area - Grace

advertisement

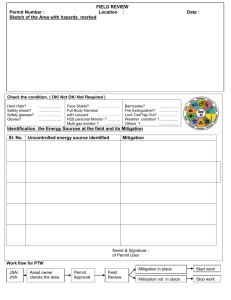

Contractor Site Specific Orientation Revision Date: April 12, 2013 1 Disclaimer • This orientation is intended to highlight some of the health and safety rules, programs and procedures in place and required by our site. • It is not all inclusive. • Critical information is highlighted in RED. • To view all aspects of these programs, please refer to the Contractor Safety Manual. 2 Disclaimer • This orientation does not replace the OSHA required training provided by the SWLA Safety Council and by your company. • This training only covers our site specific requirements. • This does not replace the dialogue required between you and the authorized Grace representative and Grace custodian. 3 Test • There will be a comprehension test following the training. • 80% passing grade • Once passed, an orientation card will be issued. • If failed, have to reschedule for another day. 4 5 What is VPP? • Voluntary Protection Program • Grace – Lake Charles Plant is an OSHA VPP Star Worksite. • Designed to recognize and promote effective safety and health management. • Management, labor, and OSHA establish a cooperative relationship at a workplace that has implemented a strong program. • Contractors will be interviewed by OSHA during onsite visits to determine if they understand the VPP program, know the site safety rules and follow them. • VPP participation does not take away your right to file a complaint with OSHA. 6 What is RCMS? • Responsible Care Management System • Grace – Lake Charles Plant is a certified RCMS site. • Provides the framework and sets performance expectations for planning, prioritizing, implementing, measuring, and reviewing EHSS activities to ensure continual improvement. • The system sets forth performance expectations that address EHSS hazards and risks, training and communication, operational control, goals and target setting, assurance, compliance management, product stewardship, and periodic internal review. 7 Entry and Exit to the Facility • All personnel must scan or log in and out whenever entering or leaving the site. • Identification badges must be visible at all times. • Contract vehicles must have company identification (i.e. on the side, etc) and have a vehicle pass from security. • Dress code: No torn work clothes are allowed or clothes with holes in them. No sleeveless shirts are allowed. This is for your own protection. 8 Entry and Exit to the Facility • Required PPE must be worn when inside the facility. – Hard Hat – Safety Glasses – Hearing Protection – Steel toed shoes – NOTE: Certain jobs/areas may require additional PPE. Refer to the maintenance job task PPE chart on the Contractor Safety page of the interlan or website. Exceptions include: – Hard hat and ear plugs not required in contractor’s compound area or maintenance shop • However, ear plugs however would be required if work being conducted such as grinding, etc. 9 Entry and Exit to the Facility • We are regulated by the US Coast Guard and the Marine Transportation Security Act. • To gain unescorted access to this facility, you must possess (and have inside our fenceline, accessible within 10 minutes) a valid TWIC card. • If you do not have a TWIC card, you must be escorted by a Grace representative at all times. 10 Vehicle Rules • Operators of vehicles must obey posted speed limit signs. (10 mph) • Seat belts must be worn at all times while in ANY moving vehicle • Pedestrians always have the right of way. • Watch for large truck and railroad activity. • When you park inside the facility, you must turn off the engine and leave the keys in the ignition before exiting your vehicle. • Do not walk in the area of the RR track unless you are there doing work. Stay on the roads to cross the tracks. • Passengers are not allowed to ride on any equipment not specifically designed for such. • There is to be no passengers riding in the beds of pick-up trucks unless equipped with appropriate seats and seatbelts. 11 Parking • There is designated parking in the contractor parking lot (Gate 5). • In the event of a large outage job, the overflow parking for contractors will be at the Recreation building parking lot (Gate 9/9A). • Only authorized vehicles are allowed to drive in the plant. • You are NOT allowed to park in the unit or on the road, unless actively unloading equipment. Then you must move your vehicle to designated area. • Your Grace representative will direct you on where authorized vehicles will be allowed to park inside the plant. – Contractor compound – West of Administration Building – North of HPC plant 12 Tobacco Products • Smoking is allowed in designated areas only Cigarette butts must be thrown in cigarette receptacles, not trash cans or on the ground! No trash should be placed in these receptacles! • Chewing tobacco is allowed in all plant areas (except HPC), but a spillresistant container (such as a cup with a napkin) must be used and deposited in appropriate trash receptacles. Do not spit directly in the trash can or on the ground or leave spit cups laying around. • Violations will result in the site taking action to make this a tobacco-free facility. 13 General Site Rules • Drinking, eating, storing or preparing food or beverages for consumption in any laboratory, maintenance or process area is prohibited. (NOT ALLOWED) • Cameras are not allowed unless permission is obtained from Grace Security. • Cell phones are not allowed in the plant unless authorized by Grace Security. • No unapproved cutting tools allowed. 14 Process Safety Hazards There are several hazards present at the GRACE Lake Charles plant. Chemical/Particulate hazards: • Acids (Sulfuric, Hydrochloric, Nitric, Phosphoric) – Skin/eye contact – immediate chemical burn/irritation – Inhalation – throat irritation, burning, coughing • Caustic (50%) Solution – Skin/eye contact – feels slimy, prolonged exposure causes chemical burn/irritation – Inhalation – throat irritation, burning, coughing • Aqua Ammonia (pungent odor) – Skin/eye contact – chemical burn – Inhalation – nausea, vomiting, breathing difficulty • Nickel Nitrate Solution (green color) – Skin/eye contact – irritation, sensitization – Inhalation – throat sensitization 15 Process Safety Hazards Chemical/Particulate hazards cont’d: • Silica quartz (crystalline silica) – Found in sand at Silicate Plant – Inhalation – chronic exposure could cause silicosis • Natural Gas (found throughout plant) – Flammable – Displaces oxygen in air • Rare Earth Chloride & NORM • Dust • – Inhalation and eye contact hazard Dusty jobs or high wind conditions warrant goggles or dust glasses as upgraded PPE • Steam (300 psi) – Thermal burns from contact with steam or steam piping 16 Process Safety Hazards Mechanical hazards include: • Screw conveyors • Pinch points • Belt Filters • Calciners • Sprockets & chains Other hazards include: • Uneven walking/working surfaces • Slipping hazards (slurry, media, floc) • Material draining to ditches (do not step in ditches) 17 Plant Areas • The facility is broken down into different units/areas/plants. • Each one will be highlighted and the it’s unique hazards briefly discussed. • There are some hazards that are common among all areas: – Thermal burns from steam and gasfired equipment – Dust (wear goggles or dust glasses to better protect eyes during windy conditions) – Natural gas • Should you have questions, concerns, or need additional information, please contact any Grace representative. 18 Additives (Z14) Plant Silica Sol (Super D) Plant DA & Alumina Plants • Acids – Sulfuric – Hydrochloric – Phosphoric • Ammonia • Caustic • Rare Earth Chloride & NORM More information on NORM will follow in a few slides. 19 Additives (Z14) Plant The Code 550 area which contains crystallizers (equipment #s: 1210, 1210A through C, 1214D, 1238F, 1211G through T) are hazardous due to the temperature (~220°F) of the product being boiled inside and potential for it to boil over. This area can only be accessed with permission from the Code 550 A or C operator! There are signs indicating this, as well as red chain around the area. 20 XP Plant • Acids – Sulfuric – Hydrochloric • Ammonia • Caustic • Rare Earth Chloride & NORM • Hydrogen The red painted area around the CX100 reactors is a restricted area due to the potential for hydrogen accumulation. This is a hot work permit required area. Equipment in this area must be intrinsically safe.21 Boilerhouse • • • • Water treatment chemicals Hot water Steam 300# steam boiler 22 Carcinogens • There are two materials in the Grace facility which are known carcinogens: – Silica quartz (Silicate Plant) – Nickel (HPC Plant) • Silicate plant – Sand (raw material) • ~97% quartz (silica quartz) – Silicate (after furnace) • amorphous silica (not a health concern) 23 Silicate Plant • Sand – Silica quartz or crystalline silica • Soda Ash (caustic soda) • Hot glass (solid & liquid) • ~2700ºF furnace When cleaning this area, air should not be used. Use broom or vacuum so as not to cause silica dust to become airborne. 24 Silicate Plant • The silicate furnace is put together similar to an igloo. • The inside of the furnace is 2700°F. • The crown of the furnace should NOT be walked on. • Remain on the catwalk at all times! The area underneath the furnace and behind the chill roll is a restricted 25 area and requires operator approval. Carcinogens cont’d • HPC (hydroprocessing catalyst) – Allergy risk (most common) – Nickel nitrate, liquid (soluble Ni) • Inhalation of fumes • Dermal contact – Nickel carbonate, powder (insoluble Ni) & Catalyst, nickel oxide, solid (insoluble Ni) • Inhalation of dust • Ingestion 26 HPC Plant • Acids – Nitric – Phosphoric • Ammonia • Nickel • Molybdenum trioxide The HPC plant is a restricted area due to the presence of nickel, which is a known carcinogen. 27 HPC Hygiene Procedures Access to HPC and its staging area are restricted areas. Coveralls (Tyvek or cloth) are required when entering any “Restricted Access Area” of the HPC plant. A change room has been provided for personnel that will exit “Restricted Access Areas.” Contract personnel can use the HPC facilities to clean up after exiting the “Restricted Access Areas.” 28 HPC Hygiene Procedures There are signs designating areas: • “Clean” areas • Outside of HPC buliding • Changeroom & control room lunchrooms • Control room • External stairs • “Restricted Access” areas • Exposure to nickel • Staging area (warehouse) and control station (by loadout) • “Transition” area • Changeroom locker rooms • Entry to control room (washroom) • MCC & Elevator 29 • Corridor (breezeway) to control room Change room - Ground floor Control room – 5th floor 30 HPC Hygiene Procedures Entry into a “Clean” Area if you have NOT been in a “Restricted Access” area: • Use “clean” pathway • Elevator or NE stairs to access control room • NOTE: You must still vacuum shoes and wash hands before entering There is no “clean” pathway to the operator control station on the ground floor. You must use the phone in the downstairs lunchroom to call the operator control stations for assistance. 31 HPC Hygiene Procedures To enter a “Restricted Access” area: • Wear clean disposable (i.e. Tyvek) coveralls over street clothes • Enter HPC through NE side (bay door or door by stairs) Food, tobacco products, gum or any other item which is handled and placed in the mouth is strictly prohibited within “Restricted Access” Areas. 32 HPC Hygiene Procedures Entry into a “Clean Area” from a “Restricted Access Area” includes additional administrative controls. It will be necessary to: 1. Clean equipment (e.g., hats, tool pouches, etc.), 2. Vacuum coveralls (or remove disposable coveralls and dispose) 3. Vacuum shoes 4. Wash exposed skin 33 HPC Hygiene Procedures Disposable coveralls can be altered (i.e. cut sleeves) as long as they completely cover street clothes. They must also remain zipped up. Disposable coveralls are: * not allowed in “Clean Areas” * or off the HPC grounds after they have been worn in a “Restricted Access Area”. 34 Other Restricted Areas ALL REQUIRE OPERATOR APPROVAL TO ENTER: • MCC/IO rooms • DA Penthouse (high pressure nozzles) • Rare Earth Tanks (presence of NORM) • High Voltage fenced in areas (13200V) • MARSEC areas for security (security areas, docks, 1040F tank) • Area under Silica Sol (Super D) control room (overflow hazard) 35 Asbestos • There are some areas in the facility which contain asbestos. • They include: – Insulation – Roofing material – Transite siding – Flooring (Maintenance Tool room) • In most instances it is impossible to determine if insulation is Asbestos by just looking at it. 36 Asbestos • If any insulation you come in contact with is not properly identified as Asbestos Free (tagged with blue ID. Markers), or is suspect, stop your work and contact the Environmental Department. • Proper testing will be conducted to determine if the insulation is Asbestos and it will be properly labeled. ASBESTOS FREE 37 Lead • There may be some vessels which still contain red lead primer. • If you are about to blast, cut or weld (for example) on a vessel and are unsure if it is lead-free, please STOP and contact your Grace representative. 38 Paint Program • Before any contractor can use paint in this facility, you must first contact the Environmental Department. • You must first be shown where to clean up and dispose of waste paint. • You will receive hazardous waste training. 39 NORM • NORM = Naturally Occurring Radioactive Material. It occurs naturally throughout the earth's crust. • At Grace, NORM is found in Rare Earth Chloride. The amount of gamma radiation emitted from NORM is relatively small and the levels associated with the rare earth chloride are generally not a hazard. • The radiation hazards associated with NORM are primarily from inhalation and ingestion of alpha radiation. • Radium 226 can concentrate to significant levels in some process systems and poses a hazard to workers handling or performing maintenance on contaminated 40 equipment. NORM • Avoid breathing in NORM contaminated material that is distributed into the air. Wetting the NORM contaminated material often prevents the material from becoming airborne. • Eating, drinking, smoking, or chewing is not allowed in the immediate work area around NORM contaminated material. • Grace Environmental/Safety Department must be notified prior to work on NORM contaminated equipment to ensure a NORM qualified person will oversee the activities to ensure compliance with state and federal regulations. 41 Hazard Communication • Protect Yourself from Chemical Hazards! – Be informed. Read the tank label and/or MSDS. Find out about the chemicals you might be dealing with before an emergency develops. – Use personal protective equipment as required by the MSDS. – Label all containers with the contents and hazards. – If you don’t know what you are dealing with or come across a substance that is not readily identifiable, please contact your supervisor or Grace representative. 42 How to Find a MSDS • For more info on any chemical or material in the facility: • From any computer in the facility, go to the Internet Explorer icon. • You will be at the LC home page. • Click on the MSDS link. • Enter the chemical name that you are searching for. • Ask for assistance if needed. 43 Plant Color Codes PIPING: Fuel Gas Piping Acid Lines (Un-insulated) High Temperature (Insulated) Fire Water Piping Potable Water Piping HOSES: Water/Air ONLY Chemical Must use Chicago coupling safety clips on all hose connections. 44 Reporting of Incidents • Report all: – Injuries – Illnesses – Incidents (Near Miss & Property Damage) IMMEDIATELY TO YOUR SUPERVISOR All incidents and near misses must also be reported to your Grace site contact or Grace safety department. 45 Emergency Procedures • To report an Emergency: – Dial 3571, 3555 or 3542 on any plant phone. – Radio channel 16 (on all zones) – State your name, location and nature of the emergency. – Remain Calm. – From all other phones, dial 583-3571, 583-3555 or 583-3542 46 Emergency Alarms • Emergency Alarms: Siren followed by verbal announcement indicating the location and nature of the Emergency. If the area you are working in is affected, you shall: – Evacuate immediately – Report to designated assembly area (either evacuation assembly area or shelter in place location depending on the nature of emergency) – Notify your supervisor that you are there – Supervisor must notify the Grace contact with headcount – Wait for further instructions 47 Emergency Alarms • General Plant: – Every Wednesday at Noon, there is a test of the emergency alarm system. • XP Plant: – In the event of an emergency at the XP plant (due to the presence of hydrogen), the XP emergency alarm will sound and you must evacuate the XP plant only. – There is a test every month of the XP alarm. 48 Emergency Procedures • There are several orange windsocks throughout the facility. • In the event of an evacuation or shelter-in-place: – To reach the designated assembly area, travel cross wind, then upwind. Call your contract coordinator to report your location. – Wait until the All-Clear message is broadcast before returning to the work area. – Once back at the work area, ensure all Permits have been re-instated before beginning any work. 49 Evacuation Assembly Areas There are five evacuation assembly areas in the Grace facility. These include: -the construction guard gate -the main gate (parking lot) -the Lagoon area -the southwest corner of HPC -west side of the plant by the water tower 50 51 Shelter-in-Place Assembly Areas There are many shelter-in-place assembly areas in the Grace facility. These include: -all operating unit control rooms -Grace maintenance lunchroom, warehouse and offices -Front and Back guard gate -Contractors trailers -Loaders station -Admin accounting area -Grace laboratory This does NOT include MCC rooms and I/O rooms. 52 Emergency Drills Grace periodically conducts drills for shelter in place and evacuation scenarios. These drills are conducted via plant radios. When operators exit the area (for evacuation drills), contractors will be notified on their way out when possible. 53 Pre-Task Hazard Analysis •Job Safety Analysis (JSA): –A hazard analysis must be done prior to each job –A copy of the completed JSA should be reviewed with the operator, attached to and turned in with the work permit/order daily. –One of the most effective tools that can be used, if used properly, in the reduction of work place incidents and injuries. –Look for items including, but not limited to: •Pinch Points •Line of Fire/Eyes on Work Path •Rotating Equipment •Hot/Cold surfaces or materials •Chemical Contact •Sharp Objects/Splinters •Proper Energy State (ZERO Energy) •Path of Travel •PPE and tool selection, condition and use 54 •Body position Protecting Employees •Eliminate the Hazard •Separate Employees From Hazards •Separate Hazards from Employees •Select Work Processes to Protect Employees •Maintain good housekeeping Each employee performing work must know and understand the safety and health requirements that apply to the work they are assigned to perform. Employees who receive assignments that they do not understand, have an obligation to request additional information and further clarification before they commence 55 their work activities. Personal Protective Equipment Employees are responsible for following all provisions of this program and related procedures. They are expected to wear PPE when and where it is required. AGAIN: •Minimum PPE to enter facility: –Hard Hat –Safety Glasses –Steel toed shoes –Hearing Protection Some maintenance tasks require additional PPE. Refer to the maintenance PPE chart on56 the interlan and website. Personal Protective Equipment • Head Protection: – Head Protection must meet current ANSI Standards. – Hard Hats must not be altered in any way – Brim must be worn facing the front; except when welding and performing rigging activities (special permission from your contract coordinator must be granted). • Eye/Face Protection: – Protective eyewear must meet ANSI Z87.1 Standards. This includes Prescription Eyewear. – Tinted eyewear is not allowed after dusk and before sunrise, nor in any enclosed areas, or covered buildings (unless specified by activity). – Additional Eye/Face Protection is required for some tasks (e.g.. Goggles, Face shields). 57 Personal Protective Equipment • Hearing Protection: – Approved hearing protection must be worn in all process areas of the facility (past the maintenance shop and admin building) and when grinding. • Foot Protection: – Sturdy leather footwear meeting ASTM standards (Steel Toe) must be worn at all times – Periodic checks will be made to ensure compliance. • Body Protection (Clothing): – Long pants, suitable for work, must be worn at all times in the plant. – Shirts may not be of the sleeveless type. – The HPC unit requires additional clothing protection as discussed in previous slides. 58 Personal Protective Equipment • • Respiratory Protection : – Where respiratory hazards are encountered, approved respirators must be worn. – Employees must be medically cleared to wear a respirator. – A current fit test must be obtained. – The wearer must be clean shaven in the sealing area. – Respirators must be chosen for the specific hazard to be encountered. – Users of respirators must be properly trained. Hand Protection : – Where hazards are encountered, appropriate hand protection (i.e. gloves) must be worn. – Canvas/Cloth gloves - wood, abrasives, rough surfaces etc. – Leather gloves - hot and cold surfaces, sharp metals (limited protection), jagged wires, sparks from welding or cutting torches – Chemical Resistant gloves - liquid and powdery substances – Cut resistant gloves must be worn when using cutting tools. – Appropriate gloves must be worn when 59 performing any type of work. Personal Protective Equipment • Fall Protection: – Employees are required to utilize fall protective equipment any time work is required to be performed greater than 6-feet above a lower surface and exposed to a fall. – On incomplete (Yellow Tag) scaffolds, the employee must wear a harness and the lanyard must be secured to a proper anchorage point when over 6-feet. – Lanyards with shock absorbers and double locking hooks are required. – Fall protection chokers “cheaters” are to be used only when necessary. They are not meant to be used for convenience to gain 60 access to work areas. Fall Protection WE HAVE ZERO TOLERANCE FOR NOT UTILIZING FALL PROTECTION WHEN REQUIRED • The attachment point of the body harness shall be located in the center of the wearer's back near shoulder level, or above the wearer's head. • Personal fall arrest systems shall be inspected prior to each use for wear, damage and other deterioration, and defective components shall be removed from service. • When attaching the lanyard, the attachment point should be at or above the shoulder. In the event that the wearer feels his/her safety harness, lanyard, or lifeline is not in perfect condition, it shall be 61 reported immediately for inspection. Tools • • • • • • Keep cutting tools sharp. Pin knives and pocket knives are not allowed. All cutting tools must be safety cutters (spring-loaded or retractable blades, concealed blades and/or blade guards), unless approved by the Safety Department. Use the right tools for the job. Do not use chisels with “mushroom” heads, cracked or splintered tools, or pipe wrenches with smooth jaws. Examine all tools before use. Turn in defective tools to your toolroom and tag “Do Not Use”. Do not drop tools to another level. When using an open end or box wrench, make certain it is the proper size for the nut. Also make sure that the jaws of the pipe wrench have a solid grip on the pipe. Always pull the wrench towards you whenever possible, to prevent smashed 62 fingers, or slipping or falling forward due to momentum. Barricading Requirements • • • • • • • • Floor holes and openings shall be covered and labeled with “HOLE” or “COVER” to provide warning of the hazard. Covers located in roadways and vehicular aisles have to be capable, without failure, of supporting at least twice the maximum axle load of the largest vehicle expected to cross over the cover. Work crews are responsible for erecting barricades for their work activity. Barricades are to be kept at least 2 ft from an excavation Appropriate barricades, including barricade tape will be used based on the hazards associated with the work. Barricades are to be maintained and removed when work is completed. Unauthorized personnel are not allowed to enter “Red” barricaded areas without permission from operator, or maintenance or contact supervisor. Road Barricades, signs, detours or other traffic control systems must be approved by Grace Security. 63 All employees must obey posted barricades. Types of Barricading • Radiation: – DO NOT ENTER – No one except the radiographic employees will be allowed entry into the barricaded area while the special colored tape is up. • Red - DANGER: – DO NOT ENTER WITHOUT PERMISSION – Give notice of areas where the hazard is not readily apparent – Hazards could possibly be life threatening or disabling. • Yellow - CAUTION: – Enter AFTER reviewing hazard(s) – Give notice of hazards that can be seen by personnel coming into the area – hazards are not to be considered life 64 threatening or disabling Barricading Requirements •Do not overlap different colored barricading. •Barricade Tags: –A tag must be placed on ALL barricades. –The tag must identify: –Company –Name of person installing barricade –Date –Nature of hazard(s) Red – Tags for DANGER barricade tape must be updated daily. 65 Railroad • Be alert at all times for a moving train. • Clearances for scaffolds, or other temporary structures, from railroad tracks is 8-feet 6-inches from the centerline of the track. To erect any scaffold closer than this clearance requires permission from a loader supervisor and adequate communication to the loader/unloader group. 66 Scaffold Safety General Safety Guidelines a. Inspect all scaffolds before using. Never use any scaffold that is damaged or defective in any way. b. Scaffolds must be erected in accordance with design and/or manufacturers’ recommendations. c. All scaffolds must be erected, dismantled and/or altered under the supervision of a “Competent Person”. d. Do not abuse or misuse the scaffold equipment. Never use equipment for purposes or in ways for which it was not intended. e. Erected scaffolds should be continually inspected by users to be sure that they are maintained in safe condition. Report any67 unsafe condition to your supervisor. Scaffold Safety General Safety Guidelines f. Do not work on scaffolds if your physical condition is such that you feel dizzy or unsteady in any way. g. Do not get on a scaffold which is not tagged. Be sure to read each scaffold tag before getting on the scaffold. h. Remember this - Even though all scaffolds may have the appropriate tag, each scaffold must be visually inspected before any workers climb on to the scaffold to perform work. i. Remove all tools/material after job completion or end of shift. j. Never take chances! If in doubt regarding the safety or use of the scaffold, consult a scaffold supervisor. 68 Scaffold Safety • Scaffold Tags: • Red Tag/No Tag – DO NOT USE: Scaffold is being dismantled, not completely erected or safe, and shall not be used by anyone except scaffold builder. • Yellow Tag – Incomplete: Scaffold cannot be fully erected with all components in place. Tag specifically cautions user what is not completed. • Green Tag – Complete: Scaffold is complete with handrails, midrails, toeboards, and decking. Green Tagged Scaffolds are preferred at Grace. 69 Maintenance Work Permits/Orders • • A work permit or work order must be obtained for all maintenance work done at the Lake Charles plant. The custodian (Grace personnel) and all craftsmen (authorized workers) shall jointly complete the work order and JSA at the job site. They shall: – Achieve a mutual understanding of the scope of work to be performed. – Physically inspect the jobsite. – Physically identify the equipment to be worked. – Assure the equipment has been properly prepared – Perform oxygen content, combustible gas (LEL), and toxic gas testing, if applicable – Determine potential hazards and/or precautions that need to be taken. – Locate the nearest shower/eyewash station if applicable. – Discuss the safe evacuation of the job site. – Identify and discuss established Grace procedures that may relate to the job. – Assure a mutual understanding of the preparations, hazards, and special procedures. – Sign on the work permit • The work order shall remain in the control room until 70 the completion of the work. Maintenance Work Permits/Orders Requirements Upon Completion of Work: • Ensure that all parties have completed and/or suspended their work activity and are aware that the Safe Work Permit is being canceled or has expired. • Notify the custodian (Grace personnel) that the work has been stopped, completed or suspended. • Complete final steps of lockout/tagout. • Ensure the jobsite is being left in a safe and clean manner. • Sign off the work permit • Remove the original work order from the control room and return the form to the contractor or Grace representative office. 71 Lock Out / Tag Out (LOTO) • Preparing the Equipment for Shut Down and Maintenance: – Know the types and amount of energy you could encounter – Understand how the energy can be released and controlled – Obtain information from an authorized Grace representative regarding the sequence of energy isolation required to safely deenergize the system – Contact your supervisor if you should encounter problems or if you have questions – On an on-going plant outage, you can leave your locks on, but the tags must be updated daily and the equipment ‘tried’ to verify zero energy. 72 Lock Out / Tag Out (LOTO) Energy Isolation Tags: • Danger-Do Not Operate tags: – All installed locks must be accompanied by a "Danger-Do Not Operate" tag properly filled out indicating: • Reason for lock out. • Date of lock out. • Signature of installer (clear and legible) – The Danger Do Not Operate tags are red and white in color with “Danger Do Not Operate” written in red. • Blind Point tags: – Any maintenance work requiring a blind flange to be installed, (such as confined space) must be accompanied by a "Blind Point" tag properly filled out indicating: • Signature of Craftsman • Signature of Custodian • Date of installation – Blind point tags are yellow in color with black stripes and “Blind Point” written in red. 73 Lock Out / Tag Out (LOTO) Energy Isolation Tags: • Job Incomplete tags: – A tag placed on a lockout device that notifies affected personnel that a job is incomplete. This tag will be used when maintenance on a system is not completed before shift change, and a decision has been made that maintenance will resume at a later date. – When the Maintenance employee or authorized worker resumes work on the job, he must re-lock, tag and try the equipment using the same procedure and then remove the job incomplete tag. – Any incomplete maintenance work requiring “Job Incomplete Tag” must be filled out properly indicating the following: • Signature of Craftsman • Date of installation – Job incomplete tags are red in color with “Job Incomplete” written in yellow. 74 Lock Out / Tag Out (LOTO) Lock, Tag and Try Data Sheets: • Equipment-specific list to be referenced by the Custodian and Authorized workers which is a guide to help identify equipment to be locked out so as to achieve zero energy state before any maintenance work can begin. The purpose of the Lock - Tag and Try data sheets is to provide the Custodian and persons performing maintenance work with the information required to identify all isolation points for energy sources. Also, to provide a list of sequential steps for the following: – Shutting down the equipment. – Installing energy isolating devices and locks/tags. – Releasing stored energy. – Removing energy isolating devices after completion of maintenance. – Inspecting equipment before re-energizing. – Re-energizing equipment. 75 – Responsibilities for each of the above. Lock Out / Tag Out (LOTO) Lock, Tag and Try Data Sheets: • LOTO data sheets identify ALL steps required to render equipment to total zero energy state. • It is recognized that some maintenance tasks will not require that equipment be rendered to zero energy state. Some tasks cannot be performed if equipment is rendered to total zero energy state. • The custodian and authorized workers are required to ascertain which isolating devices identified on the LOTO data sheet will require lockout. • ALL ENERGY WHICH COULD CAUSE INJURY IF INADVERTENT START-UP OR ACTIVATION WERE TO OCCUR MUST BE LOCKED OUT! 76 Lock Out / Tag Out (LOTO) Working within ten (10) feet of unguarded, energized equipment • Any person who will be required to work within ten (10) feet of an unguarded, energized piece of moving, rotating, or actuating equipment (including, but not limited to dampers, shafts, calciner trunions/tires, dissolver, sprockets/chains, fans, etc) must either: • 1.) Lockout out the equipment and verify zero energy state prior to working within the ten (10) foot minimum clearance; or • 2.) Adequately guard the moving, rotating or actuating equipment for protection from hazards such as those created by point of operation, ingoing nip points and rotating parts; or • 3.) Obtain an approved Management of Change (as outlined in the Management of Change Procedure), which lists additional safeguards required to work within the ten (10) foot clearance from the unguarded, energized piece of moving, rotating, or actuating equipment. 77 ARC Flash Protection NFPA 70E Standard for Electrical Safety: • When resetting breakers or locking out equipment, you are in hazard risk category 0, which REQUIRES the following PPE: – Untreated Natural Fiber (cotton) long sleeved shirt • Electrical work requires a higher level of protection. See a Grace Safety or Maintenance supervisor for more details. 78 Line Breaking Procedure covers: 1. breaking open, cutting, burning, welding, and brazing on Natural Gas pipelines 2. breaking lines containing Hazardous Chemicals 3. breaking all other lines not mentioned above to ensure their safety and the safety of fellow employees. 79 Line Breaking Hazardous chemical lines: • Barricade perimeter • Wear PPE: Wrap-around face shields with visor must be worn in addition to safety glasses – or regular face shield with goggles – hard hat, earplugs, acid suit (green), rubber gloves, and steel toed rubber boots • At a minimum, two Qualified Authorized Workers shall be assigned to any job where a Hazardous Chemical line is to be opened. Qualified authorized workers are required to wear the same level of PPE as the person performing the task • A Safety Watch will be assigned for 80 high traffic/busy areas Line Breaking • After initial line break for hazardous chemicals, • (1) If the break is below eye level, employees should wear chemical gloves when working on or handling piping, and • (2) if the break is at or above eye level, employees should wear chemical gloves and wrap around face shield with visor and safety glasses (or regular face shield with goggles) when working on or handling piping. 81 Line Breaking • OSHA regulations and Grace Lake Charles allow working behind a single block valve on Hazardous Chemicals. • If working behind a single block valve, it must be verified that the single block is holding. • Note: A line behind a single block must be pressurized to determine if the block is holding. Work can’t continue until verified. A check valve CANNOT be used as an energy isolation valve. 82 Line Breaking Natural Gas lines: • Barricade perimeter • Wear PPE: Face shields with visor must be worn in addition to safety glasses, hard hat, earplugs and longsleeved cotton shirts to protect against burns should gas combust • At a minimum, two Qualified Authorized Workers shall be assigned to any job where a Natural gas line is to be opened. Qualified authorized workers are required to wear the same level of PPE as the person performing the task • A Safety Watch will be assigned for 83 high traffic/busy areas Confined Space Entry • A "Confined Space Work Permit" must be obtained before ANYONE can enter a Permit Required Confined Space (PRCS). The proper permit will be issued by a trained, authorized Grace representative. • Contract company will be required to provide a trained, competent hole watch for each PRCS job. • The permit issuer shall review the permit with the Entry Supervisor to ensure that both are in agreement that all provisions for safe entry into the permit space have been met prior to "SIGN ON". This permit will be valid for ONE normal shift only. On jobs requiring more than one single shift, a new properly filled out permit must be obtained at the beginning of the next shift or when there is a 84 complete change of entry workers. Confined Space Entry • Any totally enclosed temporary shelter that is constructed directly adjacent to and adjoining the confined space opening, shall be considered as an extension of the confined space due to the possibility of a build-up of a hazardous atmosphere within the shelter. • When applicable the ambient air temperature in the confined space should be tested. Permissible entry air temperature must be =/< 100 degrees. If the temperature is outside the permissible range, safety precautions may be stipulated on the permit for the protection of entrants who will be working in these environments with approval from the safety department. 85 Confined Space Entry Atmospheric Testing: • Before any employee can enter a permit required confined space (PRCS), the internal atmosphere must be tested with a calibrated, direct reading instrument for oxygen, flammability, and if required, toxicity levels. • When the confined space has not been occupied for ONE hour or longer, atmospheric testing must be repeated for entry. • Any Entrant and/or their authorized representative shall be allowed to observe any/all atmospheric testing if requested. • Continuous atmospheric monitoring (LEL/O2/CO) must be conducted during the duration of the work inside the confined space, and MUST be located at the level of the worker unless approved by the Safety Department. 86 Confined Space Entry Introducing a hazardous atmosphere: • All jobs where it is necessary to use toxic or flammable chemicals in a permit space (i.e. glues, thinners, cleaners, solvents, etc.) or where conducting hot work within a confined space on stainless steel or exotic metal, entrants will be required to don supplied air while inside the confined space. • In addition, a bottle watch is required for the supplied air system. 87 Hot Work Requirements • Hot work permits are required for all electric or gas welding, riveting, cutting, brazing, or similar flame or sparkproducing operations. • Approved fire extinguishers must be readily available. • A qualified Fire Watch will be required for some hot work. This will be noted on the permit. • Welding/Burning equipment must be properly maintained. • The hot work permit must be displayed in a conspicuous area during and following the work to be performed. • A new permit must be issued if there is a break in the work of one-hour or longer in 88 duration. Hot Work Requirements Fire Watch Required when: • Hot Work is performed in locations where other than a minor fire might develop, or any of the following conditions exist: • combustible material, in building construction or contents, closer than 35 feet to the point of operation, • combustibles are more than 35 feet away but are easily ignited by sparks, • wall or floor openings within a 35 feet radius of exposed combustible material in adjacent areas including concealed spaces in walls or floors, • combustible materials are adjacent to the opposite side of metal partitions, walls, ceilings, or roofs and are likely to be ignited by conduction or radiation • CX100 Reactors are reacting and the hot work will be performed around the 1612,89A, B, C, D and E XP Reactors. Portable Ladders • Inspect ladders before each used. • Ladders must have verification of current inspection. • Must use non-conductive ladder (i.e. fiberglass). • Maintain the 4:1 ratio when working off of an extension or straight run ladder. • Extension ladders must be positioned so that there is at least a 3 section overlap. • Extension ladders must be secured (tied off) at the top or held by another employee at the bottom. 90 • 3-point contact must be maintained when climbing ladders. Mobile Equipment • All equipment operators must have in their possession, an up to date certification card • Daily inspections are required (per each shift) • Operators must operate the equipment in accordance with the manufacturers instructions • All traffic rules must be obeyed • Seatbelts must be worn • Red barricading must be used when making overhead lifts 91 Electrical Tools and Cords • All electrical tools and cords must be inspected by the user prior to use. • Defective tools and cords must be tagged “Do Not Use” and turned in to the appropriate person. • Electrical tools must have verification of a current inspection. • Electrical tools must be used in conjunction with a Ground Fault Circuit Interrupter (GFCI). • Electrical cords must be routed overhead where possible, and secured with a non-conductive material. • Do not remove ground prong from plugs. 92 Compressed Gas Cylinders • Cylinders must be maintained in an upright position. • Protective caps must remain in place unless in use. • Gauges must be removed when not in use. • Cylinders must be secured with a non-combustible material like a chain (no rope). • Backflow preventors must be used on torches and gauges. 93 Critical Life Safety Policy #418 • Purpose to promote health and welfare of Company personnel, by focusing attention on safety procedures that are critical to preventing life altering and other serious injuries at the workplace. • The policy affirms Grace’s commitment to provide training with regard to these procedures, and clarifies the implications to employees who do not follow the procedures. • The Lake Charles management also applies this policy to 94 contractors. Critical Life Safety Policy #418 Under this policy, the following listed violations will be regarded as intolerable, and will be subject to the most severe discipline permitted by law and local agreement, up to and including termination of employment to any trained employee who commits any such violation • Lockout/tagout violation – Working on energized equipment without a valid permit, unless allowed under partial or total exemption – Failure to adhere to the conditions of the permit • Line Breaking with hazardous material or high pressure violation – Conducting line breaking/securing work without a valid permit – Failure to adhere to the conditions of the permit • Confined Space Entry violation – Entry into a permit required confined space without authorization and a valid permit – Failure to adhere to the conditions of the permit • Hot Work (including cutting and welding) violation – Conducting hot work without a valid permit – Failure to adhere to the conditions of the permit • Work at heights (Fall protection) violation – Failure to use established fall protection when working 6 95 feet or more above an adjacent lower level on a surface that has an unprotected side or edge Questions? • For more information or to answer your questions, please contact your supervisor or your GRACE contact. GRACE 1800 Davison Road Sulphur, LA 70663 337-583-2611 96 Take Test Now • Do not write on test sheet, only answer sheet • Only one correct answer per question • Print Name in box • ID number is Safety Council Card Number • Fill in completely the correct response circle • GOOD LUCK! 80% passing grade required 97