Effects of lithium, indium, and zinc on the lattice parameters of

advertisement

Effects of lithium, indium, and zinc on the lattice parameters

of magnesium

A. Becerra

Hatch Associates, Montreal H3B 2G2, Quebec, Canada

M. Pekguleryuza)

McGill University, Montreal H3A 2B2, Quebec, Canada

(Received 1 July 2008; accepted 28 August 2008)

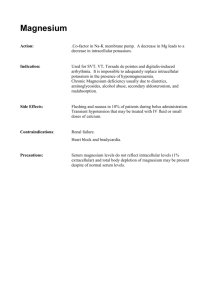

The lattice parameters of magnesium solid-solution alloys with lithium, indium, and/or

zinc have been determined via x-ray diffraction (XRD). Li decreased the axial ratio

(c/a) of Mg from 1.624 to 1.6068 within 0–16 at.% Li. Indium increased the c/a of Mg

to 1.6261 with increasing In toward 3.3 at.% while Zn showed no effect on c/a in the

0.2–0.7 at.% range. The effects were explained by electron overlap through the first

Brillouin zone and by Vegard’s Law. A relationship was determined between electron

concentration (e/a) and c/a as c/a ⳱ −15.6(e/a)2 + 60(e/a) − 55.8.

I. INTRODUCTION

The interest of automotive companies in weight reduction has led to new research in wrought magnesium sheet

alloys. Studies conducted on the deformation behavior of

magnesium1–9 have discovered that magnesium sheet can

be formed at elevated temperatures.

Improving room-temperature formability of Mg is

more challenging and would require among other properties, enhanced slip behavior. An area little discussed is

the modification of the intrinsic formability of magnesium by changing its lattice parameters and the axial ratio

(c/a) of the hexagonal close packed (HCP) crystal so that

more slip systems can be activated at lower temperatures.

This paper reports on partial results of an ongoing study

investigating the effects of solute elements on the potential formability of magnesium. As such, the present paper

focuses on the effects of Li, In, and Zn on the axial ratio

(c/a) of magnesium.

II. BACKGROUND

A. Crystallographic parameters affecting

formability10,11

It is generally known that cubic metals with bodycentered and face-centered cubic structures (BCC and

FCC) are more formable than hexagonal close packed

metals such as magnesium since they can provide at least

five independent slip systems required by the von Mises

criterion for formability. HCP metals on the other hand

have only two independent slip systems. Theoretically, if

magnesium were made either BCC or FCC, it would be

possible to improve its formability.

An important factor in influencing the formability of

HCP metals is the axial ratio.10 Within the HCP metals,

there are variations in room temperature formability,

which have been related to the axial ratio (c/a) as summarized in Table I. This effect was attributed to the

change in the critical resolved shear stress (CRSS) on the

basal plane with varying axial ratio.10 As c/a decreases to

1.59 (Ti, Be), CRSS for basal slip increases and other slip

systems of HCP (prismatic and/or pyramidal slip systems) are activated. The initiation of pyramidal type-II

slip system with (c+a) dislocations would produce five

independent slip systems making magnesium formable

(Table II). Lattice parameters of HCP Mg give a c/a ratio

of 1.62354 at 25 °C. This c/a ratio, as in Cd and Zn,

results in low CRSS on the basal plane favoring basal

slip. Ti and Be on the other hand have a much lower c/a

ratio than Mg, Cd, and Zn, they have high basal CRSS

(Table II) but low prismatic CRSS. The change in the

deformation mechanism with a reduced c/a ratio is attributed to the related change in interplanar spacing, d,

since the shear stress required to move dislocations is

given by Peierles stress,

(1)

= P ⭈ e兵−2d Ⲑ 关b共1−兲兴其 ,

where P is a factor depending on shear modulus, G, and

Poisson’s ratio, ; b is the magnitude of Burger’s vector

of the dislocation; and d is the interplanar spacing.

B. Effects of solutes on crystallographic

parameters

1. Effect of solutes on crystal structure

a)

Address all correspondence to this author.

e-mail: mihriban.pekguleryuz@mcgill.ca

DOI: 10.1557/JMR.2008.0414

J. Mater. Res., Vol. 23, No. 12, Dec 2008

Hume-Rothery has shown, after observing many alloy

systems, that the crystal structure of metallic alloys can

© 2008 Materials Research Society

3379

A. Becerra et al.: Effects of lithium, indium, and zinc on the lattice parameters of magnesium

TABLE I. Basal CRSS and c/a for HCP metals (25 °C).10

Metal

CRSS (psi)

c/a

Cd

Mg

Zn

Ti

Be

82

63

26

16,000

5,700

1.886

1.624

1.856

1.588

1.586

ratio at different temperatures and at different degrees

of deformation to improve the formability of Mg, especially at low temperatures. Au, Ce, and Pd are among the

candidates from Table V, but Au and Pd are expensive alloying additions and Ce has very limited solubility in Mg, so many more solutes need to be researched.

a. Effect of atom-size differences

TABLE II. Slip systems in magnesium.

Slip system

Slip

direction

Slip plane

and direction

Independent

slip systems

Basal

Prismatic

Pyramidal type I

Pyramidal type II

a

a

a

c+a

{0001}⟨11-20⟩

{10-10}⟨11-20⟩

{10-11}⟨11-20⟩

{11-22}⟨11-23⟩

2

2

4

5

Solid-solution alloying where solutes occupy substitutional or interstitial spaces in the crystal lattice can alter

the lattice spacing by expanding or contracting the lattice. Vegard’s Law holds only for solute atoms of similar

valency in which case the lattice parameter change is

purely based on size effects expressed in the form of

dm = ndB + 共1 − n兲dA

be related to the valence (s, p) electron-to-atom ratio

(e/a) as summarized in Table III. An explanation proposed for the tendency for HCP structure formation is the

minimization of electron pair-pair repulsion energy,

while for FCC it is the minimization of the energy of

Coulomb repulsions between nuclei. Both of these structures are favored by enthalpy. The BCC structure on the

other hand (based on the study of various structures) is

favored by high entropy.12 In magnesium, it is well

known that lithium (monovalent solute) additions transform the structure from HCP to BCC at an e/a ratio of 1.7

(30 at.%). At an e/a ratio of 2.1 an FCC structure may

also be expected for magnesium as seen from Table III.

For three-valent solute additions, the change would occur

at 10 at.%. This would be possible with indium, which

has extended solid-solubility in magnesium based on the

Mg-In phase diagram.13

2. Effect on axial ratio10,11

The effect of solutes on the lattice spacing and axial

ratio of magnesium can be regarded as the sum of many

effects: (i) effect of atom-size differences (change of

atomic volume); (ii) effect due to valency differences

(development of shear strain); (iii) effect of temperature

on lattice expansion and electron overlap; and (iv) effect

of strain. Using these principles it is possible to select a

combination of solute elements that can affect the c/a

TABLE III. Relationship between electron concentration and crystal

structure.

3380

e/a

Crystal structure

<1.5

1.7 < e/a < 2.1

2.5 < e/a < 3

e/a > 4

Body-centered cubic (BCC)

Hexagonal close packed (HCP)

Face-centered cubic (FCC)

Diamond

,

(2)

where dm is the mean interatomic distance in the solid

solution, dA and dB are the interatomic distances in the

pure components, and n is the atom fraction of B atoms.

Deviation from this law occurs as soon as the valency

difference between solvent and solute exists. Vegard’s

Law would hold for Mg for two-valent solutes. To have

a major effect, n (atom fraction B) has to be high and this

requires an extensive solid solution range, which is only

possible with elements of similar crystal structure, i.e.,

Cd. This limits the choice of alloying elements.

b. Effect due to valency differences (development of

shear strain)

Lattice spacing also depends on the e/a ratio which is

changed by solute valency. This is understood in terms of

the electronic structure of Mg, which (the first Brillouin

zone) is shown in Fig. 1(a). Brillouin zones depict polyhedra (bounded by crystallographic planes) of energy

states in k space (k ⳱ reciprocal space) which valency

electrons in a metal can occupy. An electron inside the

zone cannot change its energy to the next zone without

receiving a major increase in energy. Unlike insulators,

Brillouin zones in metals overlap; electrons may enter

the next Brillouin zone before the first one is filled and

conduction becomes possible [Fig. 1(b)].

Understanding how electron overlap occurs sheds light

to the alloying behavior of Mg, the effects of solutes on

lattice spacing and the difference from HCP Zn and Cd

which are both two-valent as well. As seen in Table IV,

in magnesium, the energy at the center of {11̄00} prismatic planes, EA, is lower than the energy at the center of

basal {0002} planes, EB. This means that electron-jump

in Mg would first occur perpendicular to the c-axis across

the {11̄00} planes, rather than parallel to it. If solutes of

higher valency than Mg are added, the electrons would

J. Mater. Res., Vol. 23, No. 12, Dec 2008

A. Becerra et al.: Effects of lithium, indium, and zinc on the lattice parameters of magnesium

overlap occurs, the expansion of the c spacing is pronounced and overriding since the resistance to expansion

parallel to the c axis is low.

Studies on the lattice spacing of magnesium alloys

confirm the electronic interpretation of changes in lattice

spacing. General trends indicate the effects of various

solutes shown in Table V.10 These studies evidently were

not exhaustive. It is known that there are other elements,

such as Li, which decrease the c/a ratio of Mg. Lithium

is known to have extensive effects on the lattice parameters, ductility, and formability of magnesium. Due to

its size factor, Li also has extensive solid solubility

(5.5 wt%) in Mg. It reduces the c/a ratio in the ␣ phase

from 1.624 to 1.61 and, correspondingly, the CRSS on

the prismatic slip and the strain-hardening rate.10

c. Effect of temperature on lattice expansion and

electron overlap

FIG. 1. (a) First Brillouin zone for Mg formed by planes {0002},

{11̄00}, and {101̄1} and adjusted for energy discontinuity. (b) Brillouin zone overlap in Mg. e/a ratio: 1.74 in the first zone.10

TABLE IV. Differences in first Brillouin zone energies of Mg, Zn,

Cd.10

Element

Approximate

c/a

n (# electrons

per atom in

the zone)

EA, energy

at center of

{11̄00} planes

EB, energy

at center of

{0002} planes

Mg

Zn

Cd

1.624

1.861

1.890

1.74

1.8

1.8

4.88

7.13

5.67

5.55

6.17

4.77

jump to the second zone resulting in a small fraction of

electrons existing outside of the Brillouin Zone. These

external electrons produce an internal stress in the crystal

causing lattice distortion. An increase in the number of

overlapping electrons pushes the k space plane toward

the center and hence the real lattice a space expands.

When solutes of lower valency are added, the opposite

happens and the a spacing contracts. On the other hand,

the c spacing dependence on alloying is more complicated. Initial alloying does not affect c spacing, until

the critical value is reached where the overlap across

the {0002} planes occurs. This is expected at around

0.75 at.% with three-valent solutes and at 0.375 at.%

with four-valent solutes. When the onset of electron

Temperature alone and in combination with alloying

can also influence the axial ratio. Temperature causes the

c spacing to expand more than the a spacing, resulting in

an increase in c/a. This is the underlying cause of the

increased formability of magnesium at temperatures

above ∼250 °C. Temperature also causes, through thermal excitation, electron overlap perpendicular to the c

axis at a critical temperature. Alloying, which changes

the e/a ratio, would cause a corresponding change in the

critical temperature for the onset of electron overlap. The

temperature for transition to non-basal slip is expected to

depend on solid-solution alloying since this affects the

electron overlap and the differential change in lattice

spacing. While these changes are difficult to predict, it is

possible to observe the overlap in damping capacity or

impact energy experiments. It is also possible to observe

these changes using in situ neutron diffraction or x-ray

diffraction analyses at high temperatures.

d. Effect of strain

Deformation also causes changes in axial ratio. Tensile

stress in the c direction may cause an increase in the c

spacing.10 It is possible that when the alloy is deformed

some of the energy received is used up to affect electronic changes such that after deformation less energy

would remain stored in the lattice than would be expected

TABLE V. Effects of certain solutes elements on a spacing and axial

ratio of Mg.10

Effect

Element

Decrease a spacing of Mg

Increase the a spacing of Mg

Decrease c/a

Increase c/a

No measurable effect on either a or c/a

Au, Mn, Rh, Zr

As, Ba, Ce, La, Ni, Pd

Au, Ce, Pd

Ba, Ir, Pt, Rh, Ti, Zr

Ca, Cu, Sb, Si, Te, W

J. Mater. Res., Vol. 23, No. 12, Dec 2008

3381

A. Becerra et al.: Effects of lithium, indium, and zinc on the lattice parameters of magnesium

TABLE VI. Compositions of magnesium alloys (at.%).

IV. RESULTS AND DISCUSSION

Mg-2.25Li

Mg-6.4Li

Mg-12.6Li

Mg-16.2Li

A. Effects of solutes on lattice parameters

Mg-0.11In Mg-2.82In Mg-0.190Zn Mg-6.2Li-0.34Zn

Mg-0.21In Mg-3.28In Mg-0.325Zn Mg-6.2Li-0.36Zn-0.2In

Mg-0.84In Mg-10In Mg-0.349Zn Mg-0.35Zn-0.19In

Mg-2.21In

Mg-0.70Zn

in alloys with less critical composition (where electronic

change does not take place).

III. EXPERIMENTAL PROCEDURE

A. Alloy synthesis

A number of binary and multi-element solid solution

and dilute magnesium alloys were synthesized using Mg,

Li, In, and Zn. The alloys were prepared from pure metals: magnesium (99.98 wt%) (Timminco Metals, Haley,

Ontario, Canada) and cerium (99.91 wt%) (Hefa Rare

Earths Canada Co. Ltd., Richmond, BC, Canada). Pure

lithium (99.98 wt%) and indium (99.999 wt%) were from

the same source (Alfa Aesar). The alloys were made by

adding the elements to a pure magnesium melt in a Lindberg electric resistance furnace at 680 °C. All alloys were

synthesized under CO2-0.5%SF6 gas cover except for the

Li-containing alloys which were prepared under argon.

Alloys were cast into copper disc molds of 40 mm diameter. The castings were homogenized under argon at

400 °C for 8 h to eliminate microsegregation. Chemical

compositions were determined via Inductively-Coupled

Plasma Atomic-Emission Spectroscopy (ICP-AES)

(Genitest Inc., Montreal). The compositions of the alloys

are shown in Table VI.

B. Characterization

X-ray diffraction (XRD) was carried out on fine

(65 mesh) annealed powder samples with a Phillips 1710

diffractometer with Cu-k␣ radiation, an accelerating

voltage of 40 kV, beam current of 20 mA, and a scan rate

of 0.025 deg/s in a 2 range of 25–120°. Fine powder

was obtained by filing the alloys. The powders were

encapsulated in a quartz tube, sealed under argon, and

annealed for 16 h at 275 °C. Pure Si was added to all

powders to correct for sample displacement. Raw XRD

data were refined and analyzed via the Rietveld method

using GSASTM software. The measurements were repeated on three different powder samples and the results

were averaged.

1. Magnesium-lithium system

The change in the lattice parameters and axial ratio of

Mg with Li additions is shown in Table VII. It can be

seen that a contraction of both c and a spacing and a

reduction in unit-cell volume occurs. Since the reduction

in c spacing is more significant, a net reduction in c/a is

observed (Fig. 2).

Vegard’s law explains the change in a spacing well

with the alloying of the small Li atom (rLi ⳱ 1.56 Å;

rMg ⳱ 1.602 Å). However, the change in c spacing

seems to be more substantial than the a spacing shift.

This may be explained by the valency effect. One-valent

lithium decreases the e/a ratio of the alloy from 2 to 1.83

as the Li concentration increases to 16 at.%. Since the

electron overlap in Mg occurs across the B faces (Fig. 1)

of the Brillouin zone, when lower valency solute is added

and e/a decreases, electrons from the second Brillouin

jump into first Brillouin zone. These produce a stress that

causes lattice distortion that pushes the B faces outward

in reciprocal space. Hence, a contraction of the c spacing

in real space occurs. This explains the decrease in the c/a

ratio as well as of the volume.

The change in the interplanar spacing of basal, prismatic, and pyramidal planes in Mg-Li alloys is shown in

Table VIII. A larger reduction in the spacing of basal

planes is observed than in the spacing for non-basal

planes. Since Peierls stress for dislocation motion increases as the interplanar spacing decreases, the activation of basal slip would be challenged and the yield stress

would increase. Using Eq. (1) and neglecting all other

changes except the interplanar spacing d, it can be understood that prismatic slip would set in when

dbasal = c Ⲑ 2 = dprismatic = a公3 Ⲑ 2

,

(3)

or at a c/a ratio ⳱ 1.73 (see Ref. 10, p. 269). Experimentally, the activation of prismatic slip has been seen to

set in the range 1.624–1.610. Extensive prismatic slip has

been observed at Mg-16 at.% Li alloys (see Ref 10, pp.

268–269).

Pyramidal slip with c + a dislocations (i.e., {11-22 <

11-23}system) is expected to be activated when the

TABLE VII. Effects of Li on lattice parameters of Mg.

Alloy

wt% Li

at.% Li

e/a

a (Å)

sd a

sd c

c/a

sd c/a

Volume (Å)3

Mg

Mg-2.3Li

Mg-6.4Li

Mg-13Li

Mg- 16Li

0.00

0.65

1.92

3.97

5.24

0.00

2.25

6.41

12.64

16.22

2.000

1.978

1.936

1.874

1.838

3.2088

3.2076

3.2034

3.1964

3.1930

0.0002

0.0006

0.0004

0.0004

0.0004

0.0004

0.0006

0.0002

0.0005

0.0004

1.6240

1.6227

1.6200

1.6129

1.6068

0.0001

0.0002

0.0002

0.0002

0.0001

46.47

46.38

46.12

45.62

45.30

3382

J. Mater. Res., Vol. 23, No. 12, Dec 2008

A. Becerra et al.: Effects of lithium, indium, and zinc on the lattice parameters of magnesium

slip activation at room temperature. However, in polycrystalline material, the change in d spacings may potentially alter the balance of deformation systems and positively influence room temperature formability.

2. Magnesium-indium system

The effects of three-valent In on the lattice parameters

of Mg are shown in Fig. 3 and Tables IX and X. Figure

3(a) shows that the effect of In on the Mg unit cell is

complicated. At low In concentrations (below 0.5 at.%

In) an expansion is seen in lattice parameters that is

followed by a contraction of both a and c spacing. While

the a spacing continues to contract, the c spacing then

shows a reversal and expands again after 2.2 at.%. The

initial increase in both a and c without any change in the

c/a ratio with In can be explained by Vegard’s law due to

the higher atomic size of In (rIn ⳱ 1.66 Å).

The decrease in lattice spacing cannot be explained by

the electron overlap of a three-valent solute such as indium. That effect would have resulted in at least an increase in c spacing. A decrease may be attributed to the

change of bonding from metallic to covalent, resulting in

FIG. 2. Effect of lithium on (a) the lattice parameters and (b) axial

ratio of Mg.

TABLE VIII. Effect of Li on interplanar spacing.

Interplanar spacing (Å)

Alloy

{0002}

{101̄0}

{112̄2}

(c/2a)(c2 + a2)1/2

Mg

Mg-2.3 Li

Mg-6.4Li

Mg-13Li

Mg-16Li

2.6056

2.6026

2.5948

2.6778

2.5653

2.7789

2.7779

2.7742

2.7682

2.7752

1.3662

1.3654

1.3629

1.3583

1.3554

4.9693

4.9608

4.9398

4.8921

4.8549

parameter d/b in Eq. (1) for the {11-22 < 11-23} system

equals that for the basal {0001}⟨11-20⟩ system. That

means pyramidal slip could be activated when

dbasal Ⲑ a = c Ⲑ 共2a兲 = dpyramidal Ⲑ 共bc+a兲 ,

(4)

or when

dpyramidal = 共c Ⲑ 2a兲共c2 + a2兲1 Ⲑ 2

.

(5)

As seen in Table VII, the pyramidal spacing and the

Burger’s vectors do not reach the values for pyramidal

FIG. 3. Effect of indium on (a) the lattice parameters and (b) axial

ratio of Mg.

J. Mater. Res., Vol. 23, No. 12, Dec 2008

3383

A. Becerra et al.: Effects of lithium, indium, and zinc on the lattice parameters of magnesium

TABLE IX. Effects of In on lattice parameters of Mg.

Alloy

wt% In

at.% In

e/a

a (Å)

sd a

c (Å)

sd c

c/a

sd c/a

Volume (Å)3

Mg

Mg-0.1In

Mg-0.2In

Mg-0.8In

Mg-2.2In

Mg-2.8In

Mg-3.3In

0.00

0.51

0.97

3.84

9.63

12.05

13.80

0.00

0.11

0.21

0.84

2.21

2.82

3.28

2.000

2.001

2.002

2.008

2.022

2.028

2.033

3.2088

3.2095

3.2094

3.2084

3.2062

3.2054

3.2049

0.0002

0.0000

0.0003

0.0001

0.0002

0.0003

0.0001

5.2111

5.2123

5.2123

5.2117

5.2103

5.2110

5.2113

0.0004

0.0003

0.0003

0.0002

0.0002

0.0001

0.0004

1.6240

1.6240

1.6240

1.6244

1.6251

1.6257

1.6261

0.0001

0.0001

0.0002

0.0000

0.0001

0.0001

0.0001

46.47

46.50

46.50

46.46

46.39

46.37

46.35

TABLE X. Effect of In on interplanar spacing.

Interplanar spacing (Å)

Alloy

{0002}

{101̄0}

{112̄2}

(c/2a)(c2 + a2)1/2

Mg

Mg-0.1In

Mg-0.2In

Mg-0.8In

Mg-2.2In

Mg-2.8In

Mg-3.3In

2.6056

2.6062

2.6062

2.6059

2.6052

2.6055

2.6056

2.7789

2.7795

2.7794

2.7786

2.7767

2.7760

2.7755

1.3662

1.3665

1.3664

1.3661

1.3653

1.3651

1.3650

4.9693

4.9705

4.9706

4.9707

4.9709

4.9729

4.9740

a decrease of indium atom size which in turn results in a

contraction of both a and c parameters. This agrees with

previous work10 performed on Mg-In alloys where lattice

parameters were seen to contract due to the smaller

atomic size of indium. The final increase in lattice spacing above 2.2 at.% In can be explained by the electron

overlap effect across the basal planes which results in a

c spacing increase. Theoretically, an expansion in c spacing for a three-valent solute is expected at 0.75 at.%. The

fact that the expansion is observed at higher at.% (2.2%)

can be attributed to the contribution from the atom size

effect. The 2.2 at.% limit for the onset of the increase in

c spacing agrees with the previous work of Batchelder

et al.14

The change in interplanar spacing (Table X) follows

the lattice parameter changes. It can be observed that a

possibility for prismatic or pyramidal slip activation at

room temperature is not likely based on the experimentally obtained c/a ratio or d spacings. However, the balance of deformation systems may be altered in a polycrystalline material for very small changes, and these

need to be investigated experimentally.

3. Magnesium-zinc system

Zinc additions in the range 0.2–0.7 at.% Zn contracts

both c and a spacing as well as the volume (Table XI).

Since Zn is two-valent, the effect can be explained by

atomic size difference (rZn ⳱ 1.39 Å). Changes to both

lattice parameters shown in Fig. 4 indicate that the contraction in both parameters is to the same degree with no

effect on the axial ratio.

Relationships between solute content and lattice parameters were developed for Li, In, and Zn additions

to Mg as aalloy ⳱ aMg + ma x; calloy ⳱ cMg + mc x;

(c/a)alloy ⳱ (c/a)Mg + mc/a x; volalloy ⳱ volMg–mvol x

where ma, mc, mc/a, and mvol are the slopes of the lattice

parameter versus composition curves experimentally determined and x is at.% solute. The relationships for Li, In,

and Zn additions are shown in Table XII.

4. Multi-component alloys

Multi-component alloys were prepared with combined

additions of Li, Zn, and In. The axial ratio of these alloys

is given in Table XIII. For the Li-containing multicomponent alloys, it is noted that the major effect on

axial ratio of these alloys is contributed by the Li addition.

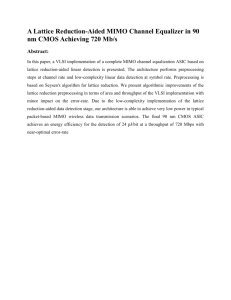

5. Relationship between axial ratio and electron

concentration of magnesium alloys

Since the effect of combined additions on lattice parameters would be complex, the effect of changing electron ratio (e/a) as a result of solid-solution alloying was

determined and related to lattice parameters. The axial

ratio (c/a) of solid-solution alloys with single and combined additions of alloying elements was related to their

valence electron concentration (e/a). The results are summarized in Table XIII. An empirical relationship [Eq.

(6)] was found between the experimentally determined

axial ratio (c/a) and the valence electron concentration

(e/a) of binary and multi-component alloys [Fig. 5(a)].

c Ⲑ a = −0.32共e Ⲑ a兲2 + 1.34共e Ⲑ a兲 + 0.25

.

(6)

TABLE XI. Effects of Zn on lattice parameters of Mg.

Nominal

wt% Zn

at.% Zn

e/a

a (Å)

sd a

c (Å)

sd c

c/a

sd c/a

Volume (Å)3

Mg

Mg-0.2Zn

Mg-3Zn

Mg-0.7Zn

0.00

0.51

0.87

1.86

0.00

0.19

0.32

0.7

2.000

2.000

2.000

2.000

3.2088

3.2084

3.2076

3.2054

0.0003

0.0005

0.0002

0.0003

5.2111

5.2107

5.2091

5.2049

0.0004

0.0002

0.0005

0.0003

1.6240

1.6241

1.6240

1.6238

0.0001

0.0003

0.0001

0.0002

46.47

46.45

46.41

46.31

3384

J. Mater. Res., Vol. 23, No. 12, Dec 2008

A. Becerra et al.: Effects of lithium, indium, and zinc on the lattice parameters of magnesium

FIG. 4. Effect of zinc on the lattice parameters of Mg.

TABLE XII. Lattice parameter versus solute content.

Solute

addition

Li

In

Zn

a

C

c/a

Volume

3.21 − 0.0059x 5.22 − 0.0053x 1.624 + 0.0011x 46.5 − 0.049x

3.21 − 0.0015x 5.21 − 0.0004x 1.624 + 0.0006x 46.5 − 0.049x

3.21 − 0.0011x 5.21 − 0.0113x

—

46.5 − 0.272x

TABLE XIII. c/a versus e/a for single and combined solute additions

to Mg.

Alloy (at.%)

c/a

e/a

Alloy (at.%)

c/a

e/a

Mg

Mg-2.25Li

Mg-6.4Li

Mg-12.6Li

Mg-0.11In

Mg-0.21In

Mg-0.84In

Mg-2.21In

Mg-2.82In

1.6240

1.6227

1.6200

1.6129

1.6240

1.6240

1.6244

1.6251

1.6257

2

1.98

1.94

1.87

2.001

2.002

2.008

2.025

2.028

—

Mg-3.28In

Mg-0.190Zn

Mg-0.325Zn

Mg-0.349Zn

Mg-0.70Zn

Mg-6.2Li-0.34Zn

Mg-6.2Li-0.36Zn-0.2In

Mg-0.35Zn-0.19In

—

1.6261

1.6241

1.6240

1.6240

1.6238

1.6219

1.6219

1.6241

—

2.033

2.0

2.0

2.0

2.0

1.9381

1.9396

2.0019

Atomic radius (Å): Mg: 1.602; In: 1.663; Li: 1.562; Zn; 1.394 (metallic

bonding as per Ref. 15).

Using Hume-Rothery rules and the data for Mg-Li from

the phase diagram,13 as well as the experimental values

of this study, a more extensive c/a versus e/a graph was

plotted [Fig. 5(b)]. The axial ratio versus electron concentration relationship here is given as

c Ⲑ a = −15.6共e Ⲑ a兲2 + 60共e Ⲑ a兲 − 55.8

.

(7)

From Fig. 5(b), it is interesting to note that an e/a of

∼1.83 and 2.03 would give an axial ratio of 1.58, similar

to Ti and Be which are known to have non-basal slip

activation at room temperature. Mg would have this c/a

value for a Li concentration of 20 at.% and, hypothetically, at In solute concentrations of ∼3–5 at.%. An

interesting study would be the determination of the deformation behavior and slip systems as the Mg structure approaches a c/a of around 1.58–1.59 or an e/a of

FIG. 5. (a) c/a versus e/a for binary, ternary and quaternary Mg solidsolution alloys and (b) experimental data of (a) plotted together with

the two theoretical points (BCC, FCC) for cubic structures.

∼2.03–2.04. Mg with 5 at.% In can also give an e/a of

2.05 and should be studied in the future for possible

non-basal slip activation. It is also possible to make calculations for other multi-component alloys that could result in electron concentrations in the range 1.7–1.8 which

would change the unit cell of Mg toward BCC structure,

and in the range 2.03–2.1 which could result in FCC

structure. Investigation of Mg with 10 at.% In and the

design of multi-component Mg solid-solution alloy to

give an e/a ratio of 2.1 to see if a near-FCC structure

develops are also worthy of study in the future.

B. Synopsis

The axial ratio (c/a) of magnesium can be effectively reduced by Li additions. Furthermore, this study

shows that the axial ratio of magnesium can be designed by developing solid-solution alloys with specific electron-to-atom (e/a) ratios using the relationship

c/a ⳱ −15.6(e/a)2 + 60(e/a) − 55.8.

J. Mater. Res., Vol. 23, No. 12, Dec 2008

3385

A. Becerra et al.: Effects of lithium, indium, and zinc on the lattice parameters of magnesium

V. CONCLUSIONS

(1) The one-valent lithium decreased the axial ratio (c/a) of magnesium from 1.624 to 1.6068 within the

0–16 at.% Li range. This was attributed to the decrease in

the e/a ratio causing electron overlap from the second

Brillouin zone to the first Brillouin which leads to a

contraction of the c spacing in real space and a decrease

in the c/a ratio.

(2) The three-valent indium increased the c/a ratio

of magnesium to 1.6261 as indium increased toward

3.3 at.%. The changes in a and c spacings were related to

changes in the e/a ratio as well as the atom size effect

through Vegard’s law.

(3) The two-valent zinc showed no effect on the c/a

ratio in the 0.2–0.7 at.% range, since, as explained by

Vegard’s law, the atom size caused similar change in

both a and c parameters.

(4) A relationship was determined between the e/a

and c/a ratios as c/a ⳱ −15.6(e/a)2 + 60(e/a) − 55.8.

ACKNOWLEDGMENTS

3.

4.

5.

6.

7.

8.

9.

10.

The authors gratefully acknowledge the financial support of Natural Sciences and Engineering Research

Council (NSERC) of Canada, General Motors (GM) of

Canada, and McGill University and thank Pierre Vermette for assisting in the casting experiments.

11.

12.

13.

14.

REFERENCES

1. J.W. Christian and S. Mohajan: Deformation twinning. Prog.

Mater. Sci. 39, 1 (1995).

2. M.M. Myshlyaev, H.J. McQueen, A. Mwembela, and E. Konopleva:

3386

15.

Twinning, dynamic recovery and recrystallization in hot-worked

Mg-Al-Zn alloy. Mater. Sci. Eng., A 337, 121 (2002).

S.L. Couling, J.F. Pashak, and L. Sturkey: Unique deformation

and aging characteristics of certain magnesium-based alloys.

Trans. ASM 51, 94 (1959).

T. Uesugi, M. Kohyama, M. Kohzu, and K. Higashi: Generalized

stacking fault energy and dislocation, properties for various slip

systems in magnesium: A first principles study. Mater. Sci. Forum

419–422, 225 (2003).

S.E. Ion, F.J. Humphreys, and S.H. White: Dynamic recrystallization and the development of microstructure during the high

temperature deformation of magnesium. Acta Metall. 30, 1909

(1982).

A. Grosvenor and C.H.J. Davies: Microstructural evolution during

hot deformation of magnesium alloy AZ31. Mater. Sci. Forum

426–432(2), 4567 (2003).

L. Cisar, Y. Yoshida, S. Kamado, and Y. Kojima: Development of

high strength and ductile magnesium alloys for automobile applications. Mater. Sci. Forum 419–422(1), 249 (2003).

W.J. Kim and H.G. Jeong: Mechanical properties and texture

evolution in ECAP processed AZ61 Mg alloy. Mater. Sci. Forum

419–422(1), 201 (2003).

P. Krajewski: Elevated temperature behavior of sheet magnesium

alloys, Magnesium Technology 2002, edited by H.I. Kaplan (TMS

Magnesium Symposium Proc., TMS, Warrendale, PA, 2002), p.

175.

G.V. Raynor: The Physical Metallurgy of Magnesium and Its

Alloys (Pergamon Press, New York, 1959).

E.F. Emley: Principles of Magnesium Technology (Pergamon

Press, London, 1966).

S. Alexander and J. McTague: Should all crystals be BCC?

Landau theory of solidification and crystal nucleation. Phys. Rev.

Lett. 41, 702 (1978).

Binary Alloy Phase Diagrams, edited by T.B. Massalski, 2nd ed.

(ASM International, Materials Park, OH, 1990).

F.W. von Batchelder and R.F. Raeuchle: Lattice constants and

Brillouin overlap in dilute magnesium alloys. Phys. Rev. 105, 1

(1957).

W.B. Pearson: The Crystal Chemistry and Physics of Metals and

Alloys (Wiley-Interscience, New York, 1972).

J. Mater. Res., Vol. 23, No. 12, Dec 2008