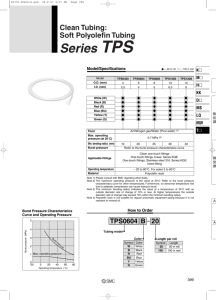

Plastic tubing, standard OD

advertisement

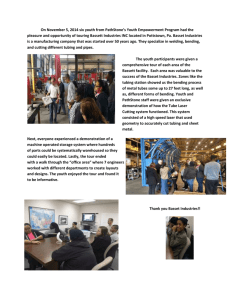

Plastic tubing, standard O.D. Plastic tubing, standard O.D. Features Application The requirements with respect to pressure, temperature, flexibility and environmental influences differ from industry to industry. Users frequently underestimate the risks: around 90% of all cases of damage can be traced back to the wrong choice of tubing or tubing materials. This can not only result in energy losses, but also machine downtimes. It is especially important to find a reliable and costeffective product that prevents tubing degradation during operation. Summary of tubing/fitting combinations Applications Tubing Fitting Description Standard PEN QS-B PUN QS PAN QS PAN-MF NPQM PAN-R NPQH PLN NPQP PUN-H NPKA PFAN NPQH PFAN NPCK Anti-static PFAN PUN-CM CRQS NPQM Flame retardant PUN-V0 NPQM Resistant to welding spatter PUN-V0-C NPQH PAN-V0 QS-V0 Suitable for a wide range of tasks and attractively priced. Flexible thanks to highly resistant materials, easy to install thanks to optimised bending radii. High level of abrasion resistance in dynamic applications. Maximum flexibility in standard applications thanks to an extremely wide range of options for combining the different types. Meets all requirements, even for standard applications with increased pressure and temperature ranges. Meets DIN standard 73378: ideal for use in mobile pneumatics. Suitable for increased temperature ranges combined with high pressure ranges. Powerful in pressure ranges up to 20 bar, for example in applications with the pressure booster DPA. Resistant to cleaning agents, FDA compliant and economical. Can be used instead of the combination with stainless steel fittings. Hydrolysis resistant and suitable for water applications. Combination suitable for use in clean rooms, FDA compliant and corrosion resistant thanks to 100% polymer construction. Very easy to install thanks to the “one click principle”. For high temperatures up to 150 °C. Suitable for use in the food industry, FDA compliant and resistant to cleaning agents. Easy to clean thanks to the union nut’s edge-free design. Maximum resistance to corrosion (CRC 4) and FDA compliant. Suitable for a wide range of media. Maximum resistance to corrosion (CRC 4) and to aggressive acids and lyes. Anti-static tubing plus solid metal fitting: maximum protection for electrical and electronic components. Very safe in areas where there is a risk of fire thanks to flame-retardant properties. The tubing has been tested to DIN 5510-2. Ideal for applications involving welding spatter. Reliable thanks to a tubing wall thickness of 2 mm for all diameters. Safe even in the immediate vicinity of welding spatter thanks to the double-walled tubing with special fitting. High pressures Resistant to chemicals, food safe and hydrolysis resistant -H- Note The ambient conditions and the oper­ ating medium transported can have a considerable effect on the service life of plastic tubing. Based on empirical values, Festo recommends the follow­ ing time specifications for the usage of plastic tubing in general and safety-related applications: 2 For general applications, a min­ imum service life of 10 years can be expected. For safety-related applications, we recommend regular inspection at least every 12 months. For applications that have an effect è Internet: www.festo.com/catalogue/... on the material, inspections must be carried out at suitable intervals. We recommend that the interval between inspections should be no more than 6 months, at most half of the period in which failures can occur. Subject to change – 2016/01 Plastic tubing, standard O.D. Technical data Note Tubing diameters that are too big or too small as well as bending radii that are too small result in flow rate losses. One of the most important rules when selecting tubing is therefore that it should be as long as necessary and as short as possible. Make sure therefore that in practice tubing is laid loosely and is not stretched. Tools for bundling tubing or for avoiding bending/pinching tubing are available as accessories: Tubing strap PB Spiral wraps for tubing PKB Tubing support NPAW Tubing support PKS Multi-tube holder KK Other accessories include connecting tools for tubing: Pipe and tubing cutter ZRS Tubing cutter PAN-V0S for flameretardant plastic tubing PAN-V0 Connecting pliers ZMS/disconnect­ ing pliers ZDS for connecting/ disconnecting the plastic tubing and barbed fitting Measuring methods Flow-relevant bending radius Rd The tubing is bent in the direction of its inherent flection until a 5% flatten­ ing of the tubing O.D. occurs. The Rd is then calculated. There is no reduction in the flow rate up until the Rd is reached. Cross section flattened as a result of bended tubing d = non deformed tubing OD d1 = deformed tubing OD Minimum bending radius Rmin The tubing attached to a movable plate is bent until the deformation results in a kink. The measured value is the minimum bending radius Rmin. This Rmin leads to considerable reductions in flow. 2016/01 – Subject to change è Internet: www.festo.com/catalogue/... 3 Plastic tubing, standard O.D. Product range overview PUN-H-DUO Polyurethane PUN-V0 Polyurethane PUN-V0-C Polyurethane 1) 2) 4, 6, 8, 10, 12 4, 6, 8, 10, 12, 14, 16 4, 6, 8, 10, 12, 14, 16 3, 4, 6, 8, 10, 12, 14, 16 4, 6, 8, 10 4, 6, 8, 10, 12, (14)1) 2 3, 4, 6, 8, 10, 12, 14, 16 4, 6, 8, 10 6, 8, 10, 16 4, 6, 8, 10, 12, 14, 16 Mineral oil – Water n (n)1) (n)1) Vacuum n Compressed air n Blue/black n White Red n Brown Green n n – n n – – – n n – – – n n – – – n n – n2) (n)1) (n)1) (n)1) (n)1) (n)1) (n)1) (n)1) (n)1) – (n)1) (n)1) n n – – – – – – (n)1) (n)1) (n)1) (n)1) (n)1) (n)1) – n n n n n n n – – n n n n – – – – – – – – n – n n n – n n n n n n (n)1) (n)1) n – n n n – n n n n (n)1) (n)1) n – n n n – n n n n n n (n)1) (n)1) – – n n – – n – – – – – – – – n n n – – – – n – – – – – – – n n – – – – n – – n – – n – n n – – n n n n n n n – n n n – – – – – – – – – – n n n n – – n n n n n n n – – n n n – – n n n n n n n – – n n n – (n)1) (n)1) (n)1) (n)1) Please note the information below. As a precaution, please agree the operating medium with Festo. -H- Note Product options in brackets can only be ordered using the modular product system. Please note the minimum ordering quantity of 3,000 m for tubing with O.D. 8 mm and 1,500 m with O.D. 8 mm. 4 4, 6, 8, 10, 12, 14, 16 4, 6, 8, 10, 12 n Natural PAN-MF Polyamide PAN-V0 Polyamide PFAN Perfluoralkoxyalkan PEN Polyethylene PLN Polyethylene PUN Polyurethane PUN-DUO Polyurethane PUN-CM Polyurethane PUN-H Polyurethane 4, 6, 8, 10, 12, 14, 16 4, 6, 8, 10, 12, (14)1), 16 22, 28 Operating medium Yellow [mm] PAN Polyamide PAN-R Polyamide Colour Black Outside j Blue Type Silver Version There is a modular product system for plastic tubing. PAN è 16 PEN è 22 PLN è 25 PUN è 41 è Internet: www.festo.com/catalogue/... Subject to change – 2016/01 Plastic tubing, standard O.D. Product range overview PUN-CM PUN-H PUN-H-DUO PUN-V0 PUN-V0-C +++ Very well suited ++ Well suited UV radiation Hydrolysis Flexibility – – – n n ++ n n3) + ++ + ++ ++ – – – n n ++ n – + ++ + ++ + – – – n n ++ – – + ++ + ++ + – – – n n +++ – – + ++ + ++ + – – – – n ++ – – + ++ ++ ++ ++ n UL94 V0 – – n – n – +++ ++ ++ +++ + – – – n n +++ n – ++ ++ ++4) +++ ++ n – – n n – n – ++ ++ ++4) +++ + – n n7) ++ n – – – ++4) + +++ – n n7) ++ n – – – + + ++ UL94 HB UL94 HB – – – – n n n +++ – – + ++ ++ ++ ++ – – – n n ++ – – + ++ ++4) ++ +++ n – – n n ++ n – + ++ ++4) ++ +++ n – – n n ++ n – + ++ + ++ ++ – n n ++ n – + ++ ++4) ++ ++ – n n ++ n – + ++ ++4) ++ ++ UL94 V2 UL94 V2 – – + – 2016/01 – Subject to change Limited suitability (upon request) Unsuitable 3) 4) 5) 6) Applies for silver colour Applies for black colour External conduit Internal conduit 7) 8) Shore hardness8) Microbes PUN-DUO Chemicals PUN Germanischer Lloyd PLN Approved by German Technical Control Board PEN Suitable for chain link trunking PFAN Contact with electrical cables PAN-V0 Halogen-free PAN-MF Antistatic PAN-R Fire test material PAN è Page/ Internet Resistance Suitability for use in the food industry Type D 55 _3 7 D 62 _3 10 D 62 _3 11 D 65 _3 12 A 72 _45) 14 D 57 _36) D 60 +5 17 D 52 _3 19 – 23 D 52 _3 26 D 52 _3 29 D 52 _3 31 D 52 _3 32 D 52 _3 33 D 52 _3 36 D 54 _3 37 D 54 _3 39 Under unfavourable conditions, cables which contain phosphoric acid ester may damage PUN tubing. Values are determined using test boards. Values determined using tubing may vary. è Internet: www.festo.com/catalogue/... 5 Plastic tubing, standard O.D. Type codes PUN — — 12x2 — — BL — 200 Material PAN PFAN PEN PLN PUN Polyamide Perfluor-alkoxyalkan Polyethylene Polyurethane Certification CM H V0 R MF Antistatic Hydrolysis resistant Flame retardant to UL 94 V0 Heavy-duty Automotive certification (DIN 73378) Outside j x wall thickness [mm] Twin tubing DUO Twin tubing Colour SW BL GN RT WS GE BR SI NT BS Black Blue Green Red White Yellow Brown Silver Natural Blue/black Packaging unit [m] 6 è Internet: www.festo.com/catalogue/... Subject to change – 2016/01 Plastic tubing PAN Technical data Plastic tubing PAN High thermal and mechanical load capacities. Operating and environmental conditions Type PAN-4/8 Temperature dependent operating pressure Operating medium Ambient temperature Approval PAN-6 PAN-10/12/14 PAN-16 –0.95 … +19 è diagram –0.95 … +17 è diagram –0.95 … +14 è diagram [bar] –0.95 … +15 è diagram [°C] Compressed air in accordance with ISO 8573­1:2010 [7:–:–] –30 … +80 German Technical Control Board (TÜV) Operating pressure p as a function of temperature t PAN-6 PAN-4/8 PAN-10/12/14 PAN-16 Possible fittings Push-in fittings QS, Quick Star1) è Internet: qs Push-in fittings NPQH1) è Internet: npqh Push-in fittings NPQM è Internet: npqm Quick connectors CK è Internet: ck Barbed fittings CN è Internet: cn 1) Recommended fitting Materials Shore hardness Tubing Note on materials 2016/01 – Subject to change D 55 _3 TPE-A Conforms to RoHS Free of copper and PTFE è Internet: www.festo.com/catalogue/... 7 Plastic tubing PAN Technical data Dimensions and ordering data O.D. I.D. [mm] [mm] Min. bending radius [mm] 4 2.9 12 18 0.006 6 4 14 32 0.016 8 5.9 22 43 0.024 10 7 27 58 0.042 1) 8 Flow-relevant bending radius [mm] Weight Colour Part No. PU1) Type [kg/m] [m] Silver Silver Blue Blue Black Black Natural Green Red Yellow Silver Silver Blue Blue Black Black Natural Green Red Yellow Silver Silver Blue Blue Black Black Natural Green Red Yellow Silver Silver Blue Blue Black Black Natural Green Red Yellow 152697 553888 553906 553894 553912 553900 546284 553918 553924 553930 152699 553889 553907 553895 553913 553901 546285 553919 553925 553931 152700 553890 553908 553896 553914 553902 546286 553920 553926 553932 152701 553891 553909 553897 553915 553903 546287 553921 553927 553933 PAN-4x0,75-SI PAN-4x0,75-SI-500 PAN-4x0,75-BL PAN-4x0,75-BL-500 PAN-4x0,75-SW PAN-4x0,75-SW-500 PAN-4x0,75-NT PAN-4x0,75-GN PAN-4x0,75-RT PAN-4x0,75-GE PAN-6x1-SI PAN-6x1-SI-500 PAN-6x1-BL PAN-6x1-BL-500 PAN-6x1-SW PAN-6x1-SW-500 PAN-6x1-NT PAN-6x1-GN PAN-6x1-RT PAN-6x1-GE PAN-8x1,25-SI PAN-8x1,25-SI-400 PAN-8x1,25-BL PAN-8x1,25-BL-400 PAN-8x1,25-SW PAN-8x1,25-SW-400 PAN-8x1,25-NT PAN-8x1,25-GN PAN-8x1,25-RT PAN-8x1,25-GE PAN-10x1,5-SI PAN-10x1,5-SI-300 PAN-10x1,5-BL PAN-10x1,5-BL-300 PAN-10x1,5-SW PAN-10x1,5-SW-300 PAN-10x1,5-NT PAN-10x1,5-GN PAN-10x1,5-RT PAN-10x1,5-GE 50 500 50 500 50 500 50 50 50 50 50 500 50 500 50 500 50 50 50 50 50 400 50 400 50 400 50 50 50 50 50 300 50 300 50 300 50 50 50 50 Packaging unit è Internet: www.festo.com/catalogue/... Subject to change – 2016/01 Plastic tubing PAN Technical data Dimensions and ordering data O.D. I.D. [mm] [mm] Min. bending radius [mm] 12 8.4 29 64 0.060 14 16 10 12 50 67 80 94 0.077 0.092 1) Flow-relevant bending radius [mm] Weight Colour Part No. Type [kg/m] PU1) [m] Silver Silver Blue Blue Black Black Natural Green Red Yellow Silver Silver Silver Blue Blue Black Black Natural Green Red Yellow 152702 553892 553910 553898 553916 553904 546288 553922 553928 553934 570392 152703 553893 553911 553899 553917 553905 546289 553923 553929 553935 PAN-12x1,75-SI PAN-12x1,75-SI-200 PAN-12x1,75-BL PAN-12x1,75-BL-200 PAN-12x1,75-SW PAN-12x1,75-SW-200 PAN-12x1,75-NT PAN-12x1,75-GN PAN-12x1,75-RT PAN-12x1,75-GE PAN-14x2-SI PAN-16x2-SI PAN-16x2-SI-100 PAN-16x2-BL PAN-16x2-BL-100 PAN-16x2-SW PAN-16x2-SW-100 PAN-16x2-NT PAN-16x2-GN PAN-16x2-RT PAN-16x2-GE 50 200 50 200 50 200 50 50 50 50 50 50 100 50 100 50 100 50 50 50 50 Packaging unit 2016/01 – Subject to change è Internet: www.festo.com/catalogue/... 9 Plastic tubing PAN-R Technical data Plastic tubing PAN-R With tubing outside diameters of 4 … 16 mm For high-pressure applications. Operating and environmental conditions Temperature dependent operating pressure Operating medium Ambient temperature Approval [bar] –0.95 … +35 è diagram [°C] Compressed air in accordance with ISO 8573­1:2010 [7:–:–] –30 … +80 German Technical Control Board (TÜV) Operating pressure p as a function of temperature t Possible fittings p [bar] Push-in fittings NPQH1) è Internet: npqh t [°C] 1) Recommended fitting Materials D 62 _3 TPE-A Conforms to RoHS Free of copper and PTFE Shore hardness Tubing Note on materials Dimensions and ordering data O.D. I.D. [mm] [mm] Min. bending radius [mm] 4 6 8 10 12 16 2.5 3.8 5 6.2 7.6 10 7 12 16 18 24 33 1) 10 Flow-relevant bending radius [mm] Weight 16 21 29 44 46 73 0.0079 0.0174 0.0316 0.0498 0.0698 0.1262 PU1) Colour Part No. Type Silver 541674 541675 541676 541677 541678 541679 PAN-R-4x0,75-SI PAN-R-6x1,1-SI PAN-R-8x1,5-SI PAN-R-10x1,9-SI PAN-R-12x2,2-SI PAN-R-16x3-SI [kg/m] [m] 50 50 50 50 50 50 Packaging unit è Internet: www.festo.com/catalogue/... Subject to change – 2016/01 -V- New Plastic tubing PAN-R Technical data Plastic tubing PAN-R With tubing outside diameters of 22 and 28 mm High thermal and mechanical load capacities. Operating and environmental conditions Temperature dependent operating pressure Operating medium Ambient temperature [bar] –0.95 … +14 è diagram [°C] Compressed air in accordance with ISO 8573­1:2010 [7:–:–] –30 … +80 Operating pressure p as a function of temperature t Possible fittings Push-in fittings QS-G¾-22 è Internet: qs Push-in fittings CQ-…-22/28 è Internet: cq Accessories -H- Note When using the pipe cutter ZR to cut to length, we recommend rotating the tube through approx. 90° at the start of the cutting process. Rotating the tube gives a drawing cut so that the tube can be cut with a signific­ antly lower force. This also minimises deformation of the tube. Pipe cutter ZR è Internet: tool Materials D 62 _3 TPE-A Conforms to RoHS Free of copper and PTFE Shore hardness Tubing Note on materials Dimensions and ordering data O.D. I.D. [mm] [mm] Flow-relevant bend­ ing radius [mm] 22 28 18 23 350 350 1) Weight 1.31 2.07 Colour Part No. Type Black 8036207 PAN-R-22x2-SW 8036208 PAN-R-28x2,5-SW [kg/m] PU1) [m] 50 50 Packaging unit 2016/01 – Subject to change è Internet: www.festo.com/catalogue/... 11 Plastic tubing PAN-MF Technical data Plastic tubing PAN-MF High thermal and mechanical load capacities. Meets the requirements according to DIN 73378 "Polyamide tubing for use in motor vehicles". Operating and environmental conditions Type PAN-MF-4 Temperature dependent operating pressure Conforms to standard Operating medium [bar] Ambient temperature [°C] PAN-MF-6 PAN-MF-8/10/12 –0.95 … +31 –0.95 … +27 –0.95 … +19 è diagram è diagram è diagram DIN 73378-PA12-PHL Compressed air in accordance with ISO 8573­1:2010 [7:–:–] Mineral oil –60 … +100 Operating pressure p as a function of temperature t PAN-MF-14 PAN-MF-16 –0.95 … +22 è diagram –0.95 … +19 è diagram Possible fittings Push-in fittings QS, Quick Star1) è Internet: qs Push-in fittings NPQH1) è Internet: npqh Push-in fittings NPQM1) è Internet: npqm PAN-MF-4 PAN-MF-6 PAN-MF-8/10/12/16 PAN-MF-14 1) Recommended fitting Materials Shore hardness Tubing Note on materials 12 D 65 _3 PA12-P Conforms to RoHS Free of copper and PTFE è Internet: www.festo.com/catalogue/... Subject to change – 2016/01 Plastic tubing PAN-MF Technical data Dimensions and ordering data O.D. I.D. [mm] [mm] Min. bending radius [mm] 4 2.5 10 15 0.008 6 4 15 35 0.016 8 10 12 14 16 6 7.5 9 10 12 35 45 50 50 75 50 65 70 75 130 0.022 0.035 0.051 0.077 0.09 1) Flow-relevant bending radius [mm] Weight Colour Part No. Type [kg/m] PU1) [m] Black 570357 572091 570358 572093 570359 570360 570361 570362 570363 PAN-MF-4x0,75-SW PAN-MF-4x0,75-SW-500 PAN-MF-6x1-SW PAN-MF-6x1-SW-500 PAN-MF-8x1-SW PAN-MF-10x1,25-SW PAN-MF-12x1,5-SW PAN-MF-14x2-SW PAN-MF-16x2-SW 50 500 50 500 50 50 50 50 50 Packaging unit 2016/01 – Subject to change è Internet: www.festo.com/catalogue/... 13 Plastic tubing PAN-V0, flame retardant Technical data Plastic tubing PAN-V0 PVC casing, flame-retardant to UL 94 V0. The tube casing must be cut to length X (table è 15) before being inserted in the push-in fitting QS-V0. The tubing cutter PAN-V0S is the perfect tool for this task. The tubing cutter PAN-V0S will always cut the casing to the right length. Operating and environmental conditions Temperature dependent operating pressure Operating medium [bar] –0.95 … +12 è diagram Ambient temperature [°C] Compressed air in accordance with ISO 8573­1:2010 [7:–:–] Mineral oil Water as per manufacturer's declaration è www.festo.com –30 … +90 Operating pressure p as a function of temperature t Air Water and mineral oil Possible fittings Push-in fittings QS, Quick Star è Internet: qs Push-in fittings NPQH è Internet: npqh Push-in fittings QS-V0, Quick Star, flame-retardant1) è Internet: qs-v0 Push-in fittings CRQS, Quick Star, stainless steel è Internet: crqs 1) Recommended fitting Accessories Tubing cutter PAN-V0S è Internet: tool Materials Shore hardness Tubing Note on materials 14 Outer tubing Inner tubing Outer tubing Inner tubing A 72 _4 D 57 _3 PVC-P PA12-P Conforms to RoHS è Internet: www.festo.com/catalogue/... Subject to change – 2016/01 Plastic tubing PAN-V0, flame retardant Technical data Dimensions and ordering data For push-in O.D. I.D. fitting O.D. [mm] [mm] [mm] Min. bending radius Max. cut length X Weight [mm] Flow-relevant bending radius [mm] [mm] [kg/m] 4 6 6 8 2.5 4 10 13 20 30 15 17 0.0335 0.049 8 10 6 24 45 18 0.065 10 12 7.5 34 56 20 0.088 12 14 9 43 65 23 0.133 1) Colour Part No. Type PU1) [m] Blue Black Blue Green Red White Yellow Brown Black Blue Green Red White Yellow Brown Black Blue Green Red White Yellow Brown Black Blue Green Red White Yellow Brown 132899 160550 525466 525470 525474 525478 525482 525486 160551 525467 525471 525475 525479 525483 525487 160552 525468 525472 525476 525480 525484 525488 160553 525469 525473 525477 525481 525485 525489 PAN-V0-4x0,75-BL-50 PAN-V0-6x1-SW PAN-V0-6x1-BL PAN-V0-6x1-GN PAN-V0-6x1-RT PAN-V0-6x1-WS PAN-V0-6x1-GE PAN-V0-6x1-BR PAN-V0-8x1-SW PAN-V0-8x1-BL PAN-V0-8x1-GN PAN-V0-8x1-RT PAN-V0-8x1-WS PAN-V0-8x1-GE PAN-V0-8x1-BR PAN-V0-10x1,25-SW PAN-V0-10x1,25-BL PAN-V0-10x1,25-GN PAN-V0-10x1,25-RT PAN-V0-10x1,25-WS PAN-V0-10x1,25-GE PAN-V0-10x1,25-BR PAN-V0-12x1,5-SW PAN-V0-12x1,5-BL PAN-V0-12x1,5-GN PAN-V0-12x1,5-RT PAN-V0-12x1,5-WS PAN-V0-12x1,5-GE PAN-V0-12x1,5-BR 50 50 20 20 20 20 20 20 50 20 20 20 20 20 20 50 20 20 20 20 20 20 50 20 20 20 20 20 20 Packaging unit 2016/01 – Subject to change è Internet: www.festo.com/catalogue/... 15 Plastic tubing PAN Ordering data – Modular products Ordering table (minimum order quantity 3,000 m, rounding-off value 25 m) Size 4 6 8 10 0 M Module No. 14 16 Condi­ tions Code Enter code Polyamide tubing, standard O.D. PAN PAN Standard Automotive certification (DIN 73378) Heavy-duty -MF -R 553610 Function 0 O Alternative material characteristic 0 M Tubing O.D. [mm] 4 – – – – – – Silver Blue Black Yellow Green Red Brown White Natural Colour 0 O Inscription text (on request) 0 M Packaging unit Packaging – 6 – – – – – – – 8 – – – – – – – 10 – – – – – – – 12 – – – – – – – 14 – – – – – – – 16 -4 -6 -8 -10 -12 -14 -16 -SI -BL -SW -GE -GN -RT -BR -WS -NT Standard Customer-specific tubing inscription [m] 25 50 100 200 300 400 500 Cardboard box Polyurethane bag Reel – – – – – – – – – 1 -TXT 24 25 3 -25 -50 -100 -200 -300 -400 -500 -CB -BA -HA – – – – 1 TXT Only on request 4 CB Not with alternative material characteristic MF 2 CB, BA Only with packaging unit 25, 50 5 BA Only with alternative material characteristic MF 3 HA Not with packaging unit 25, 50 Transfer order code 553610 PAN 16 12 – – è Internet: www.festo.com/catalogue/... – – – – Subject to change – 2016/01 Plastic tubing PFAN Technical data Plastic tubing PFAN Pneumatic tubing with resistance to high temperatures and chemicals. Operating and environmental conditions Type PFAN-4/8 PFAN-6/10/12 [bar] –0.95 … +15 è diagram –0.95 … +16 è diagram Ambient temperature Fire test material Approval [°C] Compressed air in accordance with ISO 8573­1:2010 [7:–:–] Water as per manufacturer's declaration è www.festo.com –20 … +150 UL94 V0 German Technical Control Board (TÜV) Operating pressure p as a function of temperature t Possible fittings p [bar] Temperature dependent operating pressure Operating medium Push-in fittings QS, Quick Star è Internet: qs Push-in fittings NPQH1) è Internet: npqh Push-in fittings CRQS, Quick Star, stainless steel1) è Internet: crqs Quick connectors CK è Internet: ck t [°C] 1 PFAN-6/10/12 2 PFAN-4/8 -HBarbed fittings CN è Internet: cn 1) Recommended fitting Note Greater force is required when as­ sembling the fittings CK/CN. Flaring the tube ends using a tapered man­ drel makes pushing them on easier. Materials Shore hardness Tubing Note on materials 2016/01 – Subject to change D 60 +5 PFA Conforms to RoHS è Internet: www.festo.com/catalogue/... 17 Plastic tubing PFAN Technical data Dimensions and ordering data O.D. I.D. [mm] [mm] Min. bending radius [mm] 4 6 8 10 12 2.9 4 5.9 7 8.4 11 12 25 22 29 1) 18 Flow-relevant bending radius [mm] Weight 37 50 110 140 165 0.012 0.034 0.049 0.087 0.125 Colour Part No. PU1) Type [kg/m] [m] Natural 197061 197062 197063 197064 197065 PFAN-4x0,75-NT PFAN-6x1-NT PFAN-8x1,25-NT PFAN-10x1,5-NT PFAN-12x1,75-NT 50 50 50 50 50 Packaging unit è Internet: www.festo.com/catalogue/... Subject to change – 2016/01 Plastic tubing PEN Technical data Plastic tubing PEN Polyethylene tubing is distinguished by its high resistance to chemicals and hydrolysis. It is also resistant to most cleaning agents and lubricants. Operating and environmental conditions Temperature dependent operating pressure Operating medium [bar] Ambient temperature Approval [°C] –0.95 … +10 è diagram Compressed air in accordance with ISO 8573­1:2010 [7:–:–] Water as per manufacturer's declaration è www.festo.com –30 … +60 German Technical Control Board (TÜV) Operating pressure p as a function of temperature t Possible fittings Push-in fittings QS, Quick Star1) è Internet: qs Push-in fitting QS-B, Quick Star1) è Internet: qs-b Push-in fittings CRQS, Quick Star, stainless steel è Internet: crqs Push-in fittings NPQH è Internet: npqh Push-in fittings NPQM1) è Internet: npqm Quick connectors CK è Internet: ck -HBarbed fittings CN è Internet: cn 1) Note Greater force is required when as­ sembling the fittings CK/CN. Recommended fitting Materials Shore hardness Tubing Note on materials 2016/01 – Subject to change D 52 _3 PE Conforms to RoHS Free of copper and PTFE è Internet: www.festo.com/catalogue/... 19 Plastic tubing PEN Technical data Dimensions and ordering data O.D. I.D. [mm] [mm] Min. bending radius [mm] 4 2.7 10 20 0.0064 6 4 13.5 26 0.0148 8 5.7 22.5 35 0.0233 10 7 23.5 40 0.0377 12 8.4 33 58 0.0542 1) 20 Flow-relevant bending radius [mm] Weight Colour Part No. PU1) Type [kg/m] [m] Black Black Blue Blue Silver Silver Natural Green Red Yellow Black Black Blue Blue Silver Silver Natural Green Red Yellow Black Black Blue Blue Silver Silver Natural Green Red Yellow Black Black Blue Blue Silver Silver Natural Green Red Yellow Black Black Blue Blue Silver Silver Natural Green Red Yellow 543240 551438 551456 551444 551462 551450 543246 551468 551474 551480 543241 551439 551457 551445 551463 551451 543247 551469 551475 551481 543242 551440 551458 551446 551464 551452 543248 551470 551476 551482 543243 551441 551459 551447 551465 551453 543249 551471 551477 551483 543244 551442 551460 551448 551466 551454 543250 551472 551478 551484 PEN-4x0,75-SW PEN-4x0,75-SW-500 PEN-4x0,75-BL PEN-4x0,75-BL-500 PEN-4x0,75-SI PEN-4x0,75-SI-500 PEN-4x0,75-NT PEN-4x0,75-GN PEN-4x0,75-RT PEN-4x0,75-GE PEN-6x1-SW PEN-6x1-SW-500 PEN-6x1-BL PEN-6x1-BL-500 PEN-6x1-SI PEN-6x1-SI-500 PEN-6x1-NT PEN-6x1-GN PEN-6x1-RT PEN-6x1-GE PEN-8x1,25-SW PEN-8x1,25-SW-400 PEN-8x1,25-BL PEN-8x1,25-BL-400 PEN-8x1,25-SI PEN-8x1,25-SI-400 PEN-8x1,25-NT PEN-8x1,25-GN PEN-8x1,25-RT PEN-8x1,25-GE PEN-10x1,5-SW PEN-10x1,5-SW-300 PEN-10x1,5-BL PEN-10x1,5-BL-300 PEN-10x1,5-SI PEN-10x1,5-SI-300 PEN-10x1,5-NT PEN-10x1,5-GN PEN-10x1,5-RT PEN-10x1,5-GE PEN-12x1,75-SW PEN-12x1,75-SW-200 PEN-12x1,75-BL PEN-12x1,75-BL-200 PEN-12x1,75-SI PEN-12x1,75-SI-200 PEN-12x1,75-NT PEN-12x1,75-GN PEN-12x1,75-RT PEN-12x1,75-GE 50 500 50 500 50 500 50 50 50 50 50 500 50 500 50 500 50 50 50 50 50 400 50 400 50 400 50 50 50 50 50 300 50 300 50 300 50 50 50 50 50 200 50 200 50 200 50 50 50 50 Packaging unit è Internet: www.festo.com/catalogue/... Subject to change – 2016/01 Plastic tubing PEN Technical data Dimensions and ordering data O.D. I.D. [mm] [mm] Min. bending radius [mm] 14 9.5 45 80 0.0773 16 10.8 57.5 122 0.1029 1) Flow-relevant bending radius [mm] Weight Colour Part No. Type [kg/m] PU1) [m] Black Natural Black Black Blue Blue Silver Silver Natural Green Red Yellow 570516 570517 543245 551443 551461 551449 551467 551455 543251 551473 551479 551485 PEN-14x2-SW PEN-14x2-NT PEN-16x2,5-SW PEN-16x2,5-SW-100 PEN-16x2,5-BL PEN-16x2,5-BL-100 PEN-16x2,5-SI PEN-16x2,5-SI-100 PEN-16x2,5-NT PEN-16x2,5-GN PEN-16x2,5-RT PEN-16x2,5-GE 50 50 50 100 50 100 50 100 50 50 50 50 Packaging unit 2016/01 – Subject to change è Internet: www.festo.com/catalogue/... 21 Plastic tubing PEN Ordering data – Modular products Ordering table (minimum order quantity 3,000 m, rounding-off value 25 m) Size 4 6 8 10 0 M Module No. 14 16 Condi­ tions Code Enter code PEN PEN 553769 Function Polyethylene tubing, standard O.D., economical Tubing O.D. [mm] 4 – – – – – – Silver Blue Black Yellow Green Red Brown White Natural Colour 0 O Inscription text (on request) 0 M Packaging unit Packaging – 6 – – – – – – – 8 – – – – – – – 10 – – – – – – – 12 – – – – – – 14 – – – – – – – 16 Standard Customer-specific tubing inscription [m] 25 50 100 200 300 400 500 Cardboard box Reel 1 TXT Only on request 2 CB Only with packaging unit 25, 50 Transfer order code 553769 PEN 22 12 – – – – – 3 HA – – è Internet: www.festo.com/catalogue/... – – – -4 -6 -8 -10 -12 -14 -16 -SI -BL -SW -GE -GN -RT -BR -WS -NT 1 -TXT 2 3 -25 -50 -100 -200 -300 -400 -500 -CB -HA – – – – Not with packaging unit 25, 50 – – – Subject to change – 2016/01 Plastic tubing PLN Technical data Plastic tubing PLN Polyethylene tubing is distinguished by great resistance to chemicals and hydrolysis. It is resistant to most cleaning agents and lubricants. Operating and environmental conditions Temperature dependent operating pressure Operating medium [bar] Ambient temperature Approval [°C] –0.95 … +14 è diagram Compressed air in accordance with ISO 8573­1:2010 [7:–:–] Water as per manufacturer's declaration è www.festo.com –30 … +80 German Technical Control Board (TÜV) p [bar] Operating pressure p as a function of temperature t t [°C] Possible fittings Push-in fittings QS, Quick Star è Internet: qs Push-in fittings NPQH1) è Internet: npqh Push-in fittings CRQS, Quick Star, stainless steel è Internet: crqs Push-in fittings NPQM è Internet: npqm Push-in fittings NPQP1) è Internet: npqp Quick connectors CK è Internet: ck -HBarbed fittings CN è Internet: cn 1) 2016/01 – Subject to change Recommended fitting è Internet: www.festo.com/catalogue/... Note Greater force is required when as­ sembling the fittings CK/CN. Flaring the tube ends using a tapered man­ drel makes pushing them on easier. 23 Plastic tubing PLN Technical data Materials Tubing Note on materials PE Conforms to RoHS Free of copper and PTFE Dimensions and ordering data O.D. I.D. [mm] [mm] Min. bending radius [mm] 4 2.9 12 25 0.0056 6 4 11 32 0.0147 8 5.9 23 50 0.0214 10 7 22 57 0.0375 12 8.4 23 65 0.0540 14 10 40 80 0.07 16 12 55 95 0.0820 1) 24 Flow-relevant bending radius [mm] Weight PU1) Colour Part No. Type Natural Black Blue Silver Red Natural Black Blue Silver Red Natural Black Blue Silver Red Natural Black Blue Silver Red Natural Black Blue Silver Red Natural Black Natural Black Blue Silver Red 193403 195280 558205 558211 558217 193404 195281 558206 558212 558218 193405 195282 558207 558213 558219 193406 195283 558208 558214 558220 193407 195284 558209 558215 558221 570424 570423 539064 539065 558210 558216 558222 PLN-4x0,75-NT PLN-4x0,75-SW PLN-4x0,75-BL PLN-4x0,75-SI PLN-4x0,75-RT PLN-6x1-NT PLN-6x1-SW PLN-6x1-BL PLN-6x1-SI PLN-6x1-RT PLN-8x1,25-NT PLN-8x1,25-SW PLN-8x1,25-BL PLN-8x1,25-SI PLN-8x1,25-RT PLN-10x1,5-NT PLN-10x1,5-SW PLN-10x1,5-BL PLN-10x1,5-SI PLN-10x1,5-RT PLN-12x1,75-NT PLN-12x1,75-SW PLN-12x1,75-BL PLN-12x1,75-SI PLN-12x1,75-RT PLN-14x2-NT PLN-14x2-SW PLN-16x2-NT PLN-16x2-SW PLN-16x2-BL PLN-16x2-SI PLN-16x2-RT [kg/m] [m] 50 50 50 50 50 50 50 50 50 50 50 50 50 50 50 50 50 50 50 50 50 50 50 50 50 50 50 50 50 50 50 50 Packaging unit è Internet: www.festo.com/catalogue/... Subject to change – 2016/01 Plastic tubing PLN Ordering data – Modular products Ordering table (minimum order quantity 3,000 m, rounding-off value 25 m) Size 4 6 8 10 0 M Module No. 12 14 16 Condi­ tions Code Enter code PLN PLN 553850 Function Polyethylene tubing, standard O.D., resistant to cleaning agents Tubing O.D. [mm] 4 – – – – – – Silver Blue Black Yellow Green Red Brown White Natural Colour 0 O Inscription text (on request) 0 M Packaging unit Packaging [m] 25 50 100 200 300 400 500 Cardboard box Reel Only on request 2 CB Only with packaging unit 25, 50 2016/01 – Subject to change – – 8 – – – – – – – 10 – – – – – – – 12 – – – – – – 14 – – – – – – – 16 Standard Customer-specific tubing inscription 1 TXT Transfer order code 553850 PLN – 6 – – – – – – – – – – – 3 HA – – – – – -4 -6 -8 -10 -12 -14 -16 -SI -BL -SW -GE -GN -RT -BR -WS -NT 1 -TXT 2 3 -25 -50 -100 -200 -300 -400 -500 -CB -HA – – – – Not with packaging unit 25, 50 – – è Internet: www.festo.com/catalogue/... – 25 Plastic tubing PUN Technical data Plastic tubing PUN Highly flexible plastic tubing Operating and environmental conditions Temperature dependent operating pressure Operating medium Ambient temperature Fire test material Approval –0.95 … +10 è diagram [bar] Compressed air in accordance with ISO 8573­1:2010 [7:–:–] –35 … +60 UL94 HB German Technical Control Board (TÜV) [°C] p [bar] Operating pressure p as a function of temperature t t [°C] Possible fittings Push-in fittings QS, Quick Star1) è Internet: qs Push-in fittings QS-B, Quick Star1) è Internet: qs-b Push-in fittings CRQS, Quick Star, stainless steel è Internet: crqs Push-in fittings NPQM è Internet: npqm Quick connectors CK è Internet: ck Barbed fittings CN è Internet: cn 1) Recommended fitting -H- Note Greater force is required when as­ sembling the fittings CK/CN. Flaring the tube ends using a tapered man­ drel makes pushing them on easier. Materials Shore hardness Tubing Note on materials 26 D 52 _3 TPE-U(PU) Conforms to RoHS Free of copper and PTFE è Internet: www.festo.com/catalogue/... Subject to change – 2016/01 Plastic tubing PUN Technical data Dimensions and ordering data O.D. I.D. [mm] [mm] Min. bending radius [mm] 3.0 2.1 9 12 0.0044 4.0 2.6 8 17 0.0089 6.0 4.0 16 26.5 0.0192 8.0 5.7 24 37 0.0302 10.0 7.0 28 54 0.0489 1) Flow-relevant bending radius [mm] Weight Colour Part No. Type [kg/m] PU1) [m] Silver Silver Blue Blue Black Black Yellow Green Red Silver Silver Blue Blue Black Black Yellow Green Red Silver Silver Blue Blue Black Black Yellow Green Red Silver Silver Blue Blue Black Black Yellow Green Red Silver Silver Blue Blue Black Black Yellow Green Red 152583 525738 159660 525745 159661 553936 178416 178423 178409 152584 525739 159662 525746 159663 553937 178417 178424 178410 152586 525740 159664 525747 159665 553938 178418 178425 178411 152587 525741 159666 525748 159667 553939 178419 178426 178412 152588 525742 159668 525749 159669 553940 178420 178427 178413 PUN-3x0,5-SI PUN-3 x 0,5-SI-500 PUN-3x0,5-BL PUN-3x0,5-BL-500 PUN-3x0,5-SW PUN-3x0,5-SW-500 PUN-3x0,5-GE PUN-3x0,5-GN PUN-3x0,5-RT PUN-4x0,75-SI PUN-4x0,75-SI-500 PUN-4x0,75-BL PUN-4x0,75-BL-500 PUN-4x0,75-SW PUN-4x0,75-SW-500 PUN-4x0,75-GE PUN-4x0,75-GN PUN-4x0,75-RT PUN-6x1-SI PUN-6x1-SI-500 PUN-6x1-BL PUN-6x1-BL-500 PUN-6x1-SW PUN-6x1-SW-500 PUN-6x1-GE PUN-6x1-GN PUN-6x1-RT PUN-8x1,25-SI PUN-8x1,25-SI-400 PUN-8x1,25-BL PUN-8x1,25-BL-400 PUN-8x1,25-SW PUN-8x1,25-SW-400 PUN-8x1,25-GE PUN-8x1,25-GN PUN-8x1,25-RT PUN-10x1,5-SI PUN-10x1,5-SI-300 PUN-10x1,5-BL PUN-10x1,5-BL-300 PUN-10x1,5-SW PUN-10x1,5-SW-300 PUN-10x1,5-GE PUN-10x1,5-GN PUN-10x1,5-RT 50 500 50 500 50 500 50 50 50 50 500 50 500 50 500 50 50 50 50 500 50 500 50 500 50 50 50 50 400 50 400 50 400 50 50 50 50 300 50 300 50 300 50 50 50 Packaging unit 2016/01 – Subject to change è Internet: www.festo.com/catalogue/... 27 Plastic tubing PUN Technical data Dimensions and ordering data O.D. I.D. [mm] [mm] Min. bending radius [mm] 12.0 8.0 33 62 0.0767 14.0 9.8 45 84 0.0949 16.0 11.0 45 88 0.1294 1) 28 Flow-relevant bending radius [mm] Weight Colour Part No. PU1) Type [kg/m] [m] Silver Silver Blue Blue Black Black Yellow Green Red Silver Blue Black Silver Silver Blue Blue Black Black Yellow Green Red 152589 525743 159670 525750 159671 553941 178421 178428 178414 570389 570390 570391 152590 525744 159672 525751 159673 553942 178422 178429 178415 PUN-12x2-SI PUN-12x2-SI-200 PUN-12x2-BL PUN-12x2-BL-200 PUN-12x2-SW PUN-12x2-SW-200 PUN-12x2-GE PUN-12x2-GN PUN-12x2-RT PUN-14x2-SI PUN-14x2-BL PUN-14x2-SW PUN-16x2,5-SI PUN-16x2,5-SI-100 PUN-16x2,5-BL PUN-16x2,5-BL-100 PUN-16x2,5-SW PUN-16x2,5-SW-100 PUN-16x2,5-GE PUN-16x2,5-GN PUN-16x2,5-RT 50 200 50 200 50 200 50 50 50 50 50 50 50 100 50 100 50 100 50 50 50 Packaging unit è Internet: www.festo.com/catalogue/... Subject to change – 2016/01 Plastic tubing PUN-DUO Technical data DUO tubing PUN-DUO Highly flexible paired plastic tubing distinguished by great resistance to abrasion and kinks. Two lengths of tubing are fused together into a tubing pair. For fitting, the paired tubing is separated as required at both ends. Operating and environmental conditions Temperature dependent operating pressure Operating medium Ambient temperature Fire test material Approval –0.95 … +10 è diagram [bar] Compressed air in accordance with ISO 8573­1:2010 [7:–:–] –35 … +60 UL94 HB German Technical Control Board (TÜV) [°C] p [bar] Operating pressure p as a function of temperature t t [°C] Possible fittings Push-in fittings QS, Quick Star1) è Internet: qs Push-in fittings QS-B, Quick Star1) è Internet: qs-b Push-in fittings CRQS, Quick Star, stainless steel è Internet: crqs Push-in fittings NPQM è Internet: npqm Quick connectors CK è Internet: ck Barbed fittings CN è Internet: cn 1) Recommended fitting -H- Note Greater force is required when as­ sembling the fittings CK/CN. Flaring the tube ends using a tapered man­ drel makes pushing them on easier. Materials Shore hardness Tubing Note on materials 2016/01 – Subject to change D 52 _3 TPE-U(PU) Conforms to RoHS Free of copper and PTFE è Internet: www.festo.com/catalogue/... 29 Plastic tubing PUN-DUO Technical data Dimensions and ordering data O.D. I.D. [mm] [mm] Min. bending radius [mm] 4 2.6 8 17 0.018 6 4 14 26.5 0.038 8 5.7 20 37 0.060 10 7 25 54 0.098 1) 30 Flow-relevant bending radius [mm] Weight Colour Part No. PU1) Type [kg/m] [m] Silver Blue/black Silver Blue/black Silver Blue/black Silver Blue/black 152822 159674 152823 159675 152824 159676 152825 159677 PUN-4x0,75-DUO-SI PUN-4x0,75-DUO-BS PUN-6x1-DUO-SI PUN-6x1-DUO-BS PUN-8x1,25-DUO-SI PUN-8x1,25-DUO-BS PUN-10x1,5-DUO-SI PUN-10x1,5-DUO-BS 50 50 50 50 50 50 50 50 Packaging unit è Internet: www.festo.com/catalogue/... Subject to change – 2016/01 Plastic tubing PUN-CM, antistatic Technical data Plastic tubing PUN-CM Highly flexible plastic tubing, electrically conductive. Operating and environmental conditions Temperature dependent operating pressure Operating medium Ambient temperature Surface resistance [bar] –0.95 … +10 è diagram [°C] [Ω] Compressed air in accordance with ISO 8573­1:2010 [7:–:–] –35 … +60 104 … 107 Operating pressure p as a function of temperature t Possible fittings Push-in fittings NPQM è Internet: npqm Materials D 52 _3 TPE-U(PU) Conforms to RoHS Free of copper and PTFE Shore hardness Tubing Note on materials Dimensions and ordering data O.D. I.D. [mm] [mm] Min. bending radius [mm] 4 6 8 10 12 2.5 4 5.5 7 8 5 13 14 19 22 1) Flow-relevant bending radius [mm] Weight 17 26.5 37 54 70 0.0089 0.0192 0.0368 0.0544 0.0754 Colour Part No. Type [kg/m] PU1) [m] Black 188882 188883 130816 130817 130818 PUN-CM-4-SW PUN-CM-6-SW PUN-CM-8-SW PUN-CM-10-SW PUN-CM-12-SW 50 50 50 50 50 Packaging unit 2016/01 – Subject to change è Internet: www.festo.com/catalogue/... 31 Plastic tubing PUN-H, hydrolysis resistant Technical data Plastic tubing PUN-H With tubing outside diameter of 2 mm Operating and environmental conditions [bar] –0.95 … +10 è diagram [°C] Compressed air in accordance with ISO 8573­1:2010 [7:–:–] –35 … +60 Operating pressure p as a function of temperature t Possible fittings p [bar] Temperature dependent operating pressure Operating medium Ambient temperature Push-in fittings QSM, Quick Star, mini è Internet: qsm t [°C] Materials D 52 _3 TPE-U(PU) Conforms to RoHS Free of copper and PTFE Shore hardness Tubing Note on materials Dimensions and ordering data O.D. I.D. [mm] [mm] Min. bending radius [mm] 2 1.2 5 1) 32 Flow-relevant bending radius [mm] Weight 8 0.0024 Colour Part No. PU1) Type [kg/m] [m] Natural Black Red 133038 133039 133040 PUN-H-2x0,4-NT PUN-H-2x0,4-SW PUN-H-2x0,4-RT 50 50 50 Packaging unit è Internet: www.festo.com/catalogue/... Subject to change – 2016/01 Plastic tubing PUN-H, hydrolysis resistant Technical data Plastic tubing PUN-H With tubing outside diameters of 3 … 16 mm Operating and environmental conditions Temperature dependent operating pressure Operating medium [bar] Ambient temperature Approval [°C] –0.95 … +10 è diagram Compressed air in accordance with ISO 8573­1:2010 [7:–:–] Water as per manufacturer's declaration è www.festo.com –35 … +60 German Technical Control Board (TÜV) p [bar] Operating pressure p as a function of temperature t t [°C] Possible fittings Push-in fittings QS, Quick Star è Internet: qs Push-in fittings NPQH è Internet: npqh Push-in fittings CRQS, Quick Star, stainless steel è Internet: crqs Push-in fittings NPQP1) è Internet: npqp Quick connectors CK è Internet: ck 1) Recommended fitting Materials Shore hardness Tubing Note on materials 2016/01 – Subject to change D 52 _3 TPE-U(PU) Conforms to RoHS Free of copper and PTFE è Internet: www.festo.com/catalogue/... 33 Plastic tubing PUN-H, hydrolysis resistant Technical data Dimensions and ordering data O.D. I.D. [mm] [mm] Min. bending radius [mm] 3 2.1 6 12 0.0042 4 2.6 6 16 0.0085 6 4 10 26 0.0183 8 5.7 20 37 0.0287 1) 34 Flow-relevant bending radius [mm] Weight Colour Part No. PU1) Type [kg/m] [m] Natural Natural Blue Blue Black Black Silver Silver Red Green Yellow Natural Natural Blue Blue Black Black Silver Silver Red Green Yellow Natural Natural Blue Blue Black Black Silver Silver Red Green Yellow Natural Natural Blue Blue Black Black Silver Silver Red Green Yellow 197375 558263 197382 558256 197389 558249 558277 558270 558284 558291 558298 197376 558264 197383 558257 197390 558250 558278 558271 558285 558292 558299 197377 558265 197384 558258 197391 558251 558279 558272 558286 558293 558300 197378 558266 197385 558259 197392 558252 558280 558273 558287 558294 558301 PUN-H-3x0,5-NT PUN-H-3x0,5-NT-500 PUN-H-3x0,5-BL PUN-H-3x0,5 BL-500 PUN-H-3x0,5-SW PUN-H-3x0,5-SW-500 PUN-H-3x0,5-SI PUN-H-3x0,5-SI-500 PUN-H-3x0,5-RT PUN-H-3x0,5-GN PUN-H-3x0,5-GE PUN-H-4x0,75-NT PUN-H-4x0,75-NT-500 PUN-H-4x0,75-BL PUN-H-4x0,75-BL-500 PUN-H-4x0,75-SW PUN-H-4x0,75-SW-500 PUN-H-4x0,75-SI PUN-H-4x0,75-SI-500 PUN-H-4x0,75-RT PUN-H-4x0,75-GN PUN-H-4x0,75-GE PUN-H-6x1-NT PUN-H-6x1-NT-500 PUN-H-6x1-BL PUN-H-6x1-BL-500 PUN-H-6x1-SW PUN-H-6x1-SW-500 PUN-H-6x1-SI PUN-H-6x1-SI-500 PUN-H-6x1-RT PUN-H-6x1-GN PUN-H-6x1-GE PUN-H-8x1,25-NT PUN-H-8x1,25-NT-400 PUN-H-8x1,25-BL PUN-H-8x1,25-BL-400 PUN-H-8x1,25-SW PUN-H-8x1,25-SW-400 PUN-H-8x1,25-SI PUN-H-8x1,25-SI-400 PUN-H-8x1,25-RT PUN-H-8x1,25-GN PUN-H-8x1,25-GE 50 500 50 500 50 500 50 500 50 50 50 50 500 50 50 500 500 50 500 50 50 50 50 500 50 500 50 500 50 500 50 50 50 50 400 50 400 50 400 50 400 50 50 50 Packaging unit è Internet: www.festo.com/catalogue/... Subject to change – 2016/01 Plastic tubing PUN-H, hydrolysis resistant Technical data Dimensions and ordering data O.D. I.D. [mm] [mm] Min. bending radius [mm] 10 7 25 52 0.0465 12 8 23 62 0.0729 14 9.8 38 78 0.091 16 11 38 88 0.1230 1) Flow-relevant bending radius [mm] Weight Colour Part No. Type [kg/m] PU1) [m] Natural Natural Blue Blue Black Black Silver Silver Red Green Yellow Natural Natural Blue Blue Black Black Silver Silver Red Green Yellow Natural Blue Black Natural Natural Blue Blue Black Black Silver Silver Red Green Yellow 197379 558267 197386 558260 197393 558253 558281 558274 558288 558295 558302 197380 558268 197387 558261 197394 558254 558282 558275 558289 558296 558303 570388 570386 570387 197381 558269 197388 558262 197395 558255 558283 558276 558290 558297 558304 PUN-H-10x1,5-NT PUN-H-10x1,5-NT-300 PUN-H-10x1,5-BL PUN-H-10x1,5-BL-300 PUN-H-10x1,5-SW PUN-H-10x1,5-SW-300 PUN-H-10x1,5-SI PUN-H-10x1,5-SI-300 PUN-H-10x1,5-RT PUN-H-10x1,5-GN PUN-H-10x1,5-GE PUN-H-12x2-NT PUN-H-12x2-NT-200 PUN-H-12x2-BL PUN-H-12x2-BL-200 PUN-H-12x2-SW PUN-H-12x2-SW-200 PUN-H-12x2-SI PUN-H-12x2-SI-200 PUN-H-12x2-RT PUN-H-12x2-GN PUN-H-12x2-GE PUN-H-14x2-NT PUN-H-14x2-BL PUN-H-14x2-SW PUN-H-16x2,5-NT PUN-H-16x2,5-NT-100 PUN-H-16x2,5-BL PUN-H-16x2,5-BL-100 PUN-H-16x2,5-SW PUN-H-16x2,5-SW-100 PUN-H-16x2,5-SI PUN-H-16x2,5-SI-100 PUN-H-16x2,5-RT PUN-H-16x2,5-GN PUN-H-16x2,5-GE 50 300 50 300 50 300 50 300 50 50 50 50 200 50 200 50 200 50 200 50 50 50 50 50 50 50 100 50 100 50 100 50 100 50 50 50 Packaging unit 2016/01 – Subject to change è Internet: www.festo.com/catalogue/... 35 Plastic tubing PUN-H-DUO, hydrolysis resistant Technical data DUO tubing PUN-H-DUO Highly flexible paired plastic tubing distinguished by great resistance to abrasion and kinks. Two lengths of tubing are fused together into a tubing pair. For fitting, the paired tubing is separated as required at both ends. Operating and environmental conditions Temperature dependent operating pressure Operating medium [bar] Ambient temperature Approval [°C] –0.95 … +10 è diagram Compressed air in accordance with ISO 8573­1:2010 [7:–:–] Water as per manufacturer's declaration è www.festo.com –35 … +60 German Technical Control Board (TÜV) Possible fittings p [bar] Operating pressure p as a function of temperature t t [°C] Push-in fittings QS, Quick Star è Internet: qs Push-in fittings NPQH è Internet: npqh Push-in fittings CRQS, Quick Star, stainless steel è Internet: crqs Push-in fittings NPQP1) è Internet: npqp Quick connectors CK è Internet: ck 1) Recommended fitting Materials D 52 _3 TPE-U(PU) Conforms to RoHS Free of copper and PTFE Shore hardness Tubing Note on materials Dimensions and ordering data O.D. I.D. [mm] [mm] Min. bending radius [mm] 4 6 8 10 2.6 4 5.7 7 6 10 20 25 1) 36 Flow-relevant bending radius [mm] Weight 16 26 37 52 0.0170 0.0366 0.0574 0.0930 Colour Part No. PU1) Type [kg/m] [m] Blue/black 197396 197397 197398 197399 PUN-H-4x0,75-DUO PUN-H-6x1-DUO PUN-H-8x1,25-DUO PUN-H-10x1,5-DUO 50 50 50 50 Packaging unit è Internet: www.festo.com/catalogue/... Subject to change – 2016/01 Plastic tubing PUN-V0, flame retardant Technical data Plastic tubing PUN-V0 -H- Highly flexible single-sheath plastic tubing, flame retardant Due to the included flame retardant, the colour of the tubing deviates from the standard colour. Note For use in indirect proximity to welding applications. Operating and environmental conditions Temperature dependent operating pressure Operating medium [bar] Ambient temperature Fire test Fire test material Approval [°C] –0.95 … +10 è diagram Compressed air in accordance with ISO 8573­1:2010 [7:–:–] Water as per manufacturer's declaration è www.festo.com –35 … +60 DIN 5510-2 S4/SR2/ST2 UL94 V2 German Technical Control Board (TÜV) Operating pressure p as a function of temperature t PUN-V0-… PUN-V0-16 Possible fittings Push-in fittings QS, Quick Star è Internet: qs Push-in fittings NPQH1) è Internet: npqh Push-in fittings QS-V0, Quick Star, flame-retardant è Internet: qs-v0 Push-in fittings CRQS, Quick Star, stainless steel è Internet: crqs Push-in fittings NPQM1) è Internet: npqm Quick connectors CK è Internet: ck -HBarbed fittings CN è Internet: cn 1) Note Greater force is required when as­ sembling the fittings CK/CN. Recommended fitting Materials Shore hardness Tubing Note on materials 2016/01 – Subject to change D 54 _3 TPE-U(PU) Conforms to RoHS Free of copper and PTFE è Internet: www.festo.com/catalogue/... 37 Plastic tubing PUN-V0, flame retardant Technical data Dimensions and ordering data O.D. I.D. [mm] [mm] Min. bending radius [mm] 6 4 12 26.5 0.020 8 5.7 18 37 0.031 10 7 20 54 0.051 16 11.8 50 90 0.122 1) 38 Flow-relevant bending radius [mm] Weight Colour Part No. PU1) Type [kg/m] [m] Black Blue Green Red White Yellow Brown Black Blue Green Red White Yellow Brown Black Blue Green Red White Yellow Brown Black Blue 525438 525442 525446 525450 525454 525458 525462 525439 525443 525447 525451 525455 525459 525463 525440 525444 525448 525452 525456 525460 525464 570767 570768 PUN-V0-6x1-SW PUN-V0-6x1-BL PUN-V0-6x1-GN PUN-V0-6x1-RT PUN-V0-6x1-WS PUN-V0-6x1-GE PUN-V0-6x1-BR PUN-V0-8x1,25-SW PUN-V0-8x1,25-BL PUN-V0-8x1,25-GN PUN-V0-8x1,25-RT PUN-V0-8x1,25-WS PUN-V0-8x1,25-GE PUN-V0-8x1,25-BR PUN-V0-10x1,5-SW PUN-V0-10x1,5-BL PUN-V0-10x1,5-GN PUN-V0-10x1,5-RT PUN-V0-10x1,5-WS PUN-V0-10x1,5-GE PUN-V0-10x1,5-BR PUN-V0-16x2-SW PUN-V0-16x2-BL 50 50 50 50 50 50 50 50 50 50 50 50 50 50 50 50 50 50 50 50 50 50 50 Packaging unit è Internet: www.festo.com/catalogue/... Subject to change – 2016/01 Plastic tubing PUN-V0-C, flame retardant Technical data Plastic tubing PUN-V0-C -H- Highly flexible single-sheath plastic tubing, flame retardant Due to the included flame retardant, the colour of the tubing deviates from the standard colour. Note For use in the immediate vicinity of welding applications. Operating and environmental conditions Type PUN-V0-4 Temperature dependent operating pressure Operating medium [bar] Ambient temperature Fire test Fire test material Approval [°C] 1) PUN-V0-6 PUN-V0-8 PUN-V0-10 –0.95 … +10 –0.95 … +301) –0.95 … +201) –0.95 … +161) è diagram è diagram è diagram è diagram Compressed air in accordance with ISO 8573­1:2010 [7:–:–] Water as per manufacturer's declaration è www.festo.com –35 … +60 DIN 5510-2 S3/SR2/ST1 UL94 V2 German Technical Control Board (TÜV) PUN-V0-12 PUN-V0-14 PUN-V0-16 –0.95 … +10 è diagram –0.95 … +9 è diagram –0.95 … +10 è diagram Limited to 10 bar in applications with welding spatter. Operating pressure p as a function of temperature t PUN-VO-…-C PUN-VO-14x2-…-C For applications without welding spatter PUN-VO-6x2-…-C PUN-VO-8x2-…-C PUN-VO-10x2-…-C Possible fittings Push-in fittings QS, Quick Star è Internet: qs Push-in fittings NPQH1) è Internet: npqh Push-in fittings QS-V0, Quick Star, flame-retardant è Internet: qs-v0 Push-in fittings CRQS, Quick Star, stainless steel è Internet: crqs Push-in fittings NPQM1) è Internet: npqm Quick connectors CK è Internet: ck -HBarbed fittings CN è Internet: cn 1) 2016/01 – Subject to change Note Greater force is required when as­ sembling the fittings CK/CN. Recommended fitting è Internet: www.festo.com/catalogue/... 39 Plastic tubing PUN-V0-C, flame retardant Technical data Materials D 54 _3 TPE-U(PU) Conforms to RoHS Free of copper and PTFE Shore hardness Tubing Note on materials Dimensions and ordering data Outer Inner [mm] [mm] [mm] Bending radius relevant for flow rate [mm] 4 2 10 20 0.012 6 2 7 24 0.032 8 4 9 35 0.049 10 6 12 42 0.064 12 8 19 55 0.080 14 9.8 45 70 0.096 16 11 50 90 0.147 1) 40 Min. bending radius Weight PU1) Colour Part No. Type Black Blue Black Blue Green Red White Yellow Brown Black Blue Green Red White Yellow Brown Black Blue Green Red White Yellow Brown Black Blue Green Red White Yellow Brown Black Blue Black Blue 570349 570350 561698 561702 561706 561710 561714 561718 561722 561699 561703 561707 561711 561715 561719 561723 561700 561704 561708 561712 561716 561720 561724 561701 561705 561709 561713 561717 561721 561725 570351 570352 570353 570354 PUN-V0-4x1-SW-C PUN-V0-4x1-BL-C PUN-V0-6x2-SW-C PUN-V0-6x2-BL-C PUN-V0-6x2-GN-C PUN-V0-6x2-RT-C PUN-V0-6x2-WS-C PUN-V0-6x2-GE-C PUN-V0-6x2-BR-C PUN-V0-8x2-SW-C PUN-V0-8x2-BL-C PUN-V0-8x2-GN-C PUN-V0-8x2-RT-C PUN-V0-8x2-WS-C PUN-V0-8x2-GE-C PUN-V0-8x2-BR-C PUN-V0-10x2-SW-C PUN-V0-10x2-BL-C PUN-V0-10x2-GN-C PUN-V0-10x2-RT-C PUN-V0-10x2-WS-C PUN-V0-10x2-GE-C PUN-V0-10x2-BR-C PUN-V0-12x2-SW-C PUN-V0-12x2-BL-C PUN-V0-12x2-GN-C PUN-V0-12x2-RT-C PUN-V0-12x2-WS-C PUN-V0-12x2-GE-C PUN-V0-12x2-BR-C PUN-V0-14x2-SW-C PUN-V0-14x2-BL-C PUN-V0-16x2,5-SW-C PUN-V0-16x2,5-BL-C [kg/m] [m] 50 50 50 50 50 50 50 50 50 50 50 50 50 50 50 50 50 50 50 50 50 50 50 50 50 50 50 50 50 50 50 50 50 50 Packaging unit è Internet: www.festo.com/catalogue/... Subject to change – 2016/01 Plastic tubing PUN Ordering data – Modular products Ordering table (minimum order quantity 3,000 m, rounding-off value 25 m) Size 3 4 6 8 0 M Module No. 10 12 14 16 Condi­ tions Enter code PUN PUN 553573 Function Polyurethane tubing, standard O.D. 0 O Alternative material characteristic 0 M Tubing O.D. Standard Hydrolysis-resistant – Antistatic – – Flame-retardant – Resistant to welding spatter [mm] 3 – – – – – – – Silver Blue Black Yellow Green Red Brown White Natural Colour 0 O Inscription text (on request) 0 M Packaging unit Packaging – 4 – – – – – – – – 6 – – – – – -H -CM -V0 -V0C – – – – – 8 – – – – – – – – 10 – – – – – – – – 12 – – – – – – 14 – – – – – – – – – 16 -3 -4 -6 -8 -10 -12 -14 -16 12 -SI 13 -BL 3 -SW 1 -GE 1 -GN 1 -RT 1 -BR 1 -WS 1 3 4 -NT Standard Customer-specific tubing inscription [m] 25 50 100 200 300 400 500 Cardboard box Reel – – – 1 SI, BL, GE, GN, RT, BR, WS, NT 5 TXT Not with alternative material characteristic CM – – – – – – – 5 -TXT 6 7 -25 -50 -100 -200 -300 -400 -500 -CB -HA – – – – Not in the online shop. Festo logo, order code, TÜV, operating pressure, dimensions omitted 2 SI Not with alternative material characteristic V0, V0C 6 CB Only with packaging unit 25, 50 3 BL, SW, NT In combination with alternative material characteristic H: 7 HA Not with packaging unit 25, 50 approved for use in the food industry 4 NT Code Not with alternative material characteristic V0, V0C, CM Only with alternative material characteristic H Transfer order code 553573 PUN 2016/01 – Subject to change – – – – – è Internet: www.festo.com/catalogue/... – 41