino and computer. In Arduino

Promini

microcontroller used in the circuitry of wireless ultrasonic sensor, the

digital pin D6 and D7 have been set as the input of Ultrasonic sensor. Then, the

digital pin D9 to D13 for activate NRF24L01 transmitter. The set of program code

for the circuitry of wireless ultrasonic sensor was repeated for the preparation of

another three sets. For the Arduino UNO microcontroller used in the circuitry of

warning light indicator, the digital pin D8 to D13 had been set to activate NRF24L01

receiver and the digital pin D3to D7 and analogue pin A0 to A3 as the output to

activate LED and BUZZER. Based on the programmed codes, the digital pin D6 and

D7 will be activated to detect the object from detection range. The NRF24L01

34

transmitter will transmit the signal or data from the distance read by the ultrasonic

sensor. The NRF24L01 receiver will react to receive the signal or data from the

NRF24L01 transmitter. The LED and BUZZER will be activated to show the

warning alert. The overall programming codes are attached in APPENDIX B.

3.5

System integration: interfacing hardware and software BSD system

Next, the project continues by interfacing hardware and software BSD

system. The testing of hardware and software BSD system is carried on until the

desired BSD system is obtained.

CHAPTER 4

RESULTS AND DISCUSSION

4.1

Introduction

This chapter discuss regarding the experiments carried out to monitor blind

spot region. The experiments carried out is BSD system positioning. In this BSD

system positioning experiment, there are three zone needs to be considered which are

the objects behind, left and right of the sensor, the objects next to the rear left and

right of the sensor, and the object next to the front left and right of the sensor. The

rear left and right of the sensor were activated by triggering ON the GREEN LED in

the warning light indicator to indicate NO objects entered the blind spot area. Then,

the rear left and right of the sensor were activated by triggering the blinked GREEN

LED in the warning light indicator to indicate objects entered the first zone of blind

spot area. This situation is called as first alert zone. The front left and right of the

sensor will be activated by triggering ON the RED LED and ORANGE LED in the

warning light indicator to show objects entered the second zone of blind spot area.

36

4.2

BSD position experiment

Figure 4.1 demonstrates the installation of BSD system on the prototype car.

Two circuitry of wireless ultrasonic sensor were installed on the rear and front left

side of small car. Meanwhile, another circuitry of wireless ultrasonic sensor was

installed on rear and front the right side of small car. The circuitry of warning light

indicator was put at the dashboard of small car.

Figure 4.1: The installation of BSD system on prototype car.

37

4.3

Activation of BSD system on the left side sensor of small car.

As shown in Figure 4.2, the GREEN LED on left side of warning light

indicator was activated to show there is NO object entered at the rear left blind spot

region. This situation is called safe zone on the left side area.

Figure 4.2: The GREEN LED on the left side of the warning light indicator was

activated.

The Figure 4.3 shows the rear left side sensor of BSD system was activated.

It is activated when the object enter the rear blind spot region of small car. The

GREEN LEDs in the warning light indicator was blinked for a second to show the

first upcoming potential hazard on the left blind spot area. At the same time,

BUZZER was triggered on follow the blink of GREEN LED. This situation is called

first alert zone on the left blind spot area.

38

Figure 4.3: The rear left side sensor of BSD system was activated.

When the object keep moving as shown in the Figure 4.4, the front left side

sensor of BSD system was activated due to the object enter the front blind spot

region of small car. Three of RED LEDs in the warning light indicator was triggered

ON and triggered OFF until the object moving out of left blind spot area.

Figure 4.4: The front left side sensor of BSD system was activated.

39

4.4

Activation of BSD system on the right side sensor of small car.

As illustrated in Figure 4.5, the GREEN LED on right side of warning light

indicator was activated to show there is NO object entered in the right blind spot

region. This situation is called safe zone on the right side area.

Figure 4.5: The GREEN LED on the right side of the warning light indicator was

activated.

Figure 4.6 shows the rear right side sensor of BSD system was activated. It is

activated when the object enter the rear blind spot region of small car. The GREEN

LED in the warning light indicator was blinked for a second to show the first

upcoming potential hazard on the right blind spot area. At the same time, BUZZER

was triggered on follow the blink of GREEN LED. This situation is called first alert

zone on the right blind spot area.

40

Figure 4.6: The rear right side sensor of BSD system was activated.

Figure 4.7, the front right side sensor of BSD system was activated because

of the object entered the front right blind spot region of small car. Three of

ORANGE LEDs in the warning light indicator was triggered ON and triggered OFF

until the object moving out of right blind spot area.

Figure 4.7: The front right side sensor of BSD system was activated.

41

Figure 4.8: The complete results of BSD system experiment.

42

4.5

Discussion

This section will discuss on the problems encountered during the process of

completing this project. There are a lot of errors during development of hardware and

programming of BSD system. The first problem, it is hard to interface between the

circuitry of wireless ultrasonic sensor and the circuitry of warning light indicator.

The ultrasonic sensor detected object but the warning light indicator did not receive

the signal from the ultrasonic sensor. To overcome this problem, I had troubleshot

the circuit connection of BSD system using multi meter. The problem was

determined due to the misconnection between trigger pin of ultrasonic sensor and

CSN pin of the NRF240L01. The problem was solved and the BSD system functions

as expected which follows the desired output of BSD system.

Another problem is the performance of BSD system installed at the small car

is not stable. Sometimes, the BSD system was activated while at certain time, the

BSD sensor was not activated properly. This problem occurred due to the no enough

current supplied to operate Arduino Promini in the circuitry of wireless ultrasonic

sensor. To overcome this problem, I had changed the battery supply that consists of

high current to operate the Arduino Promini . As result, the performance of BSD

system was become stable.

CHAPTER 5

CONCLUSION AND RECOMMENDATION

5.1

Conclusion

The prototype of the BSD system has been successfully developed to achieve

the three objectives:

1

To design a portable and wirelessly controlled BSD system for lowend vehicle.

2.

To design suitable algorithm to calculate distance for detecting object

when vehicle enter blind spot region.

3

To design a hardware system for producing visible alert when a

vehicle enter the blind spot region.

Literature review on BSD system was successfully done by referring to

previous projects conducted by others. The hardware of BSD system and software of

BSD system were created at the end of this project. The system integration between

the hardware and software of BSD system were successfully done. Through this

project, a reliable and effective system is achieved to detect and monitor blind spot

region of vehicle. It has been successfully tested, and the BSD system work well for

the small scale of car.

44

5.2

Recommendation for future works

For long range monitoring distance object, it is suggested to use the

XL-MaxSonar-EZL1 Sensor instead of HC-SR04 Ultrasonic sensor. The

XL-MaxSonar-EZL1 Sensor has many advantages which are:

Can detect small object.

Sensor small in size

Maximum range of detecting object is1068cm (420 inches).

Operating voltage from 3.3v to5.5v.

Resolution 1cm

Real time noise rejection algorithm

Read from three sensor outputs: Analoq voltage, Serial and Pulse Width

Figure 5.1: XL-MaxSonar-EZL1Sensor.

CHAPTER 6

PROJECT MANAGEMENT

6.1

Introduction

The objective of project management is to achieve all project goals with

effective project, planning, organizing and controlling resource within a specified

time period [15]. The primary constraints in this project are research scope, research

time and research budget to perform required activity to achieve the required

specifications. In this process, based on stated constraints, project schedule had been

tabulated on Gantt chart. Next, cost estimation on the components is performed to

ensure minimal project cost while keeping project to achieve the desired

requirement.

6.2

Project schedule

Table 6.1 shows project Gantt chart for semester one. The majority of the

work done in the first part of the project was focused on proposing and

46

understanding of the project through literature review. In addition, much effort was

spent to understand the blind spot detection system (BSD system) by referring to the

previous work. Besides that, some effort also has been spent to understand the

concept of the interconnected BSD system. Then, the work proceeds with the list of

components design and model the BSD system. The important task of the first part of

the project was the preparation for presentation as well as writing the first part of the

project report.

Table 6.1: Project Gantt chart for semester one

Week

Activities

2 3 4 5 6 7 8 9

1

11

12 13 14 15

16

0

1.Brief Idea FYP

2.Literature and

3.Study blind spot

detector of vehicle

4. Study the journal,

thesis and article related

Semester Break

theoretical study

system.

5. Submit Proposal

6. List the components

and model hardware

configuration of blind

spot detection system

7. Draw flowchart and

block diagram of blind

spot detection system.

8.Report preparation

9.Presentation

Study Week

to blind spot detection

47

Table 6.2 shows project Gantt chart for semester two which describes the

possible task for the second part of the project with the estimated time that will be

spent for each task. Firstly, the hardware implementation will be conducted. After

completion of that part, the works continue by applying that software implementation

and verify the performance of BSD system.

Table 6.2: Project Gantt chart for semester two.

Week

1 2 3 4 5 6 7 8 9

10

11 12 13 14 15

16

Activities

Study

Week

1.Hardware

implementation

3. Testing the

product

4. Verify

specification/

analysis

Semester Break

2. Software

implementation

5.Presentation

6.Thesis

preparation

6.3

Cost estimation

Table 6.3 demonstrates the cost estimation for assembling the circuitry of

wireless ultrasonic sensor. The most expensive components in this board is Arduino

Promini. As the circuitry of wireless ultrasonic sensor is designed in rather small

dimension, so the small microcontroller is really needed. As far as stock availability

48

on closest warehouse and price concern, hence the Arduino Promini was selected in

this project to act as a brain for the circuitry of wireless for ultrasonic sensor.

Table 6.3: The cost estimation for assembling the circuitry of wireless ultrasonic

sensor

No

Materials

Quantity

.

Price

Price

per unit

(RM)

(RM)

1

Ultrasonic sensor

4

22.00

88.88

2

NRF240L01 module transmitter

4

15.00

60.00

3

Arduino Pro mini

4

30.00

120.00

4

Battery supply 9v

4

05.00

20.00

5

PCB connector 10 ways

2

01.00

02.00

6

Donut board

2

03.00

06.00

7

Resistor 0.25W 5% (330R)

9

00.05

00.60

8

Acrylic 2mm

1

10.00

20.00

9

PCB connector 4 ways

4

00.40

01.60

10

PCB connector 3 ways

8

00.30

02.40

11

Wire rainbow 1.5mm

0.5m

02.00

02.00

12

PCB connector 2 ways

4

00.20

00.80

13

Wire 1.5mm single core

1m

01.00

01.00

14

Battery holder

4

03.00

12.00

15

Voltage regulator LM 3.3V

4

05.00

20.00

Subtotal

336.48

16

17

Next, table 6.4 demonstrates the cost estimation for assembling the circuitry

of warning light indicator. The most expensive components in this board is Arduino

UNO. Although, the price quick expensive, the Arduino UNO was selected in this

project to act as a brain for the circuitry of warning light indicator.

49

Table 6.4: The cost estimation for assembling the circuitry of warning light

indicator

No

Materials

Quantity

.

Price

Price (RM)

per

unit (RM)

1

Arduino Uno

1

50.00

50.00

2

NRF240L01 module receiver

1

15.00

15.00

3

Donut board

1

03.00

03.00

4

LED 234 green

2

00.10

00.20

5

LED 234 orange

3

00.10

00.30

6

LED 234 red

3

00.10

00.30

7

Resistor 0.25W 5% (330R)

9

00.05

00.45

8

Buzzer

1

03.00

03.00

9

Wire rainbow 1.5mm

0.5m

02.00

02.00

10

PCB connector 10 ways

2

01.00

02.00

11

PCB connector 4 ways

2

0.40

00.80

12

PCB connector 2 ways

4

00.20

00.80

13

Wire 1.5mm single core

1m

01.00

01.00

Subtotal

76.85

14

15

50

Table 6.5 shows the total cost estimation for BSD system. The complete BSD

system consists of the circuitry of wireless ultrasonic sensor board and the circuitry

of warning light indicator board. The cost to build up this BSD system is about

RM413.33.

Table 6.5: The total cost estimation for BSD system.

Components

Subtotal

The circuitry of wireless ultrasonic sensor

RM336.48

The circuitry of warning light indicator

RM76.85

Total

RM413.33

51

REFERENCES

1. Ollis, M., H. Herman, et al. (1999). Analysis and design of panoramic stereo

vision using equi-angular pixel cameras, Citeseer.

2. Volvo

cars.com.

(2013).Blind

spot

Information

system.

[Online].Available:http://www.volvocars.com/us/top/about/conceptcarsfuture

vehicles/pages/default.aspx92013

3. Auto.howstuffworks.com (2013). Safety regulatory devices. [Online].

Available:

http://auto.howstuffworks.com/car-driving-safety/safety

regulatory-devices/cars-making-blind-spot-less-dangerous1.htm

4. Kuwana, J., M. Itoh, et al. (2013). Dynamic side-view mirror: Assisting

situation awareness in blind spots. Intelligent Vehicles Symposium (IV),

2013 IEEE, IEEE.

5. M. R. Endsley, (1995). Toward a theory of situation awareness in dynamic

systems .Human Factors, vol. 37, no. 1, pp. 32–64.

6. R. R. Kinpling, (1993). IVHS technologies applied to collision avoidance.

Perspectives on six target crash types and countermeasures, in Proc. 1993

Annual Meeting of IVHS America, Surface Transportation: Mobility,

Technology, and Society, pp. 249–259.

7. bmwusa.com (2013). Model highlights 528i sedan. [online]. Available:

http://www.bmwusa.com/Standard/Content/Vehicles/2014/5/528iSedan/

ModelHighlights/528iSedanSafety.aspx?Id=377

8. Yu, F., B. Kaminska, et al. (2008). "A Wireless Sensor-Based Driving

Assistant for Automobiles." ICGST-ACSE Journal, ISSN: 1687-4811.

9. Institute of Communications and Computer Systems (2005). Integrated

Drivers’ Lateral Support System: The Lateral Safe Project [Online].

Available:

52

http://www.preventip.org/download/Events/20050601%20ITS%20Hannover

%20papers/2683.pdf

10. Mahapatra, R., K. V. Kumar, et al. (2008). Ultra sonic sensor based blind spot

accident prevention system. Advanced Computer Theory and Engineering,

2008. ICACTE'08. International Conference on, IEEE.

11. Watson, B., J. Friend, et al. (2009). "Piezoelectric ultrasonic micro/milli-scale

actuators." Sensors and Actuators A: Physical 152(2): 219-233.

12. Tabib, M. and M. Tajudin (2008). Smart system of ultrasonic car parking,

Universiti Malaysia Pahang.

13. Song, K.-T., C.-H. Chen, et al. (2004). Design and experimental study of an

ultrasonic sensor system for lateral collision avoidance at low speeds.

Intelligent Vehicles Symposium, 2004 IEEE, IEEE.

14. Lin, Y. R. and Y. H. Li (2010). "FPGA Implementation of a Vision-Based

Blind Spot Warning System." World Academy of Science, Engineering and

Technology: 896-900.

15. Kerzner, Harold R. Project management: a systems approach to planning,

scheduling, and controlling. John Wiley & Sons, 2013.

16. R.P. Mahapatra, K.V. Kumar, G. Khurana, and R. Mahajan, "Ultra Sonic

Sensor Based Blind Spot Accident Prevention System," in International

Conference on Advanced Computer Theory and Engineering, pp. 992-995,

2008.

17. Diaz, E. Ros, S. Mota, G. Botella, A. Canas, S. Sabatini, "Optical Flow For

Cars Overtaking Monitor: The Rear Mirror Blind Spot Problem," in IEEE

Intelligent Vehicles Symposium, pp.50-57, Las Vegas, 2005.

18. A. Techmer, "Real-time motion analysis for monitoring the rear and lateral

road," in Proc. IEEE Intel. Vehicles Symp., Parma, Italy, pp.704-709, 2004.

19. M. Krips, 1. Velten, A. Kummert, and A. Teuner, "AdTM tracking for blind

spot collision avoidance," in Proc. IEEE Intel. Vehicles Symp Parma, Italy,

pp. 544-548, 2004.

20. R. Okada, Y. Taniguchi, K. Furukawa, and K. Onoguchi, "Obstacle Detection

Using Projective Invariant and Vanishing Lines.

53

APPENDIX A

DATASHEET OF COMPONENTS

54

55

APPENDIX B

BSD SYSTEM CODING

1.

Programming of circuitry for wireless ultrasonic sensor REAR LEFT

SIDE.

#include <NewPing.h>

#define TRIGGER_PIN 5

#define ECHO_PIN 4

#define MAX_DISTANCE 300.

#include <SPI.h>

#include <nRF24L01.h>

char mypacket[3]; //int sendingByte;

NewPing sonar_LB (TRIGGER_PIN, ECHO_PIN, MAX_DISTANCE);

void setup()

{

Serial.begin(115200);

Serial.begin(9600);

Mirf.spi = &MirfHardwareSpi;

Mirf.csnPin = 8;

// define CSN pin

Mirf.cePin = 9;

// define CE pin

Mirf.init();

Mirf.setRADDR((byte *)"00010"); // receiving address

Mirf.setTADDR((byte *)"00010"); // transmitting address

Mirf.payload = sizeof(mypacket); // up to 32 byte only

Mirf.channel = 50;

// pipeline channel

Mirf.config();

}

void loop() {

delay(50)

unsigned int uS_LB = sonar_LB.ping();

Serial.print("\n Ping: ");

Serial.print(uS_LB / US_ROUNDTRIP_CM);

Serial.println("cm");

if((uS_LB / US_ROUNDTRIP_CM) > 10)

{

mypacket[0]='L';

mypacket[1]='B';

mypacket[2]='O';

Mirf.send((byte *) &mypacket);

while(Mirf.isSending()){}

Serial.print("\n sending LB detected");

//delay (100);

}

56

else if((uS_LB / US_ROUNDTRIP_CM) >0 && (uS_LB /

US_ROUNDTRIP_CM) < 10)

{

mypacket[0]='L';

mypacket[1]='B';

mypacket[2]='F';

Mirf.send((byte *) &mypacket);

while(Mirf.isSending()){}

Serial.print("\n sending LB not detected");

delay (100);

}

2.

Programming of circuitry for wireless ultrasonic sensor FRONT LEFT

SIDE.

---------------------------------------------------------#include <NewPing.h>

#define TRIGGER_PIN 6

#define ECHO_PIN 5

#define MAX_DISTANCE 300

#include <SPI.h>

#include <nRF24L01.h>

---------------------------------------------------------char mypacket[3];

//int sendingByte;

NewPing sonar_LB(TRIGGER_PIN, ECHO_PIN, MAX_DISTANCE);

void setup()

{

Serial.begin(115200);

Serial.begin(9600);

Mirf.spi = &MirfHardwareSpi;

Mirf.csnPin = 8;

// define CSN pin

Mirf.cePin = 9;

// define CE pin

Mirf.init();

Mirf.setRADDR((byte *)"00010"); // receiving address

Mirf.setTADDR((byte *)"00010"); // transmitting address

Mirf.payload = sizeof(mypacket); // up to 32 byte only

Mirf.channel = 50;

// pipeline channel

Mirf.config();

}

void loop() {

delay(50);

unsigned int uS_LB = sonar_LB.ping();

Serial.print("\n Ping: ");

Serial.print(uS_LB / US_ROUNDTRIP_CM);

Serial.println("cm");

57

-------------------------------------------------------------------------if((uS_LB / US_ROUNDTRIP_CM) > 10)

{

mypacket[0]='R';

mypacket[1]='B';

mypacket[2]='O';

Mirf.send((byte *) &mypacket);

while(Mirf.isSending()){}

Serial.print("\n sending RB detected");

//delay (100);

}

else if((uS_LB / US_ROUNDTRIP_CM) > 0 && (uS_LB /

US_ROUNDTRIP_CM) < 10)

{

mypacket[0]='R';

mypacket[1]='B';

mypacket[2]='F';

Mirf.send((byte *) &mypacket);

while(Mirf.isSending()){}

Serial.print("\n sending RB not detected");

delay (100);

}

}

3.

Programming of circuitry for wireless ultrasonic sensor REAR RIGHT

SIDE.

// -------------------------------------------------------------------#include <NewPing.h>

#define TRIGGER_PIN 6

#define ECHO_PIN 5

#define MAX_DISTANCE 400

#include <SPI.h>

#include <nRF24L01.h>

----------------------------------------------------------------------char mypacket[3];

//int sendingByte;

NewPing sonar_LB(TRIGGER_PIN, ECHO_PIN, MAX_DISTANCE);

void setup()

{

Serial.begin(115200);

Serial.begin(9600);

Mirf.spi = &MirfHardwareSpi;

Mirf.csnPin = 8;

// define CSN pin

58

Mirf.cePin = 9;

// define CE pin

Mirf.init();

Mirf.setRADDR((byte *)"00010"); // receiving address

Mirf.setTADDR((byte *)"00010"); // transmitting address

Mirf.payload = sizeof(mypacket); // up to 32 byte only

Mirf.channel = 50;

// pipeline channel

Mirf.config();

}

void loop() {

delay(50);

unsigned int uS_LB = sonar_LB.ping();

Serial.print("\n Ping: ");

Serial.print(uS_LB / US_ROUNDTRIP_CM);

Serial.println("cm");

---------------------------------------------------------------------if((uS_LB / US_ROUNDTRIP_CM) > 0 && (uS_LB /

US_ROUNDTRIP_CM) < 10 )

{

mypacket[0]='F';

mypacket[1]='1';

mypacket[2]='O';

Mirf.send((byte *) &mypacket);

while(Mirf.isSending()){}

Serial.print("\n sending F1 detected");

}

else if((uS_LB / US_ROUNDTRIP_CM) > 10)

{

mypacket[0]='F';

mypacket[1]='1';

mypacket[2]='F';

Mirf.send((byte *) &mypacket);

while(Mirf.isSending()){}

Serial.print("\n sending F1 not detected");

//delay (100);

}

else if((uS_LB / US_ROUNDTRIP_CM) == 0)

{

mypacket[0]='F';

mypacket[1]='1';

mypacket[2]='F';

Mirf.send((byte *) &mypacket);

while(Mirf.isSending()){}

Serial.print("\n sending F1 not detected");

}

}

59

4.

Programming of circuitry for wireless ultrasonic sensor FRONT RIGHT

SIDE.

// -------------------------------------------------------------------#include <NewPing.h>

#define TRIGGER_PIN 6

#define ECHO_PIN 5

#define MAX_DISTANCE 400

#include <SPI.h>

#include <nRF24L01.h>

----------------------------------------------------------------------char mypacket[3];

//int sendingByte;

NewPing sonar_LB(TRIGGER_PIN, ECHO_PIN, MAX_DISTANCE);

void setup()

{

Serial.begin(115200);

Serial.begin(9600);

Mirf.spi = &MirfHardwareSpi;

Mirf.csnPin = 8;

// define CSN pin

Mirf.cePin = 9;

// define CE pin

Mirf.init();

Mirf.setRADDR((byte *)"00010"); // receiving address

Mirf.setTADDR((byte *)"00010"); // transmitting address

Mirf.payload = sizeof(mypacket); // up to 32 byte only

Mirf.channel = 50;

// pipeline channel

Mirf.config();

}

void loop() {

delay(50);

unsigned int uS_LB = sonar_LB.ping();

Serial.print("\n Ping: ");

Serial.print(uS_LB / US_ROUNDTRIP_CM);

Serial.println("cm");

---------------------------------------------------------------------if((uS_LB / US_ROUNDTRIP_CM) > 0 && (uS_LB /

US_ROUNDTRIP_CM) < 10 )

{

mypacket[0]='F';

mypacket[1]='2';

mypacket[2]='O';

Mirf.send((byte *) &mypacket);

while(Mirf.isSending()){}

Serial.print("\n sending F1 detected");

60

}

else if((uS_LB / US_ROUNDTRIP_CM) > 10)

{

mypacket[0]='F';

mypacket[1]='2';

mypacket[2]='F';

Mirf.send((byte *) &mypacket);

while(Mirf.isSending()){}

Serial.print("\n sending F1 not detected");

//delay (100);

}

else if((uS_LB / US_ROUNDTRIP_CM) == 0)

{

mypacket[0]='F';

mypacket[1]='2';

mypacket[2]='F';

Mirf.send((byte *) &mypacket);

while(Mirf.isSending()){}

Serial.print("\n sending F1 not detected");

}

5.

}

Programming of circuitry for warning light indicator

----------------------------------------------------------------#include <SPI.h>

#include <nRF24L01.h>

char mypacket[3];

int led = 4;

int led_1 =7;

int led_2 = 6;

int led_3 = 5;

int led_4 = A1;

int led_5 = A2;

int led_6 = A0;

int led_7 = 2;

int BUZZ = A5;

------------------------------------------------------------------void setup() {

// initialize the digital pin as an output.

pinMode(led, OUTPUT);

pinMode(led_1, OUTPUT);

pinMode(led_2, OUTPUT);

pinMode(led_3, OUTPUT);

pinMode(led_4, OUTPUT);

pinMode(led_5, OUTPUT);

pinMode(led_6, OUTPUT);

pinMode(led_7, OUTPUT);

pinMode (BUZZ, OUTPUT);

Serial.begin(9600);

61

Mirf.spi = &MirfHardwareSpi;

Mirf.csnPin = 9;

// define CSN pin

Mirf.cePin = 8;

// define CE pin

Mirf.init();

Mirf.setRADDR((byte *)"00010"); // receiving address

Mirf.setTADDR((byte *)"00010"); // transmitting address

Mirf.payload = sizeof(mypacket); // up to 32 byte only

Mirf.channel = 50;

// pipeline channel

Mirf.config();

}

----------------------------------------------------------------void loop()

{

Mirf.getData((byte *) &mypacket);

-----------------------------------------------------------------if(mypacket[0]=='L')

{

if(mypacket[1]=='B')

{

if(mypacket[2]=='O')

{

digitalWrite(led, HIGH);

Serial.print("\n receive LB detected");

}

else if(mypacket[2]=='F')

{

digitalWrite(led, HIGH); // turn the LED on (HIGH is the voltage level)

digitalWrite(BUZZ, HIGH);

delay(250);

digitalWrite(led, LOW);

digitalWrite(BUZZ, LOW);

delay(250);

Serial.print("\n receive LB not detected");

}

}

}

----------------------------------------------------------------------if(mypacket[0]=='F')

{

if(mypacket[1]=='1')

{

if(mypacket[2]=='O')

{

digitalWrite(led_1, HIGH);

digitalWrite(led_2, HIGH);

digitalWrite(led_3, HIGH);

Serial.print("\n receive F1 detected");

62

}

else if(mypacket[2]=='F')

{

digitalWrite(led_1, LOW

digitalWrite(led_2, LOW);

digitalWrite(led_3, LOW);

Serial.print("\n receive F1 not detected");

//delay (100);

}

}

}

-------------------------------------------------------------------if(mypacket[0]=='R')

{

if(mypacket[1]=='B')

{

if(mypacket[2]=='O')

{

digitalWrite(led_7, HIGH);

Serial.print("\n receive RB detected");

}

else if(mypacket[2]=='F')

{

digitalWrite(led_7, HIGH

digitalWrite(BUZZ, HIGH);

delay(250);

digitalWrite(led_7, LOW);

digitalWrite(BUZZ, LOW);

delay(250); // turn the LED on (HIGH is the voltage level)

Serial.print("\n receive RB not detected");

}

}

}

----------------------------------------------------------------------------if(mypacket[0]=='F')

{

if(mypacket[1]=='2')

{

if(mypacket[2]=='O')

{

digitalWrite(led_4, HIGH);

digitalWrite(led_5, HIGH);

digitalWrite(led_6, HIGH);

Serial.print("\n receive F2 detected");

}

else if(mypacket[2]=='F')

{

digitalWrite(led_4, LOW);

digitalWrite(led_5, LOW);

digitalWrite(led_6, LOW);

63

Serial.print("\n receive F2 not detected");

//delay (100);

}

}

}

}

.-----------------------------------------------------------------------------------------------