Separation of a Mixture

advertisement

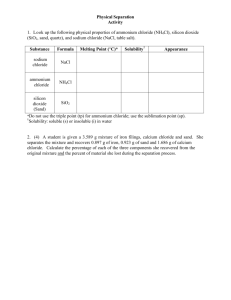

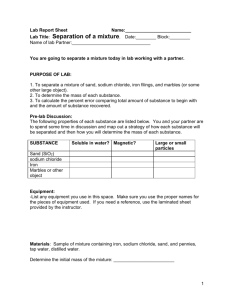

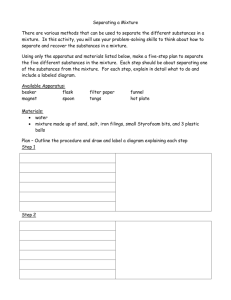

Separation of a Mixture By Justin Wright Portland Community College General Chemistry I 11/2/2012 Abstract An unknown mixture containing Fe, NH4Cl, SiO2, and NaCl was obtained and the percentage composition for each component was to be identified. A separation scheme was devised to separate the four known components using magnetism, sublimation, filtration, and evaporation. The experimental results indicate that the unknown mixture was 15.4% Fe, 15.3% NH4Cl, 49.70% SiO2, and 18.5% NaCl. Introduction In nature, matter usually occurs in the form of a mixture (1). Therefore it is important to be able to separate mixtures into their individual components in order to better study them. There are many ways to separate mixtures by taking advantage of the unique physical properties of each component in a mixture. A few common techniques include magnetism, distillation, and filtration. Since separation techniques take advantage of the variations in physical properties, the best way to devise a separation scheme is to become familiar with the physical properties of each individual component. Once the physical properties for each component are known, specific separation techniques can be selected that take advantage of the unique characteristics of the various components. For example, in this particular experiment, it was known that one of the components of the mixture was ammonium chloride. A unique characteristic of ammonium chloride is that it sublimates at 338 degrees Celsius, therefore this technique was used in the experimental process to isolate the ammonium chloride from the other components of the mixture (2). Other separation techniques were then added to the separation scheme to isolate the remaining components of the mixture. Experimental Methods The first step of the experiment was to obtain the mass of the unknown mixture. An empty beaker was weighed using a scale and the unknown mixture was then added to the beaker and weighed again. The final weight was subtracted from the initial weight of the empty beaker to attain the mass of the unknown sample. Next, the iron was separated from the mixture via magnetism. A small magnet covered in plastic wrap was placed in the beaker, which attracted the iron from the remaining components of the mixture. The beaker containing the remaining three components of the mixture was weighed on the scale. The mass of Fe in the mixture was then obtained by subtracting the measurement from the measurement recorded in the previous step. The next step of the separation scheme was to remove the ammonium chloride via sublimation. The beaker containing the three remaining components was heated over a Bunsen burner inside a fume hood. The mixture was then removed from the heat once no more gas was visible. After cooling to room temperature, the beaker was weighed on the scale. The mass of ammonium chloride was calculated by subtracting the measurement from the previously recorded mass measurement. 2 To separate the silicon dioxide, approximately 10 mL of deionized water was measured in a graduated cylinder and added to the mixture. A piece of filter paper was weighed on the scale and then formed into a cone. An empty beaker was also weighed on the scale and the mass was recorded. The mixture was then poured into the empty beaker through a funnel containing the filter paper and the silicon dioxide was separated via filtration. The filter paper containing the sand was placed in the oven to dry. After the sand was completely dry, it was then weighed with the filter paper and the mass of silicon dioxide was obtained by subtracting the previously recorded mass of the filter paper. Heating the remaining salt-water solution on a hot plate until all the water evaporated isolated the final component, salt. The beaker was weighed and the total mass of salt was obtained by subtracting the initial beaker measurement from the beaker and salt measurement. Results The devised separation scheme effectively separated the unknown mixture into its individual components. The experimental results indicated that sand was the primary component of the mixture, which accounted for 49.70% of the total mass of the mixture. The experimental results and known composition percentages for each component in the mixture are displayed in Table 1 below: Table 1: Experimental Results Substance Unknown #5 Fe NH4Cl SiO2 NaCl Mass of Substance ± 0.001 (g) 3.012 0.463 0.460 1.497 0.558 % Composition (Experimental) 15.4 15.3 49.70 18.5 % Composition (Known) 15 15 50 20 % Error 2.7 2.0 0.60 7.5 The following equations were used to calculate the percent composition and percent error values for each substance: 𝑃𝑒𝑟𝑐𝑒𝑛𝑡 𝐶𝑜𝑚𝑝𝑜𝑠𝑖𝑡𝑖𝑜𝑛 = 𝑃𝑒𝑟𝑐𝑒𝑛𝑡 𝑒𝑟𝑟𝑜𝑟 = 𝑀𝑎𝑠𝑠 𝑜𝑓 𝐼𝑛𝑑𝑖𝑣𝑖𝑑𝑢𝑎𝑙 𝐶𝑜𝑚𝑝𝑜𝑛𝑒𝑛𝑡 × 100 𝑇𝑜𝑡𝑎𝑙 𝑀𝑎𝑠𝑠 𝑜𝑓 𝑆𝑎𝑚𝑝𝑙𝑒 𝐸𝑥𝑝𝑒𝑟𝑖𝑚𝑒𝑛𝑡𝑎𝑙 𝑣𝑎𝑙𝑢𝑒 – 𝐴𝑐𝑡𝑢𝑎𝑙 𝑣𝑎𝑙𝑢𝑒 × 100 𝐴𝑐𝑡𝑢𝑎𝑙 𝑣𝑎𝑙𝑢𝑒 As seen in Table 1 above, an acceptable percent error of less than 5% was achieved for Fe, NH4Cl, and SiO2. The experimental percent composition obtained for NaCl was inaccurate due to a percent error of more than 5%. 3 Discussion There were a few limitations and possible sources of error during the experimental process. Each of these items may have had an impact on the accuracy of the experimental results. While removing the Fe from the mixture via magnetism, a few grains of sand and/or salt were mixed in with the iron on the magnet. Special care was taken to remove the sand and/or salt from the magnet, but it was not possible to remove every noticeable grain. During the sublimation process, a white gas was released and formed a residue on the side of the beaker. Each side of the glass was held over the flame until the white residue was completely gone to ensure that all of the ammonium chloride was removed from the mixture. A small amount of red residue was also found on the side of the beaker and could not be removed. Another possible source of error occurred during the filtration phase. A small tear was discovered in the filter paper when transporting the sand to the oven. The tear was noticeably bigger after being subjected to the heat of the oven. Special care was taken to ensure that no sand was lost as a result of the tear. Conclusion The results of the experiment indicate that the mixture was 15.4% Fe, 15.3% NH4Cl, 49.70% SiO2, and 18.5% NaCl. The respective percent errors for each individual component were 0%, 0%, 0%, and 0%. References 1. Silberberg, Martin S. 2012. Chemistry: The Molecular Nature of Matter and Change, 6th Edition. The McGraw-Hill Companies, United States of America. 2. Haynes, W. M. 2011. CRC Handbook of Chemistry and Physics – 92nd Edition. CRC Press, United States of America. 4