EXAMPLE 1

advertisement

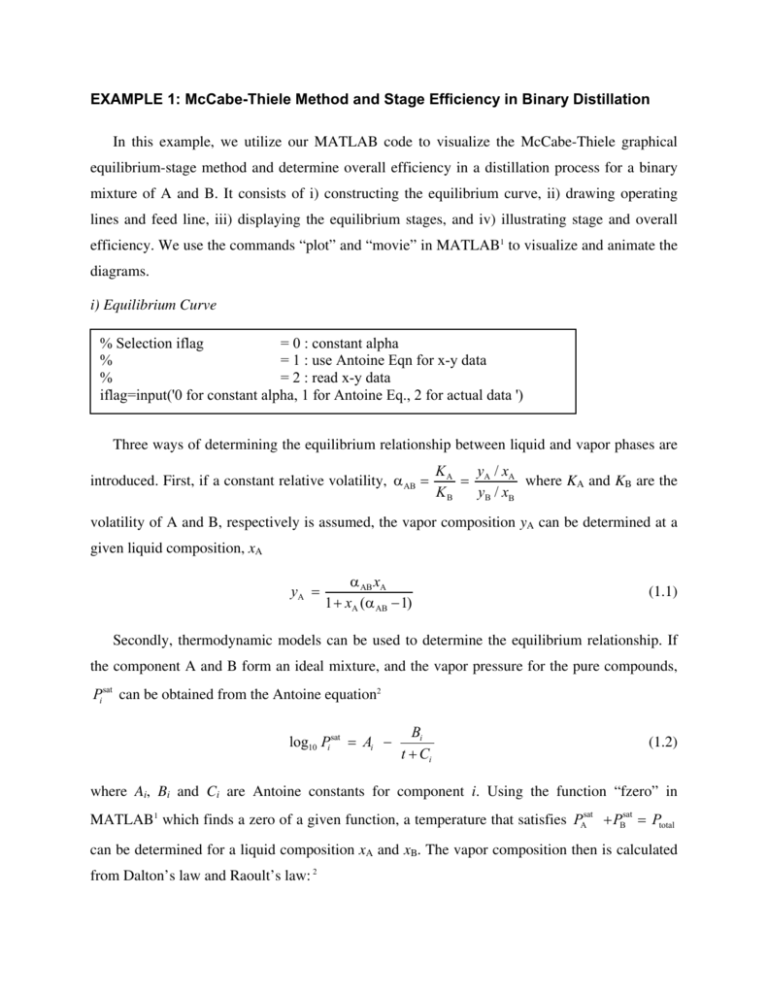

EXAMPLE 1: McCabe-Thiele Method and Stage Efficiency in Binary Distillation

In this example, we utilize our MATLAB code to visualize the McCabe-Thiele graphical

equilibrium-stage method and determine overall efficiency in a distillation process for a binary

mixture of A and B. It consists of i) constructing the equilibrium curve, ii) drawing operating

lines and feed line, iii) displaying the equilibrium stages, and iv) illustrating stage and overall

efficiency. We use the commands “plot” and “movie” in MATLAB1 to visualize and animate the

diagrams.

i) Equilibrium Curve

% Selection iflag

= 0 : constant alpha

%

= 1 : use Antoine Eqn for x-y data

%

= 2 : read x-y data

iflag=input('0 for constant alpha, 1 for Antoine Eq., 2 for actual data ')

Three ways of determining the equilibrium relationship between liquid and vapor phases are

introduced. First, if a constant relative volatility, α AB =

KA

y /x

= A A where KA and KB are the

KB

yB / xB

volatility of A and B, respectively is assumed, the vapor composition yA can be determined at a

given liquid composition, xA

yA =

α AB xA

1 + xA (α AB − 1)

(1.1)

Secondly, thermodynamic models can be used to determine the equilibrium relationship. If

the component A and B form an ideal mixture, and the vapor pressure for the pure compounds,

Pi sat can be obtained from the Antoine equation2

log10 Pi sat = Ai −

Bi

t + Ci

(1.2)

where Ai, Bi and Ci are Antoine constants for component i. Using the function “fzero” in

B

MATLAB1 which finds a zero of a given function, a temperature that satisfies PAsat + PBsat = Ptotal

can be determined for a liquid composition xA and xB. The vapor composition then is calculated

B

from Dalton’s law and Raoult’s law: 2

PAsat

yA =

xA Ptotal

(1.3)

Finally, the liquid and vapor compositions, xA and yA can directly be read from the actual data.

With the liquid and vapor compositions in equilibrium xA and yA, the equilibrium curve, i.e. the y

– x diagram is plotted.

figure(1), clf

for i = 1:itotal

xnew=x+dx;

if iflag==0

% Contant alpha

ynew=a*xnew/(1+xnew*(a-1));

elseif iflag==1

% Using Antoine Eq. (2)

t=fzero('antoine',tguess,optimset('disp','iter'),xnew,a1,b1,c1,a2,b2,c2,Ptotal);

tguess=t;

ynew=pvapor(a1,b1,c1,t)/Ptotal*xnew

else

% Actual Data

xnew=xdata(i+1);

ynew=ydata(i+1);

end

plot([x,xnew],[y,ynew],'b','LineWidth',2) % Plot y vs. x diagram (eq. curve)

hold on

title('McCabe-Thiele Method')

xlabel('x')

ylabel('y')

axis([0 1 0 1])

axis('square')

plot([x xnew], [x xnew], 'b--','LineWidth',2)

hold on

Frames(:,i)=getframe;

x=xnew;

y=ynew;

end

ii) Operating Lines and Feed Line

Under the assumption of constant molar overflow, i.e. constant molar liquid and vapor rates,

L and V in the rectifying section (and L and V in the stripping section), the operating lines for

the rectifying and stripping sections can be displayed using

2

⎛ R ⎞

⎛ 1 ⎞

y =⎜

⎟x+⎜

⎟ xD

⎝ R +1⎠

⎝ R +1⎠

(1.4)

⎛ V +1⎞ ⎛ 1 ⎞

y = ⎜ B ⎟ x − ⎜ ⎟ xB

⎝ VB ⎠ ⎝ VB ⎠

(1.5)

where R = L/D and VB = V / B are the reflux ratio and boil-up ratio, and D and B are the distillate

and bottoms product rate, respectively. In Eqs. (1.4) and (1.5), xD and xB are the overhead

product and bottom product composition, respectively.

Meanwhile, the q-line which describes the feed condition can also be displayed using

⎛ q ⎞ ⎛ zF ⎞

y =⎜

⎟ x −⎜

⎟

⎝ q −1 ⎠ ⎝ q −1 ⎠

where q =

(1.6)

L−L

is the ratio of the increase in molar flux rate across the feed stage to the molar

F

feed rate, F, and zF is the feed composition. Once any two of these three parameters, the reflux

ratio, R, boil-up ratio VB and feed condition q are specified, the operating lines from Eqs. (1.4)

and (1.5), and the q-line from Eq. (1.6) are uniquely determined.

iii) Theoretical Equilibrium Stages

Once the equilibrium curve, operating lines and feed line are drawn, the equilibrium composition

at each stage is determined by the McCabe-Thiele method. Starting from the distillate xD (or

bottoms product xB), the procedure for plotting the graphical solution is as follows:

a. Draw a horizontal line from (xD, xD) to the equilibrium curve

b. Drop a vertical line to the operating line

c. Repeat a and b until x reaches xB.

When actual data is used for the equilibrium curve, the Matlab interpolation function called

“interp1” is used to find the intersection points in procedure a.1 The transfer in the operating line

from the rectifying section to stripping section is made when the liquid composition, x passes

that of the intersection of the two operating lines and feed line.

3

while x >= x_B

% loop for stepping

ynew=y

% using constant alpha for eq. relation

if iflag==0

xnew=ynew/(a-ynew*(a-1));

% using Antoine Eq. (2) for eq. relation

elseif iflag==1

t=fzero('antoine2',tmid,optimset('disp','iter'),ynew,a1,b1,c1,a2,b2,c2,Ptotal);

xnew=ynew*Ptotal/pvapor(a1,b1,c1,t);

% using actual data for eq. relation

else

xnew=interp1(ydata,xdata,ynew);

end

plot([x,xnew],[y,ynew],'r','LineWidth',2) % a. Draw a horizontal line to the eq. curve

hold on

Frames(:,i)=getframe;

pause

i=i+1;

x=xnew

if x >= x_c

%if x >= z

% using the op. line for rectifying section

y=LoverV_D*x+x_D/(R+1)

else

% using the op. line for stripping section

y=LoverV_B*x-x_B/V_B

end

plot([xnew,x],[ynew,y],'r','LineWidth',2) % b. Draw a vertical line to the op. line

hold on

Frames(:,i)=getframe;

pause

% calculating # of stages

if x >= x_B

nstage=nstage+1

else

nstage=nstage+x/x_B

end

end

% c. Repeat a and b until x reaches x_B

iv) Stage and Overall Efficiency

Using the Murphree vapor efficiency, EMV for each stage, the actual vapor composition can

be obtained as2,3

yi = yi +1 + EMV ( yieq − yn +1 )

(1.7)

4

where i+1 is the stage below and yieq is the composition in the vapor in equilibrium with the

liquid composition leaving stage i, xi. The overall efficiency, Eo is determined by the ratio of the

number of the theoretical equilibrium stages to that of the actual stages, i.e. Eo = N t / N a .

REFERENCES

1. Pratap, R., Getting Started with MATLAB, A Quick Introduction for Scientists and

Engineers (Oxford University Press, 2002).

2. McCabe, W. L., Smith, J. C. and Harriott, P., Unit Operations of Chemical Engineering

(McGraw Hill, 6th ed., 2000)

3. Seader, J.D. and Henley, E.J., Separation Process Principles (John Wiley & Sons, 1998)

Obtain equilibrium data

Thermodynamic Input

Constant relative volatility/ Antoine equation/

Actual data

• Step 1: Display y vs. x diagram (eq. curve)

Design Input

Reflux ratio & feed condition

or

Reflux ratio & boilup ratio

or

Boilup ratio & feed condition

• Step 2: Display operating lines and feed line

• Step 3: Determine theoretical equilibrium stages, Nt

• Horizontal line to equilibrium curve

• Vertical drop to operating line

Design Input

Murphree vapor efficiency, Emv

• Step 4: Display new stepping based on Emv

Determine actual stages Na and overall efficiency Eo

Figure 1.1. Flow chart of Example 1: graphical method for binary distillation

5

0.9

0.9

0.8

0.8

0.7

0.7

0.6

0.6

0.5

0.5

0.4

0.4

0.3

0.3

0.2

0.2

0.1

0.1

0

y

y

1

0

0.1

0.2

0.3

0.4

0.5

x

0.6

0.7

0.8

0.9

0

1

1

1

0.9

0.9

0.8

0.8

0.7

0.7

0.6

0.6

0.5

0.5

y

y

1

0.4

0.4

0.3

0.3

0.2

0.2

0.1

0.1

0

0

0.1

0.2

0.3

0.4

0.5

x

0.6

0.7

0.8

0.9

1

0

0

0.1

0.2

0.3

0.4

0.5

x

0.6

0.7

0.8

0.9

1

0

0.1

0.2

0.3

0.4

0.5

x

0.6

0.7

0.8

0.9

1

Figure 1.2. Snap shots of graphical output of Example 1: McCabe-Thiele method for binary

distillation of acetone and toluene. a) Equilibrium curve from Antoine equations, b) operating

lines and feed line for zA = 0.5, xD = 0.95, xB = 0.05, q = 0.5, R = 2, c) theoretical equilibrium

stages, and d) actual stages (shown in dashed line) with Emv = 0.7.

B

6