SP Oct 04 P26 Laminating

advertisement

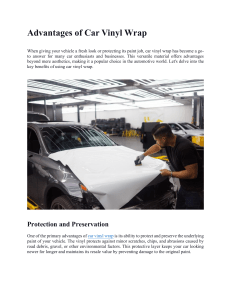

FEATURE LAMINATING APPLICATIONS PART 6: FLEXIBLE OUTDOOR DISPLAYS by Mick Budd In this column, I present profitable applications in a series of eight contributions, discuss their respective pros and cons and, at the same time, show how to avoid faults in production. In this sixth article, I deal with a classic and widespread form of image processing: the Flexible Outdoor Display. IN THE PAST this application tended to be regarded as a nesscessary evil rather than being recognised for the opportunities it can present. Vehicle livery was restricted to sign painting or vinyl lettering stuck on the back of a truck to announce its owners. Today, we see fully liveried vehicles carrying full colour graphics portraying the latest marketing messages from the manufacturers, effectively they have become huge mobile billboards. Big brands such as Coca Cola will wrap minis and smart cars in printed vinyl to advertise their latest drinks or to promote their latest campaign. The opportunities are boundless. Digital printing as the basis Flexible outdoor displays fall into three categories: full vehicle wraps (such as a VW beetle done as a Ladybird for Wrangler jeans); partial wraps (large areas of vinyl on the sides of trucks, buses and trains); and truck sides (liveried tarpaulins for curtain sided trucks). The basis for all these applications is a vinyl-based film which is printed using a solvent based system to deliver maximum durability. Before starting to print any of the above, care must be taken to use the right components for the finished application. Considerations include: the vinyl’s life span; ink durability; expected wear and tear; and whether or not a warranty is required. All of these affect material choice. For instance, to produce a fully wrapped vehicle you should be looking at a solvent based printing system with cast vinyl (for conformity) and either a durable compatible overlaminate for long term protection or a liquid coat such as the Seal AquaSeal solution. (The liquid solution is particularly good when looking for a warranteed application). Typical vinyls for this application fall into three types: cast vinyl (high end product, conformable in threedimensions) for tricky full wraps; polymeric calendered vinyl (conformable in two-dimensions) for curves and large areas in medium term applications; and monomeric vinyls for basic short term flat signage. In all cases, if the signage is to remain for extended periods then, to ensure maximum longevity and protection, you should be looking at a liquid laminate. | 26 | Screen Process & Digital Imaging | October 2004 This application needs careful consideration before entering into any commitment to produce. Let’s look at a typical example: a fully wrapped Smart car. I’m sure we have all seen this example. These vehicles have lots of curves and angles and need particular care even from experienced applicators. Such a car could take up to seven-hours to wrap and such an amount of labour needs to be considered in any price calculation. Although the material is designed specifically for this purpose, it can be troublesome to apply. It is important to identify the correct film for the job. There are many types of vinyl and you need to remember this film has to be stretched in many different dimensions. Ensure you have material with the right adhesive qualities; the last thing you want is the image popping off when the vehicle drives away from site. If the vehicle is to be sold after a couple of years of being wrapped it’s important that the vinyl can be easily removed without leaving any detritus (particularly important if leasing). Remember, pick the right product, cost the job correctly, create the right image and you will have a profitable application. Vehicles with box-type bodies or largely flat surfaces (buses and trains) represent less of a problem. Generally, lifetimes here are three to five-years or even longer. With this application you would use mediumquality polymer films which are calendered or moulded products: the latter used mainly on vehicles or objects that require a higher degree of conformity (small rivets protruding from the surface for example) which have to be covered. For finishing and protection against environmental influences, laminates or lacquers are ideal here too. With curtain sided trucks, however, special ABOVE & LEFT: When planning vehicle wrap applications considerations include: vinyl life span; ink durability; expected wear and tear; and the level of warranty required. tarpaulins of up to 1,000g/m2 are used. These are printed lengthwise in widths of approximately 2.5m and then finished with a quality lacquer. Typically a 32m coating is employed. The tarpaulins are then finished, joined together by high frequency welding, with stiffeners and tensioning straps applied to provide a fit-for-purpose product. Some manufacturers offer guarantees. For instance, the wide format printer company, Vutek, in cooperation with Seal (finishing solutions) and a tarpaulin manufacturer, offer a guarantee called the Integrated Graphics Protection System (IGPS), which promises the customer a useful life up to five-years. Mick Budd is key accounts manager, SEAL Graphics. Find more information on laminating techniques at www.sealgraphics.com