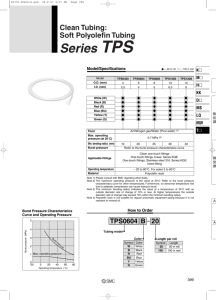

Thermoplastic Tubing

advertisement

Thermoplastic Tubing Burst vs. Temperature Data IMPOLENE TUBING Burst Versus Temperature -IMPOLENE PY AND PP BLACK 1000 900 MINIMUM BURST PRESSURE. PSI 22,33,44,55,66, PY & PPBK 800 700 88PY & 88PPBK 600 500 400 300 200 100 0 70 200 150 TEMPERATURE (˚F), SUGGESTED WORKING PRESSURE IS 1/4 OF BURST PRESSURE AT THE SYSTEM OPERATING TEMPERATURE Burst Versus Temperature -NYLO SEAL NT, NH, SNBK, NSRBK, AND NF TUBING 3000 NH & NSRBK (EXCEPT 88 SIZE) MINIMUM BURST PRESSURE. PSI 2500 88NH & 88NSRBK 2000 NT & SNBK - ALL SIZES 1500 NF - ALL SIZES 1000 500 0 70 150 200 TEMPERATURE (˚F), SUGGESTED WORKING PRESSURE IS 1/4 OF BURST PRESSURE AT THE SYSTEM OPERATING TEMPERATURE 98 Thermoplastic Tubing Burst vs. Temperature Data POLY-FLO TUBING Burst Versus Temperature - POLY -FLO P, PE, PF TUBING 450 MINIMUM BURST PRESSURE. PSI 400 44 P, PE, PF 350 300 66 P, PE, PF 250 200 88 P, PE, PF 150 100 50 0 70 175 150 TEMPERATURE (˚F), SUGGESTED WORKING PRESSURE IS 1/4 OF BURST PRESSURE AT THE SYSTEM OPERATING TEMPERATURE PVC CLEAR TUBING Burst Versus Temperature - PVC TUBING 250 MINIMUM BURST PRESSURE. PSI 44PVCCLR 200 66PVCCLR 150 88PVCCLR 100 50 0 70 135 105 165 TEMPERATURE (˚F), SUGGESTED WORKING PRESSURE IS 1/4 OF BURST PRESSURE AT THE SYSTEM OPERATING TEMPERATURE 99 Thermoplastic Tubing Poly-Flo, PE (NSF Approved) Linear Low Density Polyethylene Tubing Burst Pressure at 73˚ F (PSI) Working Pressure at 73˚ F (PSI) Min. Bend Radius (Inches) Weight (Approx.) Per C Ft. (Lbs.) Part No. Tube O.D. (Inches) Tube Wall Thickness (Inches) 22PE 532PE 33PE 44PE 66PE 88PE 1/8 5/32 3/16 1/4 3/8 1/2 0.020 0.025 0.030 0.040 0.062 0.062 500 500 500 400 350 250 125 125 125 100 87 62 1/2 5/8 3/4 1 1 1/4 2 1/2 0.29 0.44 0.65 1.10 2.50 3.40 22P 532P 33P 44P 55P 66P 88P 1/8 5/32 3/16 1/4 5/16 3/8 1/2 0.020 0.025 0.030 0.040 0.062 0.062 0.062 500 500 500 400 600 350 250 125 125 125 100 150 87 62 1/2 5/8 3/4 1 1 1/8 1 1/4 2 1/2 0.29 0.44 0.65 1.10 1.90 2.50 3.40 44PF 66PF 88PF 1/4 3/8 1/2 0.040 0.062 0.062 400 350 250 100 87 62 1 1 1/4 2 1/2 1.10 2.50 3.40 22PY 33PY 44PY 66PY 88PY 1/8 3/16 1/4 3/8 1/2 0.023 0.034 0.040 0.062 0.062 900 900 900 900 750 225 225 225 225 187 1/2 3/4 1 1 1/4 2 1/2 0.28 0.63 1.10 2.40 3.30 22PP 33PP 44PP 66PP 88PP 1/8 3/16 1/4 3/8 1/2 0.023 0.034 0.040 0.062 0.062 900 900 900 900 750 225 225 225 225 187 1/2 3/4 1 1 1/4 2 1/2 0.28 0.63 1.10 2.40 3.30 Impolene Poly-Flo, P Black (Non-NSF Approved) Linear Low Density Polyethylene Tubing POLY-FLO ® Poly-Flo, PF Black (Non-NSF Approved) Flame Retardent Tubing Linear Low Density Polyethylene Tubing POLY-FLO ® Impolene, PY (NSF Approved) Polyallomer Tubing Impolene Impolene, PP Black (Non-NSF Approved) Polyallomar Tubing Black Impolene 100 Thermoplastic Tubing APPLICATIONS Usual Service and Temperature Range Part No. Colors Available 22PE 532PE 33PE 44PE For pneumatic lines, instrumentation systems, water piping and limited food service. 88PE Natural Natural Natural Natural, Blue, Red, Green, Orange, Purple, Gray, Yellow Natural, Blue, Red Green, Orange, Purple, Gray, Yellow Natural 22P 532P 33P 44P 55P 66P Black Black Black Black Black Black For pneumatic lines, instrumentation systems and water piping. 88P Black 44PF 66PF 88PF Black Black Black 66PE PERFORMANCE DATA Construction/Conformances Resists most solvents and chemicals. Withstands more than 500 hours in Igepal solution. Temperature Range: –80˚ F to +175˚ F Temperature Range: –80˚ F to +175˚ F For heating control systems in commercial building, chemical conduit, data control equipment systems. Ideal in gas and liquid conducting applications. • Natural: ASTM D-1248, Type 1, Class A, Category 3 • Federal Spec: LP390C, Type 1, Class L, Grade 2, Category 3 • Colors: ASTM D-124B, Type 1, Class B, Category 3 • Federal Spec: LP 370C, Type 1, Class L, Grade 2, Category 3 • Flexible Tubing Resists most solvents and • ASTM D-1248, Type 1, chemicals. Withstands more Class C, Category 4 than 500 hours in Igepal solution. • Federal Spec: LP-390C, Type 3, Class L, Grade 2, Category 4 • Flexible Tubing • Black Tubing offers outstanding resistance to sunlight Highest resistance to environmental stress cracking of all regular polyethylene resins. Withstands more than 500 hours in Igepal solution. • Flammability characteristic: Maximum allowable burning rate for PF tubing=3.9 cm/min per ASTM D635 • Flexible Tubing Excellent corrosion resistances. It can be used with greater range of liquids and gases than nylon or polyethylene. Good acid and chemical resistance. • Can be repeatedly steam stabilized. • Not subject to environmental stress cracking. • Flexible Tubing Excellent corrosion resistances. It can be used with greater range of liquids and gases than nylon or polyethylene. Withstands boiling sulfuric acid, concentrated hydrochloric acid up to the boiling point and saline solution up to 200˚ F. • Can be repeatedly steam stabilized. • Not subject to environmental stress cracking. • Black tubing offers outstanding resistance to sunlight. • Flexible Tubing Temperature Range: –80˚ F to +175˚ F 22PY 33PY 44PY 66PY 88PY White White White White White For instrumentation, pneumatic and lubricant lines, hydraulic lines, process lines forgases, chemicals, and solvents. Ideal for use at higher temps. Limited food service. Temperature Range: –20˚ F to +212˚ F 22PP 33PP 44PP 66PP 88PP Black Black Black Black Black For instrumentation, pneumatic and lubricant lines, process lines for gases, chemicals and solvents. Ideal for use at higher temps. Temperature Range: –20˚ F to +212˚ F 101 Thermoplastic Tubing Nylo-Seal, NH & NT (NSF Approved) Nylon 11 Tubing Nylo-Seal, SN & NSR (Non-NSF Approved) Black Nylon 11 Tubing NYLO-SEAL ® Nylo-Seal, NF (Non-NSF Approved)Plasticized Tubing Nylon 11 Tubing NYLO-SEAL ® Polyvinyl Chloride (Non-NSF Approved) PVC Tubing Style C6 Air Brake Tubing SAE J844 DOT FMVSS 106 HYTRON ® AIR BRAKE TUBIN 102 Burst Pressure at 73˚ F (PSI) Working Pressure at 73˚ F (PSI) Min. Bend Radius (Inches) Weight (Approx.) Per C Ft. (Lbs.) Part No. Tube O.D. (Inches) Tube Wall Thickness (Inches) 22NT 532NT 33NT 44NT 55NT 66NT 88NT 1/8 5/32 3/16 1/4 5/16 3/8 1/2 0.017 0.022 0.024 0.033 0.040 0.048 0.062 1,500 1,500 1,500 1,500 1,500 1,500 1,500 375 375 375 375 375 375 375 1/2 5/8 3/4 1 1 1/2 1 3/4 2 3/8 0.26 0.44 0.60 1.00 1.50 2.20 3.20 22NH 33NH 44NH 66NH 88NH 1/8 3/16 1/4 3/8 1/2 0.026 0.039 0.050 0.075 0.075 2,500 2,500 2,500 2,500 2,500 625 625 625 625 625 3/8 5/8 7/8 1 1/2 2 1/2 0.37 0.81 1.40 3.19 4.50 22SN 532SN 33SN 44SN 55SN 66SN 88SN 1/8 5/32 3/16 1/4 5/16 3/8 1/2 0.017 0.022 0.024 0.033 0.040 0.048 0.062 1,500 1,500 1,500 1,500 1,500 1,500 1,500 375 375 375 375 375 375 375 1/2 5/8 3/4 1 1 1/2 1 3/4 2 3/8 0.26 0.44 0.60 1.00 1.50 2.20 3.20 22NSR 33NSR 44NSR 66NSR 88NSR 1/8 3/16 1/4 3/8 1/2 0.026 0.039 0.050 0.075 0.075 2,500 2,500 2,500 2,500 2,500 625 625 625 625 625 3/8 5/8 7/8 1 1/2 2 1/2 0.37 0.81 1.40 3.19 4.50 22NF 532NF 33NF 44NF 55NF 66NF 88NF 440NF 660NF 1/8 5/32 3/16 1/4 5/16 3/8 1/2 1/4 3/8 0.023 0.024 0.024 0.033 0.040 0.048 0.062 0.040 0.060 1,000 1,000 1,000 1,000 1,000 1,000 1,000 1,000 1,000 250 250 250 250 250 250 250 250 250 3/8 5/8 5/8 7/8 1 1/4 1 1/2 2 1/2 3/4 0.33 0.45 0.54 1.02 1.56 2.24 3.89 1.20 2.78 44PVC 66PVC 88PVC 1/4 3/8 1/2 0.040 0.062 0.062 200 160 140 50 40 35 1/2 1 2 1.13 3.20 4.50 C602 C603 C604 C605 C606 C608 C610 C612 1/8 3/16 1/4 5/16 3/8 1/2 5/8 3/4 0.023 0.035 0.040 0.040 0.063 0.063 0.092 0.092 1,000 1200 1000 1000 1400 950 900 800 150 150 150 150 150 150 150 150 3/8 1 1 1 1/4 1 1/2 2 2 1/2 3 0.26 0.78 1.20 1.50 2.80 4.30 6.80 8.50 Thermoplastic Tubing Part No. Colors Available 22NT 532NT 33NT 44NT 55NT 66NT 88NT Natural Natural Natural Natural Natural Natural Natural 22NH 33NH 44NH 66NH 88NH Natural Natural Natural Natural Natural 22SN 532SN 33SN 44SN 55SN 66SN 88SN Black Black Black Black Black Black Black 22NSR 33NSR 44NSR 66NSR 88NSR Black Black Black Black Black 22NF 532NF 33NF 44NF 55NF 66NF 88NF 440NF 660NF Black, Black, Black, Black, Black, Black, Black, Black, Black, 44PVC 66PVC 88PVC APPLICATIONS Usual Service and Temperature Range For instrumentation lines, lubrication and process piping systems, fuel, oil and refrigerant lines. PERFORMANCE DATA Construction/Conformances Resists vermin attack. Flexible Tubing Temperature Range: –60˚ F to +212˚ F For instrumentation lines, lubrication and process piping systems, fuel, oil and refrigerant lines. Limited food service. Resists vermin attack. Temperature Range: –60˚ F to +225˚ F Natural Natural Natural Natural Natural Natural Natural Natural Natural Clear Clear Clear • Moisture not required for flexibility. For instrumentation lines, lubrication and process piping systems, fuel, oil and refrigerant lines. • Moisture not required for flexibility. • Black tubing offers outstanding resistance to sunlight. Flexible Tubing Resists vermin attack. Temperature Range: –60˚ F to +225˚ F • Moisture not required for flexibility. • Black tubing offers outstanding resistance to sunlight. Flexible Tubing For pneumatic lines and water piping. Clear tubing is ideal where visual inspection of flow and cleanliness is desired. Flexible Tubing Temperature Range: –20˚ F to +165˚ F C602 C603 C604 C605 C606 C608 C610 C612 Black Black Black, Blue, Red, Yellow, Green, Brown, Orange Black Black, Brown, Blue, Green, Orange, Red, Yellow Black, Blue, Red, Green, Brown, Yellow Black, Blue, Red, Green, Black For replacing metal air brake tubing on air brake systems, except for the compressor discharge lines and other temperature limiting locations. Material Specifications: Tube: Nylon Reinforcement: Polyester Fiber Cover: Nylon. Totally Bonded Conformances: • DOT FMVSS 106 • SAE J844 Temperature Range: -40°F to +200°F 103