john deere timeline & history

advertisement

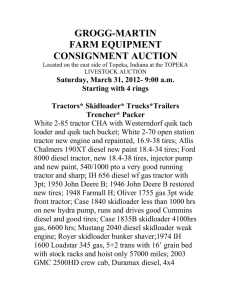

JOHN DEERE Composed from sources below by Jim Tombrink JOHN DEERE TIMELINE Deere & Company began in 1836 when thirty-two year old John Deere moved to Grand Detour, Illinois. Already an established blacksmith, Deere opened a 1,378 square feet shop in Grand Detour in 1837 which allowed him to serve as a general repairman in the village, as well as a manufacturer of small tools such as pitchforks and shovels. 1837 - John Deere fashioned a polished-steel plow in his Grand Detour, Illinois blacksmith shop. His implement was the first successful self-scouring plow. Success of the plow transformed Deere from a blacksmith to a manufacturer. He built 10 plows in 1839, 75 in 1841 and 100 in 1842. Special Insert – Page 1 1848 - The growing plow business moved to Moline, Illinois to take advantage of better water power and transportation. A year later, in 1849, a workforce of some 16 employees built 2136 plows. 1852 - John Deere bought out his business partners. For the next 16 years, the company was known variously as John Deere, John Deere & Company, Deere & Company, and Moline Plow Factory. 1858 - Day-to-day management of the company passed to 21-year-old Charles Deere, John Deere’s son. John Deere remained president. Charles joined the company as a 16-yearold after graduation from a Chicago commercial college. He ran the company for the next 49 years. 1868 - After 31 years as a partnership or single proprietorship, the enterprise was incorporated as Deere & Company. 1876 - The ‘leaping deer’ trademark was first registered. 1890 – Company founder John Deere died in Moline at 82. 1907 – Charles Deere died and William Butterworth, his son-in-law, became CEO. In addition, the company established a non-contributory pension plan for employees with 20 or more years of service and who reached 65 years old or older. Special Insert – Page 2 1918 - Deere bought the maker of Waterloo Boy tractors to enter the tractor business after the Board debated whether to focus only on horse-drawn plows or invest in the manufacturing of gasoline-powered tractors. The tractor soon became the company's basic product. 1928 - William Butterworth was elected president of the US Chamber of Commerce and Charles Deere Wiman took over leadership of the company. 1933 - Business was almost at a standstill. Sales plunged to $8.7 million. Though it was losing money, the company decided to carry the debt of farmers as long as necessary, an initiative that greatly strengthened farmer loyalty to John Deere. 1938 - Industrial designer Henry Dreyfuss worked with Deere engineers to streamline the model A and B tractors, initiating the innovative concept that attractive design could join traditional utilitarian values as hallmarks of John Deere products. 1949 - Deere's first diesel-powered unit, the Model R tractor, entered production. 1955 - William A Hewitt was elected president and later became CEO following the death of Charles Deere Wiman, his father-in-law. He directed the company for the next 27 years and was the last representative of the Deere family to do so. 1963 - John Deere surpassed International Harvester to become the world's largest producer of farm and industrial tractors and equipment. In addition, Deere ventured into the consumer market. 1971 – The well-known advertising slogan ‘Nothing Runs Like a Deere’ is used for the new snowmobile line, which was built at John Deere Horicon Works. The slogan lasted far longer than the snowmobile line, which was sold in 1984. Special Insert – Page 3 1979 - Employment reached an all-time high of 65,392. Sales topped $5 billion and earnings were $310 million, both were records. 1982 - Robert A Hanson succeeded retiring Chairman William A Hewitt and became the first company leader who did not have any family ties to company founder John Deere. 1986 – A severe downturn in the farm economy throughout the decade had significant impact on the company. Employment at year's end totaled 37,481, down 43 per cent from the 1979 high of 65,392. 1988 - The farm economy rebounded after six years of recession during which many agricultural companies failed. Deere & Company sales grew 30 per cent from 1987. 1991 – Lawn and grounds care equipment operations in the US and Canada became a separate division. 1993 - New tractor models increased John Deere’s market share of agricultural equipment sales in North America and Europe. 1997 - The John Deere Pavilion, with equipment exhibits and interactive displays, opened in downtown Moline. 2002 - Business Ethics magazine named John Deere among its 100 Best Corporate Citizens. 2006 - Growing global market presence helped drive earnings to a record $1.69 billion. Chairman and CEO Robert W Lane was named ‘CEO of the Year’ by Industry Week magazine. John Deere Tianjin Works, a new transmission factory in Tianjin, China, opened. 2007 - A tractor manufacturing facility was acquired in Ningbo, China. John Deere was chosen again among the world's 100 Most Ethical Companies. 2011 - The company announced its ninth dividend increase in the past seven years. Deere was listed among the 50 most-admired companies globally by Fortune magazine and ranked as one of the 100 best global brands by a leading brand-consulting firm. The company began work on factories to produce engines, loaders, and agricultural equipment in China, and tractors and combines in India. 2012 – Deere began its recognition of the company’s 175th anniversary. Special Insert – Page 4 THE REST OF THE STORY…….. Why Deere went west The pioneer spirit was very contagious as word spread of successful settlements in the Wild West. Conestoga caravans carried entire families and all their portable possessions in search of a new life out West. After a trip west to Illinois, John Deere’s good friend, Major Leonard Andrus, returned to recruit, raving of the potential for a new community. Andrus actually found the country around Grand de Tour, named by the French for the big bend in the Rock River. "Eventually Deere decided he had less to lose and more to gain by casting his lot anew on the virgin prairies." John Deere sold his shop and followed suit on a solo trip out west, leaving his family behind in Vermont. He reached Grand Detour in 1836 where Andrus had built a sawmill and wood-working business. The need for a blacksmith shop was obvious as none could be found closer than 40 miles from the town. Soon, John Deere was a very busy man. In between repair jobs, Deere managed to build himself a shop and little frame house of 18 by 24 feet, with five rooms. When the home was ready, Deere sent for his wife and five children. "A family tradition of their arrival at the end of a long six-week trip tells of Mrs. Deere handing her husband a squirming little bundle containing their year-old son Charles Deere, whom the father looked upon for the first time." A plowing problem Deere’s business became more focused on plows as the prairie needed to be opened. "The land was easily broken — the first year —and it produced abundantly. The disillusionment was to come the second year." "It was when the northern Illinois pioneers went back into their fields the second year that they learned of the plowing tribulations that were to be their lot. The sticky, mucky soil refused to fall away from the moldboards. It stuck until the plow could no longer move in the furrow. It made little difference if one or two ox teams were hitched to the plow; they stalled despite all the power the farmer could assemble." "Farmers gradually learned to carry with them a wooden paddle, with which to scrape the mud from the plow as it accumulated. Plows could be cleaned with the paddle, a fresh start made down the furrow, only to face the necessity of stopping to repeat the operation every rod or less. An acre a day was impossible." Deere listened to their complaints and considered them a challenge. When he spied a broken sawmill blade at the Andrus mill, he thought the bright shiny surface just might be the answer to shedding the sticky soil. And as they say, the rest is history…Deere’s self-scouring steel plow worked magic on Lewis Crandall’s field in 1837. The next year, he built two plows; and 10 the year after that. By 1842 he was building about 100 a year, at an approximate rate of almost two a week. He shipped his plows to farmers to try. If the plows worked, the farmers owed Deere $10; if the plows didn’t work well, Deere sent for them back. Special Insert – Page 5 Steel in short supply Eventually, Deere ran out of broken sawmill blades in the area. He knew he needed to get his own steel supply. He ordered specially rolled slabs of steel that could be cut into a dozen moldboards. By the time the steel was shipped across the Atlantic and over land to Grand Detour, it cost Deere about $300 per ton. Then Deere discovered Pittsburgh’s steel production and ordered the first slab of cast steel plow ever rolled in the U.S. in 1846. That year, 1,000 plows were made in Deere’s factory. However, Deere was disappointed with the location of Grand Detour as river transportation never materialized and road transportation was rough and rut-filled. When Deere found Moline with its dam for water power and good navigation of the Mississippi, he was sold and began plans to relocate his plow factory at the age of 43. After several failed partnerships in his early days in Moline, the business was reorganized in 1868 as Deere & Company, with the senior Deere as president and his son Charles as vicepresident. At his funeral in 1886, most of Moline turned out to pay their respects to the man who made the town "Plow City." The pastor said this in Deere’s eulogy: "Nothing left his shop but spoke the truth, was just as represented…He was not a theorizer, or one who dealt in impractical things, but in solid facts." "Wealth was a natural product of business growth and John Deere was generous with it. A tender heart was beneath the rough exterior and great human sympathy behind the furrowed brow. Much of his money went for the establishment of Sunday schools in the new sections of Kansas, Nebraska and the Dakotas. Much of it went to help fellow workmen and the less fortunate of his older friends. Also he was generous in contributions for worthy civic enterprises in his home community." By the time Deere died and left his legacy of a highly successful farm equipment manufacturing business to his son…"The mechanical needs of the farmer were growing and John Deere developed numerous other implements along with the steel plow, harrows, cultivators, etc. Later the expansion of Deere & Co. was to add new factories making non-competing lines, and in each of which had developed eminent standing in its particular field. The village forge of 1837 has grown into the eleven mammoth factories of 1937." Sources: AntiqueFarming.com Implement & Tractor magazine, January 9, 1937. BleedingGreen.com John Deere Company Special Insert – Page 6