Sustainability Report 2007

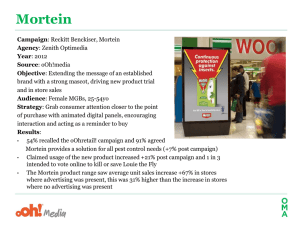

advertisement