Development of a new thermodynamic chart for isentropic

advertisement

14th Annual (International) Mechanical Engineering Conference - May 2006

Isfahan University of Technology, Isfahan, Iran

DEVELOPMENT OF A NEW THERMODYNAMIC CHART FOR

ISENTROPIC EXPANSION OF CONDENSING STEAM FLOW

M. J. Kermani 1

M. Zayernouri 2

M. Saffar-Avval 3

Department of Mechanical Engineering

Amirkabir University of Technology (Tehran Polytechnic)

Tehran, Iran 15875–4413

Abstract

A new thermodynamic chart for isentropic expansion of compressible steam flow is developed. The steam is assumed

to obey local equilibrium thermodynamic model, where condensation onsets as soon as the saturation line is crossed

at “c.o.”. Above the “c.o.”, the stagnation properties reflect those at inflow. However, beyond the “c.o.”, the transfer

of latent heat toward the vapor portion of the two-phase mixture, rises its stagnation temperature. A non-dimensional

function “ζ”, is defined, which represents the increase in vapor stagnation temperature. The vapor is assumed to be a

real gas obeying the “Lee-Kesler” EOS.

Keywords: Analytical Solution of Steam – Equilibrium Thermodynamics – Compressible Steam Flow

Introduction

Correct prediction of moisture levels in wet steam

flows is both scientifically interesting and of engineering importance.

Applications include condensing flows of most air

or combustion product, aerosol formation in mixing

processes, aerodynamic testing in cryogenic wind tunnels and wetness problems in steam turbines and expansion in nozzles. In many industrial equipments

such as vapor nozzles, it has been shown that focusing

on the gas phase and constructing a correct relation

between its static and stagnation conditions at each

point on the process line, it is possible to predict the

flow field characteristics and its thermodynamic properties [1]. Therefore, knowing the stagnation properties such as total temperature and pressure at any

point is a vital issue. Following single-phase measuring techniques, stagnation probes are often used in

two phase flow situation [2, 3, 4]. In practice if the

size of liquid droplets is small (less than one micron)

the momentum (inertia) and thermal equilibrium between the two phases are maintained, and the pitot

tube would measure the equilibrium stagnation pressure [5]. Hence, all interphase transfer processes re1 Assistant

2 Graduate

3 Professor

main essentially frozen. Although, imposing the assumption of equilibrium thermodynamic model in the

wet flow studies is restrictive, but the development of

non-equilibrium multi-phase models begins with the

knowledge of equilibrium state.

In our earlier work we developed an algorithm to

numerically compute the flow characteristics along a

converging-diverging duct, [6], and we modelled condensing steam flow under equilibrium thermodynamic

model. Later an analytical solution was provided for

an identical problem, [1], and an excellent agreement

between the results were obtained. In [1, 6] we used

the ideal gas equation of state for vapor.

The present paper is a continuation to our analytical solution, and reports a progress in our on-line development. Here, we provide a new chart and table to

conveniently determine the local stagnation states of

the vapor portion of a two-phase mixture through an

isentropic expansion of the mixture. These conditions

are used to fix the thermodynamic states and flow conditions along the duct. Here we use the “Lee-Kesler”

equation of state for the vapor. Although it is observed

that the equation of states “Lee-Kesler” and ideal gas

provide same results in low pressure application (less

than 30 kPa used in this study), however, the equation

Professor, Corresponding Author, E-mail: mkermani@aut.ac.ir

Student

14th Annual (International) Mechanical Engineering Conference - May 2006

Isfahan University of Technology, Isfahan, Iran

of state “Lee-Kesler” is suitable for higher values of

pressure too. Accuracy assessment tests show excellent agreement between the predictions of numerical

results and analytical solutions.

Process Evaluation

Consider a dry steam flow entering a convergingdiverging nozzle that isentropically expands along the

duct, as illustrated in Fig. 1. According to the equilibrium thermodynamic model, the flow remains dry

up to the “condensation onset” point (“c.o.”), beyond

which a second phase (liquid water) in generated. The

stagnation conditions attributed to the dry flow (the

flow between the inlet and “c.o.”) stay constant, and

can be obtained from:

¶

µ

γ−1 2

T0,res.

(1)

= 1+

M

T

2

dry

where γ is the ratio of specific heats of the vapor,

T0,res. is the stagnation temperature at inflow, and

M and T represent the local Mach number and static

temperature, respectively. However, beyond the “c.o.”

point, the transfer of latent heat from the condensate

toward the vapor, rises the stagnation temperature of

the vapor portion of the two-phase mixture, where

Eqn. 1 cannot be used. As a result a “local stagnation” temperature for the vapor portion of the twophase mixture can be defined [1]:

µ

¶

T0,local

γ−1 2

= 1+

M

(2)

T

2

wet

T0,local is the “local stagnation” temperature of the vapor portion of the two-phase mixture, which is larger

than that of the inflow (T0,local > To,res. ) due to the

transfer of latent heat from the condensate toward the

vapor.

We define a non-dimensional function “ζ” representing the rise in the stagnation temperature of the

vapor portion of the two-phase mixture, as:

ζ≡

T0,local − T0,res.

T

Using Eqn. 2, “ζ” becomes:

¶

µ

T0,res.

γ−1 2

−(

M

).

ζ = 1+

2

T

wet

(3)

(4)

Applying the first law of thermodynamics for a

control volume between the nozzle inlet, and an arbitrary point in two-phase region along the nozzle, one

can write:

ṁtot. h0,res. = ṁg (hg +

Vf2

Vg2

) + ṁf (hf +

) , (5)

2

2

where h0,res. is the stagnation enthalpy at the nozzle

inlet, ṁtot. is the mass flow through the nozzle, ṁg

and ṁf are the vapor and liquid mass flow, hg and hf

are the enthalpy of the vapor and liquid, and Vg and Vf

are the vapor and liquid velocities at the arbitrary section. From the mass balance around our control volume (with no mass accumulation within the nozzle),

we can write, ṁtot. = ṁg + ṁf . If the slip velocity

between the phases is ignored (i.e., Vf = Vg = V ),

and assuming an average iso-bar specific heat value

CP for the gas (vapor) phase, Eqn. 5 can be written

as:

hf g

V2

T0,res.

= 1 − (1 − χ)

+

,

T

Cp T

2 Cp T

(6)

where χ = ṁg /ṁtot. is the quality at any arbitrary

section. On the other hand, for a two-phase mixture χ = (S0,res. − Sf )/Sf g , where S represents

entropy. Using the concept of frozen Mach number

(M 2 = V 2 /γRT ), Eqn. 6 results:

Sg − S0,res.

=

CP

µ

1+

γ−1 2

M

2

¶

−

wet

T0,res.

(7)

T

Comparing the Eqns. 7 and 4:

ζ=

Sg − S0,res.

CP

(8)

The Eqn. 8 is an interesting and conceptual equation,

describing that ζ is proportional to the entropy rise of

the gas phase (vapor) from inlet. This entropy rise is

due to reversible heat flow from the condensate toward

the vapor phase. It is noted that ζ takes a zero value

from inlet to the “c.o.” point. However, beyond this

point ζ accepts positive values, and it is an increasing

function along the process. That is:

ζ = 0.0

for

T ≥ Tc.o.

(9)

ζ > 0.0

for

T < Tc.o. .

(10)

The locus of isentropic process (along S = S0,res. =

constant) on T − S diagram is optional, and depends

on the inlet conditions T0,res. and P0,res. . The lowest

value that the inflow entropy can take corresponds to

the value at the critical point, (Tcr. , Pcr. ) = (647.29

K, 220.09 bar), and is Sc r. = S0,res. = 4.4298

kJ/kg.K, [8]. On the other hand, the highest value

that the inflow entropy can possess corresponds to

the value of the triple point, (Ttr. , Ptr. ) = (273.16

K, 0.00611 bar), which is Str. = S0,res. = 9.1562

kJ/kg.K. Therefore, S0,res. can accepts any value

between the entropy of the critical point and that of

the triple point, i.e. Scr. < S0,res. < Str. .

14th Annual (International) Mechanical Engineering Conference - May 2006

Isfahan University of Technology, Isfahan, Iran

In Eqn. 8, Sg is a function of only temperature, T .

Therefore, ζ, becomes a function of two independent

variables T and S0,res. :

ζ = ζ(T, S0,res. )

(11)

Noting that Sc.o. = S0,res. , therefore, ζ = ζ(T, Sc.o. ),

and:

Sg − Sc.o.

.

(12)

ζ=

CP

Therefore, the range of variation of Sc.o. ∈ [Scr. , Str. ],

and T ≥ Ttr. .

In the present study we assume the vapor as a real

gas, and a compressibility factor is employed to include deviations from ideal gases.

The ζ Function

To develop an equation describing the variation of ζ,

Eqn. 12 will be used. To do so, we concentrate on

the entropy rise of the vapor portion of the two-phase

mixture (the numerator in Eqn. 12).

It can be shown that the entropy rise between two

arbitrary and distinct points 1 and 2 in superheated region (including the saturated vapor line) is obtained

using, [7]:

S2 − S1 =

Z

2

Cp

1

dT

−

T

Z

1

2

(

∂v

) dP

∂T P

(16)

Differentiating Eqn. 13 along an iso-bar line:

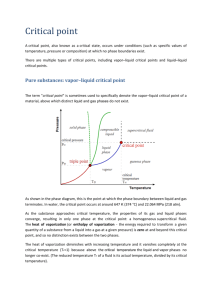

Equation of State

Deviations between the real and ideal gases at low

pressure and high temperature conditions (i.e. large

values of specific volume) is negligible, as shown in

Fig. 2 (the gray region), [7]. These deviations become

significant as the specific volume reduces. To take into

account the real gas effects, the “Lee-Kesler” generalized equation of state has been used in this study. This

equation has twelve constants and is written as, [7]:

Z=

Pv

RT

or

P v = ZRT

(13)

where Z is the compressibility factor that shows deviations from the ideal gas equation of state, v is the

specific volume of the gas, and R is the gas constant.

The non-dimensional virial form of Eqn. 13 can be

written as:

Z

=

Pr vr0

B(T ) C(T ) D(T )

= 1+

+ 0 2 + 0 5

Tr

vr0

(vr )

(vr )

c4

γ

γ

+ 3 0 2 (β + 0 2 ) exp(− 0 2 )

(Tr )(vr )

(vr )

(vr )

(14)

where

B(T ) = b1 − (b2 /Tr ) − (b3 /Tr2 ) − (b4 /Tr3 )

C(T ) = c1 − (c2 /Tr ) − (c3 /Tr3 )

D(T ) = d1 + (d2 /Tr )

in which the non-dimensional variables vr0 , Tr and Pr

are:

v

T

P

=

, Tr =

and Pr =

,

RTcr. /Pcr.

Tcr.

Pcr.

(15)

where Tcr. and Pcr. are the critical temperature and

pressure of steam, respectively. Empirical constants

for pure substances like water are given in Appendix A.

·

¸

R

∂v

∂Z

)P =

)P

(

Z + T(

∂T

P

∂T

(17)

The compressibility factor along the saturated vapor

line, Zg , can be obtained from the Lee-Kesler equation of state. Using the data provided for Zg and Pr

along the saturated vapor line, [7], we fit a polynomial

of degree n for Zg :

Zg = An Prn + An−1 Prn−1 + ... + A1 Pr + A0 (18)

where n = 6 represents enough accuracy for the

curve-fit, and the coefficients A1 to A6 are given

in Appendix A. In the case of an ideal gas again,

Zg = 1 and in Eqn. 18, A0 =1 and Ak = 0.0 for

k ∈ {1, 2, . . . , n}.

Applying Eqn. 16, along the saturated-vapor line

between the “c.o.” point and an arbitrary point along

the saturation vapor line (g):

Z g

dT

Sg − Sc.o. =

Cp

T

c.o.

¸

·

Z g

∂Zg

dP

−

)P

.

R Zg + T (

∂T

P

c.o.

(19)

Again, in the case of ideal gases, Zg is a constant, =1,

and Eqn. 19 is simplified to:

∆Sideal = Cp ln(

P

T

) − R ln(

),

Tc.o.

Pc.o.

(20)

vr0

where ∆Sideal is the entropy rise in the case of ideal

gas. In the case of real gases, the entropy change is

obtained from:

Sg − Sc.o. = ∆Sideal + ∆Sdeviation

(21)

14th Annual (International) Mechanical Engineering Conference - May 2006

Isfahan University of Technology, Isfahan, Iran

in which ∆Sdeviation represents the deviation from

the ideal gas predictions, where,

∆Sdeviation

= R [ (1 − A0 ) ln(

−

−

n

X

Ak

k=1

Z g

c.o.

k

P

)

Pc.o.

k

k

(Pr,g

− Pr,c.o.

)]

RT (

∂Zg dP

)P

.(22)

∂T

P

It is noted that in case of ideal gases, ∆Sdeviation = 0,

so, Eqn. 21 is converted to Eqn. 20.

Now, using Eqns. 12, 21 and 20, a formula for ζ is

developed as:

γ−1

P

γ−1

T

)−

ln(

)+

×

Tc.o.

γ

Pc.o.

γ

n

X

Ak k

P

[ (1 − A0 ) ln(

)−

(Pr,g −

Pc.o.

k

k=1

¶

µ

Z g

dP

∂Zg

k

]

(23)

Pr,c.o.

)−

RT

∂T P P

c.o.

ζ = ln(

where γ = 1.32 for vapor.

Equation 23 reiterates our earlier claim that ζ is

a function of two variables T , and Sc.o. (or S0,res. ).

This is explained below. Along the saturated vapor

line P = Psat , and it is a function of only temperature. On the other hand the term (∂Zg /∂T )P in the

integrand can be written as:

¶ µ

¶

¶ µ

¶

µ

µ

dPr

dP

dZg

∂Zg

×

×

(24)

=

∂T P

dPr

dP

dT

The first term in the right hand side of Eqn. 24 is obtained from the polynomial curve fit of Eqn. 15 being

a function of pressure and consequently temperature

only along the saturated vapor line, the second term

is equal to 1/Pcr. , and the last term is the slope of

the salutation line, and is obtained from Eqn. 15 in

Appendix A. On the other hand the Tc.o. and Pc.o. in

Eqn. 24 are fixed based on the value Sg (Tc.o. ) = Sc.o. .

Therefore, as stated in Eqn. 15, ζ = ζ(T, S0,res. ) .

The ζ Chart

In this section, we derive a relationship between

T0,res. and T0,local for an isentropic process.

As shown in Fig. 3, for any point along an isentropic expansion process and within the two-phase region, there exists a point on the saturated vapor line

that if an imaginary stagnant condition (called “local

stagnation”) adiabatically and reversibly expands, it

will arrive to the same point on saturated-vapor line.

Similarly, as the flow marches along the nozzle, a set

of “local stagnation” points are sought, as shown in

Fig. 3. The locus of these “local stagnation” points

form a curve as shown in Fig. 4.

Replacing Eqn. 2 in Eqn. 4, we obtain:

T0,local = T0,res. + T ζ(T, S0,res. ),

(25)

and substituting ζ from Eqn. 23 into Eqn. 25, one can

obtain:

T0,local

T

γ−1

)−

×

Tc.o.

γ

P

P

( ln(

) + (1 − A0 ) ln(

)

Pc.o.

Pc.o.

n

X

Ak k

k

)

−

(Pr,g − Pr,c.o.

k

k=1

Z g

∂Zg dP

−

RT (

)P

)]

∂T

P

c.o.

(26)

= T0,res. + T [ ln(

It is noted that for T ≥ Tc.o. the flow is dry,

and T0,local is equal to T0,res. . Otherwise, T0,local >

T0,res. (see Figs. 3 and 4), as the flow is in wet region.

Assessing Eqns. 11 and 25, it is noticed that

T0,local is a function of three variables, including two

reservoir properties T0,res. , S0,res. and the local temperature T . Since the inflow stagnation properties, i.e.

T0,res. and S0,res. , are optional, and given we can suppose them as two constants C1 and C2 , respectively,

T0,res. = C1

S0,res. = C2 .

(27)

This makes Eqn. 11 a general formula to depict a family of curves describing the locus of “local stagnation”

conditions in a T −S diagram. These family of curves

for given C1 and C2 are obtained in the following

form:

T0,local = T0,local (C1 , C2 , T )

(28)

Figure 5 shows a family of curves which describe the

“local stagnation” conditions of the vapor portion of

the two-phase mixture. These curves start from the

saturated-vapor line, where the first curve onsets from

the critical point.

At this point the question is how can this figure

(Fig. 5) help us to obtain the “local stagnation” conditions of the vapor portion of a two-phase mixture?

Figure 6 shows a superheated inflow vapor that expands through an isentropic process from the reservoir

stagnation conditions. When the process crosses the

saturated vapor line, the gas phase starts to move the

saturated-vapor line (the blue line shown in Fig. 6).

The “local stagnation” conditions of an arbitrary

point on saturated vapor line is obtained as follows.

A horizontal line, extended from an arbitrary point on

the process line (see Fig. 6), crosses the saturated vapor line. Then this point is vertically extended until to

meet a curve that the inflow stagnation point belongs

14th Annual (International) Mechanical Engineering Conference - May 2006

Isfahan University of Technology, Isfahan, Iran

to that curve at T = T0,local and S = S0,local , see

Fig. 6.

The limiting case, when the inflow stagnation

point is located right on the saturated vapor line, is

illustrated in Fig. 7.

The ζ Table

In the previous section, we developed a new chart that

contains a family of curves, which its significance was

to give a profile for the behavior of “local stagnation”

conditions of the vapor portion of the two-phase mixture. In this section, we aim to reword our discussions

in previous section in order to give a user friendly way

to extract the local stagnation states. To do so, we focuss on the variation of ζ function.

Using the Eqns. 8, 9, 10 and 23, a 3-D surface

is obtained in S-T -ζ space, which is describing the

behavior of ζ function in any isentropic expansion of

condensing steam flow. Figure 8 shows the ζ-surface.

Now, it is possible to develop a table using the

data of ζ surface. This table can simplify the calculation procedure of the “local stagnation” conditions.

As shown in Fig. 9, the first left column is representing the temperature and along the another columns

which has an special entropy, the ζ function is varying corresponding to temperature. In fact each column

in this table is representing a isentropic process with

special amount of entropy which is specified at the top

of each column. Now, to extract the local stagnation

state along an isentropic expansion process, knowing

the initial stagnation properties, (T0,res. and s=s0,res.

), it is enough that one marches downward along the

column which has s=s0,res. . So, at each cell on the

column one can read a value for ζ corresponding to

a static temperature T in the same row on the firs

left column. Now, having T0,res , s0,res and extracted

T and ζ from the table, the local stagnation corresponding to T along the process line, is derived as :

T0,local = T0,res. + T ζ and s0,local = s0,res. + CP ζ.

It is clear that, before “c.o.” point ( the cell which is

specified by light green on the column), ζ function is

equal to zero, hence the local stagnation properties are

same with those of initial values of upstream imaginary reservoir. But beyond the “c.o.” point on the column, ζ accepts the positive values and therefore local

stagnation state is varied.

Verification of the Computation

For the compressions of analytical solutions (developed in the present paper) with numerical computation

(developed in Ref. [6]), several test cases with various nozzle geometries and different expansion rates

are tested. Excellent agreement in all the cases were

achieved. A sample of compressions (between the numerical results and analytical solutions) are given in

this section. To do so, a nozzle geometry with a relatively high value of expansion rate (i.e. a large exit

to throat area ratio) has been chosen. These comparisons are performed in Table 1. Table 1 shows

the nozzle cross sectional area (A) along the nozzle

axis (X), and compares the numerical values (obtained

in Ref. [6]) for temperature TN um. and Mach number MN um. , and analytical solutions (obtained in the

present study), for TAnal. and MAnal. are given. As

shown in Table 1, excellent agreement between the results are achieved.

Summary and Conclusions

The highlights of the present study are given here. A

new non-dimensional function ζ is introduced in the

present study, which represents the deviation of “local

stagnation” condition from that of the inflow. A thermodynamic chart and table for this function has been

provided. ζ takes values equal to zero in dry regions,

and positive in wet regions. The developed table is

general and can be used for any geometry of nozzle,

with arbitrarily selected inflow stagnation properties.

The method is applied to several test cases and the results were compared with numerical computations [6].

Excellent agreement in all cases were obtained. The

vapor, in the present study, has been taken as a real

gas obeying the “Lee-Kesler” equation of state.

Appendix A

Constants of Lee-Kesler Equation of state. The

sets of constants of Lee-Kesler Equation of state is as

follows:

b1 = +0.1181193

b2 = +0.265728

b3 = +0.154790

b4 = +0.030323

c1 = +0.0236744

c2 = +0.0186984

c3 = 0.0

c4 = +0.042724

d1 × 104 = +0.155488

d2 × 104 = +0.623689

β = +0.65392

γ = +0.060167

(29)

Using the above equation of state, compressibility

factor of saturated vapor, Zg , can be determined by

14th Annual (International) Mechanical Engineering Conference - May 2006

Isfahan University of Technology, Isfahan, Iran

sixth order as a function of reduced pressure of vapor:

Zg

= A6 Pr6 + A5 Pr5 + A4 Pr4 + A3 Pr3

+A2 Pr2 + A1 Pr1 + A0

(30)

where the coefficients A0 to A6 are:

A6

A5

A4

A3

A2

A1

A0

= 14.7523

= -45.2802

= +52.6399

= -29.7745

= +8.6910

= -1.7379

= +0.9995

(31)

Saturated Pressure Value. The saturation pressure

for steam is determined by a fifth order polynomial

least square curve fit to the steam data taken from [6]

and [8]. given by:

psat

= B5 (T − t0 )5 + B4 (T − t0 )4

+B3 (T − t0 )3 + B2 (T − t0 )2

+B1 (T − t0 ) + B0 ,

(32)

where p and T are in terms of P a and K, t0 =

273.15 K.

Entropy. The entropy of the mixture is determined

from s = sf + χsf g , where sf g = hf g /T and sg

is obtained from sg = Cp ln T − R ln p, and sf =

sg − sf g .

References

[1] Zayernouri, M. and Kermani, M. J. (2006) “Development of an Analytical Solution for Com-

pressible Two-Phase Steam Flow”, Transctions–

Canadian Society for Mechanical Engineers, Accepted.

[2] Petr, V. & Kolovrant’k, M. 1994 “Laboratory

and field measurements of droplet nucleation in

expansion steam ”. 12th Int. Conf. on Properties

of Water and Steam, Sept. 11-16. FL, ASME.

[3] Stastny, M. & Sejna, M. 1994 “Condensation

effects in transonic flow through turbine cascade”. 12th Int. Conf. on Properties of Water and

Steam, Sept. 11-16. FL, ASME.

[4] White, A. J., Young, J. B. & Walters, P. T. 1996 “

Experimental validation of condensing flow theory for a stationary cascade of steam turbine

blade”. Phi. Trans. R. Soc. Lond. A354, 59-88

[5] Guha, A., “A unified theory for the interpretation

of total pressure and temperature in two-phase

flows at subsonic and supersonic speads,” Proc.

R. Soc. Lond. A (1998) 454, 671-695.

[6] Kermani, M. J., Gerber, A. G., and Stockie, J.

M., Thermodynamically based Moisture Prediction using Roe’s Scheme, The 4th Conference of

Iranian AeroSpace Society, Amir Kabir University of Technology, Tehran, Iran, January 27–29,

2003.

[7] Van Wylen, Borgnakke, Sonntag, “Fundamentals of Thermodynamics,” 6th Edition, John Wiley & Sons, 2002.

[8] Moran, M. J. and Shapiro, H. N., “Fundamentals

of Engineering Thermodynamics,” 4th Edition,

John Wiley & Sons, 1998.

14th Annual (International) Mechanical Engineering Conference - May 2006

Isfahan University of Technology, Isfahan, Iran

Figure 1: Schematic of an isentropic expansion of

steam flow through a nozzle.

Figure 4: The locus of “ local stagnation” conditions

of the vapor portion of the two phase mixture.

Figure 2: Deviation of superheated and saturated vapor from ideal-gas equation of state.

1400

1350

1300

1250

1200

1150

1100

1050

1000

T(K)

950

900

850

800

750

700

650

600

critical point

550

500

450

400

Two Phase Region

350

300

4 4.2 4.4 4.6 4.8 5 5.2 5.4 5.6 5.8 6 6.2 6.4 6.6 6.8 7 7.2 7.4 7.6 7.8 8 8.2 8.4 8.6 8.8 9

S ( kJ / kg.K )

Figure 5: Locus of the family of curves for the local

stagnation conditions.

Figure 3: Schematic of isentropic processes from the

saturated vapor line to their corresponding “local stagnation” conditions.

14th Annual (International) Mechanical Engineering Conference - May 2006

Isfahan University of Technology, Isfahan, Iran

Zeta

2.48978

2.40419

2.3421

2.24431

1300

Local stagnation state of the vapor,

corresponding to specified point on

the saturated vapor line.

1250

1200

1150

1.8235

1.7183

( S 0,local , T0,local )

T = T0, local

1100

2.13911

2.03391

1.9287

1.6131

1.5079

1.40269

950

1.29749

1.19229

2.5

1.08709

0.981886

0.876684

2.25

0.771482

0.66628

2

0.561078

0.455876

0.350674

1.75

T(K)

900

850

Stagnation state of

imaginary reservoir

800

750

S = S 0,local

700

Inlet point

650

0.245472

0.140269

600

550

1.5

0.0422393

0.0139029

0

Condensation onset

500

1.25

1

450

400

350

Zeta

1000

1050

300

0.75

An arbitrary point on

the process line

350

300

Z

4.6 4.8

5

5.2 5.4 5.6 5.8

6

6.2 6.4 6.6 6.8

7

7.2 7.4 7.6 7.8

8

8.2 8.4 8.6 8.8

9

S ( kJ / kg.K )

X

Te

m

pe 450

ra

tu

re

Y

0.5

400

0.25

500

(K

)

550

5.5

600

Figure 6: Schematic of the procedure to determine the

local stagnation.

650

9

8.5

5

0

4.5

6

6.5

)

7

kg.K

(kJ/

opy

E ntr

8

7.5

Figure 8: Chart (surface view) of “ζ” function.

1300

Local stagnation state of the vapor,

corresponding to specified point on

the saturated vapor line.

1250

1200

1150

1100

( S 0,local , T0,local )

T = T0, local

1050

1000

950

T(K)

900

850

800

750

S = S 0,local

700

Stagnation state of

imaginary reservoir

650

600

550

500

Inlet point

450

An arbitrary point on

the process line

400

350

X (m)

A (m2 )

TN um. (K)

TAnal. (K)

MN um.

MAnal.

-0.2

0.0379

337

337.5

0.562

0.561

-0.1

0.0353

332.2

332.2

0.650

0.650

0

0.0315

326.3

326.7

0.928

0.933

0.1

0.0366

315.9

315.9

1.203

1.203

X (m)

A (m2 )

TN um. (K)

TAnal. (K)

MN um.

MAnal.

0.2

0.0417

311.1

311.1

1.440

1.439

0.3

0.0468

307.4

307.4

1.546

1.545

0.4

0.0519

304.5

304.5

1.630

1.629

0.50

0.0570

302

302

1.696

1.695

300

4.6 4.8

5

5.2 5.4 5.6 5.8

6

6.2 6.4 6.6 6.8

7

7.2 7.4 7.6 7.8

8

8.2 8.4 8.6 8.8

9

S ( kJ / kg.K )

Figure 7: Schematic of the procedure to determine the

local stagnation (the limiting case in which inflow is

on the saturated vapor line).

Table 1: Comparison between temperature and Mach

number along an arbitrary nozzle with a relatively

high value of expansion rate. The subscripts N um.

and Anal. refer to numerical values (obtained in

Ref. [6]) and analytical solutions (obtained in the

present study), respectively.

14th Annual (International) Mechanical Engineering Conference - May 2006

Isfahan University of Technology, Isfahan, Iran

Figure 9: Table of ζ function.